Time for a humor break

I just pulled out an old Columbia LP with a note on the back about how you should change your osmium needles every 50 hours. Seems the devil is in the details and the world was always rife with disagreement on these issues.

EDIT - And what do you know they're fake.

I just pulled out an old Columbia LP with a note on the back about how you should change your osmium needles every 50 hours. Seems the devil is in the details and the world was always rife with disagreement on these issues.

EDIT - And what do you know they're fake.

Preliminary analysis by x-ray fluorescence spectroscopy at the Center for Microanalysis of Materials, University of Illinois (partially supported by the U.S. Department of Energy under grant DEFG02-91-ER45439) indicates that there is absolutely no osmium in this needle.

Attachments

Last edited:

Patent search is the next step

Attachment may help

as the plastic surround is a key stiffener in what is otherwise a wobbly metal box!

I have my M97xE superglued, my AT-110E epoxied.

(next stop, Longhorn mod)

I downloaded them

Good to know, thanks Ricardo.

Scott, how did the kebab-tzatziki event go?tomorrow

George

Attachments

Thank you for another interesting post, Charlie.I would not totally discount the stiffness and damping loss at the groove-tip interface. Wouldn't the relative importance of stylus groove springiness and cantilever flexure depend on specific engineering design? As more delicate pickup designs evolve to lower tracking force the relative importance of the former decreases and that of the latter increases.

In formulating my FORTRAN model I applied the experimental results of James V. White in his paper "An Experimental Study of Groove Deformation in Phonograph Records" (J.AES 18,5, Oct 1970, pp.497-506) which was based on his Ph.D. dissertation at Harvard University.

Abstract: "Groove deformation has been analyzed in the literature primarily in terms of classical elasticity theory, which is based on assumptions that are not appropriate for stylus-groove contact. To determine the actual deformation-force relations, complex groove impedances have been measured as a function of tracking force, groove speed, etc. The results obtained are contrasted with classical predictions."

White used custom vinyl pressings to determine the complex mechanical groove impedance presented to the playback stylus as a function of tracking force, groove speed, etc.

A few of White's conclusions that are perhaps pertinent to the current discussion are: (1) "Hertzian theory incorrectly describes the groove deformation even when tracking force is small enough to preclude macroscopic plastic deformation. The grooves were softer at small tracking forces, and harder at high tracking forces than Hertz's theory predicts." White cites numerous reasons explaining why Hertz's theory does not apply to phonographs. (2) "Experimental results ... at 6.32 kHz with a 0.7 mil stylus showed that losses were small at audio frequencies and that the resistance function was inversely proportional to the groove velocity in the range from 0.30 to 0.45 m/s. The hardness function, on the other hand, was independent of the groove velocity."

I like White's paper, perhaps the best experimental attempt at investigation of groove deformation AFAIK. If one takes results at face value, and addressing your first question, at 2gf VTF the spring constant the author obtains for vinyl deformation is c x 33 times stiffer than a typical cantilever self-flex spring, using classic bending physics, I calculate. For a 6mm long 0.46mm diameter hollow Al tube cantilever with 0.05mm thick walls.

So, if that paper had used the same method applied to driving the shank end of the cartridge, the impedance obtained would have been dominated by cantilever flex, as (it seems) must be real vinyl playback.

Also, at face value, vinyl compliance result is about 3 orders of magnitude lower than that of the suspension bung, at 2gf VTF.

This illustrates why vinyl indentation, not to be confused with cantilever flex, is insignificant in the scheme of things IMO. According to the paper, indentation in a plain groove at 2gf VTF works out to a depth of a few hundred nm, about the length of a vinyl molecule, and I think this is consistent with some of our discussions as to skate/surf.

What I also find interesting, and I had forgotten, is that the paper publishes figures for the lossy part of the vinyl/groove impedance, ie damping. This works out about 0.15Ns/m for 2gf, which is perhaps about 1/3 of the total typically observed in cartridge mechanics, about the same contribution as arm bearing friction, perhaps. And I think one might read between the lines of the Happ paper that this is the key contribution in his model, perhaps?

The above discussion takes the White paper at face value, and I hope that is the case. However, if one were doing a peer review one might enquire as to compliance elsewhere in the system, such as bulk vinyl, platter, support apparatus for the 'tonearm', the tonearm itself.......because dimensions involved are so small.

I do buy it. And, like the Happ paper, it's the detail and interpretation that matters, IMO. I don't see contradiction in either of these papers.

LD

Last edited:

. Any capacity or interest?

Interest huge, current capacity minimal 🙁

George: Thank you. I will start collecting those and reading.

Trust some of the reasons are now more clear, Richard. You need to read Happ's paper critically, with the points in mind as per previous recent posts. You'll find no contradiction.lucky, I note your continual vehement denial of vinyl compliance even in the face of Happ's most careful study of the complete problem.

I'd hope by now the penny has dropped that this isn't primarily a matter of eq. More about the nature of non-linearities concerning slew rate restrictions, the nature of group delay for stylus movement as programme material propagates along the cantilever under a dispersive law, and about factors influencing trackability, and perhaps wear....this evidence is useful for other practical stuff like digital EQ for cartridges.

Covered in discussion already 🙄...I've asked you this a couple of times without a response.

LD

Last edited:

Thank you Hans.

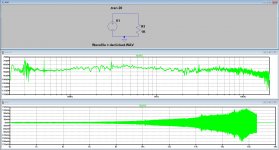

This is close to what I get (1st attachment in post #910, before doing the declicking).

I consider that the FFT shows the track to be flat (no RIAA emphasis applied during disk cut).

What do you think?

Ricardo disagrees with the flat track.

I don't want to put him under time pressure, so let's wait.

George

This is close to what I get (1st attachment in post #910, before doing the declicking).

I consider that the FFT shows the track to be flat (no RIAA emphasis applied during disk cut).

What do you think?

Ricardo disagrees with the flat track.

I don't want to put him under time pressure, so let's wait.

George

Scott, how did the kebab-tzatziki event go?

George

Very well, thankyou.

Thank you Hans.

This is close to what I get (1st attachment in post #910, before doing the declicking).

I consider that the FFT shows the track to be flat (no RIAA emphasis applied during disk cut).

What do you think?

Ricardo disagrees with the flat track.

I don't want to put him under time pressure, so let's wait.

George

I agree that LTSpice is close to what you got, BUT ...

I als agree with Ricardo that playing Riaa corrected pink noise through a flat amp does not produce a flat FR, see upper image below.

Applying Riaa correction to your recording should have produced a straight 10dB/octave downslope, which it doesn't.

See lower image below.

This just proves that the sweep on your LP (in combination with your flat amp) cannot be used for accurate measurement purposes.

Hans

Hans

The track is not pink noise. It is a sinusoidal wave frequency sweep 20Hz to 20KHz.

If the FFT of the flat playback of this vinyl track is the one you showed, the question is: Is this frequency sweep vinyl track cut as flat or cut with RIAA emphasis?

George

The track is not pink noise. It is a sinusoidal wave frequency sweep 20Hz to 20KHz.

If the FFT of the flat playback of this vinyl track is the one you showed, the question is: Is this frequency sweep vinyl track cut as flat or cut with RIAA emphasis?

George

For clarification, I mean vinyl deformation is about 33 times stiffer than a typical cantilever self-flex spring. By c, I meant 'circa', not some constant 'c'..........(!).... at 2gf VTF the spring constant the author obtains for vinyl deformation is c x 33 times stiffer than a typical cantilever self-flex spring, using classic bending physics, I calculate. For a 6mm long 0.46mm diameter hollow Al tube cantilever with 0.05mm thick walls.

LD

Hans

The track is not pink noise. It is a sinusoidal wave frequency sweep 20Hz to 20KHz.

If the FFT of the flat playback of this vinyl track is the one you showed, the question is: Is this frequency sweep vinyl track cut as flat or cut with RIAA emphasis?

