Thums up your skills to design and actual find all below very stylish even if they mounted higher up on wall think would look good for my eyes.

Neat stuff here.

But I had to comment on one early post --

You know, it isn't hard to reduce sensitivity of a speaker! Resistors are cheap, and even give lots of availability for response shape adjustment!

But I had to comment on one early post --

The very high sensitivity makes them noisy with my amplifiers.

You know, it isn't hard to reduce sensitivity of a speaker! Resistors are cheap, and even give lots of availability for response shape adjustment!

That's a neat idea, I'll try to figure something out that doesn't get tipped over by my daughters.Also I was going to say, what about a stand in the center of the speaker. One that is not very visible. A floating stand you could say. You may even give it a bit of an angle pointing up?

I guess I'll have to make a serious CAD to try this out 🙂 But the design is not a lot smaller than xrk971 or Buschmeisters using COTS WG and 8" woofers.I'd worry more of being able to fit all you want into the package 🙂.

Thanks! Not sure how I would mount them on the wall without it looking very bulky though. The media console is quite large, which is good as it makes speakers standing on it look small 🙂Thums up your skills to design and actual find all below very stylish even if they mounted higher up on wall think would look good for my eyes.

This is true! I have other hesitations using compression drivers:Neat stuff here.

But I had to comment on one early post --

You know, it isn't hard to reduce sensitivity of a speaker! Resistors are cheap, and even give lots of availability for response shape adjustment!

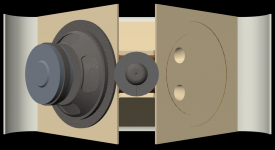

1. They are large/heavy which in most of my designs is a problem.

2. Their impulse response usually is a little ragged due to break up at high frequencies.

3. Their CSDs don't look very good. This is the quite highly regarded DE250:

This is very general as I've only tried to use one. The first one on the list is actually my biggest concern. But let's not turn this thread into why people should/shouldn't use CDs in speakers for home use, I had an idea of how to use stuff I have that seem to measure nice in a package that is easy to get a nice finish on.

/Anton

That's a neat idea, I'll try to figure something out that doesn't get tipped over by my daughters.

Have you ever used that blue sticky tack? With some weight on it that stuff can really put a hold on something.

I'd rather not use anything that might leave a stain on the oak of the media console:Have you ever used that blue sticky tack? With some weight on it that stuff can really put a hold on something.

So it's rubber or felt feet against the wood. It might be possible to make some kind of leg that is nearly invisible if it is painted in correct color (dark brown I assume) and kept away from edges.

/Anton

I'd rather not use anything that might leave a stain on the oak of the media console:

So it's rubber or felt feet against the wood. It might be possible to make some kind of leg that is nearly invisible if it is painted in correct color (dark brown I assume) and kept away from edges.

/Anton

No and no again!

I pretty sure Mindsource was thinking of blue tacking the children. It slows them down considerably😎

😀No and no again!

I pretty sure Mindsource was thinking of blue tacking the children. It slows them down considerably😎

Truth is the 901 on the tulip pedestal is imo still the most timeless design to date.

We share the same opinion. I've been sketching a Synergy/901 type thing for months now.

Nice build(s) and design work onni! Your RRSinergy and supercardiod woofer system should have some hifidelity potential. Those Faital Pro woofers have some nice parameters and look to be great value too. Am eager to see the bandwidth you can achieve with those woofers once mounted and the final directivity. All the best.

onni - that csd for the de250 doesn't look right. What wg is it on? Showing it with eq as it would be used would be better.

The CSD is from here: https://sites.google.com/site/drivervault/driver-measurements/acoustic-elegance-td12monni - that csd for the de250 doesn't look right. What wg is it on? Showing it with eq as it would be used would be better.

Measured on a QSC waveguide at 2 m.

There are of course CDs that have better looking CSDs, as the ringradiator 4550, but also worse ones as the Selenium-d220ti.

/Anton

I had a pair of those DE250 and felt they were poor examples of a 1" compression driver. The sound is hard and brittle in the treble like the CSD shows. The Celestion drivers offer much better treble quality for the money. The CDX1730 is the one I like the best. I don't understand how people tolerate the treble in the DE250 - some claim it's as good as it gets? 🙄

This is true! I have other hesitations using compression drivers:

1. They are large/heavy which in most of my designs is a problem.

2. Their impulse response usually is a little ragged due to break up at high frequencies.

3. Their CSDs don't look very good. This is the quite highly regarded DE250:

This is very general as I've only tried to use one. The first one on the list is actually my biggest concern. But let's not turn this thread into why people should/shouldn't use CDs in speakers for home use, I had an idea of how to use stuff I have that seem to measure nice in a package that is easy to get a nice finish on.

/Anton

I had a pair of those DE250 and felt they were poor examples of a 1" compression driver. The sound is hard and brittle in the treble like the CSD shows. The Celestion drivers offer much better treble quality for the money. The CDX1730 is the one I like the best. I don't understand how people tolerate the treble in the DE250 - some claim it's as good as it gets? 🙄

Agree. Very unnatural treble with de250. Lacks resolution yet has an edgy quality to it. Don't understand the hype at all. Much better choices out there from radian, rcf, 18 sound. Have not heard the celestions

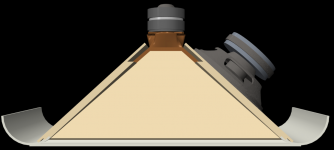

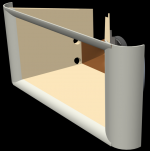

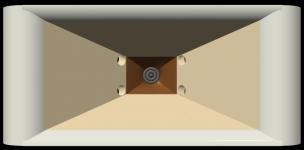

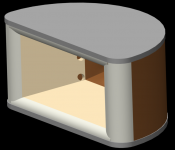

CAD

Here are some renderings of a 3D-model that should be correct and includes the 3D-printed throat adapter and to scale models of the tweeter and woofers.

Everything seems to fit. Next step is to make some saw dust I suppose!

Oh, and it's a 90x50 horn, total size of box is 55 x 28 x 33 cm (W x H x D).

/Anton

Here are some renderings of a 3D-model that should be correct and includes the 3D-printed throat adapter and to scale models of the tweeter and woofers.

Everything seems to fit. Next step is to make some saw dust I suppose!

Oh, and it's a 90x50 horn, total size of box is 55 x 28 x 33 cm (W x H x D).

/Anton

Attachments

Last edited:

Those are some pretty models. Super elliptical oblate spheroid would seemingly be the natural evolution of this.

Thanks 🙂Those are some pretty models. Super elliptical oblate spheroid would seemingly be the natural evolution of this.

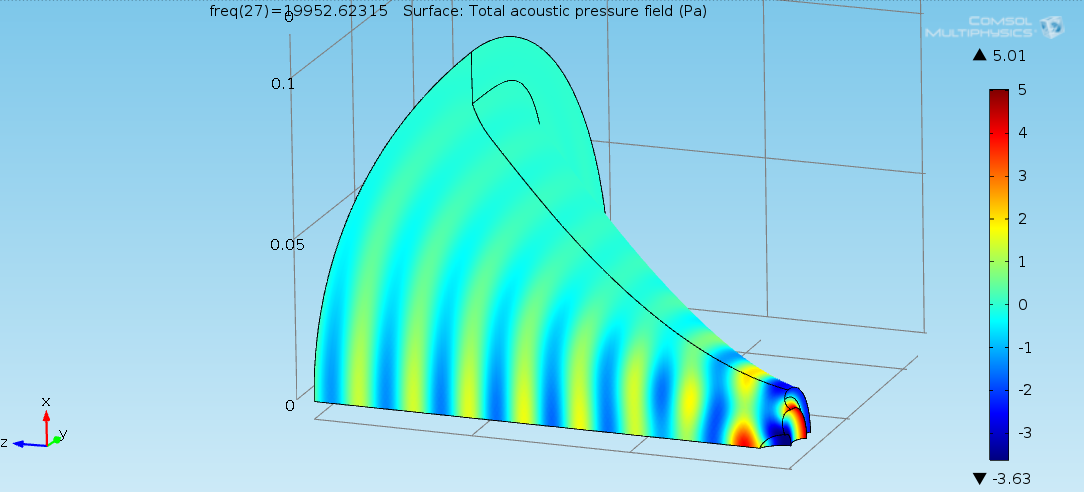

Well, I'm not so sure. The point of the oblate spheroid is to take a flat wavefront (typically from a compression driver) and convert it to a spherical wavefront that can travel down a conical horn. The ringradiator does not emit a flat wavefront as evident from sims:

So the goal must be to make a profile that as fast as quickly turns the wavefront from the ringradiator to a spherical one and then use a conical horn (if constant directivity is the goal).

A super elliptical horn would possibly be better than a rectangular, but much harder to build, especially when it comes to getting the woofers close to the bandpass holes (for short hole length).

/Anton

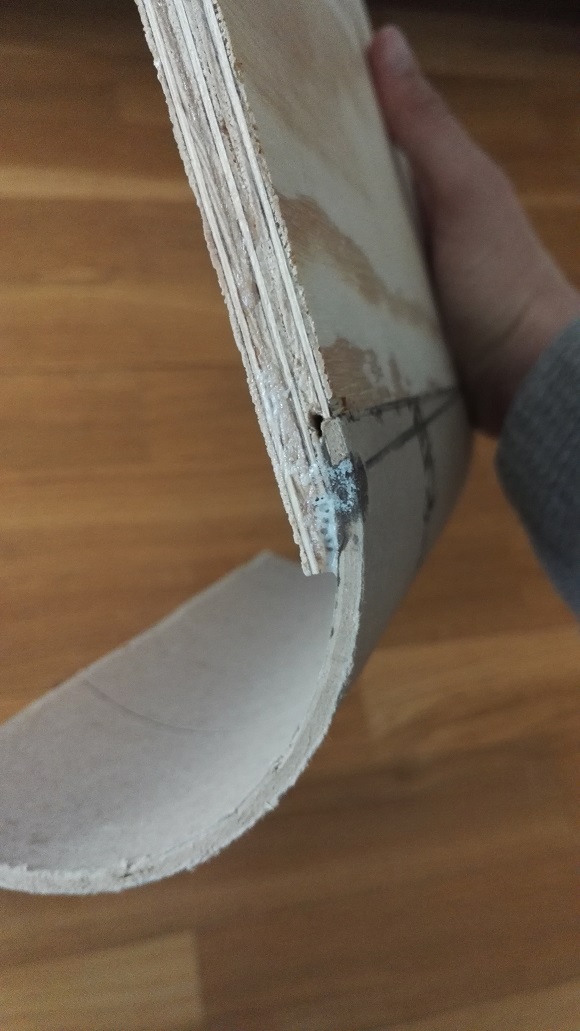

Some progress

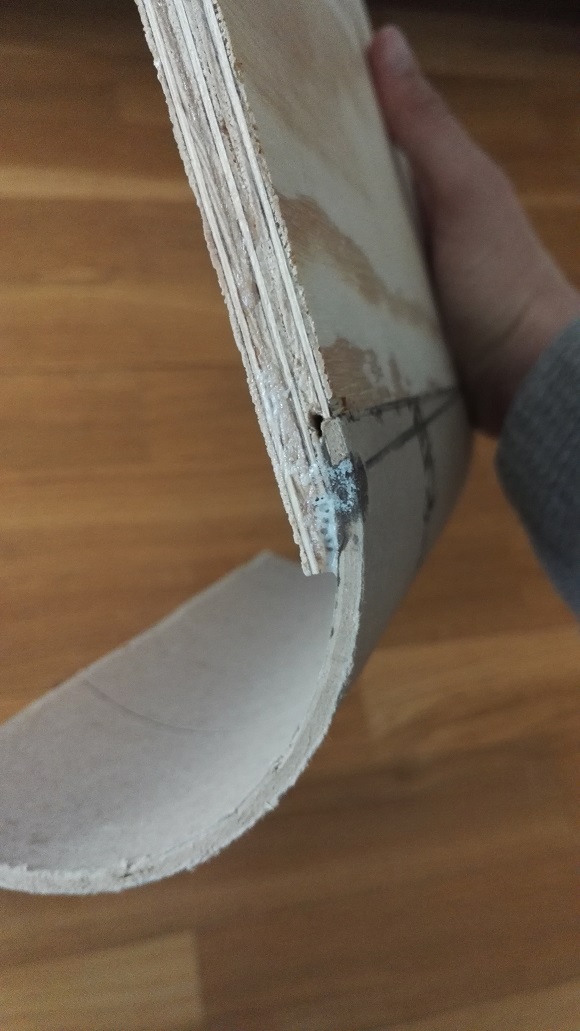

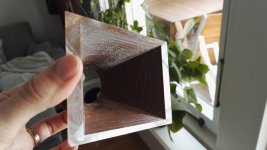

I'm glueing some of the horn sides atm:

The sonotubes are adhered using polyurethane glue, as are the plywood sheets (to each other).

I've done some sims of the horn with two large simplifications:

1. Only tweeter (no mid BP holes).

2. Infinite baffle.

Other than that I'm assuming that the membrane has a constant acceleration (varying linearly from voice coil to edge).

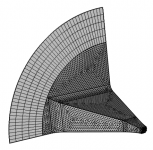

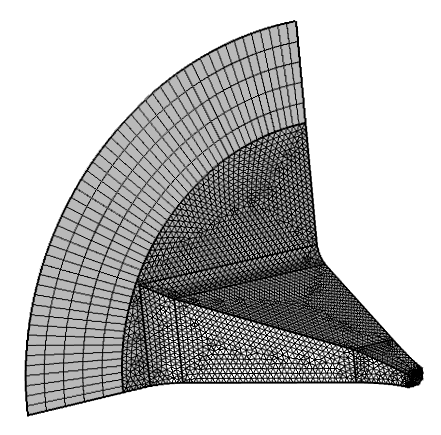

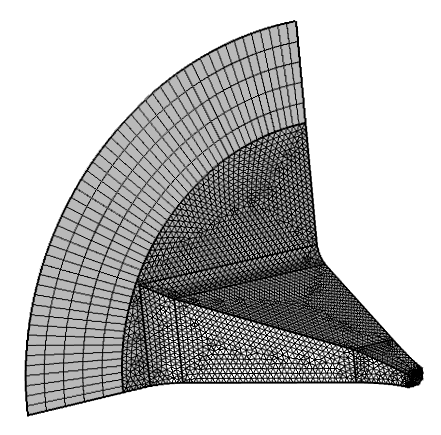

This is what the geometry (1/4) looks like with mesh for 10 kHz:

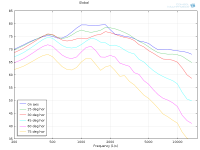

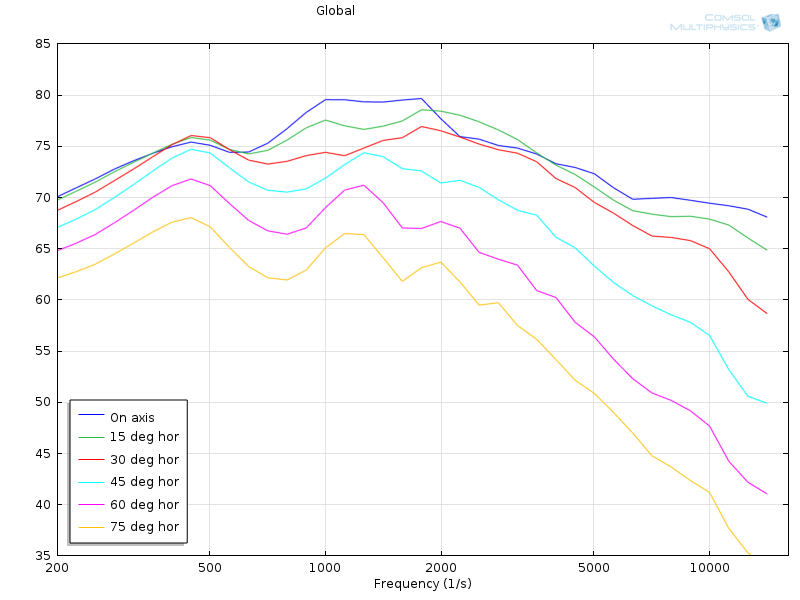

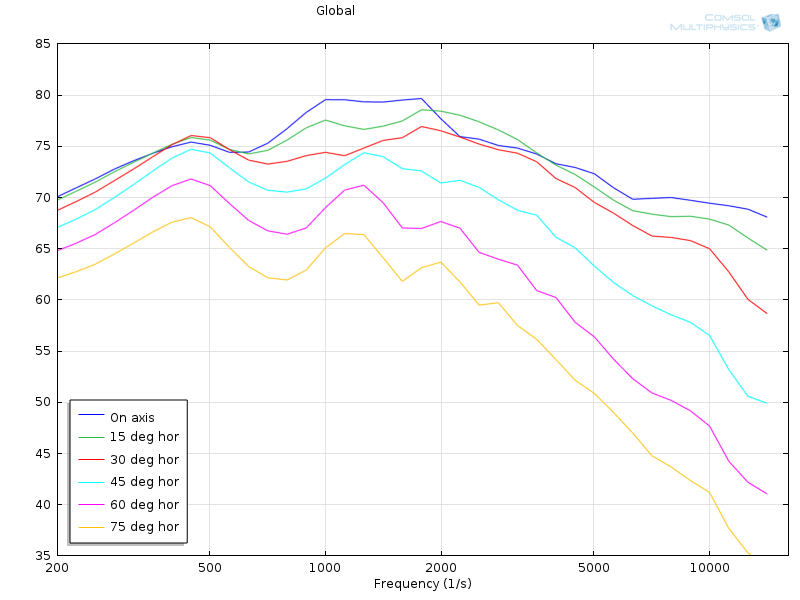

It ran out of memory after 14 kHz, so here's horisontals 200 Hz to 14 kHz:

