would also make it easier to remove ticks n pops as you could do that before digitally speeding things back up. Gotta be work playing with some time...

Not really, Hans. In fact it might only represent c 12.5um of tracking deflection, peak groove angle c 9 deg, peak groove curvature c 500um, and about 50G of peak stylus acceleration. That is all pretty modest and undemanding stuff.

Where did you find the figures of 50G that you presented for a 1Khz odB signal ?

I did some calculation and came to quite different results.

F=m*a and F=m*v^2/r where r is the radius at the top of the sinus where the tangential motion is reverted.

Combining both gives m*a = m*v^2/r or a = v^2/r

Speed of the record at the outer side is Pi*27cm/2 at 33 1/3 rpm or ca 40 cm/sec.

At tone of 1Khz takes 1msec, in that time the LP has travelled 400um.

The 0db 1Khz on my test record has a measured peak to peak amplitude of roughly 100um.

With this amplitude the speed at the zero crossing of the sinewave is 125um/0.25msec or 0.5m/sec.

The radius of the sinuswave at the top is ca 12.5um or 12.5e-6m.

So as a result, a = V^2/r = 0.5^2/12.5e-6 = 20.000 m/sec^2.

This is equivalent to 2000G.

This differs a factor 40 with your figure of 50G !

Hans

My measurements confirm that dry playback friction can permanently increase, significantly so, after wet playback. As to why, at the surface level, I don't know. Using clean distilled water, and reasonably clean conditions.

When playing back with fluid is supposed to render an LP worthless for dry playback in a later stage, why is this not the case after having cleaned the record on a wet cleaning machine.

If fluid would invade the PVC, this would also happen at cleaning.

My experience with wet playback with Lenco-clean was that all dust and whatever contamination sinked to the bottom of the groove and formed an almost solid mud.

Playing dry the LP at a later stage, showed a huge pick up of this mud from the groove to the needle causing huge distortion of the sound.

This was never the case with LP's that were always played dry.

But after having dry played such a muddy LP several times, mud was more or less scraped away and things were back to normal.

But that is experience from many years ago.

These LP's are still in my possession thoroughly cleaned and sounding O.K. but the Lenco-clean was discarded long ago.

Hans

I remember experimenting with wet play, a very long time ago, back when my system was mono, included a "GE Variable Reluctance" cart, an "Altec" amplifier, and "James Lansing" speaker. I think I was 12. A second dry play after was ok, as Hans noted. It was messy, and I stopped doing it even though it seemed to sound better...

Yes, excitation of the sub-audio cart-arm resonance does not show up in audioband spectra of surface noise. But it does show up in FM analysis, pitch stability or vibrato of programme material, which is a different sort of degradation of programme playback. Amplitude of the resonance can be a benchmark for friction in a specific setup and record combination, which IME correlates with surface noise.

Where LF resonance really shows up is as IM distortion.

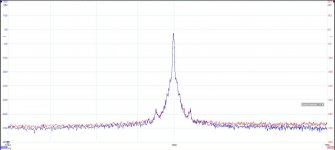

Look at my stretched recording below of a 1Khz tone and you will notice the IM products at 1Khz +/- (n*fres)

The better the damping of the resonance peak, the lower these IM products will be.

Hans

My experience with wet playback with Lenco-clean was that all dust and whatever contamination sinked to the bottom of the groove and formed an almost solid mud.

I thought the point of the record cleaner was to clean. I wonder how the folks in the ultrasonic cleaning thread are doing with noise.

When playing back with fluid is supposed to render an LP worthless for dry playback in a later stage, why is this not the case after having cleaned the record on a wet cleaning machine.

If fluid would invade the PVC, this would also happen at cleaning.

Yes, it can. The simple act of cleaning mint records with water/detergent/rinse, under controlled conditions, can increase friction coefficient. R Pardee JAES Dec 1981 - Billshurv posted and there was a thread on it last year here.

Pardee's paper only considers overall friction coefficient, not its dynamic nature, and doesn't discuss effect on noise., It does set out a measurement method for friction coefficient, which is handy.

However, wet playback often results in pronounced degradation in friction for subsequent dry playback IME, so I consider either some other factor, or a magnification of whatever can happen under some conditions with cleaning, is in play.

I should say that plenty of people report no such issue with cleaning, and the Pardee paper shows results can vary between records, as well as cleaning agent. But the most relevant part is the tests on mint records, which have no dirt yet can still show deterioration in friction after cleaning.

My experience with wet playback with Lenco-clean was that all dust and whatever contamination sinked to the bottom of the groove and formed an almost solid mud.

Playing dry the LP at a later stage, showed a huge pick up of this mud from the groove to the needle causing huge distortion of the sound.

This was never the case with LP's that were always played dry.

But after having dry played such a muddy LP several times, mud was more or less scraped away and things were back to normal.

I think one has to be careful when assigning exactly what is going on, and it is easy to suppose there is 'mud', whereas what one strictly observes is stylus fouling which progressively goes away. The cause of fouling could be many things. I suspect generally that decay of the groove wall might often be a factor but have no reason to associate that with any cleaning agent. If one looks at the ball of gunk that clogs the stylus microscopically, I found it can often look scarily like long strands of shavings.......

LD

Where did you find the figures of 50G that you presented for a 1Khz odB signal ?

0dB @ 1kHz, stylus velocity = 5.6cm/s rms, 8cm/s peak velocity ; reference standard

Sine wave, so peak stylus acceleration is 2*pi*f*(peak velocity); standard mechanics

use f = 1khz, gives peak stylus acceleration = 502 m/s2

1G = 9.81 m/s2 ; Sir Isaac Newton

peak stylus acceleration = 51.2G

This differs a factor 40 with your figure of 50G !

About 50G is correct, Hans.

LD

Member

Joined 2009

Paid Member

However, wet playback often results in pronounced degradation in friction for subsequent dry playback ...

I should say that plenty of people report no such issue with cleaning...

Given that subsequent wet play remains very good I conclude that if damage is made by wet play, it can be masked if kept wet.

Given that nobody reports degradation in play when switching from wet play to dry play of a different record I conclude that there is no degradation to the stylus from wet play and hence the degradation being reported must be to the vinyl that was subject to wet play.

With wet play a stylus is traversing the grooves whereas a wet clean has nothing in the groove except the water. I conclude that the degradation to the vinyl is caused by the stylus moving through the groove when it is wet and not simply because the vinyl is in contact with water.

So - what kind of change to the vinyl can be caused by dragging a diamond across it's surface when in water and can be masked if it is kept wet for subsequent play ?????

Last edited:

Given that subsequent wet play remains very good I conclude that if damage is made by wet play, it can be masked if kept wet.

I doubt it is damage, more likely changes to the nature of the groove surface.

I came to realise what really matters about playback is that the stylus follows the locus of the groove base. In wet playback, on the face of it, this happens better than during dry playback.

With wet play a stylus is traversing the grooves whereas a wet clean has nothing in the groove except the water. I conclude that the degradation to the vinyl is caused by the stylus moving through the groove when it is wet and not simply because the vinyl is in contact with water.

Sort of, except it's possible that the act of wet playback exaggerates what can happen by wetting alone, I think.

So - what kind of change to the vinyl can be caused by dragging a diamond across it's surface when in water and can be masked if it is kept wet for subsequent play ?????

I think, in general form, it is changes to the surface which affect friction. The devil is in the detail of explaining that.

LD

Member

Joined 2009

Paid Member

I use the word 'damage' because the 'changes to the nature of the groove surface' are detrimental - at least to subsequent dry playback.

I don't see how wetting alone has any effect, records are cleaned with water for many years and no accumulated damage has been reported has it ?

So the diamond, in water, changes the surface of the vinyl. What kinds of changes could it produce ? The diamond does create very high pressures at the point of contact and during wet play this happens when submerged in an incompressible fluid. The diamond is also moving around at high speed, pushing around the local fluid. Is it possible that there is a change in the surface of the vinyl created by fluid moving around rapidly under pressure ??

What kind of damage can be masked by subsequent wet play ? Well, it has been reported that the surface has increased friction after wet play, so immersing it in water again allows the water to act as a lubricant and compensate for this.

I don't see how wetting alone has any effect, records are cleaned with water for many years and no accumulated damage has been reported has it ?

So the diamond, in water, changes the surface of the vinyl. What kinds of changes could it produce ? The diamond does create very high pressures at the point of contact and during wet play this happens when submerged in an incompressible fluid. The diamond is also moving around at high speed, pushing around the local fluid. Is it possible that there is a change in the surface of the vinyl created by fluid moving around rapidly under pressure ??

What kind of damage can be masked by subsequent wet play ? Well, it has been reported that the surface has increased friction after wet play, so immersing it in water again allows the water to act as a lubricant and compensate for this.

Last edited:

What kinds of changes could it produce ? The diamond does create very high pressures at the point of contact and during wet play this happens when submerged in an incompressible fluid. The diamond is also moving around at high speed, pushing around the local fluid. Is it possible that there is a change in the surface of the vinyl created by fluid moving around rapidly under pressure ??.

I'm fairly sure the technology exists somewhere to explore this but there is no incentive save idle curiosity to drive people with access to it to put in the effort. Some kind of cavitation effect, who knows?

Is this effect still reported after a thorough ultrasonic cleaning?I use the word 'damage' because the 'changes to the nature of the groove surface' are detrimental - at least to subsequent dry playback.

Not sure its been tested. All the people on the ultrasonic thread report 'quieter' but of course no one has measured before/after on a virgin record.

0dB @ 1kHz, stylus velocity = 5.6cm/s rms, 8cm/s peak velocity ; reference standard

Sine wave, so peak stylus acceleration is 2*pi*f*(peak velocity); standard mechanics

use f = 1khz, gives peak stylus acceleration = 502 m/s2

1G = 9.81 m/s2 ; Sir Isaac Newton

peak stylus acceleration = 51.2G

About 50G is correct, Hans.

LD

I can follow how you made your calculation.

A small correction in this case should be that both channels are driven, making the lateral movement sqrt(2) larger, resulting in a peak acceleration of 73G, but that is still in the same order of magnitude.

Because it was quite difficult to measure the amplitude of the 0 dB 1Khz track, I took a 50x amplified picture, and found a pk-pk value of 36 um instead of the previous 100um, giving a substantial difference.

The main difference between our calculations is that I calculated a two-dimensional speed versus yours one-dimensional version.

With a record moving 400um per sinewave of 1Khz, the maximum two dimensional speed is sqrt[(36um*Pi/2)^2 +(400um/2)^2] = 41cm/sec instead of 11.3cm/sec for the one-dimensional speed.

I realise now that this was wrong, so we can fully agree on this point.

Hans

...11.3cm/sec......

so we can fully agree on this point.

I think so, Hans. 11.3 cm/s peak velocity was one of the reference standards for 0dB@1kHz lateral, and that tallies with your amazing measurement of groove modulation width being c 35 um pk-pk ! The test disc usually states the reference velocity for 0dB, or just states the velocity. I'd guess your test disc is 0dB = 8cm/s rms lateral, which is 11.3 cm/s peak.

That's the best thing about standards, there are so many of them 😉🙂

LD

So - what kind of change to the vinyl can be caused by dragging a diamond across it's surface when in water and can be masked if it is kept wet for subsequent play ?????

If you're accepting wild imaginations from the peanut gallery . . . . What about release agent in the vinyl. Maybe water jetting under pressure from the stylus pits it. Played dry the pitting drags the stylus, wet, the water fills the pits and the stylus doesn't register them. Like I said , total fabrication but in the absence of real testing . . . . .

Or, what about the heating that usually takes place. Perhaps the water gets involved there, boiling? cooling the heated vinyl too quickly? or perhaps the softening of the vinyl under pressure actually protects it from being chipped/fractured by stylus chatter and keeping it water cool interferes? Of course I'm making all this up, I don't know a thing, but it's an interesting issue.

Or, what about the heating that usually takes place. Perhaps the water gets involved there, boiling? cooling the heated vinyl too quickly?

Whatever happens has about 5uS (5 millionths of a second) or so to have effect, the time the contact region of the stylus spends in 'contact' with any point on the vinyl before moving on..........that's not very long in politics or thermodynamics.

There's not much heat involved in the classic sense, despite established urban myth about high temperature and melting vinyl. Available heat can be calculated from friction coefficient, VTF, and rotation rate - all can be measured. IIRC it only amounts to a few mW or so. This gets spread over a continually changing surface of vinyl, and/or conducted away from the contact region by exceptional thermal conductivity of diamond I think.

I suspect the crux is what goes on at high pressure in the contact region. Wild speculation: vapourisation, perhaps in the form of some reactive vapour zone in front of/below the stylus..........? A sort of vapour cushion that happens to be reactive for vinyl surface. Pure fantasy though, and anybody's guess is as good as mine !

LD

Last edited:

If you're accepting wild imaginations from the peanut gallery . . . . What about release agent in the vinyl.

Sadly there is no such thing, despite purveyors of vinyl cleaning solutions saying so.

Weekends are very quiet here so I'm guessing all these wacko theories are being developed in company time?

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches