Sill off topic,

Where I live on the North East coast of England, its about 76 miles to the other side of the country! I could go from the North Sea to the Atlantic in a cpl of hours. Oh & we hate driving very far as its just so congested, even more so in the South.

Being on the outskirts of the metropolis of Newcastle I'm just a few minuets from the beautiful country side of North Pennines.

Back on topic, going to make some play dough today & start to add it to tt chassis.

Whilst listening to Decca London Blue in Audiomods arm on LP12 mmmmmmm

Where I live on the North East coast of England, its about 76 miles to the other side of the country! I could go from the North Sea to the Atlantic in a cpl of hours. Oh & we hate driving very far as its just so congested, even more so in the South.

Being on the outskirts of the metropolis of Newcastle I'm just a few minuets from the beautiful country side of North Pennines.

Back on topic, going to make some play dough today & start to add it to tt chassis.

Whilst listening to Decca London Blue in Audiomods arm on LP12 mmmmmmm

It's blowing a hoolie hear,

Anyway play dough made & ready to use

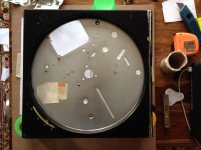

Top plate chopped & made ready for resin,

Playdough & masking tape attached to top plate.

The resin will be at different levels, inside the play dough area It will be about 10 mm thick, Outside on the black area only about 1mm.

So having the top plate level during the pore is rather important…

All it needs now for the First pore is some warmer wether!

Anyway play dough made & ready to use

Top plate chopped & made ready for resin,

Playdough & masking tape attached to top plate.

The resin will be at different levels, inside the play dough area It will be about 10 mm thick, Outside on the black area only about 1mm.

So having the top plate level during the pore is rather important…

All it needs now for the First pore is some warmer wether!

Attachments

looking good Jay.

The resin idea is one often used with Lenco tts.

now from where I live...5283 km to the RHS coast, 1085 or so to the LHS coast. I have some relations up and around Newcastle (on Tyne). Apparently world renowned sheep herders and dog breeders/judges (herding dogs)

The resin idea is one often used with Lenco tts.

now from where I live...5283 km to the RHS coast, 1085 or so to the LHS coast. I have some relations up and around Newcastle (on Tyne). Apparently world renowned sheep herders and dog breeders/judges (herding dogs)

Only about 50 miles to Scotland, & 350 to London.

I did a bit of sheepherding myself for a while, damn hard during Lambing season. Their are a lot of rare breed sheep up hear.

Do you ever get to the UK?

Geordies get everywhere! I even have some relatives that were from N Virginia, at the Alamo. Now there a bit further south in AL GA & FL.

I had to take all the dough off as I forgot to Key the top plate.

Still its ready again now.

Ive seen a few Resin based Lenco's, but not like I'm doing by encapsulating most if not all of the top plate.

I did a bit of sheepherding myself for a while, damn hard during Lambing season. Their are a lot of rare breed sheep up hear.

Do you ever get to the UK?

Geordies get everywhere! I even have some relatives that were from N Virginia, at the Alamo. Now there a bit further south in AL GA & FL.

I had to take all the dough off as I forgot to Key the top plate.

Still its ready again now.

Ive seen a few Resin based Lenco's, but not like I'm doing by encapsulating most if not all of the top plate.

Jay, I'm from Scotland originally. Came here at 3 years of age. Have been back a few times, including visiting friends in Newcastle. I know a few Geordies here. Wife is Welsh. Coming here so young, I'm really an Aussie now though. Like watching 'us' beat you in the test cricket which is in Perth today... 😉

Incidentally, it was 40 degrees C here yesterday and 41C forecast today, so spare a thought for your cricket team! It's already 40.2C at 11am. Damn hot. I'm used to it though.

Last OT, I promise...

Incidentally, it was 40 degrees C here yesterday and 41C forecast today, so spare a thought for your cricket team! It's already 40.2C at 11am. Damn hot. I'm used to it though.

Last OT, I promise...

Last edited:

now from where I live...5283 km to the RHS coast, 1085 or so to the LHS coast.

How far from the north coast? 😀

The polished turd

There's a phrase used over here and I think it sums up what Sreten and Stew have alluded to about the BSR and that is 'You can't polish a Turd'.

Well it might not be a diamond shine but the old Birminghams finest has scrubbed up into player 🙂

I managed to get a little bit more done this weekend including the drilling of a hole to fit a Linn Basik LV X arm and the fixing of a 'wobble'. This had given me real headache and I really thought it was the curse of BSR coming back to scupper my attempts to get this little deck to work. The platter when spinning looked like a warped record going round. What the heck was causing it? I checked the under platter and it didn't seem to be there when spinning on its own. Hmmm, I checked the upper platter to see if it had warped, nope it was straight and true. Ok have a look at the risers ( three blocks of wood and a 2p coin under each, I know it sounds crazy but it was just enough to sit the upper platter on the original to clear and spin smoothly 🙂 ) The wood was cut from the same piece and the thickness should be the same but no, one block was around a mm taller than the other two. Damn it!!

Ok methinks if I'm to get this working I'm gonna have to invest some money into the project. Now I've said before I don't have a lot of spare cash for my hobby and especially this time of year, what with Chrimbo creeping up on us. So I went to the cash draw to make a withdrawal. I found the plastic bag of foreign coins to see what we had. Yup as I thought we had loads of those little tiny silver American coins (?) Not the quarters, the really ickle ones that nobody spends. Three stacks piled to the height of the block and 2ps, taped up with insulating tape and positioned under the top platter and flick the go button. Taddah, it worked! Totally level, spinning on speed and near silent. I say near, there is still the faintest whurr if you listen very closely which might be the idler wheel on the platter, the bearing or possibly the motor but honestly you have to be so close to hear it. I will have a further investigation but this is so small it's not worrying me.

The next job is to make an electrics box to tidy up the wiring. I've salvaged a computer power supply and removed the plug socket which I will fit in a wooden box to sit at the back between the layers. I've found a 4 into 1 phono switch to allow me to connect the arms into with one output to the amp.

Does it play? Well I'd like to say it plays well and sounds lovely and smooth, no whines and groans as the platter turns, no motor problems, no tinny noises, no outside influences affecting playback.....

So I will! It sounds great. The Turd is whacking out the cool sound of vinyl as good as the other tables that I have and I am very very pleased with the result. Another BIG plus is that the wife likes it she thinks it looks cool and fits in nicely with my corner. OK that'll change when the second and third arm are added and it starts to resemble something outta Frankenstein's lab but for now she's happy and I'm loving it.

So for less than £40 (and around a couple of dollars in tiny ickle useless coins, I guess) I have succeeded in my mission impossible 🙂 and all done without an engineering degree in sight 😉

There's a phrase used over here and I think it sums up what Sreten and Stew have alluded to about the BSR and that is 'You can't polish a Turd'.

Well it might not be a diamond shine but the old Birminghams finest has scrubbed up into player 🙂

I managed to get a little bit more done this weekend including the drilling of a hole to fit a Linn Basik LV X arm and the fixing of a 'wobble'. This had given me real headache and I really thought it was the curse of BSR coming back to scupper my attempts to get this little deck to work. The platter when spinning looked like a warped record going round. What the heck was causing it? I checked the under platter and it didn't seem to be there when spinning on its own. Hmmm, I checked the upper platter to see if it had warped, nope it was straight and true. Ok have a look at the risers ( three blocks of wood and a 2p coin under each, I know it sounds crazy but it was just enough to sit the upper platter on the original to clear and spin smoothly 🙂 ) The wood was cut from the same piece and the thickness should be the same but no, one block was around a mm taller than the other two. Damn it!!

Ok methinks if I'm to get this working I'm gonna have to invest some money into the project. Now I've said before I don't have a lot of spare cash for my hobby and especially this time of year, what with Chrimbo creeping up on us. So I went to the cash draw to make a withdrawal. I found the plastic bag of foreign coins to see what we had. Yup as I thought we had loads of those little tiny silver American coins (?) Not the quarters, the really ickle ones that nobody spends. Three stacks piled to the height of the block and 2ps, taped up with insulating tape and positioned under the top platter and flick the go button. Taddah, it worked! Totally level, spinning on speed and near silent. I say near, there is still the faintest whurr if you listen very closely which might be the idler wheel on the platter, the bearing or possibly the motor but honestly you have to be so close to hear it. I will have a further investigation but this is so small it's not worrying me.

The next job is to make an electrics box to tidy up the wiring. I've salvaged a computer power supply and removed the plug socket which I will fit in a wooden box to sit at the back between the layers. I've found a 4 into 1 phono switch to allow me to connect the arms into with one output to the amp.

Does it play? Well I'd like to say it plays well and sounds lovely and smooth, no whines and groans as the platter turns, no motor problems, no tinny noises, no outside influences affecting playback.....

So I will! It sounds great. The Turd is whacking out the cool sound of vinyl as good as the other tables that I have and I am very very pleased with the result. Another BIG plus is that the wife likes it she thinks it looks cool and fits in nicely with my corner. OK that'll change when the second and third arm are added and it starts to resemble something outta Frankenstein's lab but for now she's happy and I'm loving it.

So for less than £40 (and around a couple of dollars in tiny ickle useless coins, I guess) I have succeeded in my mission impossible 🙂 and all done without an engineering degree in sight 😉

Last edited:

Squiffy, nice investment. Any photos?

nezbleu: First I'll kill the OT post. About 1635 from Hudson's Bay, 2040 km from the edge of the mainland, or 3920 km from Canada's most Northern point🙂

OT money talk: The American nickel is what you're talking about? We've eliminated our pennies (coppers, 1¢ or CAD $0.01) from public circulation, all prices now get rounded to the nearest nickel (5¢ or CAD $0.05) if paying with cash . If using a debit card, credit card, or cheque the actual amount is what you pay. We also recently introduced a new range of paper money (starts at CAD $5 bills on up, as we have the "loonie $1 coin and the "twoonie" $2 coin). The paper is now a polymer . It is laser etched and encoded, with some holographs on the bills. It has completely transparent sections as well. Australian might find it very similar to the notes from your country, although ours does crinkle a bit when we ball it up and throw it onto a table.

BACK ON TOPIC

Squiffy: As the title says,any photos? ...er , oops. Went back and looked. it should be quite nice to look at and easy to operate. Great that The One Who is Most Significant likes the looks, cause most don't. Amazing what a turd can become, given enough polish 😉. Now add a 219 and you're set 😎.

And you have to love the total investment (if using the 219 certainly not much more than the £40 so far into it.). Obviously you must consider the value of the Linn Basik LV X as part of the investment. In total I have about the same amount into my Connoisseur BD1/219/Grado cart, including the single wiring from cartridge clips to RCA plugs. If I had the facilities, I would make a plinth as I had done for the Connoisseur, just larger and CNC'd. I'm still working on improving my model of the old Garrard in sketchup. I have the first 3 layers roughed out (as it turned out the BB ply I have is slightly thinner than 1/2" (12.7mm vs. 12.3 or so). So a total of 4 layers to get past the motor (I've seen some automotive alternators that are smaller). Then add a final 3/4" (18mm) piece for the bottom and add some feet.

What have others used for feet? My tt sits on a Target Delta 5 welded stand with adjustable top plate for the tt. I have some nice hardwood hemispheres, and can get T-nuts easily enough. I also have a set of the Audio Technica AT605 isolating feet. Anybody else?

nezbleu: First I'll kill the OT post. About 1635 from Hudson's Bay, 2040 km from the edge of the mainland, or 3920 km from Canada's most Northern point🙂

OT money talk: The American nickel is what you're talking about? We've eliminated our pennies (coppers, 1¢ or CAD $0.01) from public circulation, all prices now get rounded to the nearest nickel (5¢ or CAD $0.05) if paying with cash . If using a debit card, credit card, or cheque the actual amount is what you pay. We also recently introduced a new range of paper money (starts at CAD $5 bills on up, as we have the "loonie $1 coin and the "twoonie" $2 coin). The paper is now a polymer . It is laser etched and encoded, with some holographs on the bills. It has completely transparent sections as well. Australian might find it very similar to the notes from your country, although ours does crinkle a bit when we ball it up and throw it onto a table.

