Evil! Truly EVIL!! Nearly as evil as da new fangle Osmium needles. 😱And I have used gramophone steel needles too.

Use THORN needles 🙂

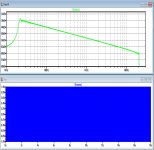

No its not.If that FFT of George's sweep come thru a flat preamp, how could it be anything but non-RIAA? It follows the line it should, more or less.

Lets ignore FFTs to start with. The 18s sweep is 20Hz - 20kHz like a B&K 2307 driving a 2010.

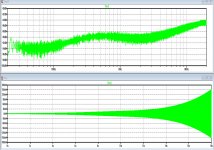

What we see in the #966 waveforms, is the sweep starting off at 20Hz at low level. By the time it reaches 17s (HF) it has risen by nearly 100x. This is entirely what I'd expect with RIAA EQ on the HFN002 sweep.

The #853 curves have ups & downs but are mostly 'flat' cos this was using a RIAA preamp.

A B&K 2307 chart recorder would rectify & plot the #853 curves and apply 'windowing' & 'smoothing' via its 'writing speed' & 'paper speed' parameters.

_____________________

But the FFTs we've seen on this thread so far are all seriously wonky. I show in #921 some of the effects using REW's FFTs

There are 3 important concerns

- HF response in particular, is wonky to the tune of 40dB or more

- far too much 'noise' in the FFTs

- the FFTs don't show the 'correct' flat or -3dB/8ve slopes for the corresponding EQ'd & non-EQ'd recordings.

I'll probably emulate B&K 2010 & 2307 in software with my 1980s compiler .. when I should really get to grips with 21st century tools. 😡

Last edited:

and of course Front wiggle with Tie Wire allows the compliance to be set with an engineering material & part, stainless steel wire, instead of a hunk of goo. AT seem to take this the most seriously.Front wiggle allows the tie wire to help set a 'precise' pivot location eg the AT compliance adjuster.

Then the goo can just do damping.

I guess I'll have to run my own analysis. The FFT posted is flat(ish), the graph is not.What we see in the #966 waveforms, is the sweep starting off at 20Hz at low level. By the time it reaches 17s (HF) it has risen by nearly 100x. This is entirely what I'd expect with RIAA EQ on the HFN002 sweep.

Goo!

YES!!! Then the goo can be REALLY good ... maybe good enough to help with the trade-offs that come with an extended shank (that there tie wire extends the shank) with maybe a lower the first resonant frequency ... blah blah blah ... FUN! And the goo is where there is likely to be a lot of bang for the buck.

At the risk of repeating myself, the world of goo is real sophisticated these days. Thanks to all those years of trying to protect PC disc drives against shocks, we now have exquisitely shaped grommets made of extraordinary elastomers that achieve well-defined and well-controlled damping, rather than the gobs of goo of yore. I wonder which, if any, cart makers have been in touch with the likes of EAR (here: https://earglobal.com/en/) for a swish bung? Len Gregory certainly found some good stuff for his cartridge isolator, somewhere ...

and of course Front wiggle with Tie Wire allows the compliance to be set with an engineering material & part, stainless steel wire, instead of a hunk of goo. AT seem to take this the most seriously.

Then the goo can just do damping.

YES!!! Then the goo can be REALLY good ... maybe good enough to help with the trade-offs that come with an extended shank (that there tie wire extends the shank) with maybe a lower the first resonant frequency ... blah blah blah ... FUN! And the goo is where there is likely to be a lot of bang for the buck.

At the risk of repeating myself, the world of goo is real sophisticated these days. Thanks to all those years of trying to protect PC disc drives against shocks, we now have exquisitely shaped grommets made of extraordinary elastomers that achieve well-defined and well-controlled damping, rather than the gobs of goo of yore. I wonder which, if any, cart makers have been in touch with the likes of EAR (here: https://earglobal.com/en/) for a swish bung? Len Gregory certainly found some good stuff for his cartridge isolator, somewhere ...

Yes, of courseI trust you mean 10db/decade (3 dB/oct)

May I refer to earlier postings where a discrepancy was found between your Riaa and your flat amp, their difference not reflecting the Riaa curve and that also D/A noise was contaminating the results.When this track is replayed through a RIAA preamplifier, the FFT at the output of the preamplifier shows the expected +/- 20dB ref. 1KHz (2nd attachment in post #910) so it must worth something.

Today I will make available a Riaa corrected 96kHz wavefile for an exponential sweep or chirp from 20Hz to 20Khz in 18sec, together with the envelope in time, corrected and uncorrected for Riaa, as well as the spectra belonging to both envelopes.

Playing this wavefile through your equipment could help you to find the source of anomalies in your chain.

Hans

YES!!! Then the goo can be REALLY good ... maybe good enough to help with the trade-offs that come with an extended shank (that there tie wire extends the shank) with maybe a lower the first resonant frequency ... blah blah blah ... FUN! And the goo is where there is likely to be a lot of bang for the buck.

At the risk of repeating myself, the world of goo is real sophisticated these days.

https://www.ortofon.com/microtech/technologies/technical-rubber. Ortofon certainly seem to have the capability and the research partners*. Whether they are 'bovvered' for their MI products is of course a completely different question. Their front wiggle top ends have platinum washers supporting the goop.

Agree there is bang for buck to be had. However I am not taking my AT150MLx apart for science quite yet.

But yes, goo is good 🙂

*Sure AT have the same being a big company and all. Interesting part is comparing how the MM and MC lines overlap for the same stylus/cantiliver.

Autopsy

You have reminded me that I have an AT-440MLa with a dead channel, and I think there may also be a dead AT-ML150OCC in the same box. Might get out the USB microscope in the next few days ...

I am not taking my AT150MLx apart for science quite yet.

You have reminded me that I have an AT-440MLa with a dead channel, and I think there may also be a dead AT-ML150OCC in the same box. Might get out the USB microscope in the next few days ...

Well, that's overstatement, but cantilever flex is far more significant to vinyl playback performance than common-knowledge would have us believe. Which view you subscribed to, at least at the start of this thread Richard, IIRC? So look how far we've come..........Cantilever modes are the answer to Life, the Universe & Everything

The common-knowledge concept of a rigid cantilever having an effective tip-mass interacting with springy vinyl to produce the top mechanical resonance is debunked.

There are corollaries and consequences since the cantilever is flexible. Motion of the stylus is not instantaneously conveyed to the generator end. At minimum, there is a frequency dependant phase shift which, AFAIK has never been discussed. However, for the DSPmeisters, one might see this as an opportunity to wade in and make corrections which have never been done before........

Essentially, the cantilever doesn't move as a rigid body, and vibrations are conveyed along it as transverse waves. A high speed video of the cantilever in action should show this....there are legends of an old film that shows exactly this 'the cantilever slewing about', but I've never seen it.

One can properly address and control the hf mechanical resonant system by design and selection, knowing what is actually moving, how and why. And in so doing, adverse side effects of wave propagation along the cantilever can be minimised.

I suspect this was probably known to a few cartridge designers back in the day, but tools available these days and speed at which we can work and simulate have moved on exponentially in the time since vinyl development was in its heyday.

I don't suppose you've even read White's paper, Richard? All his tests were at 6.32kHz, with a vinyl deformation of 100 ångströms, ie about 10nm....... in my book that is near enough to zero as makes no practical difference, consistent with skating/surfing as per discussions.Lucky are you claiming that 1/3 of the total damping is insignificant?

What he found was, under those conditions, the impedance provided by vinyl to stylus movement was dominanted by damping, rather than elasticity. He was able to quantify it, and at 2gf published a figure of about 0.15Ns/m.

If one subscribes to that model, no significant indentation is required for vinyl-stylus interface to provide about 0.15Ns/m of damping to stylus motion. Unless one thinks 100 ångströms to be significant. I think one can weakly interpret the Happ paper as supporting this, where he started out with a spring mass mass model for the tip end, and ended up with damping?

01.5Ns/m works out at about 1/3 of the total damping typically available, IMO. 1/3 of a small number is an even smaller number, but in a system typically woefully underdamped at lf cart-arm resonance, it would be typically significant.

The remainder of the damping comes from the suspension end bung, and tonearm bearing drag/friction which is relevant only if the headshell moves ie lf. Most of what matters to playback comes from the bung, typically, virtually all of it I would have said but White suggest some contribution from the vinyl-stylus contact. Typically all short of optimal, but that's another topic !

For similar reasons to White's paper, the bung has to primarily provide support for a free rotating pivot, whose pivot impedance is dominated by damping for audioband frequencies and beyond, small as it may typically be.

LD

Last edited:

Ooops! 😱 George's sweeps are indeed RIAA filtered on the LP, if he used a flat preamp. I could only get them flat by running them thru an RIAA curve before analysis. Then they were pretty flat thru most of the range.

gpapag -- thanks for the list of patents (post #962). So much more to study!

billshurv -- Re front vs. rear wigglers: Figure 1 in Karlov's paper in the Shure seminar series shows a drawing of Shure's design. His figure 5 shows the laminated pole piece structure that encases the MM armature. It appears that this is a push-pull magnetic configuration, simultaneously a front- and rear-wiggler with the magnet rocking about its center.

Re tie wires: In addition to Shure, the Stanton/Pickering cartridges (MI and MM) have tie wires, but in a slightly different configuration than Shure. My conjecture is that these tie wires primarily provide static vertical support for the stylus tracking force, relieving the elastomer "bung" of this load. Thus the bung's mechanical impedance can be tailored for other functions.

The wire possibly also serves as a manufacturing aid in positioning the armature within the surrounding metal carrier tube and in adjusting compliance and damping..

Lastly (and this is pretty far out!) the wire conducts heat from the armature outward to be dissipated in the cartridge body. I'm supposing that friction between the tip and groove generates some heat that raises temperature of the armature, and thus the bung. Since elastomers show a strong temperature dependency, perhaps this heat sinking helps stabilize cartridge performance.

ADC cartridges have no tie wire. In another forum, a former ADC engineer stated that he could always hear a tie wire. Perhaps a resonance in the steel wire? This designer also mentioned that ADC had to change the formulation of their rubber bung during the energy crisis when people lowered their home thermostats.

Re geometry: Whereas the Stanton/Pickering magnets, bungs, and metal shells have circular cross sections, those of the Shures are almost square, very slightly rhombic, with corners in the lateral and vertical directions. This geometry maintains orientation of the moving assembly (particularly the diamond tip) in use. Experience has shown that the circular cross section Pick/Stans can rotate axially with age -- a problem specially with nonspherical stylus tips.

Shure's nonsymmetric geometry allows them to adjust the bung's impedance separately to lateral and vertical motions. It would be interesting to measure differences in stylus impedance for lateral and vertical motions. Alas, beyond my capabilities.

billshurv -- Re front vs. rear wigglers: Figure 1 in Karlov's paper in the Shure seminar series shows a drawing of Shure's design. His figure 5 shows the laminated pole piece structure that encases the MM armature. It appears that this is a push-pull magnetic configuration, simultaneously a front- and rear-wiggler with the magnet rocking about its center.

Re tie wires: In addition to Shure, the Stanton/Pickering cartridges (MI and MM) have tie wires, but in a slightly different configuration than Shure. My conjecture is that these tie wires primarily provide static vertical support for the stylus tracking force, relieving the elastomer "bung" of this load. Thus the bung's mechanical impedance can be tailored for other functions.

The wire possibly also serves as a manufacturing aid in positioning the armature within the surrounding metal carrier tube and in adjusting compliance and damping..

Lastly (and this is pretty far out!) the wire conducts heat from the armature outward to be dissipated in the cartridge body. I'm supposing that friction between the tip and groove generates some heat that raises temperature of the armature, and thus the bung. Since elastomers show a strong temperature dependency, perhaps this heat sinking helps stabilize cartridge performance.

ADC cartridges have no tie wire. In another forum, a former ADC engineer stated that he could always hear a tie wire. Perhaps a resonance in the steel wire? This designer also mentioned that ADC had to change the formulation of their rubber bung during the energy crisis when people lowered their home thermostats.

Re geometry: Whereas the Stanton/Pickering magnets, bungs, and metal shells have circular cross sections, those of the Shures are almost square, very slightly rhombic, with corners in the lateral and vertical directions. This geometry maintains orientation of the moving assembly (particularly the diamond tip) in use. Experience has shown that the circular cross section Pick/Stans can rotate axially with age -- a problem specially with nonspherical stylus tips.

Shure's nonsymmetric geometry allows them to adjust the bung's impedance separately to lateral and vertical motions. It would be interesting to measure differences in stylus impedance for lateral and vertical motions. Alas, beyond my capabilities.

Charlie: Thanks, had missed the 'double wiggler that shure used. I should also rip apart an old A&R stylus I have (as I mentioned in the first post, the excel cartridge is used in so many places it would be interesting to see if that can be improved).

Other than the heat conduction I agree with everything that you say. I've been mulling over the production limitations of the different constructions and suspect that, once fully optimised on the line there is no method that stands out from the rest, although the ortofon method does seem to lend itself to more automated production.

Other than the heat conduction I agree with everything that you say. I've been mulling over the production limitations of the different constructions and suspect that, once fully optimised on the line there is no method that stands out from the rest, although the ortofon method does seem to lend itself to more automated production.

Last edited:

As to heating of cartridge suspension rubber, there's perhaps about 5mW of friction heat conduction via the cantilever, plus the losses from damping headshell motion which might well dominate, I suspect.

All of which ends up in the surface contact layer of the suspension rubber, which is probably where the action is in terms of properties. And, as Charlie says, those properties seems likely to be temp sensitive, as elastomers are.

So, intuitively, I'd rate the tie wire acting as a heatsink as and idea worth checking out.........

LD

All of which ends up in the surface contact layer of the suspension rubber, which is probably where the action is in terms of properties. And, as Charlie says, those properties seems likely to be temp sensitive, as elastomers are.

So, intuitively, I'd rate the tie wire acting as a heatsink as and idea worth checking out.........

LD

The metal stylus 'carrier' has a lot more surface area and area in contact with the suspension rubber in stylii I have seen tho. They should dominate any head flow.

Can you give exact details of how you have done this?Seems odd above 18Khz, but that may be an artifact.

This is the most sensible FFT (it is an FFT?) of George's sweeps that's appeared on this thread so far. 😱

_____________

The second pic is exactly what I expect for a 18s sweep. It has all the features I describe in #921 & #937.

But how have you applied the RIAA? Was it Minimum Phase?

How have you done the FFTs? What size? Windowing? Zero padding? bla bla 🙂

From this it appears that applying the RIAA pre-emphasis is giving the huge amount of 'noise' .. probably a 'windowing' effect. 😱

Last edited:

Actually, my view of the situation has always been Happ which I read when it first came out. IMHO, it is still the most comprehensive and accurate view.Well, that's overstatement, but cantilever flex is far more significant to vinyl playback performance than common-knowledge would have us believe. Which view you subscribed to, at least at the start of this thread Richard, IIRC? So look how far we've come..........

I've been lucky 🙂 enough to have read Happ again this Millenium and also White via friends.

But the only practical reason for participating in this exchange is cos we don't have access to Happ & his model.

In my naive way, I thought your model might be a workable substitute.

But only if it incorporates important boundary conditions.

I ask again ..

Does your model incorporate the effect of the bung on the 'first HF resonance'?

Additionally

Does it show the effects of damping introduced by stylus/vinyl on the 'first HF resonance'? By your own admission, this is about 1/3 the total damping.

Lastly

Do you intend to resurrect your mythical model? If not, I'll retire from the scene as the answers to the above questions would have no practical significance.

I used HOLMImpulse. It can compare two files to each other, although it isn't always trouble free. I compared George's sweeps to computer generated sine sweeps that I made. But for the graphs posted, George's files were run thru a software RIAA filter to flatten them, which is why they appear flat on the graph.Can you give exact details of how you have done this?

I did look at George's sweeps, they are indeed from 20Hz to 20kHz. They do seem to have been RIAA EQ'd before they were cut.

- Home

- Source & Line

- Analogue Source

- mechanical resonance in MMs