I am getting ready to seal the baffle on the box but before doing that need to treat the inside to reduce vibrations and resonances. Is it needed to line interior walls with bituminous sheets, etc before laying felt/foam? Maybe extra bracing with dowels?

I did some experiments with mdf boxes you might find interesting.

http://www.diyaudio.com/forums/multi-way/278622-2-new-cabinets-monitor-audio-silver-s2-test.html

I'm firmly in the "if it's worth building, it's worth overbuilding" camp so for a box that size I would use at least 1 square brace between tweeter and woofer. Maybe a second square brace that connects top bottom and sides. I got a roll of bituminous roofing for only 50€ and it lasts for years, no reason not to glue it on all inside walls (floortack). If you don't intend to build a lot of wooden boxes after this get the car butyl stuff that 'll probably be 30€ just for these 2 boxes.

http://www.diyaudio.com/forums/multi-way/278622-2-new-cabinets-monitor-audio-silver-s2-test.html

I'm firmly in the "if it's worth building, it's worth overbuilding" camp so for a box that size I would use at least 1 square brace between tweeter and woofer. Maybe a second square brace that connects top bottom and sides. I got a roll of bituminous roofing for only 50€ and it lasts for years, no reason not to glue it on all inside walls (floortack). If you don't intend to build a lot of wooden boxes after this get the car butyl stuff that 'll probably be 30€ just for these 2 boxes.

There might be some inspiration in this thread as well:

http://www.diyaudio.com/forums/multi-way/295467-box-damping-bracing-question-maybe-idea.html

http://www.diyaudio.com/forums/multi-way/295467-box-damping-bracing-question-maybe-idea.html

Those are helpful links guys. Thanks!

Bracing back of woofer magnet.

Add goop to backside of waveguide so it is not simply thin plastic shell.

Add dowel brace for top to bottom. Already square window brace in middle.

Add bituminous damping pads.

Bracing back of woofer magnet.

Add goop to backside of waveguide so it is not simply thin plastic shell.

Add dowel brace for top to bottom. Already square window brace in middle.

Add bituminous damping pads.

I generally don't like leaving an unbraced span of 6” or larger. Lining the walls with denim insulation will kill most internal reflections.

I might get this to line all inside surfaces:

Sonic Barrier Lightweight Vinyl Sound Damping Sheet 10" x 13"

Sonic Barrier Lightweight Vinyl Sound Damping Sheet 10" x 13"

Don't know if you can get it X, but this stuff is excellent (I think you need the 4mm thickness when not damping thin car body panels):

Silent Coat Extra 4mm Mat Door 6 Sheet Pack – Silent Coat UK

Silent Coat Extra 4mm Mat Door 6 Sheet Pack – Silent Coat UK

Don't know if you can get it X, but this stuff is excellent (I think you need the 4mm thickness when not damping thin car body panels):

Silent Coat Extra 4mm Mat Door 6 Sheet Pack – Silent Coat UK

Yes, 12 sheets for $89 in the US. Looks like good stuff - probably key to ultra low HD speakers when all is said and done.

https://silentcoat.us/product/4mm-vibration-damping-material/

This one is only 2mm thick but also looks good (all 5 star reviews) and 18 sq feet for $35 shipping included sounds like a deal:

https://www.amazon.com/Noico-deadening-automotive-Insulation-dampening/dp/B012B5EMGO/

I just ordered the Noico stuff - with 18 sq feet (1lb per sq ft) I could double up the layers if needed. 114 x 5 star reviews and they all loved it for car audio.

Last edited:

Face,

Is this the ~2" thick low density denim? Wouldn't 1/2" thicker higher density lining work better?

J Mish, Natural Performance Wool Cushion - 100% Wool Carpet Pad Underlayment - Green Building Supply

2 layers of the 1/4" material should be enough.

Edit: Just saw that X has ordered Noico. X, looks like "non-breathable" material - will result in reduction of total cabinet volume?

Last edited:

I suppose it will reduce volume a bit. Although I have played around with varying volume by 500cc and it did not change bass performance too much. If I lined all walls not including front and back panels the it is about 400cc's of volume loss for the air space.

