Hi,I have been listening to this fine amp and have noticed mine has a buzz through the speakers. I have tried many of the usual remedies have installed some copper on the small trans and a layer of EMI Shielding FF1 FLEX SHEET from Mouser . Nothing has changed in the sound or intensity.I do not have it with the Aleph J amp boards installed. So my question ,has anyone come across undamaged components on the pcb's that were adding to a noise issue like this? I don't have an oscilloscope . Thanks

I have a shielded power transformer, and both copper tape and mu metal shielding in the Edcor, and still have a very feint hum when I listen close to the speakers. I traced it down to my long RCA interconnects. One pair gave terrible hum, the current cables give the tiny hum. When I short the RCA inputs, there is no hum. I’m in process of deciding to move the amps closer to the preamp, or look for an even better set of RCA interconnect cables. OR choose a different amp, with balanced XLR input options. But I do love my M2x monoblocks.

My point, not all hum comes from inside the amp. Be sure to investigate the system.

My point, not all hum comes from inside the amp. Be sure to investigate the system.

Good point. Will also be aware of that issue now.I have it sitting on kitchen table inputs shorted and only one speaker attached to see if its same on both channels and it is buzz still there.I removed the transformer and moved it as far as possible put a can over it still no change. That's what has me thinking of something other than the edcor or it could still be it I don't know.... thanks for your input.

Attachments

Last edited:

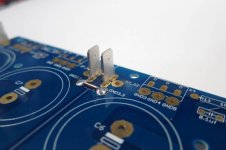

Are those pennies you’re using as washers on the mosfets? I’m guessing you’ve found that the aluminum in them helps dissipate heat better than metal washers? Just curious.

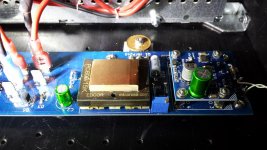

I had a hard time finding those washers cheaply... those are copper ones ,I had to research after drilling and not hitting copper first off... 🙂

In the U.S.A. our one cent piece is made of copper with the exception of some of those minted during WW 2 . In WW 2 copper was in so short supply pennys were made of steel and a lot of silver was used to make wire especialy for our airplaines not for it's better electrical properties but just because there was no copper available. But back to using a penny as a washer in the USA drilling a hole in a penny may fall under defacing the coin and not be legal. Now how do I hold the penny when I drill that hole ?

In a vice, in the corner, even a small vice will do. If you have to use wooden spacers to hold it. Drill slowly.

Tricky, I know.

Tricky, I know.

Last edited:

Woody - In the USA, pennies minted after roughly mid-1982 are copper-plated zinc. There are a number of resources available to check coin compositions (which include the multiple compositions of pennies over the years) if you're interested. Brass shell casings were also used as part of the composition for "war-time" pennies from '44 onward, I think. Why do I know these weird things? I collected "wheat pennies" and "war-time" pennies for a while. I also worked for a very large pet supply company for a while. Sadly zinc toxicity in dogs (and some other pets) from eating US pennies always came up. We never used plated zinc for materials in pet toys or any cage / crate materials, or food contact things like bowls etc. due to its toxicity.

Pennies may make a fine washer though.

Back to our regularly scheduled programming.

Pennies may make a fine washer though.

Back to our regularly scheduled programming.

Last edited:

I tried drilling pennies a couple times without much success so it was easier

(and safer) for me to just order a bunch of washers from that certain auction site.

BTW, pennies have not been produced in Canada since 2012 though there are

likely still billions of them hidden in the sofas of the nation.

(and safer) for me to just order a bunch of washers from that certain auction site.

BTW, pennies have not been produced in Canada since 2012 though there are

likely still billions of them hidden in the sofas of the nation.

Hi,I have been listening to this fine amp and have noticed mine has a buzz through the speakers. I have tried many of the usual remedies have installed some copper on the small trans and a layer of EMI Shielding FF1 FLEX SHEET from Mouser . Nothing has changed in the sound or intensity.I do not have it with the Aleph J amp boards installed. So my question ,has anyone come across undamaged components on the pcb's that were adding to a noise issue like this? I don't have an oscilloscope . Thanks

It may just be as simple to solve as re-configuring the GND cabling a bit.

For example, I saw pics of finished amps here where the speakers gnd terminals are connected back to the M2X amp board and from there to the PS star gnd... For whatever reason, that particular configuration makes a slight hum for me that goes away completely when the speaker terminal grounds are connected to the PS star ground directly. Results may vary depending on you PS board but it's worth a try. What PS board are you using?

I have a shielded power transformer, and both copper tape and mu metal shielding in the Edcor, and still have a very feint hum when I listen close to the speakers. I traced it down to my long RCA interconnects. One pair gave terrible hum, the current cables give the tiny hum. When I short the RCA inputs, there is no hum. I’m in process of deciding to move the amps closer to the preamp, or look for an even better set of RCA interconnect cables. OR choose a different amp, with balanced XLR input options. But I do love my M2x monoblocks.

My point, not all hum comes from inside the amp. Be sure to investigate the system.

That is quite interesting. Hum problems make for some of the best challenges in diy audio. IMHO if shorting the input stops the hum, the amp may not be the problem. Maybe the upstream components are, or the way they interact with the amp. What happens if you leave the amp disconnected? Nothing happens here when I tried that.

I used vise-grips with a block of wood underneath . Copper drills easy quite soft metal.

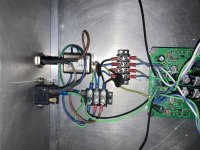

The power supply boards are from the diy store ,I played with the connections again today ,still same. Here's a couple of pics of my interpretation of the T grounding point . I have tried all positions from the original laid out in the build guide to this now.

The power supply boards are from the diy store ,I played with the connections again today ,still same. Here's a couple of pics of my interpretation of the T grounding point . I have tried all positions from the original laid out in the build guide to this now.

Attachments

Hard to comprehend the different results from basically the same set of boards. I see a copper bridge between G2 and G3 if I read correctly...why is that needed?

It's not much help but would suggest to rewire everything from scratch. Test wiring for hum one wiring step at a time. This are pics of my stupid simple wiring that is hum buzz-free. I used the SLB board but I am not using it as a CapMult but as a simple CRC for now. Best thing about the BLS board is that it reduces clutter since has on board mosfet rectification cool and low V drop. However, your results should be the same as mine.

It's not much help but would suggest to rewire everything from scratch. Test wiring for hum one wiring step at a time. This are pics of my stupid simple wiring that is hum buzz-free. I used the SLB board but I am not using it as a CapMult but as a simple CRC for now. Best thing about the BLS board is that it reduces clutter since has on board mosfet rectification cool and low V drop. However, your results should be the same as mine.

Attachments

I see. I am not sure why a new PS board would give a different result. Is it a hum or a buzz. They may have different causes. Did you try extending the transformer leads enough so that it is out of the case and rule it out as a source of interference? That maybe doable w/o cutting into the wiring too much.

I like to work with terminated wiring and crimp on loops so I can join wires using screws before finalizing everything. I try soldering wires as little as possible.

I like to work with terminated wiring and crimp on loops so I can join wires using screws before finalizing everything. I try soldering wires as little as possible.

For anyone newly building Cedarburgs... I'm finding the D45H11 transistor in T0-220-3 package difficult to find—despite what it might look like on octopart—it seems to be out of stock in a lot of places. Arrow has them in stock for low/reasonable shipping cost and Arrow's order fulfillment/shipping process is FAST.

https://www.arrow.com/en/products/d45h11/stmicroelectronics

EDIT: modified my search at Mouser... they have 26...Actually—seems the search issues are about D45H11 vs D45H11G. Non-G is even BIG and BEEFY-ER. "G", speced in Mark's example Mouser p/n column of the BOM is harder to find...

https://www.arrow.com/en/products/d45h11/stmicroelectronics

EDIT: modified my search at Mouser... they have 26...Actually—seems the search issues are about D45H11 vs D45H11G. Non-G is even BIG and BEEFY-ER. "G", speced in Mark's example Mouser p/n column of the BOM is harder to find...

Last edited:

For anyone newly building Cedarburgs... I'm finding the D45H11 transistor in T0-220-3 package difficult to find—despite what it might look like on octopart—it seems to be out of stock in a lot of places. Arrow has them in stock for low/reasonable shipping cost and Arrow's order fulfillment/shipping process is FAST.

https://www.arrow.com/en/products/d45h11/stmicroelectronics

EDIT: modified my search at Mouser... they have 26...Actually—seems the search issues are about D45H11 vs D45H11G. Non-G is even BIG and BEEFY-ER. "G", speced in Mark's example Mouser p/n column of the BOM is harder to find...

I used Mark's BOM and mouser BOM tool (upload the .xls under tools and services) and found no issues, all parts are available from Mouser. I cannot thank Mark enough for making ordering so easy!

Mouser parts in question:

863-D44H11G

863-D45H11G

Last edited:

For anyone newly building Cedarburgs... I'm finding the D45H11 transistor in T0-220-3 package difficult to find—despite what it might look like on octopart—it seems to be out of stock in a lot of places. Arrow has them in stock for low/reasonable shipping cost and Arrow's order fulfillment/shipping process is FAST.

https://www.arrow.com/en/products/d45h11/stmicroelectronics

EDIT: modified my search at Mouser... they have 26...Actually—seems the search issues are about D45H11 vs D45H11G. Non-G is even BIG and BEEFY-ER. "G", speced in Mark's example Mouser p/n column of the BOM is harder to find...

I put everything in the cart on monday and now they are out! I didn't order because we are buried in snow and arctic temps here. There hasn't even been any delivery of mail or garbage pickup for the week so I figure I'd wait. 🙁

- Home

- Amplifiers

- Pass Labs

- The diyAudio First Watt M2x