I can't find the schematic but it looks like the base ties to the output through 4R7 resistors?

..... I think it's ok ,just see partial schematic attached below😉

Alex

Attachments

I don't see that in any of the other SR200 PCBs. Have you created your own schematic? in the other PCBs there is a 220R 2W emitter resistor between the drivers but they don't connect to the output. It will be interesting to see the whole schematic.

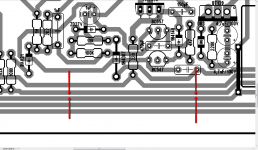

Alex,..... PCB ready , please someone check if it's correct layout . I will post in B&W the layout of PCB .

Schematic will follow soon .

Regards ,Alex

a much better layout.

The V+, V- and Power Ground enter the PCB in a tight close coupled group. This minimises Loop Area and thus minimises interference.

Output is also fairly close to this Power Group again minimising Loop Area.

Well Done.!

Here is the original PCB.Please check...

An externally hosted image should be here but it was not working when we last tested it.

..... PCB ready , please someone check if it's correct layout . I will post in B&W the layout of PCB .

Schematic will follow soon .

Regards ,Alex

Hello Alex don't get upset with me but for manufacturing PCB's will be no problem at all but for etching diy those traces are I think way too close each other maybe you can give a few extra millimeters so etching will be no problem.

Regards

Juan

Attachments

Dear Alex? proper installation of the diagram is always running and I have not changed anything on the same pcb mount components so the dc leakage....yes of course , why not , here in attachment are all files for toner transfer metod 🙂

Regards ,Alex

An externally hosted image should be here but it was not working when we last tested it.

Hi All,

Please check it if any error 😀 ...

I like the dual pot arrangement.

Works for both a lay flat skeleton pot and for an inline multi-turn pot.

Well done.

What about adding an offset pin for the staggered pin multi turn pot.

Add dual or multi pin pitch options for all your capacitors.

If possible orient all your electros in the same direction.

Works for both a lay flat skeleton pot and for an inline multi-turn pot.

Well done.

What about adding an offset pin for the staggered pin multi turn pot.

Add dual or multi pin pitch options for all your capacitors.

If possible orient all your electros in the same direction.

Hi John, do the mje340/350 inthe middle of pcb need heatsinks, so do they run cool enough on the lower supply voltage

Thanks AndrewT for your suggestionI like the dual pot arrangement.

Works for both a lay flat skeleton pot and for an inline multi-turn pot.

Well done.

What about adding an offset pin for the staggered pin multi turn pot.

Add dual or multi pin pitch options for all your capacitors.

If possible orient all your electros in the same direction.

I will add some pad latter

all the electrolyte are at same direction 🙂

Right now I already make a board to test it, I hope no oscillation or other unwanted one...

I will share the layout after it is "tested OK" 😎

Hi Vostro, I will check that out after I finish stuffing it 🙂Hi John, do the mje340/350 inthe middle of pcb need heatsinks, so do they run cool enough on the lower supply voltage

(one PCB already done)

I will add a little heatsink for each transistor (I don't know if it is need or not)

Regards

Attachments

Last edited:

Thanks AndrewT for your suggestion

I will add some pad latter

all the electrolyte are at same direction 🙂

Right now I already make a board to test it, I hope no oscillation or other unwanted one...

I will share the layout after it is "tested OK" 😎

Hi Vostro, I will check that out after I finish stuffing it 🙂

(one PCB already done)

I will add a little heatsink for each transistor (I don't know if it is need or not)

Regards

Nice pcb,

Regards

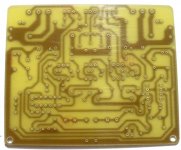

Ok, it tested OK

Dear sir Mile,

thanks for your SR100 🙂

this PCB already tested...

PCB size is : 95 * 80 mm

I need to make another channel

😎

the MJE's need small heatsink & only a little warm 🙂

Warm Regards

Dear sir Mile,

thanks for your SR100 🙂

this PCB already tested...

PCB size is : 95 * 80 mm

I need to make another channel

😎

the MJE's need small heatsink & only a little warm 🙂

Warm Regards

Attachments

Dear sir Mile,

thanks for your SR100 🙂

this PCB already tested...

PCB size is : 95 * 80 mm

I need to make another channel

😎

the MJE's need small heatsink & only a little warm 🙂

Warm Regards

Nice work, thanks for this pcb design,

Regards

who can tell me a software for pcb's please.

I use multisim software for schematics and he have ultrasim for PCB but it's look very strange...

I use multisim software for schematics and he have ultrasim for PCB but it's look very strange...

who can tell me a software for pcb's please.

I use multisim software for schematics and he have ultrasim for PCB but it's look very strange...

Hi, DipTrace - Schematic and PCB Design Software as an option...

Cheers,

Valery

Thank You Vzichenko !

B&W PCB

Any progress ?..... PCB ready , please someone check if it's correct layout . I will post in B&W the layout of PCB .

Schematic will follow soon .

Regards ,Alex

Now i work at another amplifier but the next one will be SR800Any progress ?

I will come with new when i star to build him! 🙂

- Home

- Amplifiers

- Solid State

- Studio Reference Amplifier