BACK ON TOPIC

Squiffy: As the title says,any photos? ...er , oops. Went back and looked. it should be quite nice to look at and easy to operate. Great that The One Who is Most Significant likes the looks, cause most don't. Amazing what a turd can become, given enough polish 😉. Now add a 219 and you're set 😎.

And you have to love the total investment (if using the 219 certainly not much more than the £40 so far into it.). Obviously you must consider the value of the Linn Basik LV X as part of the investment. In total I have about the same amount into my Connoisseur BD1/219/Grado cart, including the single wiring from cartridge clips to RCA plugs. If I had the facilities, I would make a plinth as I had done for the Connoisseur, just larger and CNC'd. I'm still working on improving my model of the old Garrard in sketchup. I have the first 3 layers roughed out (as it turned out the BB ply I have is slightly thinner than 1/2" (12.7mm vs. 12.3 or so). So a total of 4 layers to get past the motor (I've seen some automotive alternators that are smaller). Then add a final 3/4" (18mm) piece for the bottom and add some feet.

What have others used for feet? My tt sits on a Target Delta 5 welded stand with adjustable top plate for the tt. I have some nice hardwood hemispheres, and can get T-nuts easily enough. I also have a set of the Audio Technica AT605 isolating feet. Anybody else?

. Obviously you must consider the value of the Linn Basik LV X as part of the investment

I have 🙂 it was part of a systemdek that was given to me as a freebee when I first started out. But ultimately I will be putting the mk2 uni pivot as a second arm.

sreten: thanks for the compliment. Not so clueless if the motor is a 115 VAC one, and my domestic mains are 115 VAC, and apparently the Valhalla drops voltage to 115VAC for the motor on LP12s and similar, so clueless? Only by not continuing along with the proper cap and possible change to the pulley diameter might it be suggested that it was clueless.

Linn Manual

The Valhalla will drive almost all LP12 motors, with the possible exception of very early motors (coded MB10). It drives the

motor with 85 VAC across the red phase. The blue phase is driven through a phase shift capacitor at approximately 75 VAC.

Hi,

It is clueless as it is based on conjecture that is

wrong, that contradicts the information I posted.

Assuming 4K per winding you can use the above numbers

to calculate R for 240/115VAC and C for 50/60Hz.

No R will cause belt stretch due to start up torque

but the motor will run with just a C on 115VAC,

though the start up load will be around 10 Henries.

rgds, sreten.

Last edited:

So for less than £40 (and around a couple of dollars in tiny ickle useless coins, I guess) I have

succeeded in my mission impossible 🙂 and all done without an engineering degree in sight 😉

Hi,

Fair enough if your happy and pleased with your efforts.

However just as with "go faster stripes" looking the part

doesn't mean it does what it looks like it should, and I can

assure you application of engineering principles is the best

way to improve decent turntables and the best way of

understanding the limitations of very basic stuff.

rgds, sreten.

Sadly though I think it looks very nice, there is not much

about it I remotely agree with in any engineering detail.

I'm confused as to the new platter, which is clearly not

original, is the basic plastic platter still underneath ?

With some sort of spacer as well ?

Last edited:

Sreten I do appreciate where you come from with your comments. I don't particularly like or appreciate the constant way you negatively portray your views nor the way you do not seem to get what a person is doing with a project if it doesn't fit in with your views on how something should be done.

My project was to take a, known to be, poor cheap turntable to see if I could improve on its performance and looks and get something out of it for a relatively cheap outlay. I have done this. In doing so I have fiddled about with an idler drive for the first time, I have solved a few design problems that presented themselves as the project progressed and have ended up with a turntable that I think looks pretty good, plays well for what it is and has given me enjoyment though out my build. I have never expected it to be Hifi, it could never in a million years stand up to a turntable costing hundreds of pounds let alone thousands or tens of thousands that the top end tables can cost. But it does play a record well. It outputs sound in a pretty decent fashion through my simple system and I feel it does this as well as the few players that I have. Therefore I'm happy with the result. I don't need your approval although your begrudging comment that you like the look has made me smile. The fact that it doesn't fit your view of how it should look or that it doesn't follow the technical design that it maybe should or that you would follow doesn't mean that it doesn't work or do what I wanted it to do or perform that task as well as I feel it does.

In answer to the question of the platter, yes it is in two parts. The original platter is metal ( steel I believe) the original plastic cover was removed. It's about the size of a single (ooo I guess around 7 inches 😉 ) The idler wheel sits inside this and spins it on its rim. The spindle is fixed and the platter spins around this on its ring bearing. The new top platter sits atop the original on the nickel spacers. It had to be lifted to allow for a free run around the spindle (which it has). The original 'wobble' that I had had to be sorted by making careful calculated adjustments to each of the spacers. Ok I added a nickel here and took off another there until I got it spinning level 🙂 Yes I could have had somebody (possibly an engineer with a degree) machine me three metal spacers. I might have even had these designed with a slight conical top and finished with tiny sponge nipples to rest the vinyl on giving it a 2001 Space Odyssey feel to it but I decided not to go that way. Damn it man, it would have cost me as much as the whole thing to go that way and you can only have so much of a good thing.

The plinth it sits in while in two parts is solid and absorbs the vibrations both of the turntable itself (motor, idler setup etc) and the outside influences. It's rubber feet (walking stick finials ) also help absorb vibrations. This makes the platter spin almost silently. So I have an idler drive spinning a level platter setup, almost silently, to a given speed, with no vibrations coming through to affect the stylus as it picks up the music from the groove of the record and passes it through the amplifier then out to the speakers where it arrives and separates into stereo sound placing individual musicians at different points in front and to the side of me each blending together to play beautiful music to my ears. Which bit of the above is it not suppose to do or what else should I be expecting it to do?

Using your car analogy I would say its definately not a Ferrari. I'd put it more like a Ford Cortina mk1, old and not the best in the world as a car but with a few tweaks and improvements from ooo let's say the Lotus parts bin and a lovely pale green go faster stripe down the side the little old Cortina can look beautiful, perform much better than in its original state and in some cases out perform cars with a much higher pedigree 😉

My project was to take a, known to be, poor cheap turntable to see if I could improve on its performance and looks and get something out of it for a relatively cheap outlay. I have done this. In doing so I have fiddled about with an idler drive for the first time, I have solved a few design problems that presented themselves as the project progressed and have ended up with a turntable that I think looks pretty good, plays well for what it is and has given me enjoyment though out my build. I have never expected it to be Hifi, it could never in a million years stand up to a turntable costing hundreds of pounds let alone thousands or tens of thousands that the top end tables can cost. But it does play a record well. It outputs sound in a pretty decent fashion through my simple system and I feel it does this as well as the few players that I have. Therefore I'm happy with the result. I don't need your approval although your begrudging comment that you like the look has made me smile. The fact that it doesn't fit your view of how it should look or that it doesn't follow the technical design that it maybe should or that you would follow doesn't mean that it doesn't work or do what I wanted it to do or perform that task as well as I feel it does.

In answer to the question of the platter, yes it is in two parts. The original platter is metal ( steel I believe) the original plastic cover was removed. It's about the size of a single (ooo I guess around 7 inches 😉 ) The idler wheel sits inside this and spins it on its rim. The spindle is fixed and the platter spins around this on its ring bearing. The new top platter sits atop the original on the nickel spacers. It had to be lifted to allow for a free run around the spindle (which it has). The original 'wobble' that I had had to be sorted by making careful calculated adjustments to each of the spacers. Ok I added a nickel here and took off another there until I got it spinning level 🙂 Yes I could have had somebody (possibly an engineer with a degree) machine me three metal spacers. I might have even had these designed with a slight conical top and finished with tiny sponge nipples to rest the vinyl on giving it a 2001 Space Odyssey feel to it but I decided not to go that way. Damn it man, it would have cost me as much as the whole thing to go that way and you can only have so much of a good thing.

The plinth it sits in while in two parts is solid and absorbs the vibrations both of the turntable itself (motor, idler setup etc) and the outside influences. It's rubber feet (walking stick finials ) also help absorb vibrations. This makes the platter spin almost silently. So I have an idler drive spinning a level platter setup, almost silently, to a given speed, with no vibrations coming through to affect the stylus as it picks up the music from the groove of the record and passes it through the amplifier then out to the speakers where it arrives and separates into stereo sound placing individual musicians at different points in front and to the side of me each blending together to play beautiful music to my ears. Which bit of the above is it not suppose to do or what else should I be expecting it to do?

