Yes, it's so easy and tempting to write off test discs with this stuff. This one is easy and cheap though. Will check out those plug ins, though I find it hard to imagine how they can distinguish noise from content, especially in the context of comments that noise is content specific?

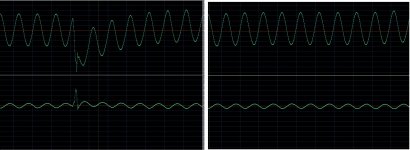

This is a worn 35yr old copy of the RCA STR100 1kHz in left (not great crosstalk probably needed adjustment) before and after Clickfix on a particularly bad pop. I still think this is sort of cool for a freebe.

Attachments

I was wondering why the correct SRA wasn't mentioned as #1 improvement for reducing tracking noise. At least in my system it worked better than anything else. The typically recommended VTA adjustments are useless in most cases because the stylus is more off than what a little up or down would be able to correct. How to Use a USB Digital Microscope to set 92 Degree Stylus Rake Angle (SRA) | Analog Planet

Yes, SRA can have a big effect on surface noise, even small changes, depending on stylus profile. I wondered why, for ages. At risk of me seeming tedious, I believe it is explained by changes in friction as the angle presented by the stylus to the groove surface is adjusted. I've measured changes in friction coefficient with SRA too, it seems to correlate, and I believe friction reduction is the mechanism for the observed reduction in SRA at a sweet spot of alignment. I don't know of another explanation ?

For sure my cart arm shows like every other 2nd order system a resonance peak when stimulating with sweeping sinewave.

So nothing special, but this is hardly reflected in the noise when playing a blank trace or a 1Khz tone.

Yes, excitation of the sub-audio cart-arm resonance does not show up in audioband spectra of surface noise. But it does show up in FM analysis, pitch stability or vibrato of programme material, which is a different sort of degradation of programme playback. Amplitude of the resonance can be a benchmark for friction in a specific setup and record combination, which IME correlates with surface noise.

I will inform Max Verstappen that 50G is still pretty modest

Ha ! Programme material typically peaks at 500-600G, which is near the limit of typical trackability IME. Acceleration is determined by groove curvature and linear velocity of the stylus, and it equates to slew rate of programme material level. It is toughest at inner tracks on a record. So although 50G would pulp us, it's easy going for a stylus, because the inertia involved is so small.

But I have the impression we are deviating from the original subject, being that playing wet has a significant bonus in noise production as opposed to dry playing.

It would be more scientifically if we both start with recording blank tracks dry and wet from 10Hz to 2Khz or if you prefer to 20 Khz using known parameters like filter bandwidth, with a known recording time and the same number of spectra used for averaging.

That prevents us from comparing apples to oranges.

My days of measuring wet-v-dry are in the past, Hans. That there can be profound reduction in surface noise, I have no doubt. That the mechanism is friction is not beyond doubt IMO, but it isn't contradicted and is supported by correlations and predictions.

Unfortunately, wet playback isn't useful because it ruins the original record. So unless the record is already beyond usable because of poor surface noise, wet playback has no place, IMO. What is does do, IMO, is serve as a pointer to seek other ways to reduce stylus-groove friction, as a means of improving surface noise and other aspects of playback such as lf arm stability.

This is a worn 35yr old copy of the RCA STR100 1kHz in left (not great crosstalk probably needed adjustment) before and after Clickfix on a particularly bad pop. I still think this is sort of cool for a freebe.

That is interesting, will check it out. If the artefacts from any miscorrection are better than those of the original noise source, that looks great. Can't fix FM issues arising from arm stability, as above, though !

LD

Last edited:

There have been other surface treatments which reduce friction, mostly attaching a fluorofunctional component. I don't know about their permanency or side-effects- they were touted as permanent, but seem to have disappeared from the market.

Yes. There are commercial PFPE lubricants with various active molecular end units that bond with polymers - that seems good in principle. 'Fomblin' is one such, used in hard drives a lubricant for the disc surface, where AFAIK the film is super thin and permanently bound to the disc surface. Somewhere on my list of things to try is this.

The problem with most lubricants IME is clogging of the stylus, and there's some hope that thin film lubricants which bind might hold great hope, I think.

Another great hope is there is might be a conditioner for the molecular vinyl polymer surface that leaves it with low friction and low surface noise, whilst retaining the properties that make it long lasting.

We can dream.......!

LD

Fomblin was the key ingredient in at least one popular treatment. I have my doubts about their permanency. Binding to PVC is a bit tricky without chewing it up and inadvertently causing crosslinking and embrittlement.

Other people have tried quats (which give a nice antistat effect), but they are efficient at fouling styli. Ditto silicones with reactive end groups (e.g., hydroxyl, amine, vinyl, epoxy...). There's a surface fluorination treatment I'm aware of that would likely work, but the expense might be a bit too high. It's great for giving chemical resistance to parts exposed to solvents in high-value industrial applications and drops the surface energy to ridiculously low numbers.

Other people have tried quats (which give a nice antistat effect), but they are efficient at fouling styli. Ditto silicones with reactive end groups (e.g., hydroxyl, amine, vinyl, epoxy...). There's a surface fluorination treatment I'm aware of that would likely work, but the expense might be a bit too high. It's great for giving chemical resistance to parts exposed to solvents in high-value industrial applications and drops the surface energy to ridiculously low numbers.

Well, not analog :

Sweet Vinyl Launches SugarCube SC-1 Pop and Tick Remover | Analog Planet

Sweet Vinyl Launches SugarCube SC-1 Pop and Tick Remover | Analog Planet

Fomblin was the key ingredient in at least one popular treatment. I have my doubts about their permanency. Binding to PVC is a bit tricky without chewing it up and inadvertently causing crosslinking and embrittlement.

What was in LAST? The LP treatment did something not sure it was all good, a 30yr. revisit seemed to still have the same impression. A one side treated experiment on a couple of Leo Kottke albums. The stylus treatment needed nasty solvent removal since it grew tiny hard white tetrahedral crystals on the tip.

Member

Joined 2009

Paid Member

well, it seems to me that understandng why wet play is irreversible could be a valuable exercise. But say its irreversible, do you care if you have to always play wet, the results will be much better no ?Yes - it's because the act of using water as a lubricant permanently alters the friction surface for dry playback. Measured friction coefficient increases significantly for dry playback after playing wet, versus original condition. Whereas during wet playback the friction coefficient is very low indeed.

Why, I don't know. But I've measured and confirmed this. Ideally, one needs a lubricant that does not do this, or even better is permanent: the grail.

Interestingly, wet playback either significantly improves or does not degrade every aspect of measured playback performance. Frequency response, slew rate, thd, noise floor, you name it. Very counter-intuitive, but the audio results are self-evident too. After much thought, all that matters is that the stylus more accurately follows the locus of the groove base, and that must be happening, and at lower friction.

LD

Scott, yes, that was LAST I was talking about. Couldn't remember the name. Fomblin is a perfluoropolyether and does not have reactive groups, hence will not covalently bond to the vinyl surface.

Hiten, the problem with coatings like that is that in order to get a good permanent bond, the substrate has to be heated enough for the coating to sinter. Vinyl records would not appreciate the oven bake. And the fluorocarbon will not be hard- the pressure at a knife blade isn't nearly as high as the pressure at the stylus contact point.

Hiten, the problem with coatings like that is that in order to get a good permanent bond, the substrate has to be heated enough for the coating to sinter. Vinyl records would not appreciate the oven bake. And the fluorocarbon will not be hard- the pressure at a knife blade isn't nearly as high as the pressure at the stylus contact point.

Scott, yes, that was LAST I was talking about. Couldn't remember the name. Fomblin is a perfluoropolyether and does not have reactive groups, hence will not covalently bond to the vinyl surface.