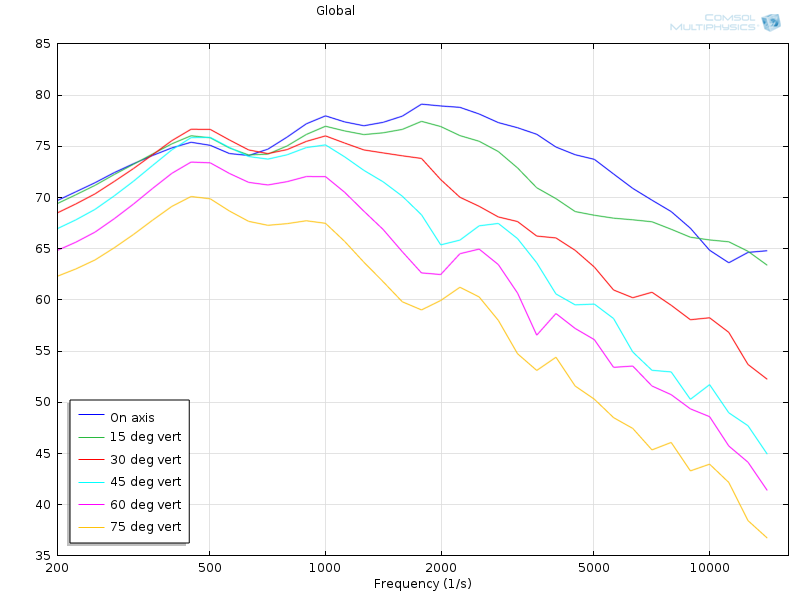

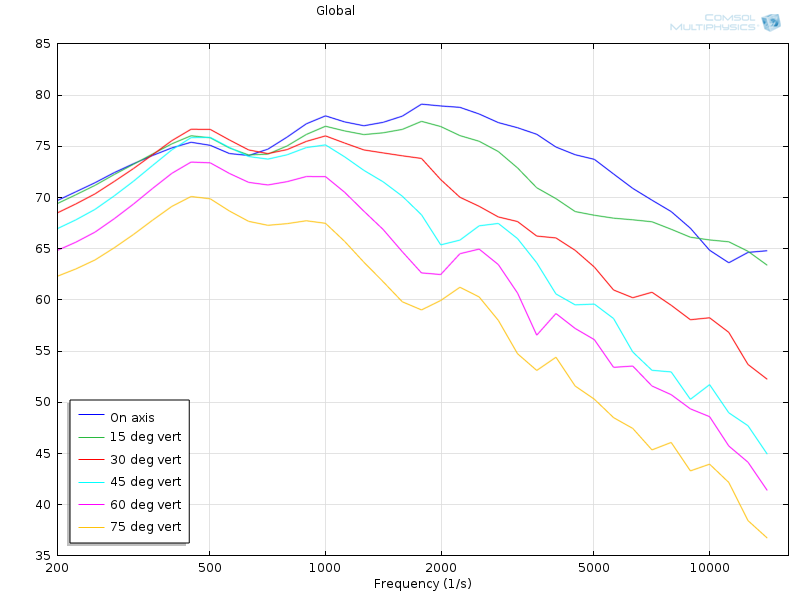

And verticals:

Both results are taken at 2 m and slightly off axis (to remove numerical problems with perfect symmetry). On axis looks a little wonky, but other than that I'm quite satisfied. Let's see how well the sims correlate with measurements.

/Anton

I'm glueing some of the horn sides atm:

The sonotubes are adhered using polyurethane glue, as are the plywood sheets (to each other).

I've done some sims of the horn with two large simplifications:

1. Only tweeter (no mid BP holes).

2. Infinite baffle.

Other than that I'm assuming that the membrane has a constant acceleration (varying linearly from voice coil to edge).

This is what the geometry (1/4) looks like with mesh for 10 kHz:

It ran out of memory after 14 kHz, so here's horisontals 200 Hz to 14 kHz:

And verticals:

Both results are taken at 2 m and slightly off axis (to remove numerical problems with perfect symmetry). On axis looks a little wonky, but other than that I'm quite satisfied. Let's see how well the sims correlate with measurements.

/Anton

Attachments

- Home

- Loudspeakers

- Multi-Way

- Synergy attempt without compression driver

so far very impressive.

so far very impressive.