And this board is good for the scrap heap LOL

That resistor must have angered the electrical gods...

That resistor must have angered the electrical gods...

Elgar CW801P AC Power Source - bought as a parts unit, problem wound up being an cold solder joint on the output header. Very hard to see, I pretty much got lucky to catch it at the right angle. The unit passed all internal diagnostics so I figured it pretty much had to be in the final stages.

Very good advice and practice. I do this as a matter of course on such repairs.Any resistors that have to handle a heavy load and heat up, I suggest raising them off the board to give them airflow and prevent heating their connections.

If the leads are too short for such a thing, then replace the resistor.

To be fair, they were reasonably sane in this. The resistors are stood on end, as it were. It may have been mechanical failure as much as heat cycling; these cans are used as floor cans so do get chucked about.

I have a PC with USB DAC so USB wire to DAC then 3.5mm socket to 6.3mm jack plug for the speaker.

Its been intermittent for a while now.

As the speaker is behind me I have to run audio cable past my chair with rollers.

I keep accidentally running chair over audio lead and it looks like it has become damaged.

So replaced audio wire and works fine now.

Routed wires around me now well out of the way to prevent further problems.

Its been intermittent for a while now.

As the speaker is behind me I have to run audio cable past my chair with rollers.

I keep accidentally running chair over audio lead and it looks like it has become damaged.

So replaced audio wire and works fine now.

Routed wires around me now well out of the way to prevent further problems.

Dog chewed my sister's laptop charger cable, cut near the pin.

Washed it, checked the charger worked, then patched it up, covered joint with heat shrink, looks normal, have to look closely for repair marks.

Voltage seems normal...laptop is in Hyderabad, 900 km away, she will report when she is back on Tuesday.

Washed it, checked the charger worked, then patched it up, covered joint with heat shrink, looks normal, have to look closely for repair marks.

Voltage seems normal...laptop is in Hyderabad, 900 km away, she will report when she is back on Tuesday.

Kitchen scale, eats batteries...redid the solder connections, will try with fresh batteries, or hack it to a 3 volt mains adapter...no batteries needed.

That sounds like the problem I fixed today with a blood pressure cuff that

was eating batteries ( 2 AAA ). Two to three uses only. It said that power

consumption was 0.5A. I made a 3.0V power supply for it with a LM317 and

a 5V wall wart. Connected it up with 30 inches of 26awg telephone wire to the

cuff and it did not work. Volt meter said that it was getting 3V at the cuff.

Took out my scope and saw that the voltage at the power supply was fine

but the voltage at the cuff was dropping down to 1V every 30 ms.

A nice 7.5A pulse ( calculated by the resistance of the telephone wires).

(duty cycle was small and it averaged out to 0.5A)

Poor little AAA batteries!

I added two 1000uF 6.3V capacitors in the battery compartment and everything

now works correctly.

I assume that there was a capacitor inside the cuff that had gone bad.

was eating batteries ( 2 AAA ). Two to three uses only. It said that power

consumption was 0.5A. I made a 3.0V power supply for it with a LM317 and

a 5V wall wart. Connected it up with 30 inches of 26awg telephone wire to the

cuff and it did not work. Volt meter said that it was getting 3V at the cuff.

Took out my scope and saw that the voltage at the power supply was fine

but the voltage at the cuff was dropping down to 1V every 30 ms.

A nice 7.5A pulse ( calculated by the resistance of the telephone wires).

(duty cycle was small and it averaged out to 0.5A)

Poor little AAA batteries!

I added two 1000uF 6.3V capacitors in the battery compartment and everything

now works correctly.

I assume that there was a capacitor inside the cuff that had gone bad.

Last edited:

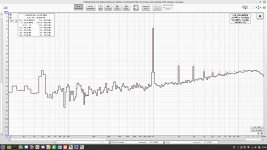

I repaired a transistor radio "Braun T1000" bought in 1967. UKW sound suffered from nasty distortions sounding like the station never was tuned in correctly. So I delved into the 10.7MHz-IF amplifier tried to tune it several times - but to no avail. A closer look to the ratio detector finally revealed a broken Ge-Diode AA119. I have a bunch of Ge-Diodes, but nothing similar to these. Finally I replaced both Ge-Diodes with a low-power Schottky-Diode BAT41 that comes quite close. At this point I could tune the IF-amp using a small FM-transmitter I had built for this purpose meanwhile. Using my soundcard setup and REW-RTA I tuned to smallest THD. Station finetuning is done by searching the minimum H2-distortion level (=max symmetric), while H3-distortion indicates if-bandwidth limits. After a long journey the sound of this old beauty now is quite satisfying.

Attachments

-

T1000-frontal.jpeg29.2 KB · Views: 84

T1000-frontal.jpeg29.2 KB · Views: 84 -

IMG_20221122_145109036.jpg72.8 KB · Views: 93

IMG_20221122_145109036.jpg72.8 KB · Views: 93 -

T1000-inside-IMG_20221129_010139901.jpg177 KB · Views: 97

T1000-inside-IMG_20221129_010139901.jpg177 KB · Views: 97 -

01-IMG_20221213_004218710.jpg97.4 KB · Views: 96

01-IMG_20221213_004218710.jpg97.4 KB · Views: 96 -

02-IMG_20221214_001042493.jpg138.1 KB · Views: 100

02-IMG_20221214_001042493.jpg138.1 KB · Views: 100 -

T1000-UCA202-2022-12-17.png54.1 KB · Views: 87

T1000-UCA202-2022-12-17.png54.1 KB · Views: 87 -

T1000-UCA202-2022-12-16.png53.8 KB · Views: 88

T1000-UCA202-2022-12-16.png53.8 KB · Views: 88

Last edited:

Fixed an unsteady -18V supply rail on a Sansui 4900Z that bled audibly into the output when it glitched. The culprit was a bad 47uF 25V cap.

This means it finally happened: after dozens of repairs I finally found an electrolytic cap that failed, seemingly in isolation, without being overvolted or reverse biased or otherwise part of a larger cascading failure. This comes after years of telling everyone that no, your vintage gear does not need new caps, and yes, it's just an internet myth that electrolytic caps are surely the culprit behind whatever symptom you have, and the problem is more likely a bad switch contact, dirty pot, cracked solder joint, or noisy failing transistor. I may have exaggerated and said it's "never" the caps. Evidently, sometimes it is.

This means it finally happened: after dozens of repairs I finally found an electrolytic cap that failed, seemingly in isolation, without being overvolted or reverse biased or otherwise part of a larger cascading failure. This comes after years of telling everyone that no, your vintage gear does not need new caps, and yes, it's just an internet myth that electrolytic caps are surely the culprit behind whatever symptom you have, and the problem is more likely a bad switch contact, dirty pot, cracked solder joint, or noisy failing transistor. I may have exaggerated and said it's "never" the caps. Evidently, sometimes it is.

never say "never"😉Fixed an unsteady -18V supply rail on a Sansui 4900Z that bled audibly into the output when it glitched. The culprit was a bad 47uF 25V cap.

This means it finally happened: after dozens of repairs I finally found an electrolytic cap that failed, seemingly in isolation, without being overvolted or reverse biased or otherwise part of a larger cascading failure. This comes after years of telling everyone that no, your vintage gear does not need new caps, and yes, it's just an internet myth that electrolytic caps are surely the culprit behind whatever symptom you have, and the problem is more likely a bad switch contact, dirty pot, cracked solder joint, or noisy failing transistor. I may have exaggerated and said it's "never" the caps. Evidently, sometimes it is.

They not only can fail, they dry out. Someone on Gearspace said they don't leak. Well, they do that too: in a second-hand Lexicon LXP-15 - a multi-effect rackmount box - they did just that and the leak not only damaged components and the PCB, but since the box was apparently stored upside-down for a while, the leak ate up the upper chassis, like in layers of the metal.This means it finally happened: after dozens of repairs I finally found an electrolytic cap that failed, seemingly in isolation, without being overvolted or reverse biased or otherwise part of a larger cascading failure. This comes after years of telling everyone that no, your vintage gear does not need new caps, and yes, it's just an internet myth that electrolytic caps are surely the culprit behind whatever symptom you have, and the problem is more likely a bad switch contact, dirty pot, cracked solder joint, or noisy failing transistor. I may have exaggerated and said it's "never" the caps. Evidently, sometimes it is.

It also smelled really bad, like rotten fish.

Kitchen sink clogged. Day 1: pull the P trap and clean out. Day 2: use the 25' auger to clean out. Day 3: rent a 50'x1/2" auger to clean out=fixed

Leaking hot water line in my smaller rental/Father-in-law house.

Will need to protect the repaired line better and replace the small wall and tile I had to remote in order to get to it.

Temperature outside only got down to -16F.

Also goes under that "Its cold today" thread.

Will need to protect the repaired line better and replace the small wall and tile I had to remote in order to get to it.

Temperature outside only got down to -16F.

Also goes under that "Its cold today" thread.

Part of the sole was coming loose on my Merrell hiking shoe. I'd tried contact cement before on some Columbia hikers without success, so this time I squirted on a generous amount of Dollarama Adhero cyanoacrylate glue, and pressed it down. After a 2.5 mile walk in the snow to fetch groceries, it's still stuck firmly.

Historically, ShoeGoo was the thing to use on shoes. No other stick-um came close, for adhesion, for shedding water, for wear. I always keep some around. Amazon, HomeDepot, or probably CanadianTire.sole was coming loose on my Merrell hiking shoe.

But...... the original recipe (literally industrial shoe adhesive) would make you high and rot your liver and caused smog in California. Each year there is less toxic solvent. It has become awful thick for cracks or for spreading.

They can't even seem to make shipping tape that sticks anymore! Grrr....