Using your car analogy I would say its definately not a Ferrari. I'd put it more like a Ford Cortina mk1, old and not the best in the world as a car but with a few tweaks and improvements from ooo let's say the Lotus parts bin and a lovely pale green go faster stripe down the side the little old Cortina can look beautiful, perform much better than in its original state and in some cases out perform cars with a much higher pedigree 😉

Sreten I do appreciate where you come from with your comments. I don't particularly like or appreciate the constant way you negatively portray your views nor the way you do not seem to get what a person is doing with a project if it doesn't fit in with your views on how something should be done.

My project was to take a, known to be, poor cheap turntable to see if I could improve on its performance and looks and get something out of it for a relatively cheap outlay. I have done this. In doing so I have fiddled about with an idler drive for the first time, I have solved a few design problems that presented themselves as the project progressed and have ended up with a turntable that I think looks pretty good, plays well for what it is and has given me enjoyment though out my build. I have never expected it to be Hifi, it could never in a million years stand up to a turntable costing hundreds of pounds let alone thousands or tens of thousands that the top end tables can cost. But it does play a record well. It outputs sound in a pretty decent fashion through my simple system and I feel it does this as well as the few players that I have. Therefore I'm happy with the result. I don't need your approval although your begrudging comment that you like the look has made me smile. The fact that it doesn't fit your view of how it should look or that it doesn't follow the technical design that it maybe should or that you would follow doesn't mean that it doesn't work or do what I wanted it to do or perform that task as well as I feel it does.

In answer to the question of the platter, yes it is in two parts. The original platter is metal ( steel I believe) the original plastic cover was removed. It's about the size of a single (ooo I guess around 7 inches 😉 ) The idler wheel sits inside this and spins it on its rim. The spindle is fixed and the platter spins around this on its ring bearing. The new top platter sits atop the original on the nickel spacers. It had to be lifted to allow for a free run around the spindle (which it has). The original 'wobble' that I had had to be sorted by making careful calculated adjustments to each of the spacers. Ok I added a nickel here and took off another there until I got it spinning level 🙂 Yes I could have had somebody (possibly an engineer with a degree) machine me three metal spacers. I might have even had these designed with a slight conical top and finished with tiny sponge nipples to rest the vinyl on giving it a 2001 Space Odyssey feel to it but I decided not to go that way. Damn it man, it would have cost me as much as the whole thing to go that way and you can only have so much of a good thing.

The plinth it sits in while in two parts is solid and absorbs the vibrations both of the turntable itself (motor, idler setup etc) and the outside influences. It's rubber feet (walking stick finials ) also help absorb vibrations. This makes the platter spin almost silently. So I have an idler drive spinning a level platter setup, almost silently, to a given speed, with no vibrations coming through to affect the stylus as it picks up the music from the groove of the record and passes it through the amplifier then out to the speakers where it arrives and separates into stereo sound placing individual musicians at different points in front and to the side of me each blending together to play beautiful music to my ears. Which bit of the above is it not suppose to do or what else should I be expecting it to do?

Using your car analogy I would say its definately not a Ferrari. I'd put it more like a Ford Cortina mk1, old and not the best in the world as a car but with a few tweaks and improvements from ooo let's say the Lotus parts bin and a lovely pale green go faster stripe down the side the little old Cortina can look beautiful, perform much better than in its original state and in some cases out perform cars with a much higher pedigree 😉

THIS is what its all about. I admire the way you just dont talk, but actually do

Steen

whats the advantage of the double plinth .....

No advantage, as such, just a means to an end.

The idler fitted the original platter which was tiny. I wanted a full size platter and had the top platter down the shed. It didn't fit the BSR idler setup so my solution was to place it on top of the original using the, soon to be patented, three piles of nickels spacer technique 🙂

With the right machinery, skills, etc etc a replacement could have been designed and machined and a better solution could be engineered but a. It would have cost too much for this project and b. I certainly couldn't have done it myself. So in the best Heath Robinson style and using the tried and tested 'Bodge it Yourself' methodology I came up with this solution. I think it does the job and does it well both in function and design

THIS is what its all about. I admire the way you just dont talk, but actually do

Steen

Steen thanks for the comment. As I've said before its the fun of the build, the challenge of the task and the final outcome that surprises and pleases me that keeps me trying new projects.

I admire Sreten for his knowledge and skill in implementing the same. Though I think his way of imparting that knowledge to others leaves a lot to be desired. But it takes all sorts to make the world and I'm happy to be the Yang to Sretens Ying. Also I do enjoy the banter which I'm learning not to take too much to heart.

Damn it you said plinth not platter Doh

The double platter was initially a concept that I'd had in mind that I wanted to implement....

Nah not really, they had a two for one offer down at TKMax in the chopping board section 😀

NO I'm kidding. The motor sits too low below the one board so I thought a double platter would allow a space for it to clear. I could have left it as a single as the feet would have given enough clearance but I will be fitting in the space a wiring box for the electrics which will be out of sight at the rear and a 5 into one phono selector switch to connect up to five arms outputting to one amp which will sit at the front.

The double platter was initially a concept that I'd had in mind that I wanted to implement....

Nah not really, they had a two for one offer down at TKMax in the chopping board section 😀

NO I'm kidding. The motor sits too low below the one board so I thought a double platter would allow a space for it to clear. I could have left it as a single as the feet would have given enough clearance but I will be fitting in the space a wiring box for the electrics which will be out of sight at the rear and a 5 into one phono selector switch to connect up to five arms outputting to one amp which will sit at the front.

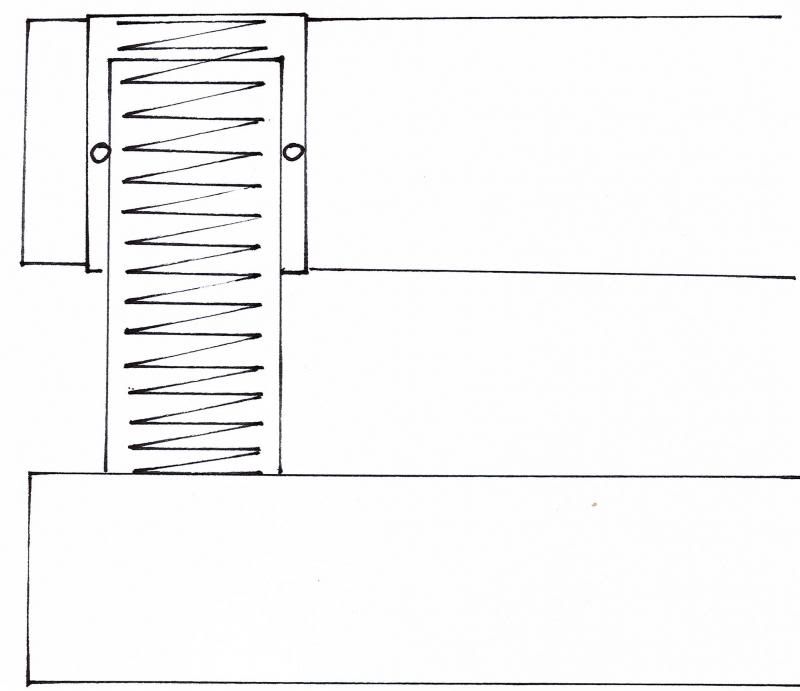

Also when thinking about the design of the two layered plinth I had originally thought of having the top section sprung using something like this:

Please remember I am not an engineer so ideas and drawings are not my forte. A steel cup cut into the top plinth layer about 3 mil wider than the leg support. A spring inside the leg support and a round rubber washer/ring to act as a guide. The spring to be fairly stiff, enough to assist in the absorption of vibrations but not to have the top plinth wobbling around like a bobble head. I may come back to this at a later date if I can source the three cups and springs needed.

Please remember I am not an engineer so ideas and drawings are not my forte. A steel cup cut into the top plinth layer about 3 mil wider than the leg support. A spring inside the leg support and a round rubber washer/ring to act as a guide. The spring to be fairly stiff, enough to assist in the absorption of vibrations but not to have the top plinth wobbling around like a bobble head. I may come back to this at a later date if I can source the three cups and springs needed.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- The Nanook turntable thread