as in any hobby it depends on how much of the result you want to "own" intellectually for your own satisfaction, interests and skills

but my playing in 123D Design so far is less time than I've spent on some single post's sim in my professional EE expertise area of interest on feedback amp issues

but my playing in 123D Design so far is less time than I've spent on some single post's sim in my professional EE expertise area of interest on feedback amp issues

Danley seems to be egging us on

and Oblate Spheroid shape is no longer (arguably never was?) under patent - once they expire patented inventions/techniques are common property for anyone's use

OS and Synergy could be subject to Danley's asserting his patent to block even home builders

Geddes still controls substantially filling with foam

as an intellectual exercise in patents - someone could patent using absorptive foam to Geddes patent spec in a Unity/Synergy and require licenses from both to use their own "new" patent

and Unity/Synergy related patents looks to be a bit of a mess with apparently overlapping expressions of the idea by JBL, others

I'm sure people will come looking for a cut if you make a commercial product but so far playing as home builders seems tolerated

and Oblate Spheroid shape is no longer (arguably never was?) under patent - once they expire patented inventions/techniques are common property for anyone's use

OS and Synergy could be subject to Danley's asserting his patent to block even home builders

Geddes still controls substantially filling with foam

as an intellectual exercise in patents - someone could patent using absorptive foam to Geddes patent spec in a Unity/Synergy and require licenses from both to use their own "new" patent

and Unity/Synergy related patents looks to be a bit of a mess with apparently overlapping expressions of the idea by JBL, others

I'm sure people will come looking for a cut if you make a commercial product but so far playing as home builders seems tolerated

while tedious I have actually used the cone primitive and sliced it to give a hyperbolic face, then rotated the face, shelled the solid to get a OS waveguide solid in free 123D Design from AutoCAD

lack of written documentation, obscurity of actual hard numerical dimensioning in 123D Design put me off going further with it

but the point is there is no need to license such a simple to generate shape as a rotationally swept hyperbola with free solid modeling tools available today

If something is patented, just because you can recreate it with simple primitives doesn't mean you don't infringe the patent or do not need a license. The idea is what is protected not how you implement or make it. The patent just gives the inventor license to sue. As a home builder of these IP items - you are probably OK as long as the inventor doesn't decide to go after you. Mostly to protect the idea from being made for commercial sale.

So as a Diy builder you can pretty much go crazy and make anything you want for personal use if you can figure out how to reverse engineer it.

Geddes himself wrote about the Oblate Spheroidal Waveguide in the early 90's and didn't file within a year of his writings so anything from those articles are in the commons

a patented idea has a limited time protection that expires - opens the idea for use by anyone after 20 years from the filing date

specifically even Geddes "Bi-Spheroidal" variation on Oblate Spheroid wave guide geometry patent no longer applies as the fee is lapsed - another way the patent protection can disappear prematurely

by not paying the renewal/maintenance fee Geddes has lost/given up the exclusive rights in Patent US7068805 - Acoustic waveguide for controlled sound radiation - Google Patents

and there is a strong argument that it always was "prior art" - in the commons, free, unprotected

because it was listed in a acoustical physics textbook as a possible geometry decades prior - the USPTO is particularly poor at finding actual prior art in their examination process - they almost exclusively rely on search for prior patents

a patented idea has a limited time protection that expires - opens the idea for use by anyone after 20 years from the filing date

specifically even Geddes "Bi-Spheroidal" variation on Oblate Spheroid wave guide geometry patent no longer applies as the fee is lapsed - another way the patent protection can disappear prematurely

by not paying the renewal/maintenance fee Geddes has lost/given up the exclusive rights in Patent US7068805 - Acoustic waveguide for controlled sound radiation - Google Patents

and there is a strong argument that it always was "prior art" - in the commons, free, unprotected

because it was listed in a acoustical physics textbook as a possible geometry decades prior - the USPTO is particularly poor at finding actual prior art in their examination process - they almost exclusively rely on search for prior patents

Last edited:

Thanks for the Geddes link. Interesting that he is not maintaining it but what would be the point for a private individual? Thanks be that a patent troll didn't get hold of it. Would have cost some companies lots of money in legal expenses regardless of the outcome.

But what is the point of this patent discussion? As far as patents go, I've been there, done that, and have the tee shirts (patent award$ and plaques) to show for it. The last thing I want to do is expose myself to a potential lawsuit. What I do in the privacy of my own shop causes no damages and thus no potential liability but I would stop short of, for example, putting the STL files for a Synergy horn in the public domain, to bring us back on topic.

But what is the point of this patent discussion? As far as patents go, I've been there, done that, and have the tee shirts (patent award$ and plaques) to show for it. The last thing I want to do is expose myself to a potential lawsuit. What I do in the privacy of my own shop causes no damages and thus no potential liability but I would stop short of, for example, putting the STL files for a Synergy horn in the public domain, to bring us back on topic.

nc535: That's interesting. It did strike me as a dilemma as well. However, fully documented Synergy horn builds are available online, also with the blessing of Tom Danley. Is there a fundamental difference with a 3D-printable variant?

Even if there would be no potential legal issues, I do want to be respectful of people's intellectual property, so I could refrain from posting any more STL files in the thread. What I've posted so far is pretty useless (wrong mid-entry geometry amongst other things) and of course even with the correct simulated geometry, who could say whether it will work as expected...

If I at some point get to a printed version, and it measures OK, I could ask Tom Danley if he minds having it available in the public domain or not.

Even if there would be no potential legal issues, I do want to be respectful of people's intellectual property, so I could refrain from posting any more STL files in the thread. What I've posted so far is pretty useless (wrong mid-entry geometry amongst other things) and of course even with the correct simulated geometry, who could say whether it will work as expected...

If I at some point get to a printed version, and it measures OK, I could ask Tom Danley if he minds having it available in the public domain or not.

I don't know where to draw the line. I would just be careful when its approaching production quality because that is what it would be if there were a crossover to go along with it. You don't want the honor of having fathered a family of clones coming from some country infamous for flouting IP laws.

At some point, I suspect Tom will speak up.

At some point, I suspect Tom will speak up.

"imitation is the sincerest form of flattery" may apply

but a fuzzy undefined concept of "respect for people's intellectual property" is not relevant - all of technology builds on other people's innovations, copying what proves to work

property is a legal concept - what doesn't meet the definitions, written rules, legal precedents simply isn't "property"

in physical hardware, or inventive ideas that is the patent

if not protected by active patent any physical product, configuration, design technique discoverable by inspection, teardown analysis, or from any public accessible writing whatsoever are "prior art" and free for use in further "advancing the useful arts" by use and adaptation - that is the basis of technological progress

my or anyone's showing Oblate Spheroid Waveguide CAD or even building, selling physical copies are not in the least "theft" or even "disrespect"

as far as active Unity/Synergy patents - Danely's participation, comments here and on other public diy audio forums does give a strong presumption of implied license for diy making

check with a lawyer on "estoppel" re enforcing a patent when the patent owner is a open, public participant in enabling diy copying

but a fuzzy undefined concept of "respect for people's intellectual property" is not relevant - all of technology builds on other people's innovations, copying what proves to work

property is a legal concept - what doesn't meet the definitions, written rules, legal precedents simply isn't "property"

in physical hardware, or inventive ideas that is the patent

if not protected by active patent any physical product, configuration, design technique discoverable by inspection, teardown analysis, or from any public accessible writing whatsoever are "prior art" and free for use in further "advancing the useful arts" by use and adaptation - that is the basis of technological progress

my or anyone's showing Oblate Spheroid Waveguide CAD or even building, selling physical copies are not in the least "theft" or even "disrespect"

as far as active Unity/Synergy patents - Danely's participation, comments here and on other public diy audio forums does give a strong presumption of implied license for diy making

check with a lawyer on "estoppel" re enforcing a patent when the patent owner is a open, public participant in enabling diy copying

Last edited:

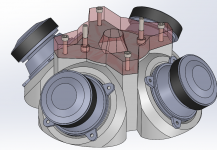

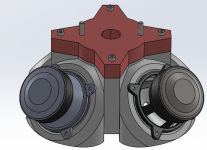

Updated mounting plate and made the adapter a bit smaller by cutting off more at the large end.

Also stretched the CD mounting flanges out to make room for mounting, and now it is aligned with where the wooden horn will continue.

Todo:

Mounting midranges. I suppose threaded inserts is the way to go here also.

Midrange cups - a bit of a headache actually, since the Faital driver looks funny with seemingly no easy place for a seal. I´m imagining resorting to hot glue here. Ideas?

Mounting adapter to wood. Some ideas already. Since I´m trying to avoid overhangs, the CD mount now continues vertically down to where the wood starts, where it will flare out 30 degrees. I am wondering if making holes for dowels would help with alignment, and then using screws to hold in place. Perhaps silicon between the wood and the plastic will increase the grip and make it more immune to buzzing?

Also stretched the CD mounting flanges out to make room for mounting, and now it is aligned with where the wooden horn will continue.

