Wow... As in there's nothing else that can be said... What an incredible project!

+1

What sort of oil do they use in the bearings?

I have a some of the stock oil SY, if you want some to check out.

Dave C, et al.: What approach would you take in regards to electrolytics on an NOS unit that's sat for ~30 years? Summarily replace all (my inclination)?

If there is no sign of leaking or bulging, and if it measures OK, then I would leave it. If you must, do one or two at a time.

Regards

Dave

Regards

Dave

I understand that. What I mean is, many folks recommend summarily replacing electrolytics of this age as a matter of good practice. You don't, and I'm wondering why; if there's a reason aside from 'if it ain't broke, don't fix it'?

I understand that. What I mean is, many folks recommend summarily replacing electrolytics of this age as a matter of good practice. You don't, and I'm wondering why; if there's a reason aside from 'if it ain't broke, don't fix it'?

Yes, on the SP-10 MKII there are only three capacitors that need changing, all others are just perfect. Changing them all needs thorough testing afterwards, so why bother ?

Dave

Sometimes a blown capacitor takes with it to kingdom come other parts of the circuit that can be hard to find...like vintage ICs...

An electrolytic that is 30 years old can give up anytime...

Great design by the way!And i mean all of it!Table plus turntable!

An electrolytic that is 30 years old can give up anytime...

Great design by the way!And i mean all of it!Table plus turntable!

That isn't going to happen in a SP-10 and all the IC's are available. Buy hey, go change them all if you want, no one stopping you !

Dave

Dave

I know there are IC replacement options for the MKII, but my NOS unit is a MK2A. I haven't been able to source all the ICs for that one.

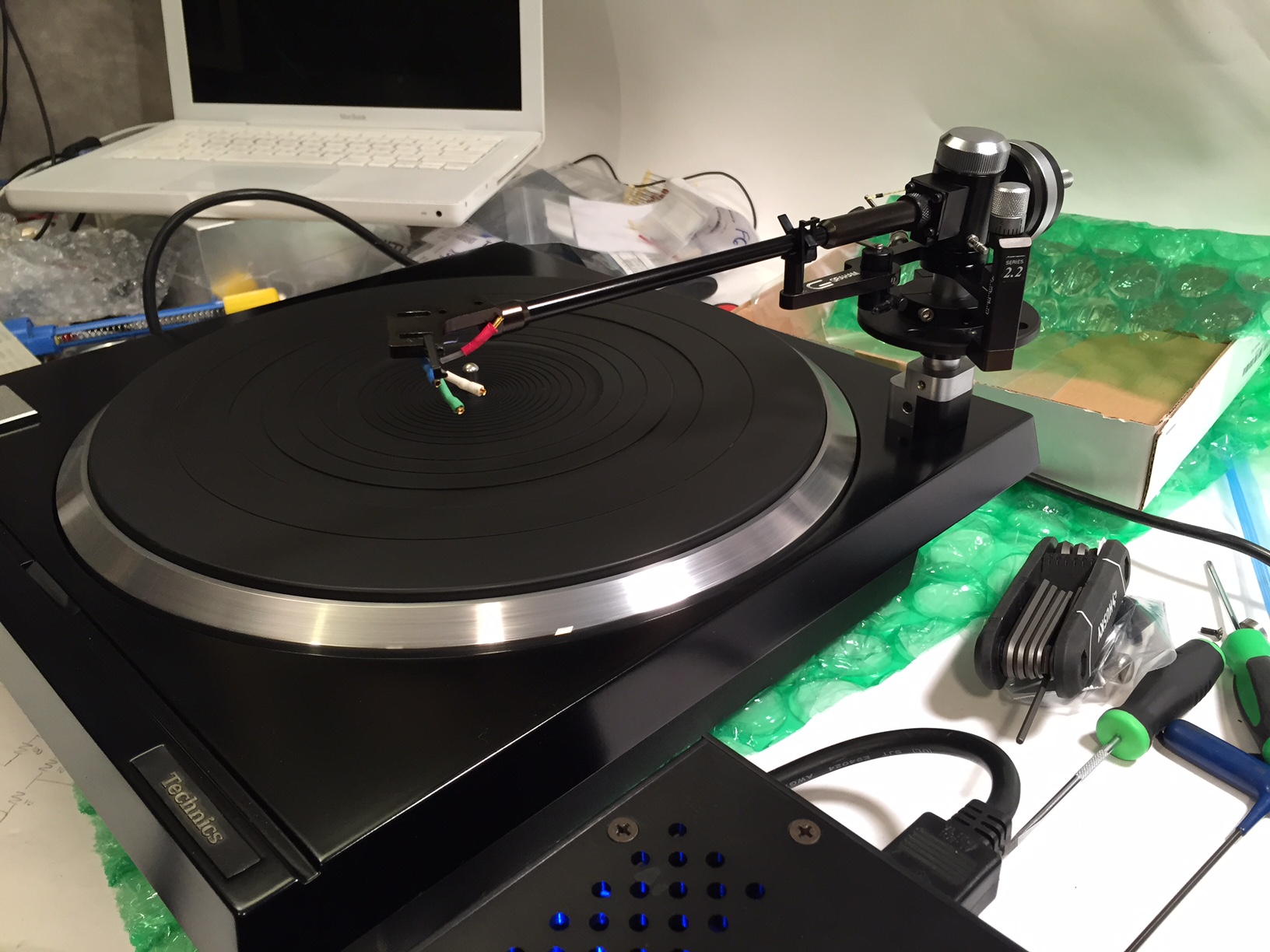

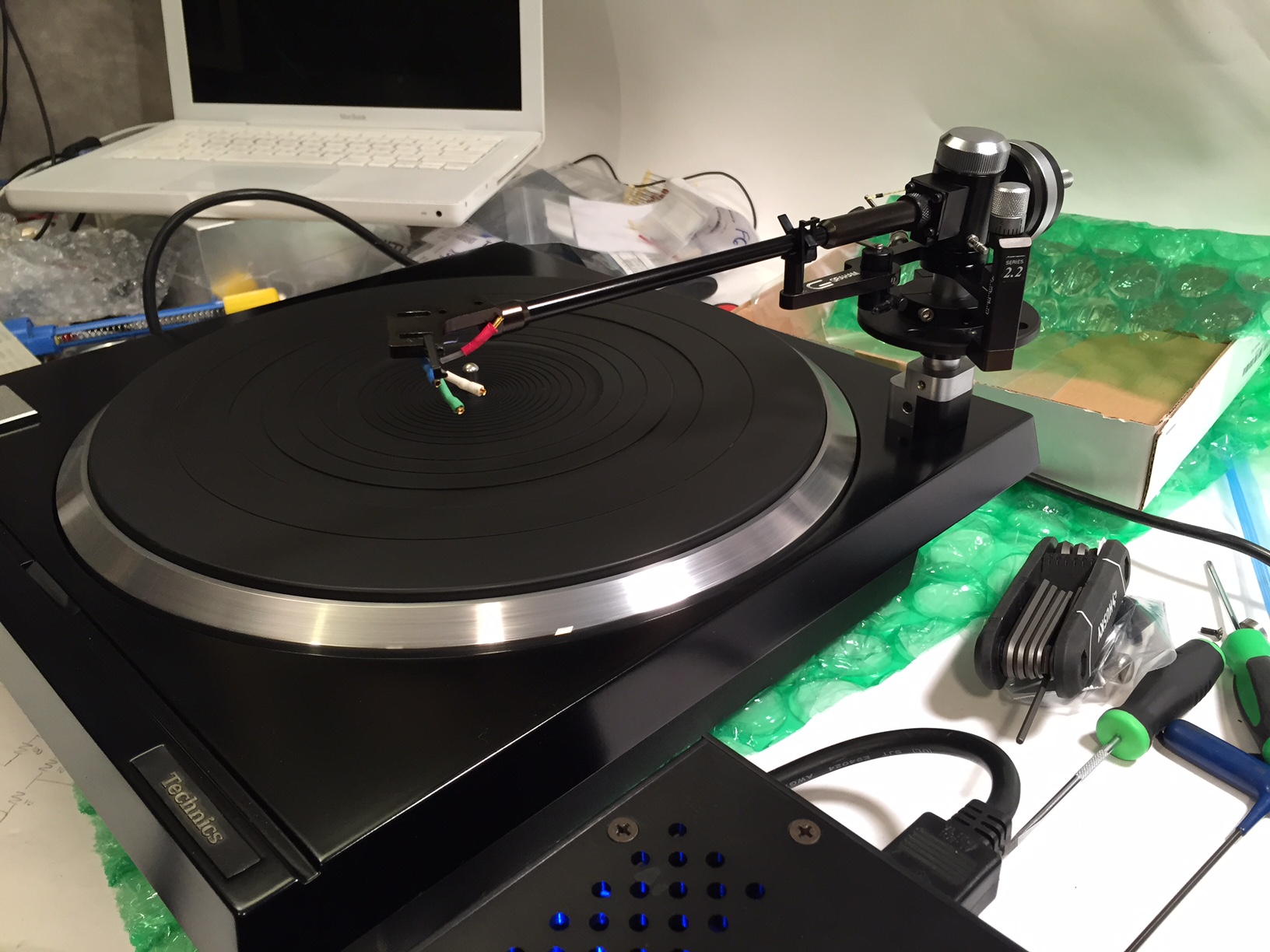

Back together and running smoothly -

Here's the arm for it -

Next, remove the guts from the other one, send it to Einric_99 who is making the plinths, then get it repainted.

Here's the arm for it -

Next, remove the guts from the other one, send it to Einric_99 who is making the plinths, then get it repainted.

No underscore on my forum name....

Just my email, LOL

I look forward to completing these for you.

The ebony veneer will look fantastic.

Just my email, LOL

I look forward to completing these for you.

The ebony veneer will look fantastic.

Looks great, what was the metal finishing process ?

I had the opportunity to talk to my brother-in-law Steve today, and got some clarification of what was done. The specifics are as follows;

Abrasive wheel to remove the old paint and corrosion.

Etching primer for aluminum

A 2-part 'glazing putty' was used to fill the deep bits

Then it was normal autobody process from there -

Prime

Sand

Paint

Clearcoat (a bit of flattening agent was put in the clear to cut the gloss to my specific request)

Last edited:

Back together and running smoothly -

Here's the arm for it -

Next, remove the guts from the other one, send it to Einric_99 who is making the plinths, then get it repainted.

looking really good. I admire your ability with electronics.

I'm using a Graham 2.2 on mine. Happy camper.

I look forward to seeing your final product.

Excellent stuff.

-Steve

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread