Scott,They sound fantastic, and I don't even have them quite waveform coherent yet. I'm well within the 1/4 wavelength spacing requirements...but I keep ending up with greater than 1'st order roll-offs.

The raw acoustical band pass from the enclosed port area and a HF driver on a conical horn usually are already greater than a first order (6 dB per octave) crossover, so even a single capacitor and coil could result in 12 dB (or more) per octave acoustical slopes.

Is there a specific acoustical crossover roll off you are looking for, and what are your reasons for wanting that roll off?

Art

Last edited:

90 deg Synergy 2 way in foam core.

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures-200.html#post3698230

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures-200.html#post3698230

Looks like uploads are working again...

Note that I have a 1" overlap for my access panels. This gives me plenty of area for sealing and putting 1/4-20 bolts for attaching the access panel sot the openings.

Note that I have a 1" overlap for my access panels. This gives me plenty of area for sealing and putting 1/4-20 bolts for attaching the access panel sot the openings.

Attachments

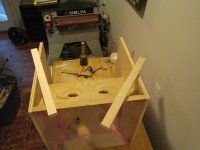

More pictures of wrapping an enclosure around the horn.

When doing this, the idea is to keep everything as square as possible. I put some serious time in here... The best part is, this way you can use a bunch of off-cuts and odd sizes...since very few pieces are very large it's efficient sheet good usage.

When doing this, the idea is to keep everything as square as possible. I put some serious time in here... The best part is, this way you can use a bunch of off-cuts and odd sizes...since very few pieces are very large it's efficient sheet good usage.

Attachments

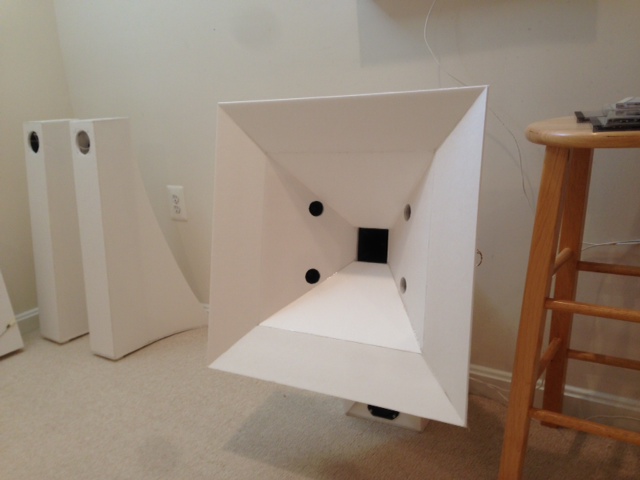

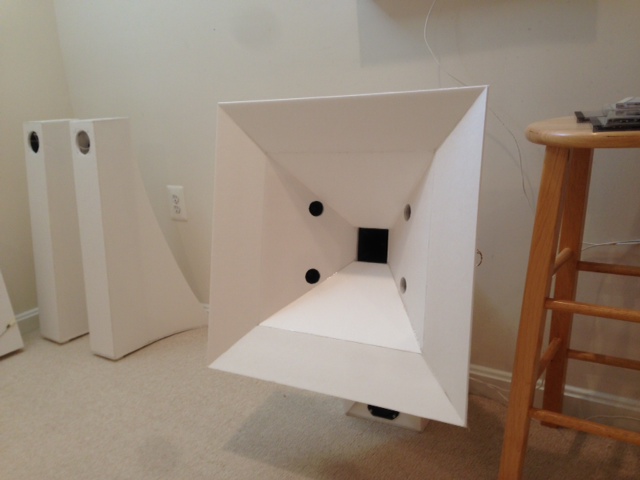

Nice work and great progress there Speakerscott. I never thought that 24 in x 24 in horn mouth is that big until I built it. It is a substantial sized speaker for most rooms. I am liking the sound a lot, albeit with some coloration from the thin foam core panels.

Nice work and great progress there Speakerscott. I never thought that 24 in x 24 in horn mouth is that big until I built it. It is a substantial sized speaker for most rooms. I am liking the sound a lot, albeit with some coloration from the thin foam core panels.

One of my prototypes that used the Dayton PA130 5" as the mid was 24x24...huge. My wife basically put her foot down....

Wow great write up. Thanks for all this VREY VERY helpful information. I was more worried about the building of the horn itself because this will be my first attempt. Glad to see so many pictures. Will definitely be using this thread as a guide for my build come January.

How difficult was designing the crossover?

I haven't a clue but do plan on using a passive crossover in my project. I would like to be able to use a single channel of an amp to driver the speaker instead of using more channels.

I haven't a clue but do plan on using a passive crossover in my project. I would like to be able to use a single channel of an amp to driver the speaker instead of using more channels.

This is indeed a great thread and I am keeping a close eye on it.

I'm having a hard time understanding something -- so bear with me. Normally, it takes a large horn to reproduce low bass frequencies. Yet this Synergy reaches down to the mid-40's with a relatively small horn (certainly too small for those low frequencies).

Are the drivers simply acting as direct radiators at the low frequencies? It would seem the horn provides no gain at the low frequencies but nevertheless the low frequencies are the same level as the mids and highs. Is this because of the "synergy magic" (whatever that is) or due to careful crossover construction?

I'm having a hard time understanding something -- so bear with me. Normally, it takes a large horn to reproduce low bass frequencies. Yet this Synergy reaches down to the mid-40's with a relatively small horn (certainly too small for those low frequencies).

Are the drivers simply acting as direct radiators at the low frequencies? It would seem the horn provides no gain at the low frequencies but nevertheless the low frequencies are the same level as the mids and highs. Is this because of the "synergy magic" (whatever that is) or due to careful crossover construction?

This is indeed a great thread and I am keeping a close eye on it.

I'm having a hard time understanding something -- so bear with me. Normally, it takes a large horn to reproduce low bass frequencies. Yet this Synergy reaches down to the mid-40's with a relatively small horn (certainly too small for those low frequencies).

Are the drivers simply acting as direct radiators at the low frequencies? It would seem the horn provides no gain at the low frequencies but nevertheless the low frequencies are the same level as the mids and highs. Is this because of the "synergy magic" (whatever that is) or due to careful crossover construction?

The last octave of a typical 3-way Synergy horn is covered by a bass reflex alignment. The front sides of the woofers are horn loaded into the horn, but the back side is ported into the horn farther down the horn. The mouth size of a Synergy is sized correctly for the lowest horn loaded frequency and then the bass reflex provides another octave of output below that. The bass reflex is tuned to be over damped and peaked in a narrow one octave bandwidth. This gets the sensitivity of the bass reflex section up to the same level as the horn loaded frequencies.

I think I read that these were sealed? Regardless, if you wanted to model this as sealed, conventional modeling would apply for the four woofers below the horn frequency to determine response vs enclosure size?

How would the small ports in front of the woofers affect this?

How would the small ports in front of the woofers affect this?

The last octave of a typical 3-way Synergy horn is covered by a bass reflex alignment. The front sides of the woofers are horn loaded into the horn, but the back side is ported into the horn farther down the horn. The mouth size of a Synergy is sized correctly for the lowest horn loaded frequency and then the bass reflex provides another octave of output below that. The bass reflex is tuned to be over damped and peaked in a narrow one octave bandwidth. This gets the sensitivity of the bass reflex section up to the same level as the horn loaded frequencies.

Exactly right. Mine are a bit different...I used a sealed alignment, so I ended up padding down the horn sections to mate up with the sensitivity of the bass section. Kind of defeats the purpose of horn loading to achieve sensitivity, but that wasn't my reason to do Synergies....I wanted the controlled directivity, wavefront summation properties without the added design difficulty of tuning the woofers for some very difficult to calculate internal volume.

Either way is perfectly valid.

Scott

Scott, do you know the lowest practical frequency the horn itself is capable of? I'm trying to get a handle whether a typical subwoofer would go high enough to match up.

Scott, do you know the lowest practical frequency the horn itself is capable of? I'm trying to get a handle whether a typical subwoofer would go high enough to match up.

For a horn placed in free space (i.e. no boundary reinforcement) the horn can support a frequency that has its wavelength equal to the circumference of the mouth. Two examples: A 24” diameter round horn can support a frequency of approximately 179Hz. A square horn with a 24" X 24" mouth can support approximately 141Hz. You must also take in consideration that a horn must be at least a quarter wavelength long too. If the horn is too short the mouth size doesn’t matter.

I think I read that these were sealed? Regardless, if you wanted to model this as sealed, conventional modeling would apply for the four woofers below the horn frequency to determine response vs enclosure size?

How would the small ports in front of the woofers affect this?

Take a look at the below thread link. You can start reading at post number 66 and down. Only a few of the Synergy models are sealed (SH-95, SM-60M, SM-80). The rest of the models are ported.

http://www.diyaudio.com/forums/multi-way/156988-gedlee-summa-vs-lambda-unity-horn.html

Since you have a forward faced cone loading into an entry port that exits into a horn, normal sealed box models do not apply. You need to use Akabak to model the effects of the rear sealed volume has on the output of the woofers. In a sealed alignment the woofer rolls off at a higher frequency, but at a much slower rate than when ported.

Exactly right. Mine are a bit different...I used a sealed alignment, so I ended up padding down the horn sections to mate up with the sensitivity of the bass section. Kind of defeats the purpose of horn loading to achieve sensitivity, but that wasn't my reason to do Synergies....I wanted the controlled directivity, wavefront summation properties without the added design difficulty of tuning the woofers for some very difficult to calculate internal volume.

Either way is perfectly valid.

Scott

I agree 100% with you Scott. Everyone has certain goals in mind. Everyone is free to design their Synergy horns however they see fit. Sealed / Ported - whatever the person wants is perfectly fine.

Scott, do you know the lowest practical frequency the horn itself is capable of? I'm trying to get a handle whether a typical subwoofer would go high enough to match up.

Tomlang,

There is a AkAbak model I posted here that you can use as a start. You can turn into sealed alignment by making vent dia very small like 0.001 in.

http://www.diyaudio.com/forums/multi-way/88237-suitable-midrange-cone-bandpass-mid-unity-horn-141.html#post3708730

John, Im curious about your comment that a 24" horn can support approximately 179hz.

in experimenting with Bill's spreadsheet its seems that it would take a far larger horn to do so.

Is it that you are speaking purely of low end rolloff and Bill is referring to pattern control?

in experimenting with Bill's spreadsheet its seems that it would take a far larger horn to do so.

Is it that you are speaking purely of low end rolloff and Bill is referring to pattern control?

Not sure what type of horn JLH was referring to, but the long exponential 17 x 17 inch (43 x43 centimeter) square horn in post #25 here:John, Im curious about your comment that a 24" horn can support approximately 179hz.

in experimenting with Bill's spreadsheet its seems that it would take a far larger horn to do so.

Is it that you are speaking purely of low end rolloff and Bill is referring to pattern control?

http://www.diyaudio.com/forums/mult...req-range-midrange-compression-drivers-3.html

has an Fc of around 75 Hz, as can be seen in the frequency response graph.

The rate of flare and the length determine the LF cutoff point.

The exponential horn referenced is basically omni at 75 Hz, and has erratic upper response.

A conical horn pattern will be equivalent to the sidewall angles down to the frequency approximately one wavelength of the width of the horn, so a 90H x 45V conical will start going omni vertically an octave above the frequency it will go omni horizontally.

That effect is called "pattern flip".

Art

Is it that you are speaking purely of low end rolloff and Bill is referring to pattern control?

Yes

- Home

- Loudspeakers

- Multi-Way

- Synergy Horns-Dayton and PRV.....