@Supersurfer:

Hi ... A couple of comments - the first of which is that you don't happen to have a bad soldering/bad connection somewhere on the oven / oscillator PCBs? The timing 60s / 30s might suggest heating and cooling phenomena associated with a bad solder joint ...

And then, if not a bad solder joint, my guess would be that you have some kind of HF or RF oscillation that causes the noise. Looking at your pictures I notice that the oven copper heating plate seems to be very close to the crystal. I reckon that if it actually shorts to the crystal the crystal's noise pick-up area would increase significantly (maybe Andrea can comment here?).

Also, even if you use twisted pair wiring it looks as if you lead them quite close to the crystal/oven assembly. Might I suggest that you try to separate the cables and make them cross at 90 degrees ...

Thirdly, depending on how your detailed schematic and practical build is I wouldn't place an overall grounding near a digital part. As you may know digital signals often are very high frequencies which causes inductive impedances in the traces leading these signals - thus potentially leading to significant voltage potentials between ground points. Personally, I likely would ground the oven onto the oscillator PCB's ground so as to keep the ground loops associated with the oven/oscillator as short as possible - and then connect the oscillator output + ground to the DAC's ground.

Additionally, I might try to increase the input/output capacitance on the 7812 regulator that feeds the oven circuitry (e.g. 1000uF). Not that it may make this circuitry work better - I don't think it will - but it may change the relative "influencing" frequencies that this circuitry has.

Well, a couple of ideas ;-)

Cheers,

Jesper

Hi Jesper,

Your thoughts are very much appreciated!

The bad solder joint: I did a fast check on them but could not find any with a magnifying glass. But to be sure I would need to reflow some joints.

I made a short ground connection between the copper oven plate and the ground of the clock board.

Regarding the wiring: I removed the power switch loop from its position next to the rpi/dac and clock unit.

These measures have not solved the noise issue 🙁

There might be so much generated rfi from the rpi/dac stack that it interferes with the clock through the oven. I will test this with some longer ufl cables the next days.

Thanks again!

Supposing the 7812 of the oven to be oscillating you could try to replace input and output capacitors C1 and C2 as Jesper suggested.

You could try 100uF/25V as the input capacitor C1 and 22/47uF/25V as the output capacitor C2, both standard electrolytic capacitor (high ESR) not organic polymer and so on.

Pay attention to the polarity of the above capacitors.

Then, if the issue has not solved you could replace the servo capacitor C3 with a 1uF/50V film capacitor.

You could try 100uF/25V as the input capacitor C1 and 22/47uF/25V as the output capacitor C2, both standard electrolytic capacitor (high ESR) not organic polymer and so on.

Pay attention to the polarity of the above capacitors.

Then, if the issue has not solved you could replace the servo capacitor C3 with a 1uF/50V film capacitor.

Finished 45mHz WTMC

I have finally finished my implementation of The Well Tempered Master Clock and could not be happier with the results. The 45mHz WTMC has been powered now for about 20 days, and it sounds fantastic.

I thought it worth recording to the best of my ability the impact on the sound. Then I will provide some info on what I think is important in implementing the WTMC. I’ll comment on power, vibration and RF isolation and SMA cable.

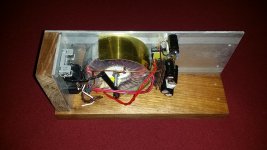

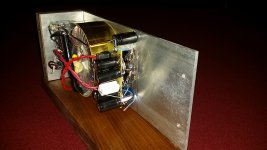

First a couple of pics of the finished chassis.

I have finally finished my implementation of The Well Tempered Master Clock and could not be happier with the results. The 45mHz WTMC has been powered now for about 20 days, and it sounds fantastic.

I thought it worth recording to the best of my ability the impact on the sound. Then I will provide some info on what I think is important in implementing the WTMC. I’ll comment on power, vibration and RF isolation and SMA cable.

First a couple of pics of the finished chassis.

Attachments

Positive sound impressions

It is tough to put into words what you like about sound. I value a full and natural sound. So I am going to borrow some comments from Aurthur Salvadore that resonate with my priorities which are provided by WTMC. He describes the accurate reproduction of low-level information.

He defines it as:

1. The harmonics that identify instruments and enables them to sound natural or "musical";

2. The decay of the individual notes and their harmonics;

3. The subtle, instantaneous shifts of dynamics and their intensity and emphasis (also known as micro-dynamics and dynamic shading) enabling musical "expression" to be sensed, heard and felt;

4. The sense of ambience and space, allowing the listener to both hear and be "there";

5. The separation, or absence of homogenization, of all of the above, reducing "boredom" and "listener fatigue";

6. and the sense of both continuity and a continual presence, which has also been described by others as "continuousness".

BTW, the WTMC is feeding a FIFOPi by Ian Canada. This in turn provides I2S to a TDA1541a S2 DAC. A Lampizator 6n2p output stage is attenuated by a Slagle autoformer volume control to OTL monobloc amps to open baffle speakers. The system is pretty transparent so improvements in the front end are readily heard.

When I replaced NDK SDA clocks with WTMC without an oven, it was clear that this was going to be a major upgrade. Everything took a big step up in definition and 3d space. Both the bass and the high ends were noticeably extended. The space around individual sounds became more defined. Everything sounded more natural. Voices became more human and bells sounded like bells.

The addition of the oven filled in all the spaces. There was just a lot more information. Everything sounded richer. Dynamics and attack became the prominent impression. This is when decay, instantaneous shifts and sense of space became apparent.

All of this was with the WTMC outside its chassis and fed by interim power supplies. With the final power supply and inside its own chassis it took another major jump in sound quality. Now the subtle harmonics of individual instruments were apparent as never before. Sound was also stabilized which makes it sound laid back but real.

The impact of the WTMC is felt on all recordings. But on really good material it is a game changer. Live recordings come to life. I have a number of Yo-Yo Ma CD’s that are really well recorded. The harmonics from his cello took on a new sound. It is haunting. Then I realized I could hear his breathing as he played. Same impact with opera and well recorded symphonies.

If you have Andrea’s kit but have not built it, do not delay. It may be the biggest single upgrade your system will see.

Pic of WTMC between amp and music server..

It is tough to put into words what you like about sound. I value a full and natural sound. So I am going to borrow some comments from Aurthur Salvadore that resonate with my priorities which are provided by WTMC. He describes the accurate reproduction of low-level information.

He defines it as:

1. The harmonics that identify instruments and enables them to sound natural or "musical";

2. The decay of the individual notes and their harmonics;

3. The subtle, instantaneous shifts of dynamics and their intensity and emphasis (also known as micro-dynamics and dynamic shading) enabling musical "expression" to be sensed, heard and felt;

4. The sense of ambience and space, allowing the listener to both hear and be "there";

5. The separation, or absence of homogenization, of all of the above, reducing "boredom" and "listener fatigue";

6. and the sense of both continuity and a continual presence, which has also been described by others as "continuousness".

BTW, the WTMC is feeding a FIFOPi by Ian Canada. This in turn provides I2S to a TDA1541a S2 DAC. A Lampizator 6n2p output stage is attenuated by a Slagle autoformer volume control to OTL monobloc amps to open baffle speakers. The system is pretty transparent so improvements in the front end are readily heard.

When I replaced NDK SDA clocks with WTMC without an oven, it was clear that this was going to be a major upgrade. Everything took a big step up in definition and 3d space. Both the bass and the high ends were noticeably extended. The space around individual sounds became more defined. Everything sounded more natural. Voices became more human and bells sounded like bells.

The addition of the oven filled in all the spaces. There was just a lot more information. Everything sounded richer. Dynamics and attack became the prominent impression. This is when decay, instantaneous shifts and sense of space became apparent.

All of this was with the WTMC outside its chassis and fed by interim power supplies. With the final power supply and inside its own chassis it took another major jump in sound quality. Now the subtle harmonics of individual instruments were apparent as never before. Sound was also stabilized which makes it sound laid back but real.

The impact of the WTMC is felt on all recordings. But on really good material it is a game changer. Live recordings come to life. I have a number of Yo-Yo Ma CD’s that are really well recorded. The harmonics from his cello took on a new sound. It is haunting. Then I realized I could hear his breathing as he played. Same impact with opera and well recorded symphonies.

If you have Andrea’s kit but have not built it, do not delay. It may be the biggest single upgrade your system will see.

Pic of WTMC between amp and music server..

Attachments

Last edited:

Power supply

Clocks in general reward great power supply with great sound. I was however surprised that I do not think the PS is as important to WTMC as one would think.

I have not tried battery, so perhaps I simply do not know what I am missing. But IMHO, a good linear supply does the job, and the sound was not particularly impacted by improvements. I built separate linear supplies for the oven and the clock.

The clock has separate LT3042 regulators for the crystal and the squarer.

The transformer is a medical grade Plitron with separate windings for each supply. I used MUR860 diodes for the bridges. The clock has a 6th order CRC filter using Panasonic FC caps and an inductor to filter out RF. The oven has a 3rd order filter and a 78m15 reg set the voltage.

Before I finished the final PS, the interim supply worked just fine. In other areas of the DAC, an upgrade from the interim PS to the final would have made a change. I am not so sure it was as impactful to WTMC. I think Supersurfer seemed to have a similar experience when he went to battery supply. Its good, but you have to strain to know if it is all that much better??

I am not saying PS is not important. I just think that a good supply is good enough. No need to go nuts.

Clocks in general reward great power supply with great sound. I was however surprised that I do not think the PS is as important to WTMC as one would think.

I have not tried battery, so perhaps I simply do not know what I am missing. But IMHO, a good linear supply does the job, and the sound was not particularly impacted by improvements. I built separate linear supplies for the oven and the clock.

The clock has separate LT3042 regulators for the crystal and the squarer.

The transformer is a medical grade Plitron with separate windings for each supply. I used MUR860 diodes for the bridges. The clock has a 6th order CRC filter using Panasonic FC caps and an inductor to filter out RF. The oven has a 3rd order filter and a 78m15 reg set the voltage.

Before I finished the final PS, the interim supply worked just fine. In other areas of the DAC, an upgrade from the interim PS to the final would have made a change. I am not so sure it was as impactful to WTMC. I think Supersurfer seemed to have a similar experience when he went to battery supply. Its good, but you have to strain to know if it is all that much better??

I am not saying PS is not important. I just think that a good supply is good enough. No need to go nuts.

Attachments

Vibration and isolation

Now here is where the magic happened IMHO. I fully admit, I expected vibration control would be important, so who knows if I am simply hearing what I want to hear. But to my ear this is as significant as adding the oven.

Based on experience with lessor clocks, I felt vibration attenuation was worth some effort. You can see from the attached pictures that I decided to build a separate small chassis for the WTMC. It would sit next to the DAC to keep SMA cable length short, but would provide vibration and RF isolation.

My design is influenced by my limited construction skills and material on hand.

Some key concepts are:

1. The clock would be attached to something massive. In this case I used a pair of ½ inch copper plates

2. The clock/copper assembly would be mounted to wood to provide some dampening.

3. The main structure would be wood

4. There would be metal enclosure to isolate electric / RF fields

5. The toroidal transformer would be shielded in brass to further isolate any radiation

6. The chassis would have sand in it to dampen vibration.

7. The entire chassis could then sit on some vibration isolation like bubble wrap or silicon.

My system sits on a solid foundation. It is on an unused fireplace. So, clock, DAC and amps sit on a granite slab that is on the house foundation which itself sits on piles to the bedrock of the Great Canadian Shield. So it does not pick up a lot of vibration from city traffic or household appliances. But it is surprising how much a chassis can pick up from the speakers. I find this works like feedback to a clock.

The impact of putting the WTMC into its chassis was good, but the real impact came by adding sand. I just put about an inch in the bottom. The clock and oven PCB’s are just above the sand. The LT3042 regs that are soldered to the clock PCB are submerged in sand.

The impact of the sand was startling. It just brought everything into sharp focus. A final blur on the sound was removed and that let more of the low-level information take over.

There are no doubt many ways to implement a vibration dampening scheme. I think I have nailed it to some extent. But if you are planning to build a WTMC, give some thought to vibration and you will be rewarded.

Now here is where the magic happened IMHO. I fully admit, I expected vibration control would be important, so who knows if I am simply hearing what I want to hear. But to my ear this is as significant as adding the oven.

Based on experience with lessor clocks, I felt vibration attenuation was worth some effort. You can see from the attached pictures that I decided to build a separate small chassis for the WTMC. It would sit next to the DAC to keep SMA cable length short, but would provide vibration and RF isolation.

My design is influenced by my limited construction skills and material on hand.

Some key concepts are:

1. The clock would be attached to something massive. In this case I used a pair of ½ inch copper plates

2. The clock/copper assembly would be mounted to wood to provide some dampening.

3. The main structure would be wood

4. There would be metal enclosure to isolate electric / RF fields

5. The toroidal transformer would be shielded in brass to further isolate any radiation

6. The chassis would have sand in it to dampen vibration.

7. The entire chassis could then sit on some vibration isolation like bubble wrap or silicon.

My system sits on a solid foundation. It is on an unused fireplace. So, clock, DAC and amps sit on a granite slab that is on the house foundation which itself sits on piles to the bedrock of the Great Canadian Shield. So it does not pick up a lot of vibration from city traffic or household appliances. But it is surprising how much a chassis can pick up from the speakers. I find this works like feedback to a clock.

The impact of putting the WTMC into its chassis was good, but the real impact came by adding sand. I just put about an inch in the bottom. The clock and oven PCB’s are just above the sand. The LT3042 regs that are soldered to the clock PCB are submerged in sand.

The impact of the sand was startling. It just brought everything into sharp focus. A final blur on the sound was removed and that let more of the low-level information take over.

There are no doubt many ways to implement a vibration dampening scheme. I think I have nailed it to some extent. But if you are planning to build a WTMC, give some thought to vibration and you will be rewarded.

Attachments

Cable length

I currently use the WTMC with a 12-inch SMA cable rated to 16gHz. I did an experiment to determine impact of cable. After getting to know the WTMC on the 12” RF cable, I removed the cable and attached the clock directly to the FIFOPi. I believe there was an improvement in sound without the cable. I heard more dynamics and attack without the cable. While I attempted to keep all other variables the same, the direct attach also had the oscillator pinned against the granite slab. So it is possible that part of the improvement was due to attenuated vibration.

The next time I moved the WTMC onto a cable was when I installed it into its new chassis with an improved power supply. In some ways the sound improved, but also the improved dynamics seemed to disappear in the chassis.

But then I added the sand into the chassis, and the sound was elevated to a level beyond any other configuration.

My conclusion is a 12” cable degraded the signal in some small measure, but that impact was more than offset with the isolation of the chassis.

Clearly anyone could be very happy with the sound from the WTMC directly attached to the FIFO or cable attached from its own chassis.

IMHO the best sound comes with a separate vibration dampened chassis using a modest length of SMA cable.

In the future I will swap the 12” cable with a 6” between the clock chassis and the FIFO. This will be a good test of only the cable length.

Again, thanks to Andrea and all the contributors on this thread. You have elevated my system to a different level.

I currently use the WTMC with a 12-inch SMA cable rated to 16gHz. I did an experiment to determine impact of cable. After getting to know the WTMC on the 12” RF cable, I removed the cable and attached the clock directly to the FIFOPi. I believe there was an improvement in sound without the cable. I heard more dynamics and attack without the cable. While I attempted to keep all other variables the same, the direct attach also had the oscillator pinned against the granite slab. So it is possible that part of the improvement was due to attenuated vibration.

The next time I moved the WTMC onto a cable was when I installed it into its new chassis with an improved power supply. In some ways the sound improved, but also the improved dynamics seemed to disappear in the chassis.

But then I added the sand into the chassis, and the sound was elevated to a level beyond any other configuration.

My conclusion is a 12” cable degraded the signal in some small measure, but that impact was more than offset with the isolation of the chassis.

Clearly anyone could be very happy with the sound from the WTMC directly attached to the FIFO or cable attached from its own chassis.

IMHO the best sound comes with a separate vibration dampened chassis using a modest length of SMA cable.

In the future I will swap the 12” cable with a 6” between the clock chassis and the FIFO. This will be a good test of only the cable length.

Again, thanks to Andrea and all the contributors on this thread. You have elevated my system to a different level.

Last edited:

@wlowes: Thanks for sharing your design choices and their impact on the sound. Very interesting, indeed ... Not least that "stability" - be it in terms of thermal or vibrational - appears to have great effect on the sound.

Cheers,

Jesper

Cheers,

Jesper

I currently use the WTMC with a 12-inch SMA cable rated to 16gHz. I did an experiment to determine impact of cable. After getting to know the WTMC on the 12” RF cable, I removed the cable and attached the clock directly to the FIFOPi. I believe there was an improvement in sound without the cable. I heard more dynamics and attack without the cable. While I attempted to keep all other variables the same, the direct attach also had the oscillator pinned against the granite slab. So it is possible that part of the improvement was due to attenuated vibration.

The next time I moved the WTMC onto a cable was when I installed it into its new chassis with an improved power supply. In some ways the sound improved, but also the improved dynamics seemed to disappear in the chassis.

But then I added the sand into the chassis, and the sound was elevated to a level beyond any other configuration.

My conclusion is a 12” cable degraded the signal in some small measure, but that impact was more than offset with the isolation of the chassis.

Clearly anyone could be very happy with the sound from the WTMC directly attached to the FIFO or cable attached from its own chassis.

IMHO the best sound comes with a separate vibration dampened chassis using a modest length of SMA cable.

In the future I will swap the 12” cable with a 6” between the clock chassis and the FIFO. This will be a good test of only the cable length.

Again, thanks to Andrea and all the contributors on this thread. You have elevated my system to a different level.

Hi Walter,

very very nice job!

And great explanation with plenty of details!

Many thanks for sharing your experience.

Andrea

When is the next GB?

As soon as the new Driscoll board will be ready and tested, I think within a couple of months.

Stay tuned!

