Now I understand!

In circumstances like this, I go raking in the tool box containing a random assortment of nuts, washers, bolts etc. left behind by my dear, departed engineer father.

I always seem to come up with something to do the job!

In circumstances like this, I go raking in the tool box containing a random assortment of nuts, washers, bolts etc. left behind by my dear, departed engineer father.

I always seem to come up with something to do the job!

For scuffing up an idler wheel, I just lay a piece of 600 grit sandpaper on a table face up and hold the idler with the other hand. Doesn't sound very precise, but you might be surprised what you can do purely by feel. You probably don't want any more power applied than that anyway. A couple passes around the circumference should do it.

All good fortune,

Chris

All good fortune,

Chris

Thanks Galu - my dear, departed engineer father also left behind a similar treasure trove of such stuff and tools but nothing seems to suit in this instance! I'll measure the diameter of the idler wheel spindle and try and source something more suitable than a metric M4 bolt.

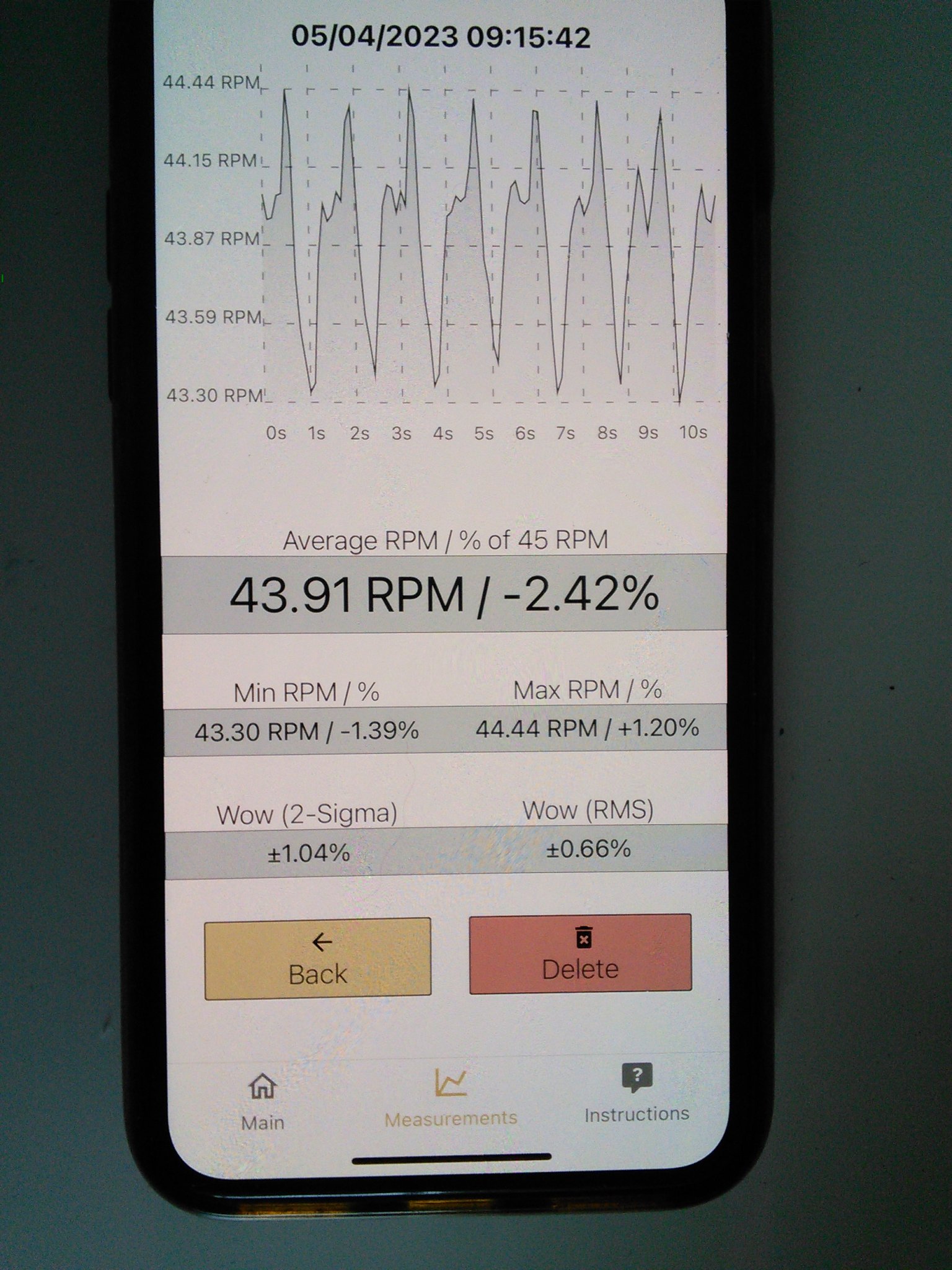

Thanks Chris - good to still have you on board. I used some 2000 grit wet and dry paper as I'm a bit cautious of making things worse. This brought about a slight improvement in the speed and wow - see below and note the regular speed variation which no doubt is coming form the idler wheel. When I spin up the motor with no idler wheel it is virtually silent but I do hear a very faint regular noise when the idler wheel is engaged.

I've ordered up some rubber restorer and I will try that in the hope the torque will improve? The platter is still a bit sticky when it engages the auto-changer mechanism and seems to lack a big enough initial kick!

Thanks Chris - good to still have you on board. I used some 2000 grit wet and dry paper as I'm a bit cautious of making things worse. This brought about a slight improvement in the speed and wow - see below and note the regular speed variation which no doubt is coming form the idler wheel. When I spin up the motor with no idler wheel it is virtually silent but I do hear a very faint regular noise when the idler wheel is engaged.

I've ordered up some rubber restorer and I will try that in the hope the torque will improve? The platter is still a bit sticky when it engages the auto-changer mechanism and seems to lack a big enough initial kick!

