I have trouble connecting to maxon motors.com including Tor through your link I will try another way.

Got it just punching it in, Switzerland --got to be good quality there , Proton Mail use a server there stops "interference " I keep it handy ,was an early user .

Got it just punching it in, Switzerland --got to be good quality there , Proton Mail use a server there stops "interference " I keep it handy ,was an early user .

Origin Live offer a range of prices from the wall wart power supply upwards obviously that link you provided Marknoir is the dearer model .

OL UK prices are-

Origin Live DC Motor Kit

Yes. Local dealers also quoted a higher version, albeit not as high. It turns out OL sells products that (with a different label) are often available from other sources at nearly half the price...

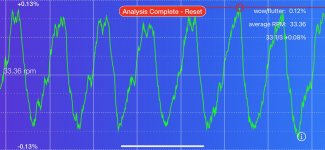

Soooo... I was pursuaded by some good faulks here and elsewhere not to throw this thing out, stop my defeetst attitude and give it another wirl (pun intended).

So I cleaned out all of the oil out of the bearing again; put a small dab the usual ptfe Superlube grease on top; but this time I used super-light bike chain CarbonPro lubricant on shaft. It’s a liquid as WD-40. And this may prove to be a problem, because WD-40 does not last. I think this one may evaporate soon. But for now, for the third day, wow/flutter figures are 0.15%, which is very low for this generation of Sota. Another thing I want to try is graphite lubricant. If I’m able to keep w/f figures this low, then I will keep this table.

So I cleaned out all of the oil out of the bearing again; put a small dab the usual ptfe Superlube grease on top; but this time I used super-light bike chain CarbonPro lubricant on shaft. It’s a liquid as WD-40. And this may prove to be a problem, because WD-40 does not last. I think this one may evaporate soon. But for now, for the third day, wow/flutter figures are 0.15%, which is very low for this generation of Sota. Another thing I want to try is graphite lubricant. If I’m able to keep w/f figures this low, then I will keep this table.

Attachments

Good for you Marknoir -perseverance as the old Indian Chief said .

I have used graphite long ago its handy for slowing down wear in steel and can add to the dimensions( in some cases ) but I have no idea whether it will make a positive difference to a turntable --it worked in heavy industry and autos.

It also depends on what type of steel (alloy ) the shaft is made out of.

I have used graphite long ago its handy for slowing down wear in steel and can add to the dimensions( in some cases ) but I have no idea whether it will make a positive difference to a turntable --it worked in heavy industry and autos.

It also depends on what type of steel (alloy ) the shaft is made out of.

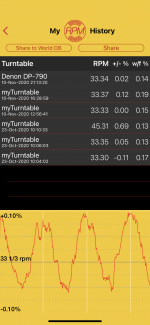

BTW, I’ve checked the speed and W/F on my Denon DO-790 DD, using the same apps. ROM app showed 0.14%, W/F App showed unreal 0.06%! For the Sota the two apps were very close. I can’t explain the figures on Denon. I wish I had a real analyzer...

Attachments

The brass bush is worn ,what you now look at is the spindle to see if wear is present on it ---at the point it revolves in the bearing.

Even slight signs of scoring /wear is not good.

But changing the bearing comes before doing anything about the spindle.

If its an expensive job there is an electrical system to deposit metal on a brass bearing.

Even slight signs of scoring /wear is not good.

But changing the bearing comes before doing anything about the spindle.

If its an expensive job there is an electrical system to deposit metal on a brass bearing.

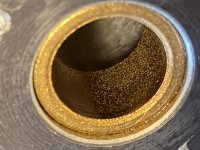

...bushings surfaces are covered with micro pitting?

That pitting is IMHO too deep and too uniform to be turntable wear.

Oilite?? https://www.amazon.com/gp/product/B001DTG3R6/

Being powdered metal with oil-holes, it can look "pitted" from new.

Attachments

Not that pitted and its shown as just one part of the bore not all the way round it.

He has already commented on wear in the bore ,even if its powered metal that amount of roughness reduces the total surface area in contact when the spindle is revolving causing fluctuations in speed.

In a high quality bush bearing there should be zero roughness and if you run your finger over your above bearing picture although it may look pitted it will be very smooth to the touch certainly not that roughness shown in Mark,s picture.

MIM -metal injection molding-- and yes I have repaired that type of equipment --goes through a process of very high pressure along with other processes to produce a Smooth finish .

As my link says --THREE microns --look at Marks photo does that look like three microns ??-

Powder metallurgy - Wikipedia

He has already commented on wear in the bore ,even if its powered metal that amount of roughness reduces the total surface area in contact when the spindle is revolving causing fluctuations in speed.

In a high quality bush bearing there should be zero roughness and if you run your finger over your above bearing picture although it may look pitted it will be very smooth to the touch certainly not that roughness shown in Mark,s picture.

MIM -metal injection molding-- and yes I have repaired that type of equipment --goes through a process of very high pressure along with other processes to produce a Smooth finish .

As my link says --THREE microns --look at Marks photo does that look like three microns ??-

Powder metallurgy - Wikipedia

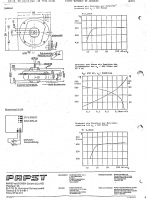

I know you would rather it to be a Papst motor supply fault or even a faulty motor--yes the bearings can go.

And yes a faulty supply can cause speed variations if the motor is driven by PWM , it could be the modulation circuit --the smoothing part of it ( not producing a good sine wave ) or other parts could all cause the same if you check using a scope .

If you cant trace out the faults in one then substitution is called for or a temporary drive of some sort.

Here is a very simple -very basic circuit just to give you the basic idea .

It is NOT your circuit but it shows basic operations , notice all the different parts of the operation that can be faulty .

But you have to decide I can only put forward theories when it comes to the electronic side of it as we are communicating virtually I do not have it on my bench to repair.-

Ebm Papst Motor Wiring Diagram | Free Wiring Diagram

And yes a faulty supply can cause speed variations if the motor is driven by PWM , it could be the modulation circuit --the smoothing part of it ( not producing a good sine wave ) or other parts could all cause the same if you check using a scope .

If you cant trace out the faults in one then substitution is called for or a temporary drive of some sort.

Here is a very simple -very basic circuit just to give you the basic idea .

It is NOT your circuit but it shows basic operations , notice all the different parts of the operation that can be faulty .

But you have to decide I can only put forward theories when it comes to the electronic side of it as we are communicating virtually I do not have it on my bench to repair.-

Ebm Papst Motor Wiring Diagram | Free Wiring Diagram

Thank you Duncan 2

I have the wiring diagram, albeit parts are not marked, from Papst website. I need to figure out where to connect the scope. I’m not familiar with these controls yet. I’m supposed to buy another motor/controller from early Sapphire, supposedly in working condition. Will try that to see if it will make a difference. But this table’sa bad cold, they just don’t go away ))). Reminds me of my old BMW.

I have the wiring diagram, albeit parts are not marked, from Papst website. I need to figure out where to connect the scope. I’m not familiar with these controls yet. I’m supposed to buy another motor/controller from early Sapphire, supposedly in working condition. Will try that to see if it will make a difference. But this table’sa bad cold, they just don’t go away ))). Reminds me of my old BMW.

Attachments

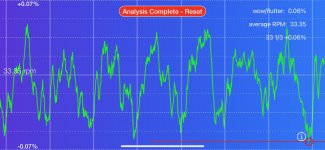

So today I bought another Papst motor. It’s identical, but wired slightly differently. Came out of a working 1984 Sapphire. Pulley is larger, but the speed is slower, so it worked the same. Goes what? Same exact wow and flutter figures. Which tells me that some faulks here and elsewhere were correct: the problem is probably, most likely in the f-d-up bearing. So the platter has to be rebuilt. I wonder if Sota can just give me a rebuilt one and take this one in trade?

This is a sintered bronze bushing and is supposed to look this way. Sintering is a achieved by applying high pressure to bronze particles to produce a solid material with high porosity to retain lubrication.This doesn’t look good to me either, bushings surfaces are covered with micro pitting?

Sintering - Wikipedia.

Thank you for the backing Bon it doesnt seem to count I repaired the equipment that produced this type of bush and actually handled the output from the machine.

So Mark after what ?-- #96posts its what I thought it was in the first place it was a bit of a journey but we got there.

So Mark after what ?-- #96posts its what I thought it was in the first place it was a bit of a journey but we got there.

The problem is that it’s not holding the oil. At least not the right viscosity. If I put in very light oil the wow disappears and figures are around 0.14%, for about a day. After that oil disappears and it goes back to wowing and 0.3%. If I put in heavier oil, it’s unlistenable right away. I think there is too much play in the bushings anyway. Thrust plate is bad it seems. I’m putting it up for sale for parts. Let’s see if I can generate any interest.

No. Good bearing. But will require too much modification for the Sota. Don’t forget this Sota also has vacuum going thru the bearing shaft.

- Home

- Source & Line

- Analogue Source

- Sota Cosmos: to restore, or?