Hiten, the problem with coatings like that is that in order to get a good permanent bond, the substrate has to be heated enough for the coating to sinter. Vinyl records would not appreciate the oven bake. And the fluorocarbon will not be hard- the pressure at a knife blade isn't nearly as high as the pressure at the stylus contact point.

Ah - you need Fromblin® Functional, sir. It's kept under the counter and you have to ask for it

Fomblin Functional PFPE|Solvay

"Fomblin® Functional perfluoropolyethers can react with conventional polymeric materials to impart to them the specific properties of the perfluoropolyether chain."

AFAIK, these are UV cured, and the functional end attaches to the polymer leaving a thin film of lubricant attached to, say, vinyl.

To my knowledge, hard drive heads 'fly' or surf in/on the thin film lubricant layer, very close to the disc surface. Unless it's flying, and in equilibrium, there's more downforce (from spring tension) and rotational speed is far higher than for vinyl playback, so one might be optimistic about it being permanent ?

Hiten, yes that sort of coating yo linked might well be similar, and work, but that one needs thermal curing.......maybe there's one with UV curing ?

LD

well, it seems to me that understandng why wet play is irreversible could be a valuable exercise. But say its irreversible, do you care if you have to always play wet, the results will be much better no ?

If the mechanism were understood there might be some additive or whatever to avoid it, I suppose? My measurements confirm that dry playback friction can permanently increase, significantly so, after wet playback. As to why, at the surface level, I don't know. Using clean distilled water, and reasonably clean conditions.

There's a 3rd party published paper that shows an increase in friction coefficient can happen just after cleaning records with distilled water plus detergent, can't recall reference. It's silent about surface noise though, if you excuse the pun ! Don't know of any other work.

But yes, why not use wet playback if its for one's own use, and results are much better ? AFAIK, records remain permanently good if always played wet, but subsequent dry playback is a no-go. The record thus becomes useless to anyone else, unless they are willing to also use wet playback, which is rare.

For archiving, when a record is already useless in a dry state due to surface noise, I confess I have been known to rip digital copies using wet playback. With impressive results!

Awaiting that magic potion........

LD

Thanks SY and LD.

So general conclusion would be stylus profile, its angle and material of stylus point (Diamond, ruby etc.) can somewhat reduce friction noise.

Some enthusiast here are using WD40 to clean (not for playing) vinyls. Dont know how much of it remains in grooves after wiping it off and wheather it reacts with vinyl material.

What we need is a chemical which forms permanent reaction with vinyl surface, forms a micro thin layer which have lower friction.

Article

Regards

So general conclusion would be stylus profile, its angle and material of stylus point (Diamond, ruby etc.) can somewhat reduce friction noise.

Some enthusiast here are using WD40 to clean (not for playing) vinyls. Dont know how much of it remains in grooves after wiping it off and wheather it reacts with vinyl material.

What we need is a chemical which forms permanent reaction with vinyl surface, forms a micro thin layer which have lower friction.

Article

Regards

I cured vinyl surface noise several years ago by removing my TD 124/II and TD 125/II from the mix and fully and embraced digital technology.

I did really try to delude myself that vinyl sounded better but I have never had much imagination. Fortunately I never got rid of my decks and are now worth crazy money so I will never knock the believers.

I did really try to delude myself that vinyl sounded better but I have never had much imagination. Fortunately I never got rid of my decks and are now worth crazy money so I will never knock the believers.

If friction is related to velocity is there going to be a fad for half speed ripping? You'll lose a little of the bottom octave, but lets face it almost no signal there on vinyl...

Yup, that should do it, Bill. Would help trackability too, but would move the cart-arm resonance near to the audioband during playback at full speed........

I wonder whether half speed mastering, which presumably has similar incidental benefits to the cutting lathe, produces some of its effects this way ?

LD

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches