Then I use regular poly' stuffing/fill for the rest of the box; usually starting at about 50% fill.

I found some relevent data:

broadway-thickness-chart - Primacoustic

One inch thickness seems to provide very useful absorption at 500Hz, two inches down to 250Hz. So, a lot less than one wavelength.

I'd suggest 1" for small boxes, and 2" for larger boxes. Plus stuffing, unless ported.

broadway-thickness-chart - Primacoustic

One inch thickness seems to provide very useful absorption at 500Hz, two inches down to 250Hz. So, a lot less than one wavelength.

I'd suggest 1" for small boxes, and 2" for larger boxes. Plus stuffing, unless ported.

Aperiodic ports are probably the least used speaker loading and there is very little research out there on which to draw. Anything you do is likely to be a pure guess and therefore of very questionable benefit; more likely detriment! Best not go there unless you have a fully equipped labe and lots of time to spare.

In my particular case; they do help. The transients in the lower bass are improved; I just do a simple blocking of the vent and listen with it blocked; then listen again without blocking. I agree there should be more data available and also agree they won't always make a difference or might make matters worse. I purposely offset the location relative to the woofer centerline. (ie, not located directly behind the woofer but down and over several inches). I did this so I could get the 4 inch foam pyramids in closer to the woofer but not fully enclosing the back of it. What little I could find to read.; a clear path from the back of the driver to the vent is recommended.

What little I did find to read is it reduces the magnitude of the impedance "hump"; supposed to improve transient response but it also makes the alignment more like 3rd order (in my case; this was a benefit).

What little I did find to read is it reduces the magnitude of the impedance "hump"; supposed to improve transient response but it also makes the alignment more like 3rd order (in my case; this was a benefit).

For a porous absorber and with matched impedance it is often said the absober starts to be effective at 1/8 wavelength

Is bass loading anything to do with "boxiness"?

I would think any kind of resonance would add to a "boxy sound"?

It just seemed to me that the thread was drifting somewhat. Boxy sound should be about midrange resonances and reflections, plus panel resonances and vibration.

You can of course avoid all of those if you just use naked drivers. 😉

You can of course avoid all of those if you just use naked drivers. 😉

That doesn't seem to tally with what I found (post 82).

1/8 wavelength is of course just a rule of thumb, but it gives you a good idea how thick an absorber needs to be. you must also decide how large and where the absorber must be and which density

For a very tall and narrow box with a thin layer of which ever material will have almost none impact on damping the lowest frequency standing wave

In my search for the cleanest non-boxy and non-resonant sound from a box speaker: while attempting to prove my measured TS Parameters through acoustic measurements coupled with measuring several different drivers in various box sizes with a few different stuffing materials, I discovered a few things.

For stuffing - felt and compressed poly fill help very little to lower box Qtc

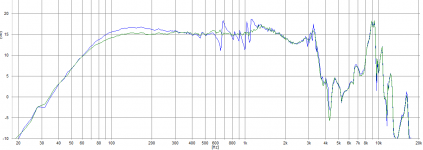

My red blanket with holes did an amazing job as shown in my nearfield measurement, green is stuffed. Old news for some on here, but nice to see for myself🙂

Comments on Post 63 about pours appears to align with my results!

A side note: If we use Manufactured TS Parameters, I believe it's a hit and miss game. All of my drivers TS measurements are out from the Posted specs, some wildly.

For stuffing - felt and compressed poly fill help very little to lower box Qtc

My red blanket with holes did an amazing job as shown in my nearfield measurement, green is stuffed. Old news for some on here, but nice to see for myself🙂

Comments on Post 63 about pours appears to align with my results!

A side note: If we use Manufactured TS Parameters, I believe it's a hit and miss game. All of my drivers TS measurements are out from the Posted specs, some wildly.

Attachments

For stuffing - felt and compressed poly fill help very little to lower box Qtc

My red blanket with holes did an amazing job as shown in my nearfield measurement

The damping material should not be to dense nor to loose, your blanket seems to be better matched, the material should have the right amount of flow resistance when you blow throu it

1/8 wavelength is of course just a rule of thumb, but it gives you a good idea how thick an absorber needs to be. you must also decide how large and where the absorber must be and which density

For a very tall and narrow box with a thin layer of which ever material will have almost none impact on damping the lowest frequency standing wave

So you ignore my reference in post 82? Which seems to indicate that a rule of thumb of 1/24 of a wavelength?

And then. I'm talking about reflections (try reading post 74), not standing waves. Standing waves are a different matter, as they're better addressed at the points of highest velocity (though don't ignore the beneficial effects of high density wall lining). Highest velocity exists in the middle of the box, but that's the most difficult location for absorptive material. Polyester filling is next to useless (though useful for "volume enlargement").

Use of stuffing in order to increase the apparent box volume isn't anything to do with acoustic absorption. It's to do with providing a thermal sink to regulate the air temperature during compression and rarefaction of the air inside the box due to the cone moving in and out. Conversion from what would be an adiabatic process to isothermal.

Only relevant for low bass frequencies. Even the otherwise useless polyester stuffing is useful in this context.

Only relevant for low bass frequencies. Even the otherwise useless polyester stuffing is useful in this context.

That is my understanding also; it is a form of energy/heat transfer on a very small scale. It has been decades since I had a class on Thermodynamics but the terms came right back to me as soon as I saw them.

There are many variables at play here. Keep in mind that the thinner and/or lighter a driver cone is; the easier it is to be affected by unwanted reflected energy; regardless of the frequency or frequencies.

Under damped boxes don't sound good; over damped boxes don't sound good either.

There are many variables at play here. Keep in mind that the thinner and/or lighter a driver cone is; the easier it is to be affected by unwanted reflected energy; regardless of the frequency or frequencies.

Under damped boxes don't sound good; over damped boxes don't sound good either.

Definitely agree about the speaker cone. Even the heaviest is going to be pretty much acoustically transparent - hence the need to stop unwanted reflections and especially resonances within the enclosure.

It's interesting to consider whether a relatively small acoustic hole in the front of the speaker is worse than the large area of mildly vibrating panels which form the enclosure.

Easiest is to overkill the internal absorption to mitigate the former and make the latter as rigid and dense as possible.

Or use naked drivers...

It's interesting to consider whether a relatively small acoustic hole in the front of the speaker is worse than the large area of mildly vibrating panels which form the enclosure.

Easiest is to overkill the internal absorption to mitigate the former and make the latter as rigid and dense as possible.

Or use naked drivers...

So you ignore my reference in post 82? Which seems to indicate that a rule of thumb of 1/24 of a wavelength?

And then. I'm talking about reflections (try reading post 74), not standing waves. Standing waves are a different matter, as they're better addressed at the points of highest velocity (though don't ignore the beneficial effects of high density wall lining). Highest velocity exists in the middle of the box, but that's the most difficult location for absorptive material. Polyester filling is next to useless (though useful for "volume enlargement").

No, i have just never seen a porous absorber that has 100% absorption for a thickness of only 1/24 wavelength

Normally you want an absorber thickness of 1/4 wavelength

I guess you can read about anechoic chambers for more info

- Home

- Loudspeakers

- Multi-Way

- What can I do against 'box sound' ?