From what I read, rubber restorer provides only a temporary solution to a hardened idler.

You say, "Note the regular speed variation which no doubt is coming from the idler wheel."

Hardened idler rubber results in two issues: slippage and the transmission of motor noise to the platter

A flat on the rubber will produce a regular 'thump' as the idler wheel rotates.

However, a slight lack of concentricity of the idler rubber surface should not affect the speed as long as positive contact between motor pulley and platter is being maintained.

You say, "Note the regular speed variation which no doubt is coming from the idler wheel."

Hardened idler rubber results in two issues: slippage and the transmission of motor noise to the platter

A flat on the rubber will produce a regular 'thump' as the idler wheel rotates.

However, a slight lack of concentricity of the idler rubber surface should not affect the speed as long as positive contact between motor pulley and platter is being maintained.

Last edited:

Thanks Galu for the additional clarification.

Based on your experience what is the likely cause of the regular speed variation shown in the graph in the above Post?

Based on your experience what is the likely cause of the regular speed variation shown in the graph in the above Post?

It could be due to a single hard spot on the idler rubber, giving a regular slippage.

You say the motor and main platter bearings are operating smoothly, but are they really?

You say the motor and main platter bearings are operating smoothly, but are they really?

Another thing to check is the condition of the rubber motor mounting grommets.

If they have deteriorated, the motor pulley may not be pressing uniformly on the idler wheel.

Just more straw clutching perhaps!

If they have deteriorated, the motor pulley may not be pressing uniformly on the idler wheel.

Just more straw clutching perhaps!

Once I find a suitable bolt to give the idler wheel a spin and sand then that should eliminate any hard spots or other anomalies?

I can certainly strip down, clean and lubricate the man bearing again but how do I check the motor?

And of course checking the condition of the rubber motor mounting grommets will be subjective based on experience? Where would I find suitable replacements?

I can certainly strip down, clean and lubricate the man bearing again but how do I check the motor?

And of course checking the condition of the rubber motor mounting grommets will be subjective based on experience? Where would I find suitable replacements?

Last edited:

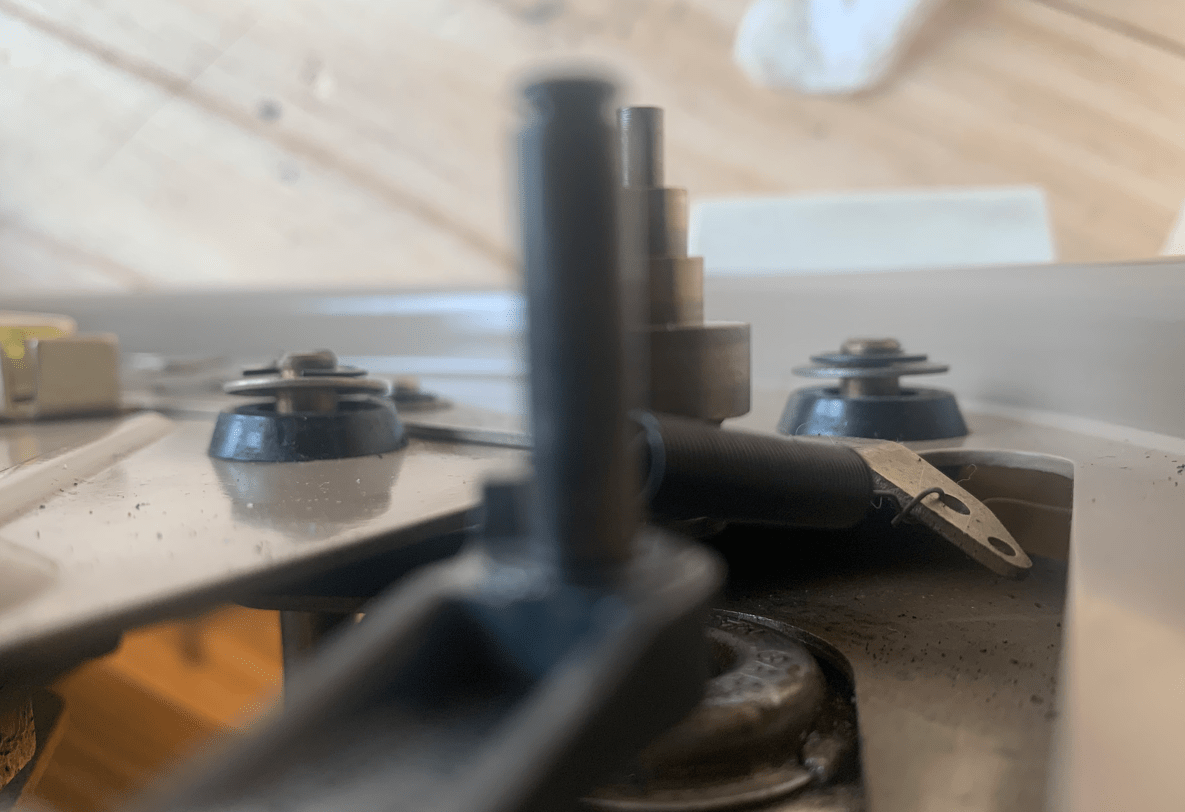

The motor does seem a bit loose but I'm no expert!

I can push the motor from the bottom and this allows the fixing bolts to move up slightly - should they be tight against the grommets, see here:-

I can push the motor from the bottom and this allows the fixing bolts to move up slightly - should they be tight against the grommets, see here:-

Donald, I'm not sure which of your question marks are intended to emphasise your uncertainty or to denote an actual question! 😉

If the rubber grommets have gone hard, they are in need of replacement.

The grommets should provide a tight but resilient grip which reduces the transmission of motor vibration to the chassis while holding the motor pulley securely in position. The free vertical movement you show is likely the result of the rubber shrinking and losing its grip.

The frequency of the speed variation may provide a clue as to its source.

Ebay is one source of replacement grommets and it's just possible that you can find a set that measures up to your requirements.

Without measurements, it is impossible to say that the Dansette grommets to which you link would fit.

The Voice of Music site may be helpful in relation to measuring the size: https://thevoiceofmusic.com/catalog/part_detail.asp?PNumberBase=M2

If the rubber grommets have gone hard, they are in need of replacement.

The grommets should provide a tight but resilient grip which reduces the transmission of motor vibration to the chassis while holding the motor pulley securely in position. The free vertical movement you show is likely the result of the rubber shrinking and losing its grip.

The frequency of the speed variation may provide a clue as to its source.

Ebay is one source of replacement grommets and it's just possible that you can find a set that measures up to your requirements.

Without measurements, it is impossible to say that the Dansette grommets to which you link would fit.

The Voice of Music site may be helpful in relation to measuring the size: https://thevoiceofmusic.com/catalog/part_detail.asp?PNumberBase=M2

Thanks Galu - most of what I write is intended to emphasise my uncertainty so is probably a question as well!

'The frequency of the speed variation may provide a clue as to its source.'

Looking at the graph in Post #103 above the pattern repeats about every 1.3-1.4 seconds (~44 rpm) - not sure what that tells me?

'The frequency of the speed variation may provide a clue as to its source.'

Looking at the graph in Post #103 above the pattern repeats about every 1.3-1.4 seconds (~44 rpm) - not sure what that tells me?

I was thinking that the frequency of speed variation equates more to a slowly rotating platter than a rapidly revolving motor.

60s divided by 45 rotations = 1.33 s per rotation.

Which leads me to suspect the platter bearing.

60s divided by 45 rotations = 1.33 s per rotation.

Which leads me to suspect the platter bearing.

As I mentioned above I can certainly strip down, clean and lubricate the man bearing again.

Job for tomorrow ... 🙄

Job for tomorrow ... 🙄

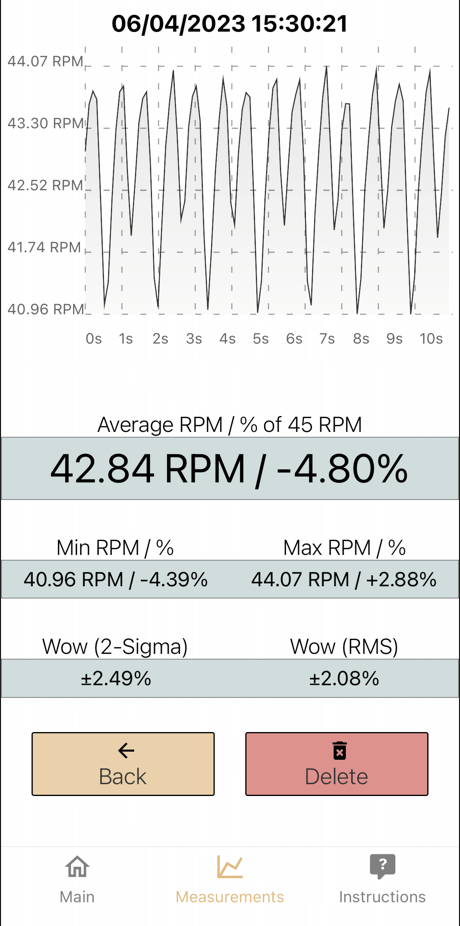

Ok, I've stripped down, cleaned and lubricated the main bearing again but have managed to make things worse :-

At least I know that I have a main bearing problem but nor sure about the cause or the solution?

At least I know that I have a main bearing problem but nor sure about the cause or the solution?

At least I know that I have a main bearing problem but NOT sure about the cause or the solution?

And just to complicate matters, the two felt washers on the idler wheel spindle have perished!

And just to complicate matters, the two felt washers on the idler wheel spindle have perished!

It's either the main bearing itself, or something else is cyclically interfering with the platter's rotation.

What's the purpose of the felt washers? Oil retention?

What's the purpose of the felt washers? Oil retention?

- Home

- Amplifiers

- Tubes / Valves

- PYE Stereo Black Box G63