Thanks to augerpro and others for their initiative and creativity on this fantastic effort. I have made a contribution to augerpro’s GoFundMe campaign.

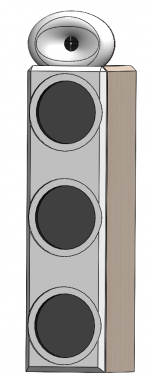

I recently completed a SB15CAC30-04 and SB26CDC two-way for my son using the 5” waveguide design that was printed by my other son in matte white. He wanted a small speaker with the “all-white” designer look and the SB15CAC30-04 modelled the “smallest” cabinet of the candidate midwoofers. See picture below.

I’m very happy with the sound of these. Crossover is about 2500 Hz. This was my first design with a waveguide and I plan to do more. Happy to share crossover details if anyone is interested.

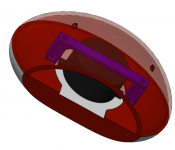

I was able to use the router template generously posted by BearX. I mounted the tweeter to the waveguide using “threaded rod” cut from a machine screw and set with epoxy into the waveguide. Pictures are posted below for anyone who has concerns or questions about how this is done.

Sorry if the picture orientation seems odd - I couldn't sort out how to upload the correct orientation.

Todd

I recently completed a SB15CAC30-04 and SB26CDC two-way for my son using the 5” waveguide design that was printed by my other son in matte white. He wanted a small speaker with the “all-white” designer look and the SB15CAC30-04 modelled the “smallest” cabinet of the candidate midwoofers. See picture below.

I’m very happy with the sound of these. Crossover is about 2500 Hz. This was my first design with a waveguide and I plan to do more. Happy to share crossover details if anyone is interested.

I was able to use the router template generously posted by BearX. I mounted the tweeter to the waveguide using “threaded rod” cut from a machine screw and set with epoxy into the waveguide. Pictures are posted below for anyone who has concerns or questions about how this is done.

Sorry if the picture orientation seems odd - I couldn't sort out how to upload the correct orientation.

Todd

Attachments

As I indicated in my previous post, I plan to do a couple more waveguide designs:

• One using the SB26CDC in a 6” waveguide with an MW16P-8, and

• One using the Peerless/Vifa OT19NC with an SB15NBAC-8.

Question for augerpro: The 5” waveguide model filename shown in the Peerless/Vifa OT19NC page of the somasonus website is “5x.75 A SS19 V2” which is the same filename as the 5” model in the ScanSpeak Revelator D2104/7120 page. Are the two files identical, or is there a different model and filename for the 5” waveguide model for the Peerless/Vifa OT19NC?

Thanks,

Todd

• One using the SB26CDC in a 6” waveguide with an MW16P-8, and

• One using the Peerless/Vifa OT19NC with an SB15NBAC-8.

Question for augerpro: The 5” waveguide model filename shown in the Peerless/Vifa OT19NC page of the somasonus website is “5x.75 A SS19 V2” which is the same filename as the 5” model in the ScanSpeak Revelator D2104/7120 page. Are the two files identical, or is there a different model and filename for the 5” waveguide model for the Peerless/Vifa OT19NC?

Thanks,

Todd

The Vifa fit perfect with the Scanpeak waveguide, so used it for both.

Great looking speakers! Definitely a great way to introduce your son to the hobby.

Great looking speakers! Definitely a great way to introduce your son to the hobby.

Hello

Here is a first print with help from NicoB for 3D modeling.

Still some work to do (fine tuning, sanding and painting...).

But first listening tests are just amazing.

Sb17 nbac (400Hz - 1800 Hz for now)

Sb26 adc

4th order LR slopes

Sb23 for bass duties in 40L BR box

Big thank you for your work, giving me the opportunity to create something really special [emoji4]

Best regards

Here is a first print with help from NicoB for 3D modeling.

Still some work to do (fine tuning, sanding and painting...).

But first listening tests are just amazing.

Sb17 nbac (400Hz - 1800 Hz for now)

Sb26 adc

4th order LR slopes

Sb23 for bass duties in 40L BR box

Big thank you for your work, giving me the opportunity to create something really special [emoji4]

Best regards

Yes 😀 , attached the next one lol, finally we do a plain front, tweeter fixation rotate 45° for be able to plug/unplug when tweeter is mounted, printed tweeter fixation larger than existing one, rear hole for pass Allen key...

glue in one piece then surface treatment + painting for both of us.

For me SB26ADC + Sica 6.5 H 2 CP + doble passive SB16PFCR-00

glue in one piece then surface treatment + painting for both of us.

For me SB26ADC + Sica 6.5 H 2 CP + doble passive SB16PFCR-00

Attachments

Although I'm not in love with that printed finish, I can tell the amount of effort that went into the work. Congrats!Hello

Here is a first print with help from NicoB for 3D modeling.

Still some work to do (fine tuning, sanding and painting...).

But first listening tests are just amazing.

Sb17 nbac (400Hz - 1800 Hz for now)

Sb26 adc

4th order LR slopes

Sb23 for bass duties in 40L BR box

Big thank you for your work, giving me the opportunity to create something really special [emoji4]

Best regardsView attachment 910951

5" SB26 w/SP.st

Hi I´m new about waveguides and 3d printings and think it´s a fantastic way to get a waveguide and I did send the file 5" SB26 w/SP.stl to a company in Sweden where I live and they said

"The file you sent seems to be on the wrong scale as it is about 5.8mm x

3.88mm x 0.83mm large"

Can anyone tell me about the waveguide exact dimension so they can change the scaling or do you have any other suggestions?

I would like to have suggestions about preferable materials for the waveguide

and if I shall use with or without the PS.

I have the aluminum tweeter SB26ADC-C000-4.

Hi I´m new about waveguides and 3d printings and think it´s a fantastic way to get a waveguide and I did send the file 5" SB26 w/SP.stl to a company in Sweden where I live and they said

"The file you sent seems to be on the wrong scale as it is about 5.8mm x

3.88mm x 0.83mm large"

Can anyone tell me about the waveguide exact dimension so they can change the scaling or do you have any other suggestions?

I would like to have suggestions about preferable materials for the waveguide

and if I shall use with or without the PS.

I have the aluminum tweeter SB26ADC-C000-4.

Units are in inches, they should be able to convert to that. I like SLS nylon process the best. Very tough, a little sandpaper-y feeling. I would use the phase shield if given the choice.

Actually had some questions on the phase shield.

I noticed that you are using a 0.25" diameter phase shield for the SB26 tweeters, the original is ~0.46". Going back through the thread I saw you mentioned it gave the best trade off of properties. From this thread it seems like a big improvement with the phase shield for the SB26 is in the distortion due to the breakup An interesting "budget" tweeter from SB Acoustics for hard dome fans.... Did you look into the distortion mitigation with your testing? Is the 0.25 still the recommended? Just a dramatic departure from the stock phase shield so had me wondering.

Did you ever evaluate ring shaped phase shields as in Wir basteln ein Waveguide oder Constant Directivity, wie geht das? - Seite 5?

My other question is on the phase shield supports. Is there a more desirable geometry or mounting point? I have re-done the model for my own mounting and was going to tweak the phase shield supports for my own aesthetics. I am assuming this isn't too critical given what I see in other tweeters.

I noticed that you are using a 0.25" diameter phase shield for the SB26 tweeters, the original is ~0.46". Going back through the thread I saw you mentioned it gave the best trade off of properties. From this thread it seems like a big improvement with the phase shield for the SB26 is in the distortion due to the breakup An interesting "budget" tweeter from SB Acoustics for hard dome fans.... Did you look into the distortion mitigation with your testing? Is the 0.25 still the recommended? Just a dramatic departure from the stock phase shield so had me wondering.

Did you ever evaluate ring shaped phase shields as in Wir basteln ein Waveguide oder Constant Directivity, wie geht das? - Seite 5?

My other question is on the phase shield supports. Is there a more desirable geometry or mounting point? I have re-done the model for my own mounting and was going to tweak the phase shield supports for my own aesthetics. I am assuming this isn't too critical given what I see in other tweeters.

Last edited:

The .25" phase shield was decided on for the frequency response measurements. I have not done distortion measurements. However I will be doing them soon to investigate an issue a user had with the T25B and I want to see if I can replicate it with both the T25B and SB26. Also have some waveguides to test for Scanpseak's most common 1" tweeters.

I had to make sure the phase shield would print without issue, that was the primary factor in the supports. I'm not sure there is much benefit to making it more aesthetically appealing in some way, so I haven't bothered.

I had to make sure the phase shield would print without issue, that was the primary factor in the supports. I'm not sure there is much benefit to making it more aesthetically appealing in some way, so I haven't bothered.

Now I got my waveguides

I decided to choose a PLA print.

Now I have to decide if and how I

should do with the surface and in that case how I should smooth it.

Don’t know how much the unsmooth surface are affekting the sound.

I decided to choose a PLA print.

Now I have to decide if and how I

should do with the surface and in that case how I should smooth it.

Don’t know how much the unsmooth surface are affekting the sound.

Attachments

I compared a SLS nylon print vs my own PLA print and they measured identically. Neither has a smooth finish, but are different, the PLA has the layers like you have, the SLS nylon has no layers but has sort of a sandpaper feel. I'm currently investigating ABS smoothed with acetone vapor for my box ports since smoothness did impact the performance in my measurements. Might be something to look at for waveguides.

BTW: make sure you use 4 layers for all sides. I can see some infill poking through in some areas.

BTW: make sure you use 4 layers for all sides. I can see some infill poking through in some areas.

Last edited:

should do with the surface and in that case how I should smooth it.

Don’t know how much the unsmooth surface are affekting the sound.

I dont think you should smooth it unless its for aesthetic reasons. Dr Geddes has been pretty clear that he doubts it matters.

if it where me, i'd build a whole speaker, validate the performance, and then make the waveguide look good

To my knowledge and experiments with XT25, 7100, 6600, 7000, R3004, they all have same mechanical interface to faceplate. D2604 will not be different. So they all should fit Augerpro waveguides, but it is better to have it confirmed from him.

Do you guys think that SS D2604/83xxx tweeter can be fitted to the WG made for the SS 6600?

Do you guys think that SS D2604/83xxx tweeter can be fitted to the WG made for the SS 6600?

Take off the faceplate and post a picture. I kind of doubt it will fit, the "standard" Scanspeak line have very distinctive shapes to the top plate aren't compatible with any other manufacturer, including Peerless and Vifa derived designs.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!