I've been curious about that as well... Seas DXT, SB Satori TW29BNWG, it's a short list.What I wonder is, why aren't there more on the (DIY) market for the past decades?

The market seems ripe for a line of dome tweeters with good quality waveguides fully integrated.

good question! We have invested much effort in an optimisation flow using comsol and matlab. The process is fully automated and the algorithm uses typically 100-500 iterations to find the optimum geometry. As the latest we can optimise a waveguide to compensate for the diffraction of the box. such WG will simulate/measure a bit strange in infinite baffle but works like a dream in its designated box.

An important detail is that each wave guide has to be optimised to the particular dome and take its breakups into consideration. That means it’s very hard to do one size fits all waveguides. Tooling costs are high so it’s difficult for us driver vendors to stock many variants. Use of 3D print and CNC would be a way forward. WG optimisation could be a design service.

Yes great work!

I'd definitely second that statement. From my point of view, alignment of the respective tweeter dome and the enclosure has a hughe potential and is by far the most important advantage of DIY vs just combining a commenrcially avilable waveguide with a good tweeter.An important detail is that each wave guide has to be optimised to the particular dome and take its breakups into consideration. That means it’s very hard to do one size fits all waveguides. Tooling costs are high so it’s difficult for us driver vendors to stock many variants.

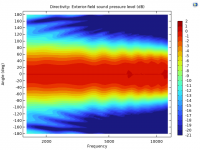

Just one example of a simulation series I did on the impact of dome shape and height on the directivity on concave and convex tweeter domes:

The image is showing both, concave and convex tweeter domes, starting form a flat membrane and then going in steps of 2.5, 5, 7.5, 10 and 12.5 mm high and deep, respectively.

Background at that time (2108) was to understand the very nice directivity of the Biesma Tweeter even in the high frequency range. Bliesma just hit the sweet spot with it's dome height (right side of th eimage, marked by a star). Pleaase note the nice (wide) directivity of concave domes in the high freuency range (accuton and the like), left side of the image.

Said that, tweeter dome geometry and directivity has to be considered when combining with a waveguide, i.e. with respect to the throat geometry when designing a waveguide.

I'll come back with simulations on that, if I'm successful finding them on my computer and if still there....

Little less??..... less than 1/5 of the price .... that's not a little - that's a LOT less 😉The T34A has 5dB more sensitivity and takes more power, goes lower (look at higher order THD), radiates wider at high frequencies and has a higher brake up frequency according to your measurements (but not the datasheet?). BUT - is a pain in waveguides.

Nevertheless for normal HiFi the SB26CDC looks really good - and costs are "a little" less 😊

Hi Augerpro 😀,

Did you have a PS version of the elliptical 8" and 6" D3004 6600 one ?

Thanks !

Did you have a PS version of the elliptical 8" and 6" D3004 6600 one ?

Thanks !

ok it's interesting, it will replace all previous one ? Elliptical and (new) rounds ?

may be new rectangular ones 😍 ^^

may be new rectangular ones 😍 ^^

I think what you are describing here is a great path forward for the DIY market. Tooling WGs for any tweeter that isn't in the top 5 best-selling is probably uneconomical and break-even at best. However, since it's the DIY market, I think this thread proves that 3D printed WGs are a pretty robust solution. Although woodworking is still the bread and butter of speaker builders, many can access 3D printing either themselves at home, or via relatively affordable printing services.Tooling costs are high so it’s difficult for us driver vendors to stock many variants. Use of 3D print and CNC would be a way forward. WG optimisation could be a design service.

Heck, a 3D printer costs less than one Bliesma tweeter - I think we can handle this. 😀

If manufacturers provided the files, the DIYers can handle the rest, and it should be a win-win. Especially if the WGs can be generated in a semi-automated optimization process, to me this seems like a low-ish incremental cost on top of developing and marketing a tweeter in the first place.

@augerpro has done more for this part of the DIY scene than basically anyone, but it would be very cool to see the top tweeter manufacturers "carry the torch" using COMSOL and other professional simulation / engineering software like you mentioned.

Today I tried the Scanspeak 6600 on the new hybrid contour waveguide. I had noticed a while ago, that these fabric domes don't usually play real nice with my constant radius contour, but others putting them on Visiton-like contours often have decent results. That was the main reason I've been wanting to try something like that contour: very fast flare right at the throat, followed by a much slower curve. Kind of like a typical OS, but OS have a conical section, which you don't usually find on the waveguides available to DIY. Anyway first try looks pretty good to me:

I also tried it with the R2904/7000, but I think I like my existing design on my website better. Proof that how the source radiates is just as important as teh waveguide itself, they have to match well.

I also printed a vB of the hybrid contour, but it was a slight step backwards for both the 6600 and 6640. But that tells me what have I have to change for a vC that should be better than vA or vB.

Before anyone asks about the hybrid contour with the SB26CDC/ADC or T25B, since both of these modeled accurately in ABEC, I had investigated the OS-SE contour pretty well, and my current contour is better. So I won't be trying it for those.

I also tried it with the R2904/7000, but I think I like my existing design on my website better. Proof that how the source radiates is just as important as teh waveguide itself, they have to match well.

I also printed a vB of the hybrid contour, but it was a slight step backwards for both the 6600 and 6640. But that tells me what have I have to change for a vC that should be better than vA or vB.

Before anyone asks about the hybrid contour with the SB26CDC/ADC or T25B, since both of these modeled accurately in ABEC, I had investigated the OS-SE contour pretty well, and my current contour is better. So I won't be trying it for those.

Ok thanks, it's very good !

So the Hybrid Contour will be available only for tweeter where your original Somasonus is nos as good so for the ADC it stay with the original version (that work very well by the way 😀), it's a very good way to do, keep the contour that works the best between each two depending of the tweeter.

I will wait your vC Elliptical 8" version of the hybrid contour for my D3004 so 😀, I will release a "bullet" version as for the ADC 6.5"

So the Hybrid Contour will be available only for tweeter where your original Somasonus is nos as good so for the ADC it stay with the original version (that work very well by the way 😀), it's a very good way to do, keep the contour that works the best between each two depending of the tweeter.

I will wait your vC Elliptical 8" version of the hybrid contour for my D3004 so 😀, I will release a "bullet" version as for the ADC 6.5"

Quick question. What would be the recommended crossover point for the SB26CDC in the 8” elliptical? I have a spare set of Dayton rs255-4 that might be a good candidate to cross with these. Did a search but no luck and haven’t had the chance to read 70+ pages fully yet.

Cheers for all the research and efforts!

Cheers for all the research and efforts!

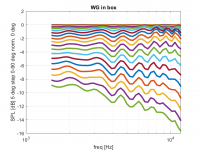

this is my best WG design so far. its optimised to work in a particular box. Here simulated in full 3D in comsol with the woofer included on the baffle (woofer cone cavity causes ripples). it’s an acoustics only simulation so effects from the mechanical domain are not included.

Attachments

Manufacturers should sell the file for 10-20 bucks - I bet many would happily buy that.If manufacturers provided the files, the DIYers can handle the rest, and it should be a win-win. Especially if the WGs can be generated in a semi-automated optimization process, to me this seems like a low-ish incremental cost on top of developing and marketing a tweeter in the first place.

But when you calculate 2 days of development time for it (the first one for sure takes way longer) or about €2000 R&D cost. Maybe €5,- per sale to cover the costs. Should be possible.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!