Thanks for the info, i guess i'll just take a look at some of those things once the enclosures are built. I'll have a proper measurement setup by then

So I've been flat out working on my house, so haven't had much of a chance to work on the speakers.

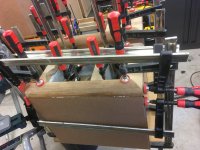

But.. This weekend I smashed out the front baffles. Made a little mistake with the tweeter recess, forgot to adjust a depth on the cnc, i'll fill that in, wont be a problem. Apart from that very happy with the results.

I've attached some pics pre/post sanding.

Let me know what you think!

I'm going to start working on the cabinets this week, i'll be asking a few questions along the way to make sure i line them correctly etc.

Thankyou all again for your help.

But.. This weekend I smashed out the front baffles. Made a little mistake with the tweeter recess, forgot to adjust a depth on the cnc, i'll fill that in, wont be a problem. Apart from that very happy with the results.

I've attached some pics pre/post sanding.

Let me know what you think!

I'm going to start working on the cabinets this week, i'll be asking a few questions along the way to make sure i line them correctly etc.

Thankyou all again for your help.

Attachments

Looks Great !

It is not a bad thing that your tweeter recess is deeper than the thickness of the tweeter face plate. I always cut my recess deeper, and then make a gasket out of dense foam. When mounting the tweeter, the screws compress the foam gasket until I get a perfectly flush installation. The foam I use is closed cell polyethylene foam that is used to protect glassware during shipping. It is about 2mm thick.

It is not a bad thing that your tweeter recess is deeper than the thickness of the tweeter face plate. I always cut my recess deeper, and then make a gasket out of dense foam. When mounting the tweeter, the screws compress the foam gasket until I get a perfectly flush installation. The foam I use is closed cell polyethylene foam that is used to protect glassware during shipping. It is about 2mm thick.

@hifijim

A quick question before i start gluing the cabinet together.

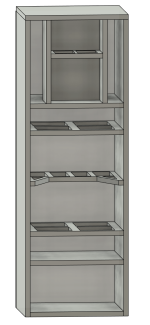

I've attached a picture of the cabinet from the back, i'll have a compartment in the bottom for the Hypex amp,

Then the section for the 12" is 70L as per your design.

I had asked earlier and you mentioned a qtc from .5 - 1.0 is ok for the mid range, so The area left for the mid & tweeter

is currently 39 litres, not including bracing, which i haven't designed yet.

For the MW16tx,

Qtc of .5 = 24 litres

Qtc of .707 = 8.8 litres

Qtc of 1.0 = 3.6 litres

Based on this. What size would you aim for for the mid/tweeter?

Thanks again!

A quick question before i start gluing the cabinet together.

I've attached a picture of the cabinet from the back, i'll have a compartment in the bottom for the Hypex amp,

Then the section for the 12" is 70L as per your design.

I had asked earlier and you mentioned a qtc from .5 - 1.0 is ok for the mid range, so The area left for the mid & tweeter

is currently 39 litres, not including bracing, which i haven't designed yet.

For the MW16tx,

Qtc of .5 = 24 litres

Qtc of .707 = 8.8 litres

Qtc of 1.0 = 3.6 litres

Based on this. What size would you aim for for the mid/tweeter?

Thanks again!

Attachments

If this were a passive system, it might be more important to think through the midrange enclosure size. The size would affect the impedance peak at Fs, and it would affect the BSC of the midrange driver. With an active design, the impedance matters little, and you control the BSC to a fine degree with DSP.

In your case, I think you should use something between 4 and 9 liters. This is a non-critical design parameter, so you should let other considerations drive the size of the midrange box. For instance, I would definitely try for a good ratio of internal dimensions. A terrible ratio would be 1: 1: 1… a bad ratio would be 1: 2: 3, or 1: 1: 2. A good ratio would be something like 1: 1.6: 2.6 or 1: 1.5: 2.4… in other words, no internal dimension should be near to being a multiple of another dimension.

The arrangement of internal bracing around the mid box is also an important consideration which might drive the size/shape of the box.

I never use threaded inserts to install the drivers, I just screw them in. But if you are using an attachment device which requires access to the both sides of the baffle (i.e. T-nut), you will need your internal mid box dimensions to accommodate that.

j.

In your case, I think you should use something between 4 and 9 liters. This is a non-critical design parameter, so you should let other considerations drive the size of the midrange box. For instance, I would definitely try for a good ratio of internal dimensions. A terrible ratio would be 1: 1: 1… a bad ratio would be 1: 2: 3, or 1: 1: 2. A good ratio would be something like 1: 1.6: 2.6 or 1: 1.5: 2.4… in other words, no internal dimension should be near to being a multiple of another dimension.

The arrangement of internal bracing around the mid box is also an important consideration which might drive the size/shape of the box.

I never use threaded inserts to install the drivers, I just screw them in. But if you are using an attachment device which requires access to the both sides of the baffle (i.e. T-nut), you will need your internal mid box dimensions to accommodate that.

j.

If you have extra space within the mid compartment, why not give the the bass driver more volume?@hifijim

A quick question before i start gluing the cabinet together.

I've attached a picture of the cabinet from the back, i'll have a compartment in the bottom for the Hypex amp,

Then the section for the 12" is 70L as per your design.

I had asked earlier and you mentioned a qtc from .5 - 1.0 is ok for the mid range, so The area left for the mid & tweeter

is currently 39 litres, not including bracing, which i haven't designed yet.

For the MW16tx,

Qtc of .5 = 24 litres

Qtc of .707 = 8.8 litres

Qtc of 1.0 = 3.6 litres

Based on this. What size would you aim for for the mid/tweeter?

Thanks again!

I could certainly do that. There is definately some litres to spare, i'll have a play around with it and see what i come up with

I have those woofers in 85lit tuned to 30hz I think; They work well.I could certainly do that. There is definately some litres to spare, i'll have a play around with it and see what i come up with

Last edited:

In a sealed box, those woofers would work well in any volume from 40 to 100 liters.

In a 40 liter box, if the woofer is driven to Xmax at 30 Hz, it will make about 101.5 dB SPL (at 1 m infinite baffle). It will require about 90 W to do it.

In a 100 liter box, if the woofer is driven to Xmax at 30 Hz, it will make about 101.5 dB SPL (at 1 m infinite baffle). It will require about 22 W to do it.

A 70 liter box is about in the middle between the two...

The advantage of the smaller box is that it can somewhat mitigate over driving the woofer. It requires more power at very low frequencies to bang the voice coil. But the downside is that it requires more power at all frequencies below 50 Hz.

This is why some designers prefer a sealed box Qtc of about 1.0 when applying a bass EQ. It helps protect the woofer. I personally don't think it offers that much protection if you have a 200+ W amplifier and a "nut behind the wheel" operator. The best way to protect the woofer is to use common sense and be cautious.

Another advantage of the smaller box is that it is easier to construct, uses less materials, and has a lower signature due to the lower surface area of the cabinet.

For this kind of design, the size of the enclosed woofer volume is another non-critical design parameter. You should let other aspects "drive the ship", such as an optimized baffle design, bracing and structural damping, room placement considerations, aesthetics.

j.

In a 40 liter box, if the woofer is driven to Xmax at 30 Hz, it will make about 101.5 dB SPL (at 1 m infinite baffle). It will require about 90 W to do it.

In a 100 liter box, if the woofer is driven to Xmax at 30 Hz, it will make about 101.5 dB SPL (at 1 m infinite baffle). It will require about 22 W to do it.

A 70 liter box is about in the middle between the two...

The advantage of the smaller box is that it can somewhat mitigate over driving the woofer. It requires more power at very low frequencies to bang the voice coil. But the downside is that it requires more power at all frequencies below 50 Hz.

This is why some designers prefer a sealed box Qtc of about 1.0 when applying a bass EQ. It helps protect the woofer. I personally don't think it offers that much protection if you have a 200+ W amplifier and a "nut behind the wheel" operator. The best way to protect the woofer is to use common sense and be cautious.

Another advantage of the smaller box is that it is easier to construct, uses less materials, and has a lower signature due to the lower surface area of the cabinet.

For this kind of design, the size of the enclosed woofer volume is another non-critical design parameter. You should let other aspects "drive the ship", such as an optimized baffle design, bracing and structural damping, room placement considerations, aesthetics.

j.

I should add that in my design, I used a different woofer. The SB34NRX75-6 has a higher Qes and Qts. In a 70 liter sealed box, my Qtc is 0.81 ... j.

sorry did not realize his were sealed. I only suggested the larger box because it seemed he had extra space in his existing enclosures. Mine are vented with no eq and seem to handle 150 watts or so no problem.

Thanks for the info.

I have more questions. I know i overthink things too much, but I'm new to this and dont want to stuff anything up.

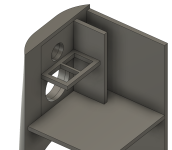

I'm working on sizing up the mid range enclosure. If I work on 7.5 litres (purely as one of the measurements works the height of the cabinet), i end up with the full depth of the tweeter & mid compartment 313mm , 193mm wide, 119mm deep (Based on the golden ratio 0.618:1:1.618).

The Mid woofer sits 30mm inside the cabinet due to my 54mm baffle.

Is 90mm clearence from the back of the driver to the back wall enough?

I've added some bracing panels, Can you give me some feedback on if you think it would be sufficient?

Also a general guide on how you would line/stuff the cabinet. What you would use where etc.

I've attached a few screenshots.

Thanks heaps

I have more questions. I know i overthink things too much, but I'm new to this and dont want to stuff anything up.

I'm working on sizing up the mid range enclosure. If I work on 7.5 litres (purely as one of the measurements works the height of the cabinet), i end up with the full depth of the tweeter & mid compartment 313mm , 193mm wide, 119mm deep (Based on the golden ratio 0.618:1:1.618).

