Yes, some manufacturers already use direct drive and air bearing technology.

It's interesting that TechDas use air bearings, air suspension, vacuum hold, yet still go for a classic asymmetric belt drive. Makes you think, doesn't it?

It does make me think. Same can be said for Bergmann and Kuzma.

A state-of-the-art rotary air bearing with ultra precision direct drive and related electronics (OEM solution) will retail for $20k, just for the parts. No plinth, no platter, no arm board, etc. By the time this kind of solution has dealer margin, distributor margin and dealer margin, the table would be approaching $100K. Very little market. So, is a state-of-the-art direct drive rotary table not used because of the solution or cost. My guess, cost.

A state-of-the-art rotary air bearing with ultra precision direct drive and related electronics (OEM solution) will retail for $20k, just for the parts. No plinth, no platter, no arm board, etc. By the time this kind of solution has dealer margin, distributor margin and dealer margin, the table would be approaching $100K. Very little market. So, is a state-of-the-art direct drive rotary table not used because of the solution or cost. My guess, cost.

I just heard today a completely different story where old mains refferenced idlers sound more "dynamic" when compared to the more modern ones although technicaly they are actually worse.Vinyl is also technically lower quality than CD yet you get the opposite feeling...Groundless speculation. Practically all the rebuilt current implementations of the classic idlers are fed from low distortion, accurate sine wave generators. No reference to mains frequency whatsoever. Being fed good power makes the idlers sound better than ever.

My guess, cost.

Perhaps so. Have you examined the RRP of Air Force Zero? A 100k is probably the standard discount a dealer offers off list 🙂

Remarkably little development around DD. Apart from the remarkable Grand Prix Monaco 2.0 i cannot recall any significant new entries.

Luxury products sales are always run by prejudice...As long a MicroSeiki aren't famous for their DD lines as they weren't big enough for the crocodile amygdala mindset , everyone thinks that a DD can't be higher quality...and audio electronic industry needs to listen to old marketing sharks if they want to sell anything.

Remarkably little development around DD. Apart from the remarkable Grand Prix Monaco 2.0 i cannot recall any significant new entries.

The new SAT XD-1 turntable is DD and use the core of the Technics SP10R which is a completely new design using coreless motor compare to their 70s (SP10Mk2) and 80s (SP10MK3) designs. Brinkmann Bardo is DD. The Thrax Yatrus is DD based on the Dual EDS-1000 design. VPI flagship is DD with Thingap motor. The STST Motus is also direct-drive. Yes, only a handful of entries.

@wiseoldtech

You're true, i just removed the whole thing becaure i found it too unnecesarily complex for my taste and needs, being a multiplayer , difficult to make it work every now and again as it had some difficult to solve problems right at his arrival, so i simply kept what was working flawless and dumped all the useless automations.We're not in the 80's anymore having no other sound source to listen to...If vinyl is only ceremonial these days , then we should keep it that way, the complete opposite of Dual being this design which honestly...looks unbeatable to me : Pioneer PL-L1000 Linear Tracking Turntable - YouTube

My main turntable, Kenwood, in use today is basically similar to that Pioneer, and has outstanding specs for what it is, but unlike the Pioneer, mine is direct drive.

No need to replace platter belts, utterly silent operation.

As for the Duals, I still regard them as quite capable machines, even in today's world of "picky and demanding" audiophiles.

That's why today they are highly praised and in demand.

They were made with fine German engineering in mind, like a Mercedes Benz.

I still own a "budget line" 1215, and find it amazing in comparison to today's turntable world, and previously owned a 1219 and a 1229, which sadly both were stolen from my first apartment back in 1982.

And being an experienced servicer, I've no problems tearing into a Dual today to bring it back to perfect operation.

I just finished up a complete restoration of a 1218 for a friend of mine, he kept it looking pristine, however the lubrication was old and needed refreshing.

And it plays like the day it was first made now.

Attachments

The Thrax Yatrus is DD based on the Dual EDS-1000 design.

Thanks. I've seen and heard it but didn't realise it was based on EDS1000. Very interesting.

The 701 sounded much better than any other DD deck i had. Used the motor in a diy concoction many years ago.

there's already a modified dual 701 1 meter away from me while refurbishing a dual 1219 in Romania isn't really a good option as sourcing parts is quite expensive here, but i never wanted that 1219 to work as in pristine condition ...Initially i took it just for experimentations as it had some missing and some broken parts anyway, even its wooden plinth was taken from a different turntable , but the platter, idler, speed changer , motor and tonearm sections had no problem so i gave up fixing the rest and when i took the decision to make a universal support for both 701 and 1219 i thought of trying more options around these turntables.Slowly but surely my Duals become linear tracking turntables...I'm not the kind of guy who spends his time on restoring things, every single equipment i bought was sighly modified to my tastes and curiosity.I have about 7 turntables around me right now, but there are only three in full working conditions and i consider them being too many already...And being an experienced servicer, I've no problems tearing into a Dual today to bring it back to perfect operation.

.

I have no idea what 701 sounding much better than any other dd means as i had a very cool japanese DD that was simply perfect ...and i still own a 701 which is absolutely ok, but i couldn't notice any differences between them apart from the automation functions that were spot on on the japanese DD.Thanks. I've seen and heard it but didn't realise it was based on EDS1000. Very interesting.

The 701 sounded much better than any other DD deck i had. Used the motor in a diy concoction many years ago.

Last edited:

Good evening to you all,

for my turntable-project i followed a lot of your comments/plans/ideas (without knowing about this thread). That turntable started a couple of years as a non-standard Caeles air-bearing turntable but, as this is a hobby, it became a sport to improve on the already good functionality.

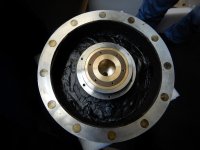

It's a real air-bearing by Eitzenberger (EZ-1320). No flimsy air bearing only in the vertical direction (small air chamber that acts as a enclosed pocket of air but fully susceptible from horizontal influences) but a proper bi-conical design. So that is self-centering and completely airfloating without any touching of any surfaces. Normally these weigh in at 7.6 kgs but that's standard stainless steel. For the Caeles they make it partly in bronce.

It's nice to have a mass-platter (several materials in order to supress resonances) but as you correctly stated that energy can be "stored" easily in this mass. There is a reason why those light weight platters can sometimes somply outplay mass turntables with crisp notes ! Simply because the energy is not contained but allowed to flow away.

I adopted that idea also here by inserting a mechanical diode in the air bearing middle void. All energy from the platter is simply channel to the subframe.

The subframe is supported by 3 airbladders. they level the turntable horizontal and smother most of the energy.

This turntable was a 3D-puzzle but very interesting

Regards,

Reinout

for my turntable-project i followed a lot of your comments/plans/ideas (without knowing about this thread). That turntable started a couple of years as a non-standard Caeles air-bearing turntable but, as this is a hobby, it became a sport to improve on the already good functionality.

It's a real air-bearing by Eitzenberger (EZ-1320). No flimsy air bearing only in the vertical direction (small air chamber that acts as a enclosed pocket of air but fully susceptible from horizontal influences) but a proper bi-conical design. So that is self-centering and completely airfloating without any touching of any surfaces. Normally these weigh in at 7.6 kgs but that's standard stainless steel. For the Caeles they make it partly in bronce.

It's nice to have a mass-platter (several materials in order to supress resonances) but as you correctly stated that energy can be "stored" easily in this mass. There is a reason why those light weight platters can sometimes somply outplay mass turntables with crisp notes ! Simply because the energy is not contained but allowed to flow away.

I adopted that idea also here by inserting a mechanical diode in the air bearing middle void. All energy from the platter is simply channel to the subframe.

The subframe is supported by 3 airbladders. they level the turntable horizontal and smother most of the energy.

This turntable was a 3D-puzzle but very interesting

Regards,

Reinout

Attachments

-

DSCN0412.JPG696.1 KB · Views: 162

DSCN0412.JPG696.1 KB · Views: 162 -

DSCN0404.JPG578 KB · Views: 158

DSCN0404.JPG578 KB · Views: 158 -

DSCN0427.JPG576.5 KB · Views: 141

DSCN0427.JPG576.5 KB · Views: 141 -

DSCN0391.JPG357.9 KB · Views: 144

DSCN0391.JPG357.9 KB · Views: 144 -

DSCN0373.JPG442.7 KB · Views: 160

DSCN0373.JPG442.7 KB · Views: 160 -

DSCN0366.JPG488.7 KB · Views: 284

DSCN0366.JPG488.7 KB · Views: 284 -

DSCN0361.JPG593.6 KB · Views: 283

DSCN0361.JPG593.6 KB · Views: 283 -

Bi-conic_Air_Bearing_Spindle.jpg48.6 KB · Views: 293

Bi-conic_Air_Bearing_Spindle.jpg48.6 KB · Views: 293 -

Bearing.jpg583 KB · Views: 296

Bearing.jpg583 KB · Views: 296 -

csm_Luftlagerrundtisch_EZ-1320_f739543df3.jpg277.2 KB · Views: 293

csm_Luftlagerrundtisch_EZ-1320_f739543df3.jpg277.2 KB · Views: 293

I have no idea what 701 sounding much better than any other dd means as i had a very cool japanese DD that was simply perfect ...and i still own a 701 which is absolutely ok, but i couldn't notice any differences between them apart from the automation functions that were spot on on the japanese DD.

Simple. The motor/platter assembly of the 701 using identical arms/carts was on par musically with a Thorens 124 and completely slaughtered a Trio L07D, the only other DD table i have owned long term.

follow up

The air bladders can not take out all nasties so the final smothering of energy is done by 3 oil baths/peddles under the subframe.

Rest assured: it works

See pictures

That whole contraption is placed on a serious heavy tripod and slowly but surely were reaching the 400 kgs....

You were mentioning the Dual direct drive. I like those Duals. Not using the ESD1000 but the ESD930 (from the 741QL direct drive turntable). Still easy to source....

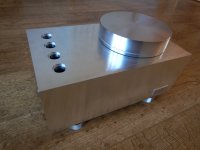

Reason for this choice is that i didn't want to run the external drive/motor with asmall spindle/pulley which runs like crazy (like 99% of all turntables with asymetric drives) but with a much lower speed huge pulley.

See pictures: this is half the size of an LP and runs comperatively slow. This solution is not only very stable but will last for ages....

Of course this air bearing turntable needs proper pneumatics. I did this with 3 separate airtanks in order to avoid pressurewaves when the compressor kicks in. 2 seperate filter-banks take out the nasties for the bearing and the bladders

More to follow

The air bladders can not take out all nasties so the final smothering of energy is done by 3 oil baths/peddles under the subframe.

Rest assured: it works

See pictures

That whole contraption is placed on a serious heavy tripod and slowly but surely were reaching the 400 kgs....

You were mentioning the Dual direct drive. I like those Duals. Not using the ESD1000 but the ESD930 (from the 741QL direct drive turntable). Still easy to source....

Reason for this choice is that i didn't want to run the external drive/motor with asmall spindle/pulley which runs like crazy (like 99% of all turntables with asymetric drives) but with a much lower speed huge pulley.

See pictures: this is half the size of an LP and runs comperatively slow. This solution is not only very stable but will last for ages....

Of course this air bearing turntable needs proper pneumatics. I did this with 3 separate airtanks in order to avoid pressurewaves when the compressor kicks in. 2 seperate filter-banks take out the nasties for the bearing and the bladders

More to follow

Attachments

-

DSCN1512.JPG175.7 KB · Views: 132

DSCN1512.JPG175.7 KB · Views: 132 -

DSCN1510.JPG161.6 KB · Views: 126

DSCN1510.JPG161.6 KB · Views: 126 -

DSCN1509.JPG132.8 KB · Views: 118

DSCN1509.JPG132.8 KB · Views: 118 -

DSCN0619.JPG520.4 KB · Views: 129

DSCN0619.JPG520.4 KB · Views: 129 -

DSCN0614.JPG476 KB · Views: 113

DSCN0614.JPG476 KB · Views: 113 -

DSCN0230.JPG699.6 KB · Views: 113

DSCN0230.JPG699.6 KB · Views: 113 -

DSCN0228.JPG671.3 KB · Views: 141

DSCN0228.JPG671.3 KB · Views: 141 -

DSCN1503.JPG235.5 KB · Views: 143

DSCN1503.JPG235.5 KB · Views: 143 -

DSCN1500.JPG180.3 KB · Views: 161

DSCN1500.JPG180.3 KB · Views: 161

Last edited:

@wiseoldtech

Well, i don't think anyone mind the fact that you're using any single turntable topic to show off with your serviceman experience in Duals, but it's a bit offtopic, don't you think so? I'm not using every single tonearm alignement topic to tell my experience with aligning helium -neon lasers , UV-vis-far infrared interferometers and lock-in amplifiers that could probably be used to track the grooves down to nanometer scale or read a magnetized tape right through it optically ...I don't see anywhere near in the future a BOMEM interferometer used to read a vinyl from 10 meters away through the dust particles , although it could be possible, but we need to pay some 40 000 dollars for the interferometer alone then...

Well, i don't think anyone mind the fact that you're using any single turntable topic to show off with your serviceman experience in Duals, but it's a bit offtopic, don't you think so? I'm not using every single tonearm alignement topic to tell my experience with aligning helium -neon lasers , UV-vis-far infrared interferometers and lock-in amplifiers that could probably be used to track the grooves down to nanometer scale or read a magnetized tape right through it optically ...I don't see anywhere near in the future a BOMEM interferometer used to read a vinyl from 10 meters away through the dust particles , although it could be possible, but we need to pay some 40 000 dollars for the interferometer alone then...

Last edited:

As i don't like asymetric drive by nature i use an external axle as well. this is placed on the opposite side of the motor/drive. The string is tensioned between the oversized pulley and this external axle. The air bearing platter is coasting in between.

The motordrive is fed by an external battery power supply.

Below that is the vacuum pump for the platter itself (sucking the vinyl to the platter if needed).

Pretty happy with the result but as this is a hobby i will not stop trying to improve.

Regards, Reinout

(and really really funny that a lot of your ideas were already succesfully implemented in my set up)

The motordrive is fed by an external battery power supply.

Below that is the vacuum pump for the platter itself (sucking the vinyl to the platter if needed).

Pretty happy with the result but as this is a hobby i will not stop trying to improve.

Regards, Reinout

(and really really funny that a lot of your ideas were already succesfully implemented in my set up)

Attachments

Last edited:

It was a long time dream to own a Trio l-07d as it looked like the best possible turntable for me for a long time, but never afforded one.Now you're shattering an old abandoned dream 🙂 Some say it's the kenwood tonearm that it's not quite the right one on that plinth.Simple. The motor/platter assembly of the 701 using identical arms/carts was on par musically with a Thorens 124 and completely slaughtered a Trio L07D, the only other DD table i have owned long term.

Never had the original tonearm, a previous owner had installed an FR64 which i also never liked much, but tried a variety of other arms as well. Dead, rather unengaging sound with slightly overdone bass. A friend with an SP10 borrowed it for a week and was similarly disappointed.

@wiseoldtech

Well, i don't think anyone mind the fact that you're using any single turntable topic to show off with your serviceman experience in Duals, but it's a bit offtopic, don't you think so? I'm not using every single tonearm alignement topic to tell my experience with aligning helium -neon lasers ,

Well I appologize for being human, and being myself.

I had no idea that I was expected to think and be the same as you.

Good evening to you all,

It's a real air-bearing by Eitzenberger (EZ-1320). No flimsy air bearing only in the vertical direction (small air chamber that acts as a enclosed pocket of air but fully susceptible from horizontal influences) but a proper bi-conical design. So that is self-centering and completely airfloating without any touching of any surfaces. Normally these weigh in at 7.6 kgs but that's standard stainless steel. For the Caeles they make it partly in bronce.

Have you measured platter vertical movement with a 0.001mm runout indicator?

How does the platter sink vibration energy away from the LP stylus interaction without any connection of the bottom of the bearing. I ask these questions because I too am designing a new TT based around a Technics DD motor and I'm interested in alternative approaches.

- Home

- Source & Line

- Analogue Source

- Ultimate turntable design: modern technology to remediate root cause issues