George

George,

I'm sure the sweep is an exponential sweep, giving the same 10dB/8ve downslope as pink noise.

So the verdict stays exactly the same:

From your recordings it shows that you cannot use this LP for an accurate FFT measurement, that's the only conclusion that can be made.

You probably better use pink noise instead of this not so perfect exponential sweep, this will most likely give you more reliable FR results.

Hans

osmium needles

Is that what you use for playing your Donnie Osmium records?

Is that what you use for playing your Donnie Osmium records?

In that case you would want the groove wear. There was a small amount of seriousness in my joke, there was a long history of real record/needle wear before the modern era. I don't think the transition was abrupt and a lot of folks probably had lasting assumptions about this being a problem. I have plenty of LP's that I've played many times over 40yr. The ones that date from my GE one piece ceramic cartridge days are worse for the wear, but the ones that have never seen anything but Shure or Grado are a different story.

there was a long history of real record/needle wear before the modern era.

The ones that date from my GE one piece ceramic cartridge days are worse for the wear, but the ones that have never seen anything but Shure or Grado are a different story.

Same story here.

And I have used gramophone steel needles too. Needle wear after a few plays (shellac records) obvious to naked eye.

Like water erodes the rock (or woman takes down a man)

George

George,

I'm sure the sweep is an exponential sweep, giving the same 10dB/8ve downslope as pink noise.

I trust you mean 10db/decade (3 dB/oct)

So the verdict stays exactly the same:

From your recordings it shows that you cannot use this LP for an accurate FFT measurement, that's the only conclusion that can be made.

When this track is replayed through a RIAA preamplifier, the FFT at the output of the preamplifier shows the expected +/- 20dB ref. 1KHz (2nd attachment in post #910) so it must worth something.

You probably better use pink noise instead of this not so perfect exponential sweep, this will most likely give you more reliable FR results.

Now, where lies the problem ? 😕😕

See attachment In this post (take out the cyan line)

http://www.diyaudio.com/forums/analogue-source/303389-mechanical-resonance-mms-68.html#post5061869

George

Same story here.

And I have used gramophone steel needles too. Needle wear after a few plays (shellac records) obvious to naked eye.

Like water erodes the rock (or woman takes down a man)

George

My grandmother had an old wind-up gramophone when I was a kid, no electrics, steel needles. Some of those old 78s sounded pretty good considering.

If that FFT of George's sweep come thru a flat preamp, how could it be anything but non-RIAA? It follows the line it should, more or less. And that's about what I get, too, on a Stanton cart. IIRC, George's Shure cart was flatter in the same track.

the paper publishes figures for the lossy part of the vinyl/groove impedance, ie damping. This works out about 0.15Ns/m for 2gf, which is perhaps about 1/3 of the total typically observed in cartridge mechanics, about the same contribution as arm bearing friction

At last !!! A chink in the armour of da Religious Fundamentalist "Cantilever modes are the answer to Life, the Universe & Everything" believers. 😀For clarification, I mean vinyl deformation is about 33 times stiffer than a typical cantilever self-flex spring.

Lucky are you claiming that 1/3 of the total damping is insignificant? 😱

And BTW, arm bearing friction has little to do with the first HF resonance though it is important for the arm/cartridge LF resonance.

_______________________

But I DO want to know if YOUR mythical model includes details of da rubber bung.

If it doesn't, it is seriously flawed. The evidence for this isn't just in Happ but is something I've tried for real and relatively easy for any one this Millenium with eg an Ortofon or ADC MM/MI cartridge.

I've asked you this a couple of times without a response.

Actually it hasn't 😱Covered in discussion already 🙄

Are you claiming da bung has no effect on the first HF resonance??

Unlike your 'no vinyl deformation' heresy which is of no practical importance .. this is of intense interest to those who want to swap cantilevers. 🙂

It might lead to better cartridges .. like my Jurassic experience with various ADCs.

- Home

- Source & Line

- Analogue Source

- mechanical resonance in MMs