Thank you guys for adding in your requirements. Good news is boardhouse is up and running from today.

Already placed the orders for the LT4320 CRC PSU.

Just about reviewing final designs for SMD and THT rectifiers before shooting the gerbers.

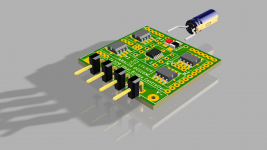

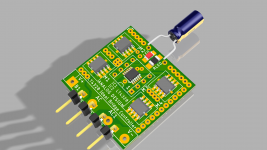

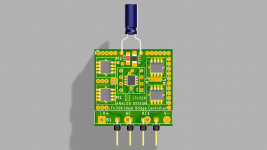

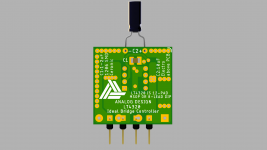

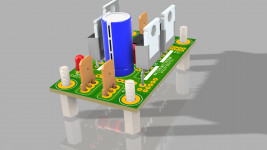

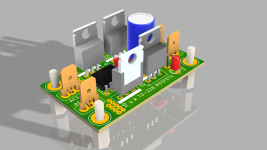

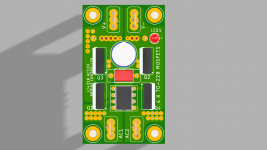

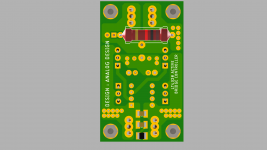

Here are some pics for LT4320 SMD. Everything looks good 🙂

shown here with MSOP package , DIP can instead be used.

Also shown are the headers spaced 5.08 mm apart.

The other header holes are compatible with SIP-4 rectifiers (PB3510). Also PCB size corresponds to Vishay PB3510 rectifier.

https://www.mouser.in/datasheet/2/427/pb3506-1767492.pdf

regards

prasi

Already placed the orders for the LT4320 CRC PSU.

Just about reviewing final designs for SMD and THT rectifiers before shooting the gerbers.

Here are some pics for LT4320 SMD. Everything looks good 🙂

shown here with MSOP package , DIP can instead be used.

Also shown are the headers spaced 5.08 mm apart.

The other header holes are compatible with SIP-4 rectifiers (PB3510). Also PCB size corresponds to Vishay PB3510 rectifier.

https://www.mouser.in/datasheet/2/427/pb3506-1767492.pdf

regards

prasi

Attachments

Last edited:

Hello Prasi,

what for layout tool are you using now?

Round SMD pads up will be helpful for reflow mask.

SMD Mosfet on both side?

JP

what for layout tool are you using now?

Round SMD pads up will be helpful for reflow mask.

SMD Mosfet on both side?

JP

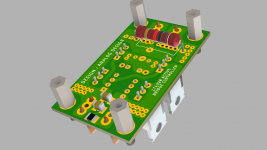

Here is for THT. Everything looks good 😉.

Off to boardhouse...

size 55 x 32.5 mm, about same as earlier. Bloody led can be made to bleed the caps with the 3 Watter. if not , options given for resistor pitch.

Off to boardhouse...

size 55 x 32.5 mm, about same as earlier. Bloody led can be made to bleed the caps with the 3 Watter. if not , options given for resistor pitch.

Attachments

Last edited:

Hi Prasi,

...seems that I've made mistake and my posting didn't shop up as it should.

Right : I've added 2 x LT4320 THTs to the list.

Thanks for your tireless efforts.

Siggi

...seems that I've made mistake and my posting didn't shop up as it should.

Right : I've added 2 x LT4320 THTs to the list.

Thanks for your tireless efforts.

Siggi

Last edited:

Hello Prasi,

what for layout tool are you using now?

Round SMD pads up will be helpful for reflow mask.

SMD Mosfet on both side?

JP

Hi JP,

I use eagle.

Rounded=

= advantageous for lead free solder

= advantageous for lead free solderNo mosfets on both sides

regards

prasi

Hello all,

thanks for adding in your requirements. Its looking to become another big GB.

I am thinking to make the THT in 2.4mm thickness and SMD (as was discussed earlier) in 1.6 mm thickness. Both will be ENIG, 70um copper.

CRC PSU will be same as earlier 2.4mm, 70 um, HASL.

regards

Prasi

P.S. To, member "tantalum nitride" I dont see any requirements mentioned against your name.

thanks for adding in your requirements. Its looking to become another big GB.

I am thinking to make the THT in 2.4mm thickness and SMD (as was discussed earlier) in 1.6 mm thickness. Both will be ENIG, 70um copper.

CRC PSU will be same as earlier 2.4mm, 70 um, HASL.

regards

Prasi

P.S. To, member "tantalum nitride" I dont see any requirements mentioned against your name.

I am working on a new design of the LT4320 with following changes

1. removal of snubbers

2. size optimization for smaller footprint (SMD could be same as Vishay PB3510 SIP rectifiers in terms of width)

3. MSOP LT4320 chip option along with earlier DIP option

4. LED indication for THT also (is it really necessary?)

5. 2.4 mm thick, 70 um copper with ENIG finish

I will post here when design is done and see the interest for such PCBs.

Regarding ENIG finish, respected member EUVL/Patrick had this to say on another thread:

UDNeSS, or You don't need Semisouth's

Regarding ENIG finish, respected member EUVL/Patrick had this to say on another thread:

UDNeSS, or You don't need Semisouth's

The ENIG finish is flat and smooth, making alignment and soldering of SMD components a bit easier and less chance of solder bridges between the tiny device legs versus using a HASL finish.

Last edited:

Ha Prasi,

Is the list still open to (pre) order? I just got pointed to this thread and would be very interested to have a quantity of thu-hole rectifier PCBs (guess that would be the THT LT4320 pairs right?

Thanks Leonard

Is the list still open to (pre) order? I just got pointed to this thread and would be very interested to have a quantity of thu-hole rectifier PCBs (guess that would be the THT LT4320 pairs right?

Thanks Leonard

Hi Leo,

Thanks for your interest. yes list is still open. . I have ordered plenty to take care of present and future requirements.

Yes, THT LT4320 = through hole rectifier board pairs.

regards

Prasi

Thanks for your interest. yes list is still open. . I have ordered plenty to take care of present and future requirements.

Yes, THT LT4320 = through hole rectifier board pairs.

regards

Prasi

Hi Prasi, that is good news!

Is there a price indication for a pair of PCBs? Not that is matters that much but it would help 🙂

Is there a price indication for a pair of PCBs? Not that is matters that much but it would help 🙂

Hi leo,

tentative pricing is in post LT4320 based active rectifier

and post 744 contains the link for google sheet to indicate the requirement of each type.

regards

prasi

tentative pricing is in post LT4320 based active rectifier

and post 744 contains the link for google sheet to indicate the requirement of each type.

regards

prasi

Hi Prasi, I just updated the order form. Not experienced with these shared Xcel sheets so I hope you have the update.

Thanks so much Leonard

Thanks so much Leonard

- Home

- Group Buys

- LT4320 based active rectifier