I fixed my central A/C. 30+ year old R22 unit - no idea where all the R22 went, but its gone - pressure zero. Pressure-leak tested it for a couple weeks, using compressed air run through one of those silica bead based air dryers I got for $7 from Harbor Freight, which fastened easily to a small tire compressor on hand. Jury rigged the rest of it to get about 50 PSI into the piping, as read by the charging manifold gauges I bought off ebay for $35. Held constant, varying up/down some with apparently, ambient temperature.

After releasing the compressed air, I started it up and dared to slowly enter into the blue line 4 of 6 cans of this R290 stuff I got off ebay (with Proseal and Prodry - sez so right on the can) for about $100, shipped. Gauges read reasonable values and now hot air comes out the outside compressor / fan assembly, cool air out the vents in the house.

The R290 is a propane based "environmentally friendly" Freon substitute. I did buy a gas leak sensing pen and a RV propane leak alarm - so far nothing reading off either of those sniffing around the various connections, leaving the alarm running in the garage next to the works. I've left the manifold connected and the meters show no drop in pressure over time, save some up and down variation, again apparently due to ambient temperature.

I bet the local heating / cooling business would have tried to gut us for a whole new system, saying the existing unit is so old, it's beyond repair. That's what the next door neighbor did, but he's a millionaire and I'm not. System takes 7 lbs of R22, which they sell in 5 or 10 lb containers, for $200 - $400. Knowing the system works now, I could just release the "environmentally friendly" stuff and get the real Freon in there, if only for peace of mind.

I still dont know where the original Freon charge went. We were out of A/C last summer and didnt want to go through that again; but it worked in the years before, as I recall.

After releasing the compressed air, I started it up and dared to slowly enter into the blue line 4 of 6 cans of this R290 stuff I got off ebay (with Proseal and Prodry - sez so right on the can) for about $100, shipped. Gauges read reasonable values and now hot air comes out the outside compressor / fan assembly, cool air out the vents in the house.

The R290 is a propane based "environmentally friendly" Freon substitute. I did buy a gas leak sensing pen and a RV propane leak alarm - so far nothing reading off either of those sniffing around the various connections, leaving the alarm running in the garage next to the works. I've left the manifold connected and the meters show no drop in pressure over time, save some up and down variation, again apparently due to ambient temperature.

I bet the local heating / cooling business would have tried to gut us for a whole new system, saying the existing unit is so old, it's beyond repair. That's what the next door neighbor did, but he's a millionaire and I'm not. System takes 7 lbs of R22, which they sell in 5 or 10 lb containers, for $200 - $400. Knowing the system works now, I could just release the "environmentally friendly" stuff and get the real Freon in there, if only for peace of mind.

I still dont know where the original Freon charge went. We were out of A/C last summer and didnt want to go through that again; but it worked in the years before, as I recall.

To be fair, the regulator heat sinks are soldered to the board by 2 pins with no connection, and they are lifted fairlyNot a good idea to run traces on the top side of the board, under the heat sinks.

with a 4-5 mm distance from the board. Time consuming repair wise, but as layout safety is concerned, this is not a problem.

I know that propane works very well as a refrigerant, but is it safe to use in domestic AC units? I thought it was never used for that reason.

That, plus AFAIK it's still illegal to intentionally vent any refrigerant, even recent environmentally friendly varieties.

AC is great when it works, but can be expensive if it breaks. This is just as true with who or what method is used to troubleshoot the problem. What I have witnessed are techs sent out that have expectations of a reported problem and then treat accordingly. This usually results in a band aid fix lasting long enough to get the tech to his next job and maybe long enough after that to forget what was done.

This sort of reminds me of the 'higher ups' who wanted to make a name for themselves by promoting a new policy that would make an impact for a short time. They would get the promotion, get out of Dodge, and then the policy would fail, leaving the next guy with cleanup.

This sort of reminds me of the 'higher ups' who wanted to make a name for themselves by promoting a new policy that would make an impact for a short time. They would get the promotion, get out of Dodge, and then the policy would fail, leaving the next guy with cleanup.

Last edited:

Seems like some flammable gas is making its way into domestic use.

https://www.nbcdfw.com/news/nbc-5-r...lodes-inside-fort-worth-familys-home/2606784/

There is another article out there of someone having house and furniture damage from a domestic refrigerator blowing up.

https://www.nbcdfw.com/news/nbc-5-r...lodes-inside-fort-worth-familys-home/2606784/

There is another article out there of someone having house and furniture damage from a domestic refrigerator blowing up.

"Looks like meat is back on the menu boys!" One of my favorite movie quotes for 'what's the worst that can happen' episodes of mine.

Repaired a detail sander today.

Must be 15-20 years old.

The switch has been glitching for years. Finally gave up.

I just bypassed it. Switch it on/off at the 13A UK power block.

A 2-bit part isn't going to kill a perfectly good tool.

I'm using it to finish sand some 1.7m long exponential mid bass horns 🤘

Must be 15-20 years old.

The switch has been glitching for years. Finally gave up.

I just bypassed it. Switch it on/off at the 13A UK power block.

A 2-bit part isn't going to kill a perfectly good tool.

I'm using it to finish sand some 1.7m long exponential mid bass horns 🤘

In Hyderabad, some dealers were complaining that LPG was being used as a refrigerant, that is 70% propane and 30% butane, mostly a kitchen fuel.

Also be aware that some makes have an issue of pinhole leaks from the joint to the coil, where the steel pipe adapter is (brazed?) to the copper or aluminum coil.

The copper pipes from the indoor unit to the outdoor unit are fastened to steel adapters, and those are in turn fastened or brazed to the coils.

The iron also corrodes over time, and develops pin holes.

The only real remedy is using a paint like material to stop corrosion on the steel parts. Brass also needs coating at times.

Also be aware that some makes have an issue of pinhole leaks from the joint to the coil, where the steel pipe adapter is (brazed?) to the copper or aluminum coil.

The copper pipes from the indoor unit to the outdoor unit are fastened to steel adapters, and those are in turn fastened or brazed to the coils.

The iron also corrodes over time, and develops pin holes.

The only real remedy is using a paint like material to stop corrosion on the steel parts. Brass also needs coating at times.

70% propane and 30% butane seems nice overall compared to good old Freon when you think about ozone holes. Just need to keep the things from blowing up.

A good tool is always worth repairing. Done a few of them myself. AC switch's must be a common problem. I have replaced TWO on my Shop Fox drill press.Repaired a detail sander today.

Must be 15-20 years old.

The switch has been glitching for years. Finally gave up.

I just bypassed it. Switch it on/off at the 13A UK power block.

A 2-bit part isn't going to kill a perfectly good tool.

I'm using it to finish sand some 1.7m long exponential mid bass horns 🤘

A capacitor across a switch can save it from burning up. It also squelches the RF generated by operating the switch.

You want to get an "X" rated capacitor intended for continuous full mains voltage.

You want to get an "X" rated capacitor intended for continuous full mains voltage.

Yes, those are cheap, but they'll always break at the same point. If you need much glue fast, you pull the trigger to hard an the thing is done. So I opened one up and looked what broke. It's a simple piece of plastic, connecting the trigger with the "glue-forwarder". Made it of a little piece aluminum. Won't break again.

So this is a hot melt glue gun? I have never owned one so I am just guessing. I would likely find a way to break it a second time.

Yes it is. Sure, it's not really a thing for glueing, there are better ways, but i.e. it's good for isolating/ making electric save against unauthorized touch.So this is a hot melt glue gun?

Those are made really cheap. Not much more parts to break 😉 .I would likely find a way to break it a second time.

Freon substitutes used in HVAC and refrigeration are mostly modified Pentane, which is inflammable.

The stuff is expensive compared to LPG, and in times of shortage, some substitution has occurred, which is dangerous.

Small fires and explosions caused by gas leakage after car accidents are common, they can lead to major fires.

Fortunately the gas charge is less than half a kilo in most vehicles, it is still a risk.

Also, the design is different, old style refrigerants do not work so well in new style systems, coil and compressor are designed for different gases.