Todo:

Mounting midranges. I suppose threaded inserts is the way to go here also.

Midrange cups - a bit of a headache actually, since the Faital driver looks funny with seemingly no easy place for a seal. I´m imagining resorting to hot glue here. Ideas?

Mounting adapter to wood. Some ideas already. Since I´m trying to avoid overhangs, the CD mount now continues vertically down to where the wood starts, where it will flare out 30 degrees. I am wondering if making holes for dowels would help with alignment, and then using screws to hold in place. Perhaps silicon between the wood and the plastic will increase the grip and make it more immune to buzzing?

Attachments

Why not print a screw thread around the boss where the Faitals mount and get a food jar with matching thread? Or print correct dia boss (with o ring groove) and slip a SCH 40 PVC pipe and end cap on it?

If you can design the horn, you can certainly design and print a cap to slip over the Faital and glue to the rim of the ram just inside of the mounting tabs.

I think the seal between the Faital and the horn might more of a concern. I have a 4FE35 here and the gasket is tall but thin. (assuming the 3FE is the same) It might be good to print a groove for that gasket to sit in and perhaps a thin bead of flexible, never hardening caulk in that groove.

I think the seal between the Faital and the horn might more of a concern. I have a 4FE35 here and the gasket is tall but thin. (assuming the 3FE is the same) It might be good to print a groove for that gasket to sit in and perhaps a thin bead of flexible, never hardening caulk in that groove.

Could you print a "recess" or "raise" the area around the midrange mounts, then you could print the caps with corresponding mounting brackets and mount it all together. Then use some glue/sealant around the midrange brackets and caps. Hope I articulated this in an understandable way?

I have used these type of threaded inserts before

Threaded Inserts

Thanks!

I should add these links to the first post of the thread for reference - will do that later on.

Nissep: Could you post some closeups of the Faital driver from various angles? I get the measurements from the datasheet, but some things are a bit unclear.

If you could measure the cone profile too, that would be nice, including the space between the mounting rim and the cone. At some point I might want to sim the driver using BEM. But it would also be nice to have an accurate model to design the adapter from. You also mentioned that you have a 3d model that you have worked on - is it possible to send it to me, so I can check if I have made any mistakes on my side?

If you could measure the cone profile too, that would be nice, including the space between the mounting rim and the cone. At some point I might want to sim the driver using BEM. But it would also be nice to have an accurate model to design the adapter from. You also mentioned that you have a 3d model that you have worked on - is it possible to send it to me, so I can check if I have made any mistakes on my side?

there is a pretty good picture on the parts express website. I'd just buy one if I were you. You are going to need it eventually.

I wonder if a 3D scanner would capture a good 3D model, the cone profile in particular. That is what they are supposed to be for...point, shoot, 3Dprint!

I wonder if a 3D scanner would capture a good 3D model, the cone profile in particular. That is what they are supposed to be for...point, shoot, 3Dprint!

4FEback detail for cup mounting

Well the PE photo tells me the 4FE is a scaled up version of the 3FE so I'll send you a 4FE shot

As you can hopefully see in the attached jpg, there is a 3/16" or so rim around the outside of the frame in back, just inside of the mounting tabs. It has a thin foam gasket on it for sealing or you could scrape off the foam and use glue.

Hope that helps,

Jack

Well the PE photo tells me the 4FE is a scaled up version of the 3FE so I'll send you a 4FE shot

As you can hopefully see in the attached jpg, there is a 3/16" or so rim around the outside of the frame in back, just inside of the mounting tabs. It has a thin foam gasket on it for sealing or you could scrape off the foam and use glue.

Hope that helps,

Jack

Attachments

Thanks Jack!

Yes, of course I could just buy a driver, but then I´d have to wait for it to arrive! 🙂

Anyway, I think I have been able to build a better mockup thanks to your help.

Looking at pictures earlier, I mistook the foam gasket for something else that couldn´t be removed. It should be easier now.

Yes, of course I could just buy a driver, but then I´d have to wait for it to arrive! 🙂

Anyway, I think I have been able to build a better mockup thanks to your help.

Looking at pictures earlier, I mistook the foam gasket for something else that couldn´t be removed. It should be easier now.

Attachments

That foam gasket keeps the surround from hitting the plate its mounted too - I would no remove it as it forms an excellent seal when screwed down. If you don't have it you will need to make your own gaskets. Why do that? Are you guys talking about the gasket on the back of the driver bezel? The front one definitely leave alone.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Synergy horn - 3d printing entry?