Last edited:

Waveguide fit makes a difference

I took measurements with the thinner waveguide adapter that now eliminates the small 1mm wide gap between the tweeter bezel and the waveguide throat. The new adapter was 0.025in thinner, exactly to account for the thickness of the foam gasket.

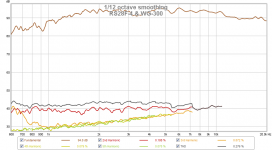

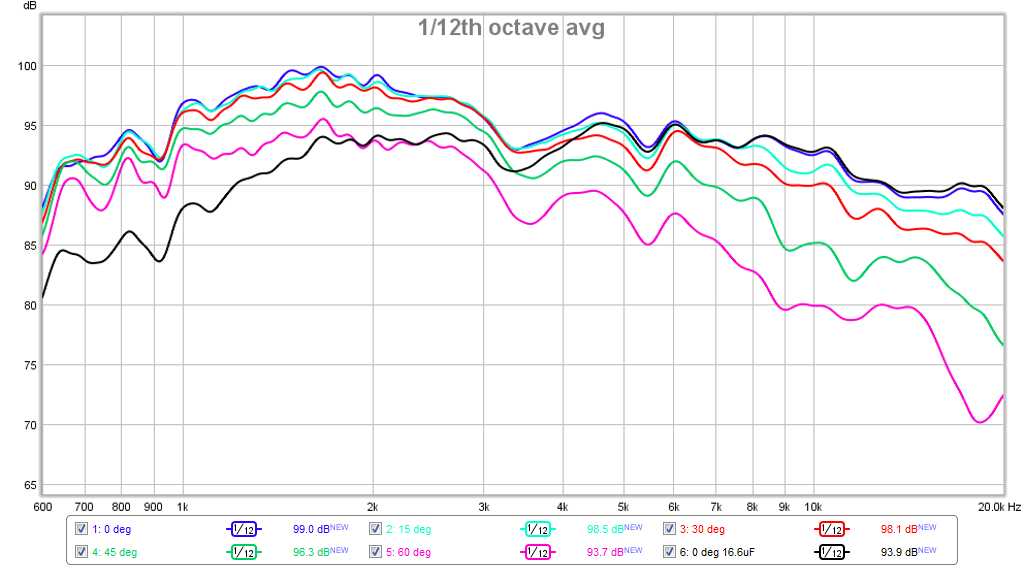

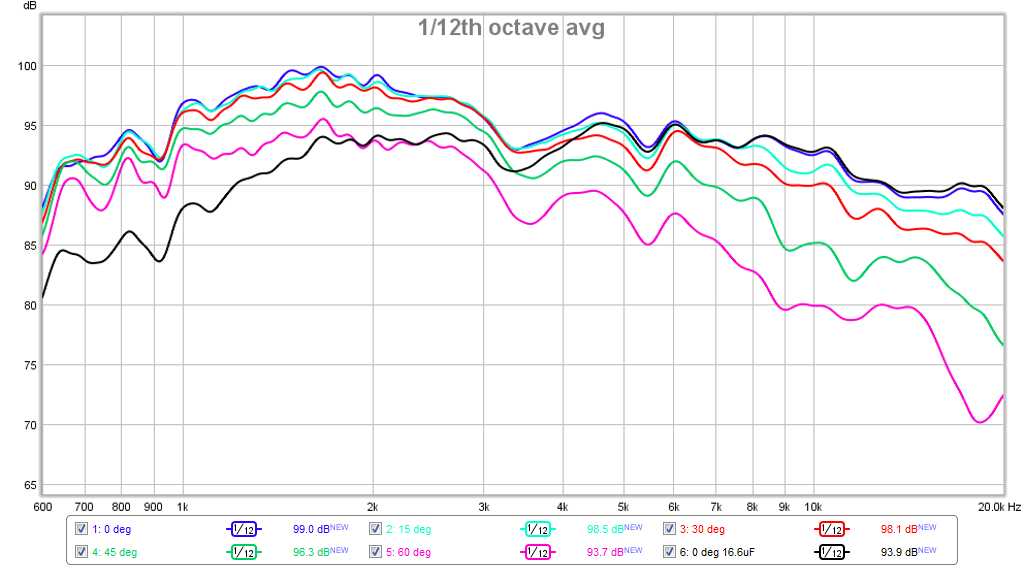

The new measurements look much better. I DC coupled the tweeter this time and ran it from 500Hz and up to reduce tweeter excursion. For one case I used a 16.6uF cap to reduce excursion and to also shape the response to show that it can flatten out nicely with 1st order high pass. You can see that the 5dB 3.7kHz dip, now is about 2dB and at 3.4kHz. Here are the (rough) polar measurements with 1/12th octave smoothing:

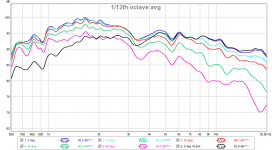

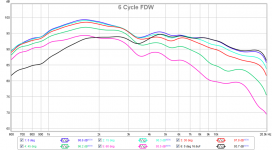

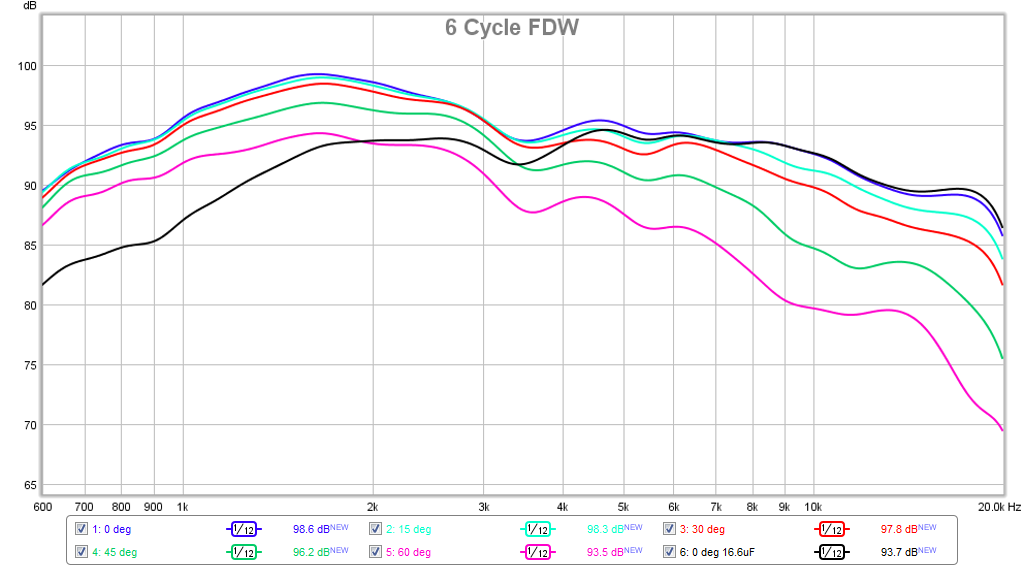

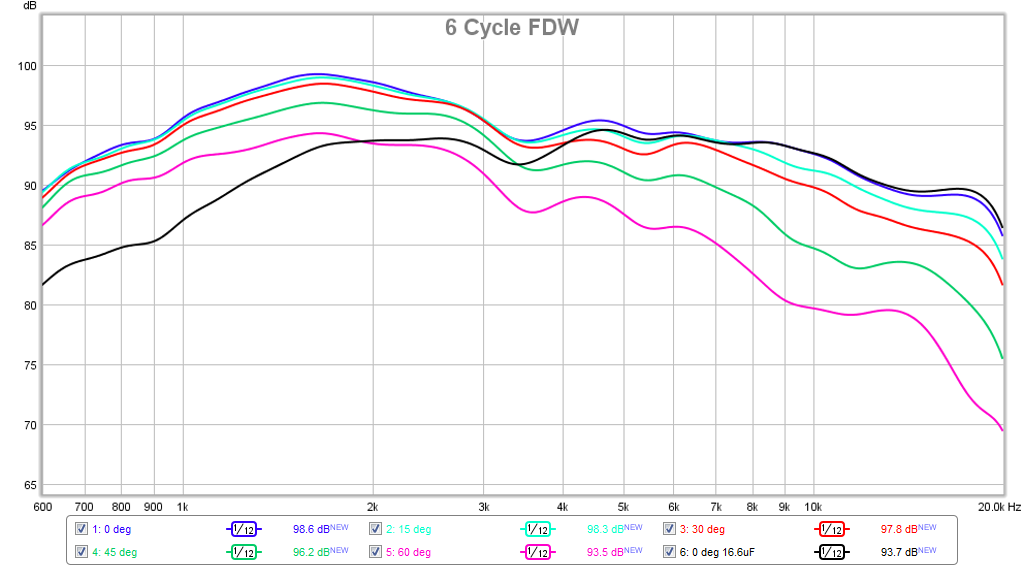

Here are the same polars with 6 cycle frequency dependent window smoothing to isolate just the effects of the driver and waveguide:

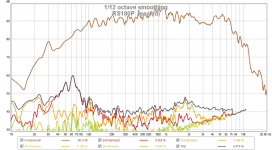

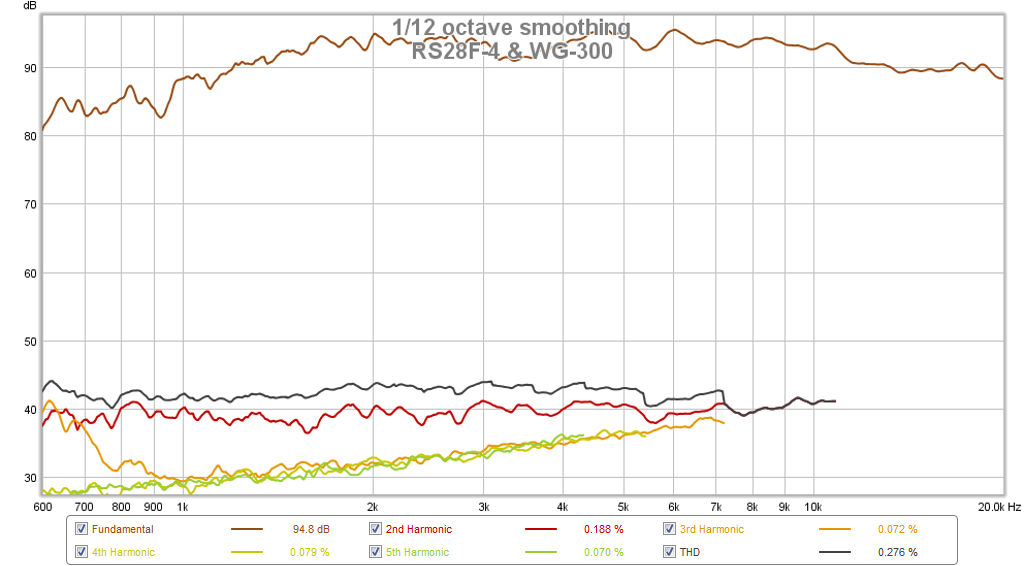

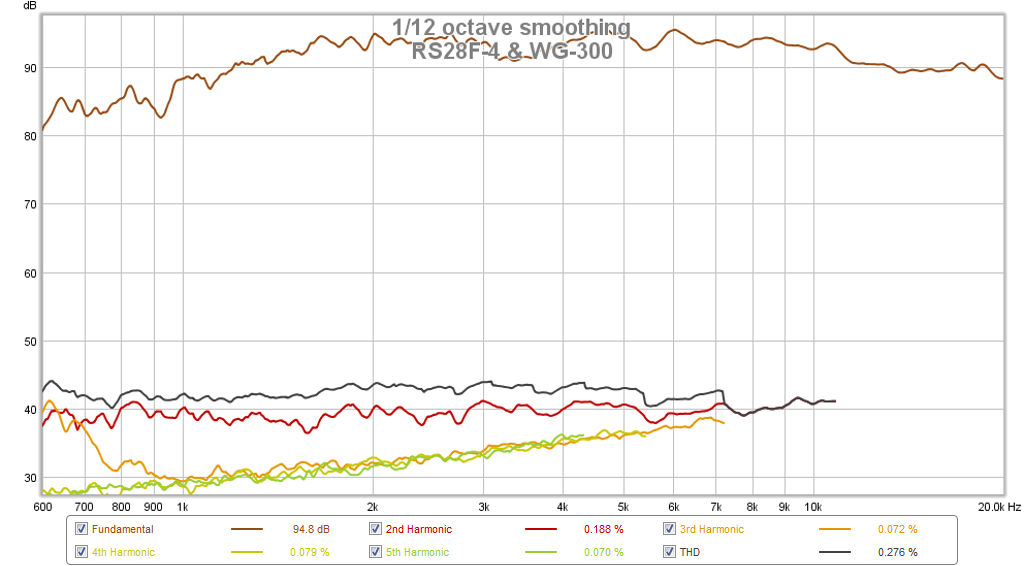

For the HD plot below, I AC coupled the tweeter with a 16.6uF film cap to reduce cone motion and limit distortion down below 2kHz.:

Anyhow, I think that this response is now good enough as a basis for me to make a passive crossover with it.

The polar response looks quite consistent and just has an amplitude fall-off.

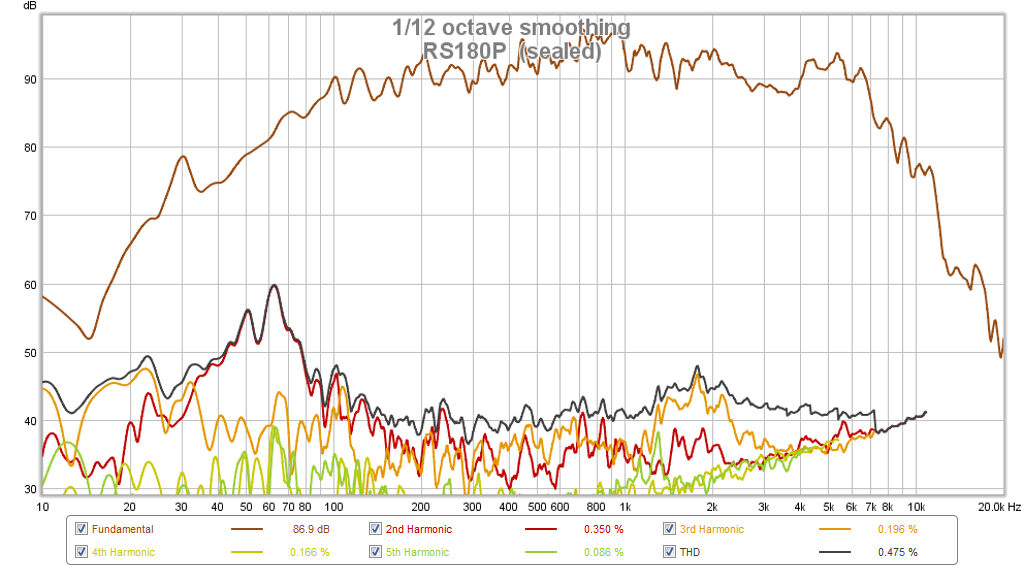

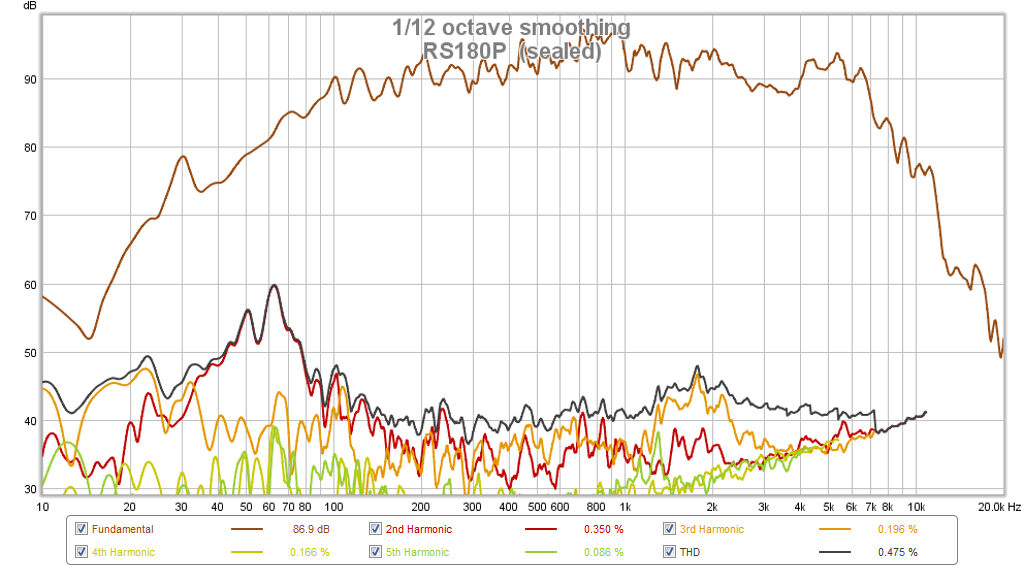

I couldn't resist, for grins, I took a measurement of the RS180P with no damping inside the cabinet with just the baffle loosely taped in place. It looks pretty good actually:

So we will see what all the box damping treatments can do for this...

I took measurements with the thinner waveguide adapter that now eliminates the small 1mm wide gap between the tweeter bezel and the waveguide throat. The new adapter was 0.025in thinner, exactly to account for the thickness of the foam gasket.

The new measurements look much better. I DC coupled the tweeter this time and ran it from 500Hz and up to reduce tweeter excursion. For one case I used a 16.6uF cap to reduce excursion and to also shape the response to show that it can flatten out nicely with 1st order high pass. You can see that the 5dB 3.7kHz dip, now is about 2dB and at 3.4kHz. Here are the (rough) polar measurements with 1/12th octave smoothing:

Here are the same polars with 6 cycle frequency dependent window smoothing to isolate just the effects of the driver and waveguide:

For the HD plot below, I AC coupled the tweeter with a 16.6uF film cap to reduce cone motion and limit distortion down below 2kHz.:

Anyhow, I think that this response is now good enough as a basis for me to make a passive crossover with it.

The polar response looks quite consistent and just has an amplitude fall-off.

I couldn't resist, for grins, I took a measurement of the RS180P with no damping inside the cabinet with just the baffle loosely taped in place. It looks pretty good actually:

So we will see what all the box damping treatments can do for this...

Attachments

Last edited:

What's interesting is I think your full range driver xBush has a better polar than a nice dome ina waveguide.

My Noico sound dampening panel sheets arrived today. Good stuff - heavy, sticky and foil embossed side provides indicator of good application. Needs to be rolled until embossed surface is smooth.

I will cut passive radiator holes today and install sound dampening sheets. Should have a working 2 way soon. Can use minidsp to get started and test out some filter settings like center frequency, basic notch filters, and baffle step shelving filters.

I will cut passive radiator holes today and install sound dampening sheets. Should have a working 2 way soon. Can use minidsp to get started and test out some filter settings like center frequency, basic notch filters, and baffle step shelving filters.

Looking forward to seeing this. With the passive radiators looks like you are packing in a lot of punch for the size of them.

I found those kind of sheets are more effective on thin metal, such as automotive doors.My Noico sound dampening panel sheets arrived today. Good stuff - heavy, sticky and foil embossed side provides indicator of good application. Needs to be rolled until embossed surface is smooth.

I will cut passive radiator holes today and install sound dampening sheets. Should have a working 2 way soon. Can use minidsp to get started and test out some filter settings like center frequency, basic notch filters, and baffle step shelving filters.

I found those kind of sheets are more effective on thin metal, such as automotive doors.

That's what they are designed for but everything helps I guess. It can be used to help dampen the thin steel basket arms on the passive radiator. I may even stick it on the backside of the waveguide to quiet it down.

- Home

- Loudspeakers

- Multi-Way

- RS28F-RS180P-B80 as Hole Filler 3-way