And vice versa, of course, if new style stuff is put in old systems, the heat transfer rate goes down a lot.

This topic must be available on the net, for those interested.

The stuff is expensive compared to LPG, and in times of shortage, some substitution has occurred, which is dangerous.

Small fires and explosions caused by gas leakage after car accidents are common, they can lead to major fires.

Fortunately the gas charge is less than half a kilo in most vehicles, it is still a risk.

Also, the design is different, old style refrigerants do not work so well in new style systems, coil and compressor are designed for different gases.

And vice versa, of course, if new style stuff is put in old systems, the heat transfer rate goes down a lot.

This topic must be available on the net, for those interested.

Last edited:

I recently repaired a National (tape) boombox from 1982. Broken belt, solved using a closely matching VCR belt of some unknown brand. The heads were fine with negligible wear, just cleaned it a little and adjusted the azimuth error that's it. Works perfectly now.

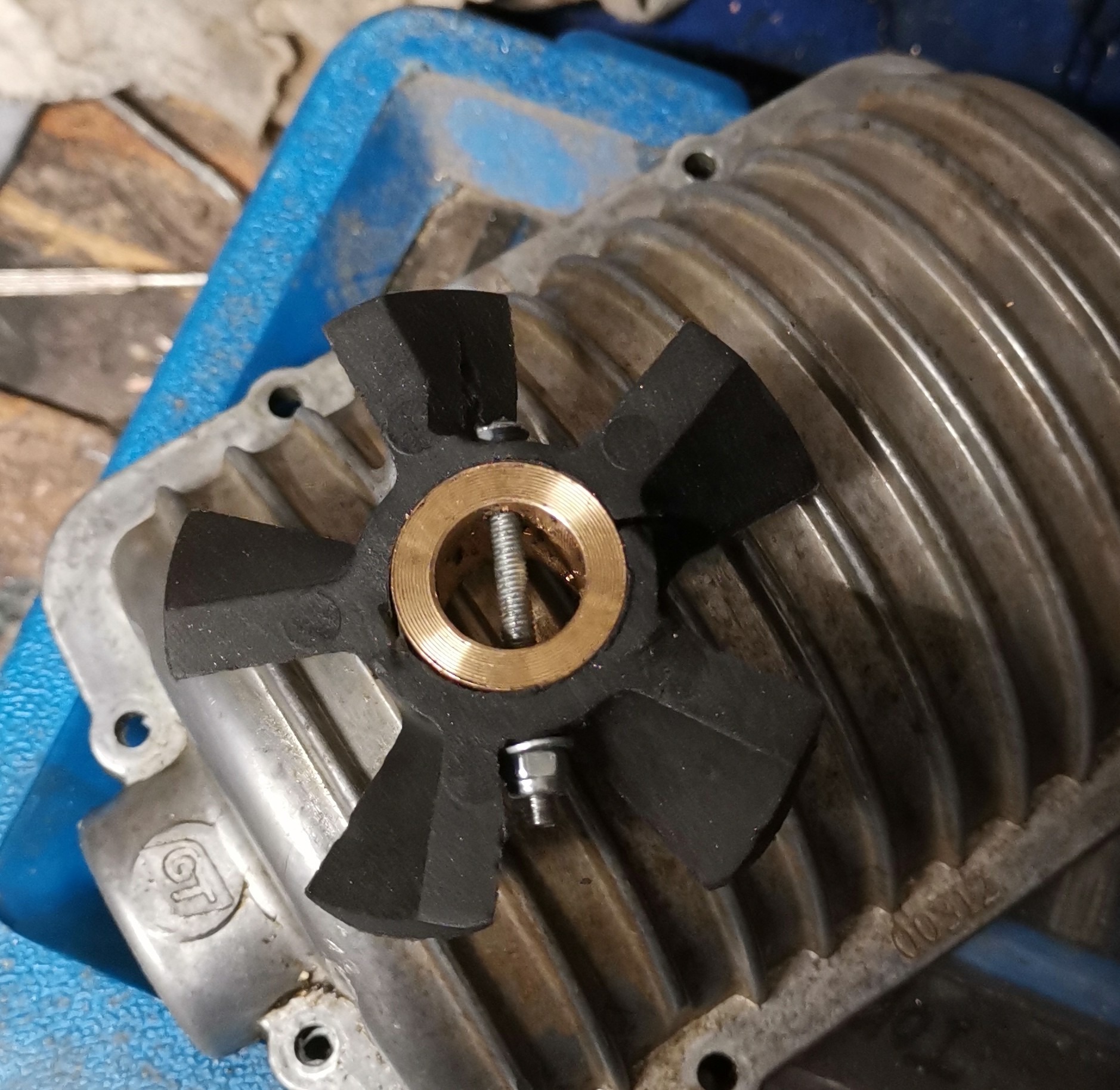

Repaired the transmission in our Toro Timemaster.

After 7 years of 'normal' domestic use, it gave up and would not drive the mower.

This is a common failure.

There's no support or parts.

You are supposed to just replace the whole thing for around £200.

This is a 30" cut, twin rotor walk behind, with Briggs Stratton engine.

After following Taryldactiles's vid on Youtube to remove the transmission.

I went beyond the usual swap it for a new one and took it apart.

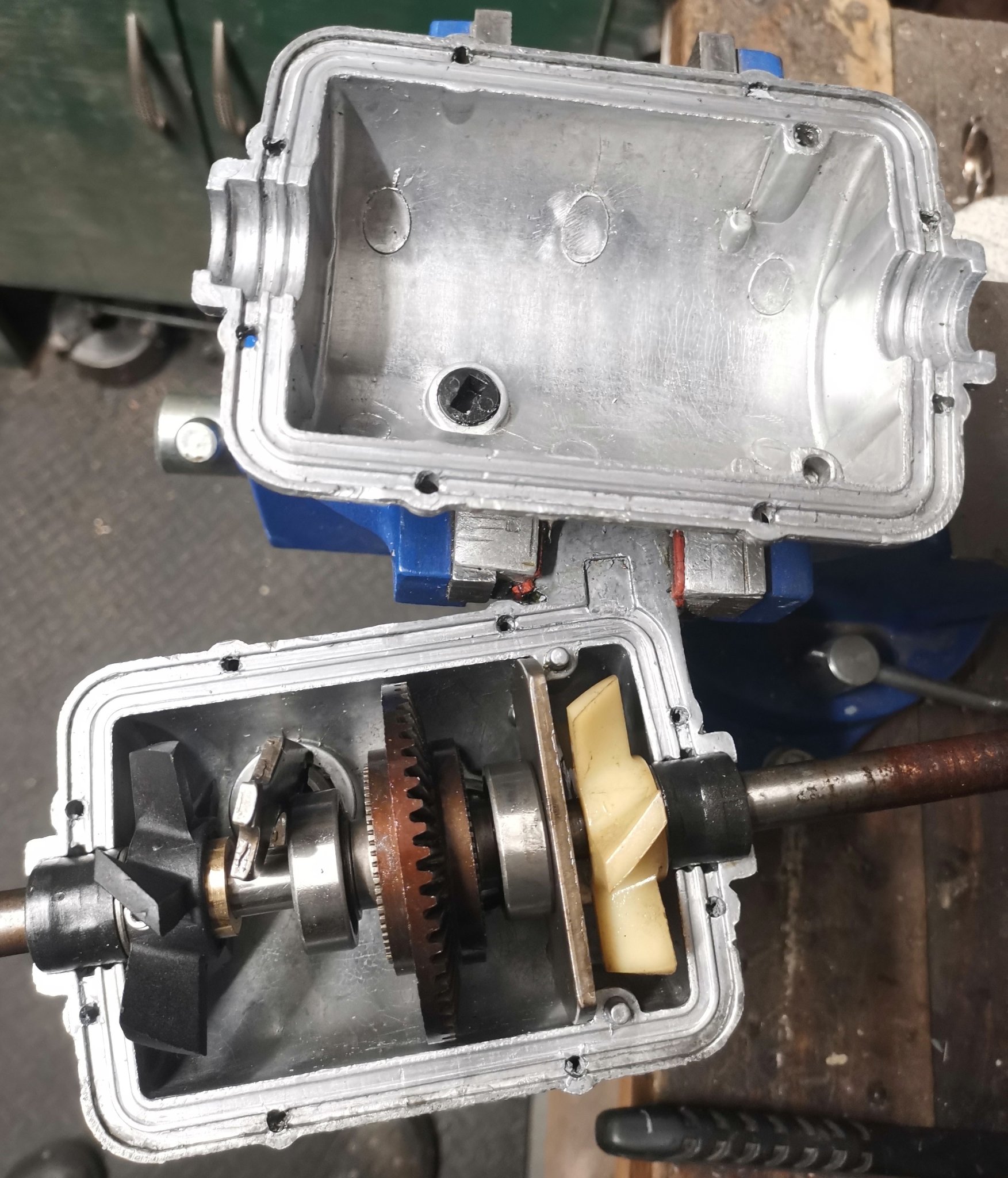

Took the cover off, drained the oil (these things are tiny compared to car diffs).

The half shaft is not supposed to just pull out!🙂

Getting into it, I was confronted by the offending part.

Another 2 bit part.

Turns out the oil pickup blade, One on each half shaft had sheared in half.

This also doubled as half shaft retaining bush!

A little pin was located to retain the half shaft.

Designed to maximize ease of assembly, once in the shaft it could just be pushed into the nylon bush! = Weakness right there!

The half shaft is the longer of the two. Gets more load in use.

Bumping around on the grass, up and down border edges etc

Once that was gone to the bottom the shaft could just float away and cease transmitting power.

I made a new bush in brass, on my little lathe.

Wanted to keep the oil distributing vanes, so machined out the centre and put a bolt through.

The plastic blades are no longer load bearing. Just flick oil about.

The stainless bolt doubles up, keeping the blades together and securing the half shaft to the retaining bush.

Fix in place..

The other nylon bush looked fine. So, I left it alone.

Put it back together with transmission sealing silicone gasket (as per original).

Reinstalled

I used auto transmission fluid, filled to the same level. This works fine.. again no recommendation or data as to the correct oil to use..

The Timemaster vs smaller plug in mower

Natural habitat

After 7 years of 'normal' domestic use, it gave up and would not drive the mower.

This is a common failure.

There's no support or parts.

You are supposed to just replace the whole thing for around £200.

This is a 30" cut, twin rotor walk behind, with Briggs Stratton engine.

After following Taryldactiles's vid on Youtube to remove the transmission.

I went beyond the usual swap it for a new one and took it apart.

Took the cover off, drained the oil (these things are tiny compared to car diffs).

The half shaft is not supposed to just pull out!🙂

Getting into it, I was confronted by the offending part.

Another 2 bit part.

Turns out the oil pickup blade, One on each half shaft had sheared in half.

This also doubled as half shaft retaining bush!

A little pin was located to retain the half shaft.

Designed to maximize ease of assembly, once in the shaft it could just be pushed into the nylon bush! = Weakness right there!

The half shaft is the longer of the two. Gets more load in use.

Bumping around on the grass, up and down border edges etc

Once that was gone to the bottom the shaft could just float away and cease transmitting power.

I made a new bush in brass, on my little lathe.

Wanted to keep the oil distributing vanes, so machined out the centre and put a bolt through.

The plastic blades are no longer load bearing. Just flick oil about.

The stainless bolt doubles up, keeping the blades together and securing the half shaft to the retaining bush.

Fix in place..

The other nylon bush looked fine. So, I left it alone.

Put it back together with transmission sealing silicone gasket (as per original).

Reinstalled

I used auto transmission fluid, filled to the same level. This works fine.. again no recommendation or data as to the correct oil to use..

The Timemaster vs smaller plug in mower

Natural habitat

Attachments

Last edited:

Great work, I appreciate those who have the shop and skill to do such things.

Wow, Looks to me like you need a bigger machine. That is a sizable patch of grass.

Wow, Looks to me like you need a bigger machine. That is a sizable patch of grass.

- Home

- Member Areas

- The Lounge

- What did you last repair?