The Mid woofer sits 30mm inside the cabinet due to my 54mm baffle.

Is 90mm clearence from the back of the driver to the back wall enough?

I've added some bracing panels, Can you give me some feedback on if you think it would be sufficient?

Also a general guide on how you would line/stuff the cabinet. What you would use where etc.

I've attached a few screenshots.

Thanks heaps

Attachments

It is incredibly difficult to hide the seams in layered mdf laminate baffles. No amount of sealing, even with extreme epoxy or fibreglass, will hide the seams long term. They will show through sooner or later. It is a real bummer to constantly be reminded every time you look at the otherwise flawless cabinet. I strongly support good diffraction control but if a single large radius solid roundover piece is not available, I go with a faceted baffle like Avalon or Rockport with the seams hidden with a glued 3mm mdf overlay. This effectively hides the long term seam movement.So I've been flat out working on my house, so haven't had much of a chance to work on the speakers.

But.. This weekend I smashed out the front baffles. Made a little mistake with the tweeter recess, forgot to adjust a depth on the cnc, i'll fill that in, wont be a problem. Apart from that very happy with the results.

I've attached some pics pre/post sanding.

Let me know what you think!

I'm going to start working on the cabinets this week, i'll be asking a few questions along the way to make sure i line them correctly etc.

Thankyou all again for your help.

Attachments

Those are cool looking speakers.

I tossed up many ideas, but the speakers are so wide it made things hard. It would have been very different if i went a tall skinny floorstander.

I am planning to get them 2 pak painted once i'm finished so i'll just have to see how it comes out.

I tossed up many ideas, but the speakers are so wide it made things hard. It would have been very different if i went a tall skinny floorstander.

I am planning to get them 2 pak painted once i'm finished so i'll just have to see how it comes out.

I was wondering what you planned for the top edge of the baffle. Do your sketch-ups suggest you are not planning to round this edge?I've attached a few screenshots.

This would be a missed opportunity IMO. The proximity of the tweeter will induce diffraction artefacts at the sharp edge.

I couldnt model anything and make it blend and work well with my limited Fusion 360 skills. I figuired the sides were more important than the top.

But i can certainly attempt something by hand

But i can certainly attempt something by hand

Yes, that is enough.he Mid woofer sits 30mm inside the cabinet due to my 54mm baffle.

Is 90mm clearence from the back of the driver to the back wall enough?

I've added some bracing panels, Can you give me some feedback on if you think it would be sufficient?

You are on the right track to use bulkhead bracing to tie all four walls together. But window pane bulkheads (which have large rectangular openings) are not very good at reacting the driver loads from the baffle into the side walls as shear loads. I have a post on this

https://www.diyaudio.com/community/threads/new-project-tower-3-way-with-twin-8s.378223/post-7037908

With your CNC router, you can easily do better. Here are some ideas.

I would line the interior walls with butyl rubber damping pads, such as Noico or Kilmat

https://kilmat.com/products/kilmat-80-mil-36-sqft/

Line the interior and exterior of the midrange box.

For stuffing I would use natural wool stuffing. Almost as good is rock wool or shredded denim insulation. My understanding is that wool is easily available in Australia, so I would not consider anything else. Here in the US, wool can be hard to get sometimes.

With wool, I would stuff the midrange box with 16 g/liter. For the woofer I would start with 10 g/liter and measure the response with a near field scan, and adjust down if it is over damped, or up to suppress a box standing wave resonance. If you use a different material, you will have to experiment to get the damping right.

It looks like your drawing shows the area behind the midrange box is sealed off from the woofer volume. That seems like a missed opportunity to get more woofer volume, or shrink the cabinet size. With so much cabinet volume, you could use a pair of SB34NRXL75-8 drivers per cabinet.

That is a really good option. I agree the top edge should be rounded or beveled. It is true that the horizontal edges are most important, but the top edge will have an influence.You can buy hardwood (Tasmanian oak) 50mm quad round from a proper timber merchant. Pinned and glued with care it can make an excellent roundover.

j.

Given the thickness of your baffle, you may want to chamfer the back side of the MW16 driver recess. Reflections off the "tunnel" created may mar the response.

Here is an example of bracing. All glue joins are rebated to a depth of approx 5 mm. The great advantage of the rebated joins is that the box can be dry assembled and held together with a few clamps to check fitting. Don't make the rebating too tight, glue takes up a surprising amount of space. It is also worth rounding over the holes in the braces to avoid any air turbulence.Yes, that is enough.

You are on the right track to use bulkhead bracing to tie all four walls together. But window pane bulkheads (which have large rectangular openings) are not very good at reacting the driver loads from the baffle into the side walls as shear loads. I have a post on this

https://www.diyaudio.com/community/threads/new-project-tower-3-way-with-twin-8s.378223/post-7037908

Attachments

- Home

- Loudspeakers

- Multi-Way

- SB Acoustics 3 way active build - Advice