When the new Driscoll board will be ready,it could be interesting to add a R.F enclosure at the height,I thought of something of this quality https://www.gquipment.com/33-thickbox_default/rf-enclosure-mini-aluminium.jpg

a design and a buying group would be possible,there are a lot of options,for example Machined Enclosures or even Custom Rf Cnc Machined Parts Aluminum Enclosure Housing Shell - Buy Aluminum Rf Enclosure,Rf Enclosure,Custom Rf Enclosure Product on Alibaba.com

a design and a buying group would be possible,there are a lot of options,for example Machined Enclosures or even Custom Rf Cnc Machined Parts Aluminum Enclosure Housing Shell - Buy Aluminum Rf Enclosure,Rf Enclosure,Custom Rf Enclosure Product on Alibaba.com

As soon as the new Driscoll board will be ready and tested, I think within a couple of months.

Stay tuned!

Hi Andrea,

I hope you will find a more easy solution for the oven of the bigger crystal enclosures than the copper pipe. Forming the pipe to the exact dimensions to fit the crystal is a difficult task and has taken me more time than soldering the driscoll and oven board.

Regards,

Hi Wlowes,

Thank you for your elaborate explanation, it is very informative!

Have fun with your new clock!

Thank you for your elaborate explanation, it is very informative!

Have fun with your new clock!

Supposing the 7812 of the oven to be oscillating you could try to replace input and output capacitors C1 and C2 as Jesper suggested.

You could try 100uF/25V as the input capacitor C1 and 22/47uF/25V as the output capacitor C2, both standard electrolytic capacitor (high ESR) not organic polymer and so on.

Pay attention to the polarity of the above capacitors.

Then, if the issue has not solved you could replace the servo capacitor C3 with a 1uF/50V film capacitor.

Hi Andrea,

I have moved the clock unit to another dac to test the rfi influence. It is a dddac feeded by rpi streamer with fifopi.

The noise has dissapeared but when I power on the oven after about a minute the music stops; the fifopi switches to the second clock. This happens with and without a second clock mounted.

Frequency lock is lost.

I must mention that I am still not able to do an accurate temperature measurement, I have ordered a good temp. measurement device; this will be shipped next week.

So it seems that there is another problem than rfi interference.

Attachments

Last edited:

If I remember correctly, a small plastic tray was needed between the crystal and the board, did you put that in?

Hi SupersurferHi Andrea,

I have moved the clock unit to another dac to test the rfi influence. It is a dddac feeded by rpi streamer with fifopi.

The noise has dissapeared but when I power on the oven after about a minute the music stops; the fifopi switches to the second clock. This happens with and without a second clock mounted.

Frequency lock is lost.

I must mention that I am still not able to do an accurate temperature measurement, I have ordered a good temp. measurement device; this will be shipped next week.

So it seems that there is another problem than rfi interference.

Sorry you are having oven issues.

If I understand correctly, the clock works as expected without the oven, but after about a minute of switching on the oven you now loose a clock signal. On ESS Dac it developed noise one minute after oven was powered??

I am shooting in the dark, but perhaps one more test would be to remove the oven. Then fire up the system and confirm it is fully operational. Then apply heat from a different source like an air station, blow dryer or heat gun. Attempt to get the temperature in the same range as the oven and see if it works or exhibits the same failure mode. It might narrow it down to a thermal issue in the clock pcb vs an electrical issue related to the oven/clock.

It's a head scratcher😕

Hi wealas,

The small plastic is inserted below the crystal. I do not know it’s purpose; electrical or heat isolation to the board?

Wlowes,

Your summary of my problem is correct.

It’s a good idea to try to heat the crystal without the oven in order to close out causes. I think this is a difficult task; using a hot air gun or hair blower will provide an overdose of hot air that will be impossible to direct to the crystal without overheating the other components. I do not own an air soldering device.

After your report of getting a clearly better sound when using the oven, I am even more frustrated that it does not function in my case. 🙁

There must be an explanation why it is not functioning, I hope Andrea can shed some light in the matter.

The small plastic is inserted below the crystal. I do not know it’s purpose; electrical or heat isolation to the board?

Wlowes,

Your summary of my problem is correct.

It’s a good idea to try to heat the crystal without the oven in order to close out causes. I think this is a difficult task; using a hot air gun or hair blower will provide an overdose of hot air that will be impossible to direct to the crystal without overheating the other components. I do not own an air soldering device.

After your report of getting a clearly better sound when using the oven, I am even more frustrated that it does not function in my case. 🙁

There must be an explanation why it is not functioning, I hope Andrea can shed some light in the matter.

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Line Level

- The Well Tempered Master Clock - Building a low phase noise/jitter crystal oscillator