Waay back in the '70s, my first real job was working for a local guy who ran a coin-op business out of his home. I was fixing his jukeboxes & pinball machines, but he also kept busy re-clothing pool tables all around the area (he did really nice work).

For that job he'd been faithfully using some kind of industrial contact cement mixed up at a place near Chicago. At some point they decided to switch to a more environmentally-friendly formula for the stuff my boss had been ordering for decades. He had no advance notice - didn't discover until it was time to reorder the usual half-dozen gallon cans, and the new stuff simply would not work. It wouldn't tack up properly to stick to the felt, or something.

So now out of nowhere this guy's pool table business was dead in the water. But Sam was one tenacious dude. After many, many phone calls & "discussions" with the glue factory, they agreed to do one "small," final batch using the original formula, just for him. He ordered cartons & cartons of the stuff; we had boxes stacked to the ceiling in the garage. Lifetime supply. Problem solved.

Poor guy died from lung cancer about 5 years later.

(Of course he also chain-smoked Lucky Strikes all his life, so...) ¯\(ツ)/¯

Waay back in the '70s, my first real job was working for a local guy who ran a coin-op business out of his home. I was fixing his jukeboxes & pinball machines, but he also kept busy re-clothing pool tables all around the area (he did really nice work).

For that job he'd been faithfully using some kind of industrial contact cement mixed up at a place near Chicago. At some point they decided to switch to a more environmentally-friendly formula for the stuff my boss had been ordering for decades. He had no advance notice - didn't discover until it was time to reorder the usual half-dozen gallon cans, and the new stuff simply would not work. It wouldn't tack up properly to stick to the felt, or something.

So now out of nowhere this guy's pool table business was dead in the water. But Sam was one tenacious dude. After many, many phone calls & "discussions" with the glue factory, they agreed to do one "small," final batch using the original formula, just for him. He ordered cartons & cartons of the stuff; we had boxes stacked to the ceiling in the garage. Lifetime supply. Problem solved.

Poor guy died from lung cancer about 5 years later.

(Of course he also chain-smoked Lucky Strikes all his life, so...) ¯\(ツ)/¯

#3 son's fiancee stayed with us for a few months prior to the wedding (everything above board). Shared a bathroom with #1 son. He gave his "soon-to-be" sister-in-law a bottle of Pequot, i.e. liquid sodium hydroxide, as her long brunette hair had clogged the shower drain.Kitchen sink clogged. Day 1: pull the P trap and clean out. Day 2: use the 25' auger to clean out. Day 3: rent a 50'x1/2" auger to clean out=fixed

Now it is 10 years later and the 3 sons have given us 9 grand-kids, so it all works out.

@Jim the Oldbie -- we do coatings which, in some respects, are a close relationship to adhesives -- there is no free lunch.

In my first real job I was charged with analyzing chemical companies' financial statements. In that era 50 years ago (almost) liver cancer from those companies engaged in coatings and specialty resins was just shocking.

In my first real job I was charged with analyzing chemical companies' financial statements. In that era 50 years ago (almost) liver cancer from those companies engaged in coatings and specialty resins was just shocking.

Sorry, liver cancer in financial statements?

Please explain.

There a a modified cyanoacrylate here, called 'Flexiquik', intended for sticking flexible stuff like table edge bands, the PVC ones used on chipboard tops.

It sets only slightly slower than super glue type adhesives.

A similar grade may be sold by Loctite, for example.

I saw my tire repair man use it, so after that I insisted on putting a drop at the site of a removed screw or nail after a puncture repair.

It prevents moisture reaching the radial tire wires, which would otherwise rust and swell up, causing tire delamination.

That is a possible candidate for shoe adhesive, also there are urethane based adhesives available for shoe manufacture, but mostly bulk packs there, the 'Flexiquik' is sold in 15 ml or so bottles, larger packs may also be available.

I have no ties to the maker, except as a user.

Bear in mind that there variations in material, and some plastics are hard to stick, some require surface treatment immediately before adhesive application.

Please explain.

There a a modified cyanoacrylate here, called 'Flexiquik', intended for sticking flexible stuff like table edge bands, the PVC ones used on chipboard tops.

It sets only slightly slower than super glue type adhesives.

A similar grade may be sold by Loctite, for example.

I saw my tire repair man use it, so after that I insisted on putting a drop at the site of a removed screw or nail after a puncture repair.

It prevents moisture reaching the radial tire wires, which would otherwise rust and swell up, causing tire delamination.

That is a possible candidate for shoe adhesive, also there are urethane based adhesives available for shoe manufacture, but mostly bulk packs there, the 'Flexiquik' is sold in 15 ml or so bottles, larger packs may also be available.

I have no ties to the maker, except as a user.

Bear in mind that there variations in material, and some plastics are hard to stick, some require surface treatment immediately before adhesive application.

Last edited:

- Home

- Member Areas

- The Lounge

- What did you last repair?