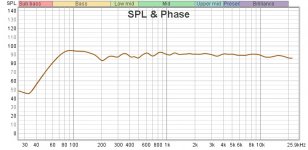

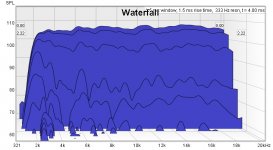

Fixed the problem with the tweeters and lowered the mid back down to 200hz(by far the best FR measurements at 50"), so now it's running from 200hz to 2khz(Again). the dip at 200hz is ceiling bounce. I'll mop everything else up with a little eq.

Attachments

Last edited:

The problem I was having at 2khz originally was due to not remembering to turn off all the PEQ's. Five of them to deal with.

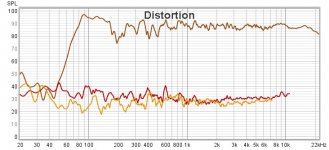

system distortion at 50". The 4" driver handles itself quite well down to 200HZ

Attachments

Last edited:

I have addressed a number of things at once with this design, and it will be very difficult to differentiate exactly what is being attributed to what. But what I'm hearing is ethereal(God, I hate subjective descriptions). There is something completely different going on here, and I've heard a lot of extremely expensive systems at Southern California audio shows going back to the early 90's. There is absolute total transparency, and this is with using inexpensive electronics. I Imagine that the baffle design has the most to do with it, with the high density felt interior keeping the internal acoustic reflections to an absolute minimum(obviously helps). The amount of labor involved was crazy. Total cost for materials, around $350. There are so many variables that need to be understood and controlled for on top of that.

As far as the parametric EQ goes, I don't think I'll be using it.

As far as the parametric EQ goes, I don't think I'll be using it.

Last edited:

Found a picture of the Sony ES SSM9ED's constrained layer baffle. I thought it would be more substantial. Looks like a layer of mdf, a very thin viscoelastic layer, and another thin layer of mdf.

which methods might have: ease of assembly and cost effective to create a functional constrained layer panel? Doe that Sony cabinet show the way to go and if so, what common inexpensive material might be used for the middle layer?

I have a 1955 Karlson "K12" - its got 5/8" plywood laminated to 1/8" hardboard/smooth Masonite on one side, and Formica on the other - somewhat dead. (some old plywood seemed to be more dead than Baltic birch plywood)

Your midrange driver has lower distortion than some pro stuff when looking at graphs from Voice Coil's Test Bench.

What happens on your system with the vocal on this old cut? Its obviously distorted in ways. On my Klipschorn the vocal had a reverberant "vibrant" sound. The same soundtrack song from my CD played on a mediocre combination of Eminence B102 and Morel CAT3-78 with 5.6uF cap as the only crossover element had a very dry and "uninspiring" sound. It like even the little Klipsch K400 horn exaggerated the reverb content - or did a better job of pulling it out of the mix. Maybe HOM are good for some music 😀

Ennio Morricone - A Gringo Like Me - YouTube

I have a 1955 Karlson "K12" - its got 5/8" plywood laminated to 1/8" hardboard/smooth Masonite on one side, and Formica on the other - somewhat dead. (some old plywood seemed to be more dead than Baltic birch plywood)

Your midrange driver has lower distortion than some pro stuff when looking at graphs from Voice Coil's Test Bench.

What happens on your system with the vocal on this old cut? Its obviously distorted in ways. On my Klipschorn the vocal had a reverberant "vibrant" sound. The same soundtrack song from my CD played on a mediocre combination of Eminence B102 and Morel CAT3-78 with 5.6uF cap as the only crossover element had a very dry and "uninspiring" sound. It like even the little Klipsch K400 horn exaggerated the reverb content - or did a better job of pulling it out of the mix. Maybe HOM are good for some music 😀

Ennio Morricone - A Gringo Like Me - YouTube

Hi Remlab, the sony cabinet is done the right way. A constrain layer usually is a combination of a thin viscouselastic layer sandwich between 2 dissimilar thickness material.If the layer is thick then u won,t have good shearing between layer.

vibration causing flexing motion is damped by shearing force between the 2 different thickness material. Only problems is the adhesive efficiency is highly temperature dependent . Another problem is its expensive and not widely available.

I am waiting for some viscoelastic glue from China . It is actually very cheap so not sur if its good or not but no harm giving it a try.

vibration causing flexing motion is damped by shearing force between the 2 different thickness material. Only problems is the adhesive efficiency is highly temperature dependent . Another problem is its expensive and not widely available.

I am waiting for some viscoelastic glue from China . It is actually very cheap so not sur if its good or not but no harm giving it a try.

Butyl is readily a available and is also used in CLD tiles for car door applications.

I've been using it between 2 dissimilar thickness alu baffles with good results.

I've been using it between 2 dissimilar thickness alu baffles with good results.

Then again, whatever Remlab used here works pretty good so far. No need to change strategy if it works. Sorbotane is an excellent damper.

Sorry for the slight OT but if we were to modify an existing box made of 15mm chipboard for instance....and assuming I am happy to lose the inner volume. I add a layer or 2 or those sticky cld sheets like used for vehicles, then I add a thin layer of mdf. What is the best way to fix this inner layer of mdf to the cld layer.?

Thanks

Thanks

It doesn't work like that, Jim. The CLD meant for car doors has a thin layer of aluminium and would not help your case. You can get butyl (often sold as butyl rope) and stick that between two layers of chipboard for CLD purposes. It's pliable and easy to form a thin layer between the two surfaces.

Attachments

Brilliant thanks. Yes I've used that butyl rope before. Would i just add a perimeter of it or attempt to cover the entire area?

And I guess this butyl acts as the adhesive to actually fix the mdf panels into the box?

And I guess this butyl acts as the adhesive to actually fix the mdf panels into the box?

I posted this earlier. I'll post again just in case anyone missed it..

US5949033A - Constrained layer damped loudspeaker enclosure

- Google Patents

US5949033A - Constrained layer damped loudspeaker enclosure

- Google Patents

- Home

- Loudspeakers

- Multi-Way

- Midrange experiment with Auto sound panel deadener and high density acoustic felt..