Had to yank down and "fix" two Carlton blue wall-mount junction boxes.

Two years ago, I put up a pair of small wall sconces in the dining room.

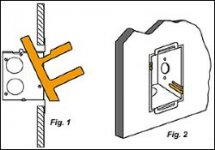

The blue plastic box uses a crappy plastic "wing" retainer that's supposed to spin and lock against the back of the drywall.

They are weak, crack, and the box becomes loose off the wall.

So....

I made metal "wings" and modded the boxes.

Them sconces are nice and tight on the wall now - forever!

Two years ago, I put up a pair of small wall sconces in the dining room.

The blue plastic box uses a crappy plastic "wing" retainer that's supposed to spin and lock against the back of the drywall.

They are weak, crack, and the box becomes loose off the wall.

So....

I made metal "wings" and modded the boxes.

Them sconces are nice and tight on the wall now - forever!

32" TV from our caravan.

No sign of life.

Checked 5V standby power was working.

Found power schematic online so sussed which pin activated power supply - all voltages correct.

Ribbon cable socket had lifted a couple of pins from the switch pcb (standby switch & ground).

Resoldered & now seems to work ok.

With my limited knowledge, anything more complicated I couldn't have fixed it.

You're lucky.

Because after a solid 26 years of repairing thousands of TV sets in the shop, and pulling my hair out, using foul language, I'm now a nasty old codger. 😱

That's why I have always refused to fix TVs or any video product. I'm still a nice guy! 🙂

-Chris

-Chris

When I need to lube faders, I use F5 from Deoxit. I used to use Super Lube for the slider bolts on my brake calipers. Now I use Lucas.

Hot tip. If you need a good and cheap penetrating lube that doesn't dry out quickly, mix diesel with dextron...

Hot tip. If you need a good and cheap penetrating lube that doesn't dry out quickly, mix diesel with dextron...

Fixed a new usb scope that didn't work.

When I solder on the SMD's sometimes a pin doesn't solder very well.

I put plenty of solder on but then have to use copper braid to get rid of excess solder.

This sometimes takes off all the solder and leaves a dry joint.

A quick wipe over the pins with a wetted soldering iron tip usually sorts it out.

When I solder on the SMD's sometimes a pin doesn't solder very well.

I put plenty of solder on but then have to use copper braid to get rid of excess solder.

This sometimes takes off all the solder and leaves a dry joint.

A quick wipe over the pins with a wetted soldering iron tip usually sorts it out.

Hi Nigel,

I normally tin the PCB and leave some fresh flux on it, add some flux to the IC pin and that generally does the trick. There is some cleaning up afterwards to do, but at least you normally get all the pins.

-Chris

I normally tin the PCB and leave some fresh flux on it, add some flux to the IC pin and that generally does the trick. There is some cleaning up afterwards to do, but at least you normally get all the pins.

-Chris

Hi Nigel,

I normally tin the PCB and leave some fresh flux on it, add some flux to the IC pin and that generally does the trick. There is some cleaning up afterwards to do, but at least you normally get all the pins.

-Chris

I wipe some flux over the pads then put some flux between the two rows of pads to hold the IC down while I gently solder the first pin.

I then run along the pads/pins with the iron with plenty of solder on it.

This often leaves blobs of solder which I have to wick off.

Sadly sometimes the wick takes too much off and leaves a dry joint.

I will try your tip next time and lightly solder the pads first.

Hopefully, with solder below the pins it wont get wicked off.

I did find on early SMD pcb's I couldn't always tell if there was a short so with subsequent pcb's I add a line of vias next to each row of pins so I can buzz them for shorts.

I spent half an hour one day trying to remove a short between pins 20 and 21 on a A2D converter and couldn't get rid of the short. It then hit me that those pins are both grounded anyway ! so shorted on the pcb anyway.

Hi Nigel,

I hope it works for you. It seemed to really help me. I would run a fat screwdriver tip along the pins with just the solder touching. Then the only cleanup was at the end of the row. Solder wick. Then I use the same tip and merely run it to the edge of the pins and draw it away, then onto the next three (3mm tip). Often it gives soldering jobs the appearance of a factory job.

-Chris

I hope it works for you. It seemed to really help me. I would run a fat screwdriver tip along the pins with just the solder touching. Then the only cleanup was at the end of the row. Solder wick. Then I use the same tip and merely run it to the edge of the pins and draw it away, then onto the next three (3mm tip). Often it gives soldering jobs the appearance of a factory job.

Oh man, that probably made you a little upset. I generally just look through a magnifying glass.It then hit me that those pins are both grounded anyway

-Chris

Drove 3-1/2 hrs, fixed 4 church organs + 1 digital piano, then 3-1/2 hrs. back in time for a late dinner! Only trouble is I'm too tired to eat anything.

Hi Nigel,

Oh man, that probably made you a little upset. I generally just look through a magnifying glass.

-Chris

I am getting better at seeing shorts but not easy with my old eyes.

I have 2.5 reading glasses plus a x10 magnifying glass.

Even then I sometimes miss something hence the added rows of vias so I can buzz them. A good buzzing doesn't tell me if a pin isn't making connection though.

I find I have to be careful with pressure from the soldering iron as a couple of times I have bent two SMD pins against each other and once soldered they are a pig to get apart.

I got real lucky - they were all minor stuff like memory battery replacements, lamp replacements (actually upgrades to LED), contact cleaning, coupla open electrolytics, voicing adjustments etc.Wow! Four church organs? What was wrong with them?

Probably shouldn't have counted the piano since I couldn't get the damn thing to act up in front of me (I swear to god sometimes these things can tell when the service tech is hanging around). But I did open it up & traumatize it for awhile, looking for funky connectors, cracked solder joints & the like. Nary a hiccup. The choir director tells me it sometimes goes for weeks without acting up. ¯\_(ツ)_/¯

a 3/4” dado stack.

Is that saw capable of doing that, or do you just run it a wee each pass?

...wall-mount junction boxes....box becomes loose off the wall. So.... I made metal "wings" and modded the boxes....

"Battleship clips". (Add "junction box" or Google gives giggles.)

Attachments

Is that saw capable of doing that, or do you just run it a wee each pass?

Amazingly it produces 5 peak hp and the gear drive gives it enough torque to power through a complete cut.

It was only equipped to handle a 1/2” stack but a little surgery and it’s good to go with 3/4”

Samsung 46" LED TV was constantly rebooting. Most probably solder problem of the "NAND Flash" chip on the mainboard.

I made a cardboard cover for the mainboard, with a rectangular hole above the chip for protecting the rest of the board from the heat.

I applied some flux on the two rows of pins of the chip and heated up the chip with a heat gun for about 20 seconds.

TV is normally working again.

Honeywell CM907 central heating thermostat with unreadable display, a well known problem with these series of thermostats.

The flat cable connection from the LCD display gets somehow delaminated and several segments of the display are not working.

Remove the PCB with display from the housing, clamp the PCB / display sandwich and aplly moderate heat for some 20 seconds and the problem shoul be fixed.

I made a cardboard cover for the mainboard, with a rectangular hole above the chip for protecting the rest of the board from the heat.

I applied some flux on the two rows of pins of the chip and heated up the chip with a heat gun for about 20 seconds.

TV is normally working again.

Honeywell CM907 central heating thermostat with unreadable display, a well known problem with these series of thermostats.

The flat cable connection from the LCD display gets somehow delaminated and several segments of the display are not working.

Remove the PCB with display from the housing, clamp the PCB / display sandwich and aplly moderate heat for some 20 seconds and the problem shoul be fixed.

Kenwood KT-8005.

Replaced all lamps with LED types. Made the "STEREO" indicator red instead of the yellow-white the rest of the indicators are. Looks good, I can always replace the red LED with a warm white one later.

Service manual is coming. I have a bunch ot circuit changes to the power supply and output section. Probably the MPX and detector as well.

I was able to get the mono THD down to 0.1%, not too shabby. Therefore the improvements in the audio path seem to be worthwhile.

-Chris

Replaced all lamps with LED types. Made the "STEREO" indicator red instead of the yellow-white the rest of the indicators are. Looks good, I can always replace the red LED with a warm white one later.

Service manual is coming. I have a bunch ot circuit changes to the power supply and output section. Probably the MPX and detector as well.

I was able to get the mono THD down to 0.1%, not too shabby. Therefore the improvements in the audio path seem to be worthwhile.

-Chris

Is there still sufficient terrestrial FM broadcasting in your area to justify that? We live on a bit of a fringe area for my local favorite- NPR and CBC affiliates, and my current domicile is in a bit of a shadow between two hills, so I’d need probably a 20ft tower and high directional to get decent enough signal. For decades we were able to get fairly OK reception via our cable supplier’s coax line, but I guess the recent years’ explosion of channels and digital streaming for internet and movie services etc forced them to get very creative on how to use the very wide, but ultimately finite bandwidth of copper.

I’ve been approached several times by the competition offering optical, but we’re both habituated to the GUI of the existing desktop machines, and Shaw’s service has always been excellent. When I used to have to with TELUS at work, rather a different story, and my sister says the same about their residential service.

That said, those old Kenwood and Onkyo tuners were excellent sounding machines.

I’ve been approached several times by the competition offering optical, but we’re both habituated to the GUI of the existing desktop machines, and Shaw’s service has always been excellent. When I used to have to with TELUS at work, rather a different story, and my sister says the same about their residential service.

That said, those old Kenwood and Onkyo tuners were excellent sounding machines.

- Home

- Member Areas

- The Lounge

- What did you last repair?