Hi Bon, I would love to hear it some day.

I had an issue with slightly warped LP's rubbing on the rear of the carriage, my LTA runs the carriage very close to the LP surface and the SP10 mat label cutout is too deep and makes LP's curl up at the edge with a spindle weight.

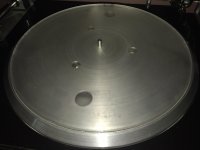

So in order to flatten these I made a mat yesterday from 5mm clear acrylic, it has 9 x 0.003" (0.08mm) steps and the label indent is 0.1mm below the 9th step. So the dish is about 0.8mm. I was not expecting to hear a difference but was surprised that a back to back plating Stevie Wonder was audible. Background noise was less. Didn't do as much to flatten the 180g Stevie Wonder LP though. I think a periphery clamp is next.

.

I had an issue with slightly warped LP's rubbing on the rear of the carriage, my LTA runs the carriage very close to the LP surface and the SP10 mat label cutout is too deep and makes LP's curl up at the edge with a spindle weight.

So in order to flatten these I made a mat yesterday from 5mm clear acrylic, it has 9 x 0.003" (0.08mm) steps and the label indent is 0.1mm below the 9th step. So the dish is about 0.8mm. I was not expecting to hear a difference but was surprised that a back to back plating Stevie Wonder was audible. Background noise was less. Didn't do as much to flatten the 180g Stevie Wonder LP though. I think a periphery clamp is next.

.

Attachments

Last edited:

Well—pick me up off the floor.

This deck is all it's reported to be—just incredible.

Some super wise-guy said about the SP-10: "...it will be the only part of your system that you can't improve...". Love that. And I think it's true.

Also, couldn't handle trying to fit the 9" SME on there... so picked up a 10" Jelco. I have to say—that arm is every bit the same quality of fit and finish as the SME—incredible value—can't recommend it highly enough—sounds awesome to me. Sound also improved with the brass weight I made...Stock OEM matt....Whole thing came in around 60lbs ... with 20lbs of lead below the platter chassis.

It's a whole new audio world over here. Also—Anyone who wants or needs a phono-pre project should check out the Salas Folded Simplistic—beyond awesome. Salas Phono-pre

This deck is all it's reported to be—just incredible.

Some super wise-guy said about the SP-10: "...it will be the only part of your system that you can't improve...". Love that. And I think it's true.

Also, couldn't handle trying to fit the 9" SME on there... so picked up a 10" Jelco. I have to say—that arm is every bit the same quality of fit and finish as the SME—incredible value—can't recommend it highly enough—sounds awesome to me. Sound also improved with the brass weight I made...Stock OEM matt....Whole thing came in around 60lbs ... with 20lbs of lead below the platter chassis.

It's a whole new audio world over here. Also—Anyone who wants or needs a phono-pre project should check out the Salas Folded Simplistic—beyond awesome. Salas Phono-pre

Attachments

When lockdown is over, you are welcome to visit. I will have three SP10's up and running. All with different versions of my resin/bentonite plinths.Hi Bon, I would love to hear it some day.

I have used hard mats on the SP10 for 20 years. I did an extensive comparison with rubber, sorbothane, graphite, copper, copper/carbon fibre, stainless steel/carbon fibre, cork, cork/rubber and a few other home concoctions. The stock mat is not bad, but the best rubber mat I have is a thick Thorens 125 mkII mat. It has a lip that needs careful trimming off to use with the SP10 platter, but is a perfect diameter. Regardless, hard mats sound best on the SP10 to me. You have to cope with possible slippage and LP edge warps, so a good peripheral clamp and centre weight is mandatory for a hard mat. My favourites are the TT Weights Ultimat copper/carbon fibre, stainless steel/carbon fibre mats and peripheral ring.So in order to flatten these I made a mat yesterday from 5mm clear acrylic, it has 9 x 0.003" (0.08mm) steps and the label indent is 0.1mm below the 9th step. So the dish is about 0.8mm. I was not expecting to hear a difference but was surprised that a back to back plating Stevie Wonder was audible. Background noise was less. Didn't do as much to flatten the 180g Stevie Wonder LP though. I think a periphery clamp is next.

.

One thing to watch for with diy hard mats, is dishing. Machining out the label recess gives uneven stresses and the mat tends to curl up at the edge. I suspect laminating a thin ring to a flat disc might not suffer similarly, but I have not tried it.

View attachment 832603

The Image is my SP10 MkII, it was discovered in a shed in a very wanting condition.

The individual who was going to work on the refurbishment,

gave me a Donor Chassis, in a slight better condition than the one I supplied.

I took the Donor Chassis to a Local Vehicle Custom Paint Shop,

and 'Voila' this is what I was returned.

Definitely not original but a nice application of the Paint Job.

I have been using this one for the past year as my go to TT.

It has been out on few visits to the homes of other Vinyl Minded Enthusiasts and has won much favour.

Your table is gorgeous. !!

pfarrell

Thank you for the Compliment, the Plinth Material is MU25, by the previous owner before it was exchanged for Panzerholz.

I do intend on changing it and returning it to the person who did my refurbishment, so another can receive the benefit if need be.

The Paint coating is about 9 coats including lacquer, there was vehicle being worked on to the same colours, I was lucky with this as Black and Gold were my wanted Colours, this was done parallel to the Vehicle, and I was charged £70 🙂

I'll reinstate the original Platter Later and put the Tenuto Mat on, and post another picture.

Thank you for the Compliment, the Plinth Material is MU25, by the previous owner before it was exchanged for Panzerholz.

I do intend on changing it and returning it to the person who did my refurbishment, so another can receive the benefit if need be.

The Paint coating is about 9 coats including lacquer, there was vehicle being worked on to the same colours, I was lucky with this as Black and Gold were my wanted Colours, this was done parallel to the Vehicle, and I was charged £70 🙂

I'll reinstate the original Platter Later and put the Tenuto Mat on, and post another picture.

More photos in post #1314.12 pin aircraft connector. Connects the 12 wire motor loom to the controller box.

When lockdown is over, you are welcome to visit. I will have three SP10's up and running. All with different versions of my resin/bentonite plinths.

My family are in Sydney so we come back once a year. When this lockdown all over I'll PM you.

One thing to watch for with diy hard mats, is dishing. Machining out the label recess gives uneven stresses and the mat tends to curl up at the edge. I suspect laminating a thin ring to a flat disc might not suffer similarly, but I have not tried it.

I machined the acrylic on the lathe held up against the platter with a live centre in the tail stock using air as a coolant. The mat is still flat on the bottom with no rocking on the platter. I machined the label recess slightly lower than the 9th step which is 0.8mm lower than the circumference.

I found the stock mat label recess is too deep and some records kicked up around the edge with the spindle weight on. I am planning on making a peripheral weight I just need to modify the arm gantry so I can fit it.

I do like this concept and will make something similar. Just need to decide if I use acrylic or polycarbonate, or a lamination of both.

Ring Clamp & Acrylic Adapter Mat

My family are in Sydney so we come back once a year. When this lockdown all over I'll PM you.

Lathe is better than the router table I used. One polyethylene mat I made was initially flat but developed a dish over time.I machined the acrylic on the lathe held up against the platter with a live centre in the tail stock using air as a coolant. The mat is still flat on the bottom with no rocking on the platter. I machined the label recess slightly lower than the 9th step which is 0.8mm lower than the circumference.

Just need to decide if I use acrylic or polycarbonate, or a lamination of both.

Ring Clamp & Acrylic Adapter Mat

A 10mm thick Acetal (POM) mat I made recently, dished during machining. Hours in the oven between plate glass, did not flatten it. It is a very temperature stable, usually a good thing but not in this instance.

This looks similar to a peripheral ring clamp I have

Shop | Wayne's Audio

Both of my peripheral rings have a very thin lip, but still sometimes a low riding cartridge will drag in the lead-in grooves. It will challenge your machining skills to keep the ring flat and the lip thin enough.

Finishing up the plinth for mine!

I got it running on lock. Platter fights fingerpressure, but I’ve still got some very slight speed/wow-flutter issues.

When I use my iPhone app it reads 33.34, 45.03 and 78.32, wow/flutter 0.10%

Don’t know where to start looking. Could there be a problem within the FG coil? IC1?

If anyone has some pointers, I’d greatly appreciate it!

I got it running on lock. Platter fights fingerpressure, but I’ve still got some very slight speed/wow-flutter issues.

When I use my iPhone app it reads 33.34, 45.03 and 78.32, wow/flutter 0.10%

Don’t know where to start looking. Could there be a problem within the FG coil? IC1?

If anyone has some pointers, I’d greatly appreciate it!

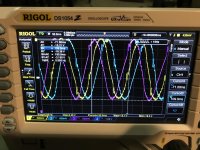

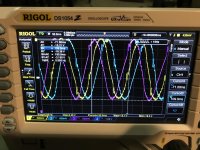

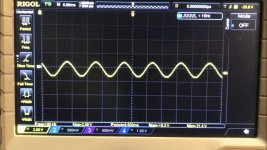

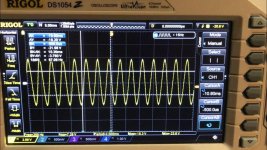

Motor waveform looks normal. Connect your scope to pin F on the same header where you measure T and S. This is the FG signal. Zoom in and watch for stability, post a video if you can.

Finishing up the plinth for mine!

I got it running on lock. Platter fights fingerpressure, but I’ve still got some very slight speed/wow-flutter issues.

When I use my iPhone app it reads 33.34, 45.03 and 78.32, wow/flutter 0.10%

Don’t know where to start looking. Could there be a problem within the FG coil? IC1?

If anyone has some pointers, I’d greatly appreciate it!

Be aware that the W&F measurement from IPhone will include warp and off centre wow. The bigger issue is being able to stop the platter with finger pressure. It should take a fair amount of pressure to slow the platter.

I use my SP10 as to clean records sometimes while playing. I use a goats hair brush and I can put a fair amount of pressure on the brush to clean stubborn LP's and the TT does not slow.

For speed stability I use the Ulimate Analog test LP 1KHz and feed output of phono pre into the frequency counter or scope.

I assume the period wave is 33 as it looks like about 6ms. Use the marker s on the scope to measure the period offset and adjust it to spec. You might need to do the adjustment multiple times as 78 effects 33 and viceversa. If this is out of spec the TT will lock but can unlock with drag on the platter.

Have you checked and adjusted the Voltages?

Check Waveform on the motor drive board A1 A2 and A3, if there is a lot of noise on the signal replace C2,4 &6

33rpm

78rpm

Thanks JP!

Can’t seem to upload the video so took some screengrabs.

Wave isn’t moving, smooth without any spikes.

Did have the cursors set for 45. Was switching between speeds in the video. Will try to upload tomorrow.

Edit: wasn’t aware vr101 & 102 effected one another. Will start playing around with those as well.

It does take more than a fair amount of pressure. My Lenco slows down while brushing records, the SP10 doesn’t want to slow down when really pushing on the rim.

Last edited:

VR101 and VR102 do not affect each other.

You'll want to zoom in on that FG wave a lot more - so you see two cycles max, and decrease your volts/div. If it's running right you shouldn't be able to see it move at all. From there you'd need a spectrum analyzer dig deeper.

I'd post an example but I'm 10 hours in to a power outage at the moment.

You'll want to zoom in on that FG wave a lot more - so you see two cycles max, and decrease your volts/div. If it's running right you shouldn't be able to see it move at all. From there you'd need a spectrum analyzer dig deeper.

I'd post an example but I'm 10 hours in to a power outage at the moment.

I'd post an example but I'm 10 hours in to a power outage at the moment.

Hope your power outage is rectified soon.😱

jeff

So... Trying to upload some videos I took from the waveforms. Really struggling to upload for some reason. 🙄

Again, any input welcome 🙂

Anyway. Don't trust the iPhone app anymore. Will look into sourcing a test LP with a 1K sine wave. Hook that one up to the scope.

JP, hope the poweroutage got sorted?

View attachment FWAVE3345.mp4

View attachment 33STWave.mp4

View attachment 45STWave.mp4

View attachment 78STWave.mp4

Thanks guys,

Have a nice day!

Again, any input welcome 🙂

Anyway. Don't trust the iPhone app anymore. Will look into sourcing a test LP with a 1K sine wave. Hook that one up to the scope.

JP, hope the poweroutage got sorted?

View attachment FWAVE3345.mp4

View attachment 33STWave.mp4

View attachment 45STWave.mp4

View attachment 78STWave.mp4

Thanks guys,

Have a nice day!

Are you sure you are not chasing rainbows here. Testing W&F with an LP has too many variables to check SP10 spec, you will not see 0.035% W&F, it will be higher. The only way to check this would be with a tacho on the platter.

Motor torque is listed as 5kg/cm and without saying in the spec I would expect that to be at the spindle so force to stop the platter edge would be 5000g/16cm = 312grams.

Motor torque is listed as 5kg/cm and without saying in the spec I would expect that to be at the spindle so force to stop the platter edge would be 5000g/16cm = 312grams.

VR101 and VR102 do not affect each other.

They are interdependent and gets worse the more the adjustment is out, I know this from experience repairing one SP10 that had been butchered by the radio station tech. Took me hours to repair all the faults after removing the additional capacitors added to the Logic PCB.

Are you sure you are not chasing rainbows here. Testing W&F with an LP has too many variables to check SP10 spec, you will not see 0.035% W&F, it will be higher. The only way to check this would be with a tacho on the platter.

I was actually thinking about the speed. A 1kHz sinewave won’t be a 1kHz wave if the speed is off...

But I’ve been wondering today if it’s my OCD kicking in hard looking for the perfect 33.33rpm.

May have been something else wrong then. I've number twenty-something on my bench presently and have never seen that type of behavior.

May have been something else wrong then. I've number twenty-something on my bench presently and have never seen that type of behavior.

We’ll see. Just found the last (I hope, but probably not) bad transistor in the second one so it’s running again. No chance to check the waveforms yet but if it runs the same on the app, I’m tossing my phone. 😉

Got an Audio Technica 1503 on the way for that one, better start thinking about a plinth...

This whole Covid thing hasn’t been bad for the projectcloset.

View attachment 833993

Finished my Quad II refurb, built a speedcontroller for the Lenco, redid the EHT’s for the ESL and installed an on/off switch, built a pair of 15ohm LS3/5a’s...

The SP10’s have been waiting for this moment.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread