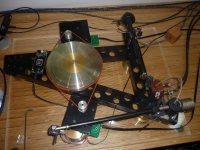

As i don't like asymetric drive by nature i use an external axle as well. this is placed on the opposite side of the motor/drive. The string is tensioned between the oversized pulley and this external axle. The air bearing platter is coasting in between.

Why not simply use 2 motors (each with its own belt) at 180 degrees orientation ... as I did?

Andy

Attachments

@andyr

tipical crocodile amygdala mindset..."bigger is better" actually there's no proof for even two motors system making any useful improvement over a one motor design, it can actually be mathematically proved that a one motor is better than two or three in a turntable no matter the transmision system .

Three ac motors would allow the use of a three phase mains supply which is theoretically much better for motor noise reduction while 3 dc motor would only alow for perfect centering of the spindle, but that is actually not true at all either ...

One motor and belt or idler allows the air or oil bearing to lubricate itself permanently by using the difference of speed and presure between the bear housing and spindle on two sides of the spindle .I'm not a mechanical engineer as many people here pretend to be, but fluids physics is largely available to be studied since the airplane wing was invented... and air difference of speed and pressure between the two sides of a wing applies perfectly in lubricating a turntable spindle when you're using only one motor allowing for perfect centering much better than a multiple motor system .

The only solid reason for he might have used three motors is that the platter is fantastically heavy to start rotating and honestly having such platers is hardly justified in a vinyl cutter lathe, but zero beneffit in a vinyl play, other than to impress your friends and buy some iron for 5 figures dollars...

I have no knowledge of an airplane using multiple motors on both sides of a wing...If you know such airplane please show it to me and i may start making concessions on the use of multiple motors in turntables!

If using such big platters , maybe it would be much more profficient to use Neumann VMS 80 transimision and drive system than to buy all Dual 741 motors on the market just to sell an overly expensive and useless ton of rotating iron...

There are some guys outhere that would be happy to have one such motor to build a one DD turntable with much better performance when using a 2...3 kg platter design.

tipical crocodile amygdala mindset..."bigger is better" actually there's no proof for even two motors system making any useful improvement over a one motor design, it can actually be mathematically proved that a one motor is better than two or three in a turntable no matter the transmision system .

Three ac motors would allow the use of a three phase mains supply which is theoretically much better for motor noise reduction while 3 dc motor would only alow for perfect centering of the spindle, but that is actually not true at all either ...

One motor and belt or idler allows the air or oil bearing to lubricate itself permanently by using the difference of speed and presure between the bear housing and spindle on two sides of the spindle .I'm not a mechanical engineer as many people here pretend to be, but fluids physics is largely available to be studied since the airplane wing was invented... and air difference of speed and pressure between the two sides of a wing applies perfectly in lubricating a turntable spindle when you're using only one motor allowing for perfect centering much better than a multiple motor system .

The only solid reason for he might have used three motors is that the platter is fantastically heavy to start rotating and honestly having such platers is hardly justified in a vinyl cutter lathe, but zero beneffit in a vinyl play, other than to impress your friends and buy some iron for 5 figures dollars...

I have no knowledge of an airplane using multiple motors on both sides of a wing...If you know such airplane please show it to me and i may start making concessions on the use of multiple motors in turntables!

If using such big platters , maybe it would be much more profficient to use Neumann VMS 80 transimision and drive system than to buy all Dual 741 motors on the market just to sell an overly expensive and useless ton of rotating iron...

There are some guys outhere that would be happy to have one such motor to build a one DD turntable with much better performance when using a 2...3 kg platter design.

Last edited:

@andyr

typical crocodile amygdala mindset..."bigger is better" actually there's no proof for even two motors system making any useful improvement over a one motor design

Hah - you must be an engineer, d. 😀

Whereas my background is science - which is based on experimentation, rather than mindlessly making assumptions. :rolleyes

Listening to one motor vs. two is an easy experiment - once the dual-motor arrangement has been set up.

Playing Vivaldi's "Gloria" - a wonderful choral piece - my listening panel all agreed that when 2 motors were driving the platter:

* you got more 'bite' to the music (you could call this better dynamics, I guess)

* and the decay of the voices in the recording space sounded better.

Of course, you need to have a motor speed controller that is set up to drive 2 motors (there's a phase difference between the two motors). The 'Number9' that I use was designed with this in mind. 🙂

Andy

Hi Andy,

i didn't have the space for another motor at that location.......

so i had to settle for the next best thing......

To be fair i tried a 2 and even a 3 motor drive at another turntable but never got that perfect (motormanagement to get those motors to work in correctly). Instead of working together these motors tried to compensate for each other. It ended up as too nervous and not stable.

So when i did this monster i wasn't unhappy that there wasn't space for that other motor/drive.

Regards,

Reinout

i didn't have the space for another motor at that location.......

so i had to settle for the next best thing......

To be fair i tried a 2 and even a 3 motor drive at another turntable but never got that perfect (motormanagement to get those motors to work in correctly). Instead of working together these motors tried to compensate for each other. It ended up as too nervous and not stable.

So when i did this monster i wasn't unhappy that there wasn't space for that other motor/drive.

Regards,

Reinout

I get this types of reviews all the time everywhere this days, as often as in the 80's purely technical reviews based on measurements were the norm.A dual 1219 run on mains 50hz sounds more "dynamical" than one run on a quartz oscillator while being much inferior to the quartz one at replaying the true vinyl sound to which the quartz version is more true. Tape, and vinyl sound more dynamic than CD...16 bit CD played on 14 bit dacs sounds more dinamic than Blue Ray and so on...Usually more perceived dynamics in mechanical playing systems tells less accuracy compared to the "boring" more precise ones.I have nothing against "dynamical " systems when listening to music, but we should not use our perceptions to define better reproduction systems called "highee end " sytems by some or boring by others.Hah - you must be an engineer, d. 😀

Whereas my background is science - which is based on experimentation, rather than mindlessly making assumptions. :rolleyes

Listening to one motor vs. two is an easy experiment - once the dual-motor arrangement has been set up.

Playing Vivaldi's "Gloria" - a wonderful choral piece - my listening panel all agreed that when 2 motors were driving the platter:

* you got more 'bite' to the music (you could call this better dynamics, I guess)

* and the decay of the voices in the recording space sounded better.

Of course, you need to have a motor speed controller that is set up to drive 2 motors (there's a phase difference between the two motors). The 'Number9' that I use was designed with this in mind. 🙂

Andy

And officially i'm not an engineer , i hold no engineering diploma in any field, never attended any university courses other than on Youtube, I just do engineering based on some 8 years of physics and chemistry studied in schools ...Up untill 25 years ago i was doing 7 hours of physics and 6 hours of chemistry every single week in highschool.I can't say i was the snappiest kid at answering those quetions, put by my teachers, some knowing me might say i was rather a mediocre student compared to the worlsd's olympics medalists I had back then studying in the same classroom with me , but i won't allow my perceptions about my rather horrible teachers to put a veil on the science itself...

Last edited:

Absolutely! And definitely what you did is the next best thing. 🙂Hi Andy,

i didn't have the space for another motor at that location.......

so i had to settle for the next best thing......

Regards,

Reinout

To be fair i tried a 2 and even a 3 motor drive at another turntable but never got that perfect (motor management to get those motors to work in correctly). Instead of working together these motors tried to compensate for each other. It ended up as too nervous and not stable.

Yes, I know the problem. I could only do what I did because the 'Number9' AC motor speed controller which I use is set up to handle 2 motors (with independent setting of the motor drive parameters).

Andy

It ended up as too nervous and not stable.

Synchronous motors?

I have nothing against "dynamical" systems when listening to music, but we should not use our perceptions to define better reproduction systems called "higher end " systems by some or boring by others.

However, my view is that you tell whether a system sounds better - and conveys the emotion in the recording better - by listening ... not by quoting measurements. 🙂

Andy

@Andy

I think it's quite easy to get my messages even though i'm not an english native speaker.Ask japanese diy-ers and audiophiles what they consider high end and you'll see a very big difference between western and eastern conceptions.Try and listen to a complete high end Kenwood setup sold only in Japan in the 80's and you'll understand that Japanese don't get the same deffinition of dynamics as the rest of the world.I had once one of their best amplifiers and while i could consider that one as the most boring i ever heard, as boring as their martial arts , it was also the most precise and accurate sytem too.Their usual vinyls are half speed cut too...so we don't really listen the same vinyls as them either.Have you also seen many japanese diy-ers on this forum? Besides Neumann VMS 80 are german machines too...so maybe we are the ones who lost the true sense of what capable engineering means.

I think it's quite easy to get my messages even though i'm not an english native speaker.Ask japanese diy-ers and audiophiles what they consider high end and you'll see a very big difference between western and eastern conceptions.Try and listen to a complete high end Kenwood setup sold only in Japan in the 80's and you'll understand that Japanese don't get the same deffinition of dynamics as the rest of the world.I had once one of their best amplifiers and while i could consider that one as the most boring i ever heard, as boring as their martial arts , it was also the most precise and accurate sytem too.Their usual vinyls are half speed cut too...so we don't really listen the same vinyls as them either.Have you also seen many japanese diy-ers on this forum? Besides Neumann VMS 80 are german machines too...so maybe we are the ones who lost the true sense of what capable engineering means.

Last edited:

To the OP of the thread, banpuku, there is no "ultimate" turntable technology, and any "root cause issues" are most likely from the record itself, which can only be partially remedied.

Built into the vinyl itself, being a mechanical/physical source, friction and background rumble are always present to varying degrees.

The quest for the most satisfying quality of playback (for human ears) has been done, decades ago.

And that's been achieved without bizzare, utterly rediculous designs, some of which have even been posted in this thread.

The use of vacuum pumps, multiple motors, 200 pound platters, etc etc etc. prove nothing to human ears, only the human mind.

Yet, the ongoing fascination with those bloated designs is driven by eccentric obsessions that only the designers seem to succumb to, for whatever reasons.

The visual attraction to impressive looking and complex physical machinery gives some the "perception" of playback perfection.

Without the visual focus involved, a well designed yet relatively sensible machine cannot be differentiated from those utterly silly designs - this has been documented elsewhere.

Built into the vinyl itself, being a mechanical/physical source, friction and background rumble are always present to varying degrees.

The quest for the most satisfying quality of playback (for human ears) has been done, decades ago.

And that's been achieved without bizzare, utterly rediculous designs, some of which have even been posted in this thread.

The use of vacuum pumps, multiple motors, 200 pound platters, etc etc etc. prove nothing to human ears, only the human mind.

Yet, the ongoing fascination with those bloated designs is driven by eccentric obsessions that only the designers seem to succumb to, for whatever reasons.

The visual attraction to impressive looking and complex physical machinery gives some the "perception" of playback perfection.

Without the visual focus involved, a well designed yet relatively sensible machine cannot be differentiated from those utterly silly designs - this has been documented elsewhere.

Last edited:

Without the visual focus involved, a well designed yet relatively sensible machine cannot be differentiated from those utterly silly designs - this has been documented elsewhere.

Can you show us where this has been documented elsewhere ?

Thanks in advance,

Dennis h

Is that a misprint? 2.4 x 10-11 meters? That's a factor of 20X better resolution than the smallest linewidth on Intel's newest integrated circuit . . . ??

Yep, around 10 times smaller than the diameter of an iron or a silicon atom, it must work with X-rays I guess... I would like to see what that sensor does. No idea about electronics, but we chemists could make good use of it

Why not simply use 2 motors (each with its own belt) at 180 degrees orientation ... as I did?

Andy

A well reputed Germany manufacturer is using this system.

Rgds

Adelmo

Can you show us where this has been documented elsewhere ?

Thanks in advance,

Dennis h

As is usual, people on the internet ask for documentation about something.

They want proof, facts, someone who's done the "measuring" and such, particularly on this website, since a plethora of critics and suspicious minds abound.

To answer your question - no, because it was years ago when I read those papers and the documented results, and at the time had no intention of saving them, except to convey from memory what I stated earlier.

I'm not obsessed with saving every tidbit I come across, I'd need a rack full of hard drives and shelves stacked with publications.

@andyr

tipical crocodile amygdala mindset..."bigger is better" actually there's no proof for even two motors system making any useful improvement over a one motor design, it can actually be mathematically proved that a one motor is better than two or three in a turntable no matter the transmision system .

Three ac motors would allow the use of a three phase mains supply which is theoretically much better for motor noise reduction while 3 dc motor would only alow for perfect centering of the spindle, but that is actually not true at all either ...

One motor and belt or idler allows the air or oil bearing to lubricate itself permanently by using the difference of speed and presure between the bear housing and spindle on two sides of the spindle .I'm not a mechanical engineer as many people here pretend to be, but fluids physics is largely available to be studied since the airplane wing was invented... and air difference of speed and pressure between the two sides of a wing applies perfectly in lubricating a turntable spindle when you're using only one motor allowing for perfect centering much better than a multiple motor system .

The only solid reason for he might have used three motors is that the platter is fantastically heavy to start rotating and honestly having such platers is hardly justified in a vinyl cutter lathe, but zero beneffit in a vinyl play, other than to impress your friends and buy some iron for 5 figures dollars...

I have no knowledge of an airplane using multiple motors on both sides of a wing...If you know such airplane please show it to me and i may start making concessions on the use of multiple motors in turntables!

If using such big platters , maybe it would be much more profficient to use Neumann VMS 80 transimision and drive system than to buy all Dual 741 motors on the market just to sell an overly expensive and useless ton of rotating iron...

There are some guys outhere that would be happy to have one such motor to build a one DD turntable with much better performance when using a 2...3 kg platter design.

Hi Dreamth,

I instead believe that 2 motors and a Fly Wheel to drive the platter are an improvement ( VPI and others have developed it ). A heavy Fly Wheel with similar weigh as the platter such as around 5 Kg ) needs 2 motors for torque reason.

I have also tried an attempt to make it, unfortunately the fly wheel made by the lathe guy did not have the necessary precision and was not well balanced so gave some short coming, but regarding the speed stability and dynamic of the sound was an improvement VS the single motor.

Allow me to add that type of belt and length is also important so the system need e total matching and not just a simple single or double motor....

Regarding the type of motors and controllers, well..........it is a jungle, almost an endless debate.

Rgds

Adelmo

I have a somewhat off-topic question here, but I see that there are TT specialists.

I have a weight for vinyls similar to the one in the photograph that weighed 1.5 KG.

My turntable's DD motor is not very robust, so I decided to take weight off it so as not to overload the vertical pressure on the bearing. (I don't really know what it is like, I imagine it will be a ball dipped in a high-density oil, because I had a hard time putting it back in its place)

I managed to get it down to 0.900 grams. But I think it's still too much, so I'm not using it.

The TT platter weighs 1.5KG.

Thoughts ?

DQ43 R-Player Micro Seiki Tokyo, build 1978, 1 pictures, Jap

I have a weight for vinyls similar to the one in the photograph that weighed 1.5 KG.

My turntable's DD motor is not very robust, so I decided to take weight off it so as not to overload the vertical pressure on the bearing. (I don't really know what it is like, I imagine it will be a ball dipped in a high-density oil, because I had a hard time putting it back in its place)

I managed to get it down to 0.900 grams. But I think it's still too much, so I'm not using it.

The TT platter weighs 1.5KG.

Thoughts ?

DQ43 R-Player Micro Seiki Tokyo, build 1978, 1 pictures, Jap

Attachments

Last edited:

HI,

I suppose it is a puc from the picture. Usually they are used to get a better sound coping with different issues. I have a puc 0.5 Kg and I need to use it as my platter is made of acrylic and the record without the puc could slip and sound worse. Indeed sound worse as I have tested, but that is my specific case.

As general speaking the puc are usually 350 to 500 grams unless there are special reasons to need a more heavy one. There are also clamp that weigh very little but clamping on the spindle help to press down or flatten down the record to the platter/mat.

What is in reality your goal. The record does sound better with the puc ?

The puc match well you mat and so the record sound better?

You have copper of other slippery platter and need a puc?

Rgds

Adelmo

I suppose it is a puc from the picture. Usually they are used to get a better sound coping with different issues. I have a puc 0.5 Kg and I need to use it as my platter is made of acrylic and the record without the puc could slip and sound worse. Indeed sound worse as I have tested, but that is my specific case.

As general speaking the puc are usually 350 to 500 grams unless there are special reasons to need a more heavy one. There are also clamp that weigh very little but clamping on the spindle help to press down or flatten down the record to the platter/mat.

What is in reality your goal. The record does sound better with the puc ?

The puc match well you mat and so the record sound better?

You have copper of other slippery platter and need a puc?

Rgds

Adelmo

I have a somewhat off-topic question here, but I see that there are TT specialists.

I have a weight for vinyls similar to the one in the photograph that weighed 1.5 KG.

My turntable's DD motor is not very robust, so I decided to take weight off it so as not to overload the vertical pressure on the bearing. (I don't really know what it is like, I imagine it will be a ball dipped in a high-density oil, because I had a hard time putting it back in its place)

I managed to get it down to 0.900 grams. But I think it's still too much, so I'm not using it.

The TT platter weighs 1.5KG.

Thoughts ?

If honestly needed, like for cupped or warped records, and a weight is not wise, use a "lighter weight"clamp type stabilizer instead.

Those clamp to the spindle instead.

12russel3456 and wiseoldtech:

I know the anchor fittings, it's just my concern of how strong the motor is to put 3/4 of its extra weight on the bearing.

Anyone know exactly how is the bearing inside?

The mat is rubber, I don't have warped vinyls and I don't hear differences, but it's just a curiosity.

I know the anchor fittings, it's just my concern of how strong the motor is to put 3/4 of its extra weight on the bearing.

Anyone know exactly how is the bearing inside?

The mat is rubber, I don't have warped vinyls and I don't hear differences, but it's just a curiosity.

12russel3456 and wiseoldtech:

I know the anchor fittings, it's just my concern of how strong the motor is to put 3/4 of its extra weight on the bearing.

Anyone know exactly how is the bearing inside?

The mat is rubber, I don't have warped vinyls and I don't hear differences, but it's just a curiosity.

Then why bother with weights or clamps?

Surely, the platter bearing is sturdy enough to support the platter, and nothing to worry about.

- Home

- Source & Line

- Analogue Source

- Ultimate turntable design: modern technology to remediate root cause issues