microphonics comes from low tension winding -- fast/high speed winding which traps air between layers. Besides making for microphonics, any air pockets represents a potentail breakdown point .... lowered reliability when stressed near rated voltage (or lower). The next step is to anneal the part and fuse all the layers together into a solid mass. This slow process is usually not done on low cost caps. REL's RTX is annealed, though.

THx-RNMarsh

THx-RNMarsh

Last edited:

Do they vacuum treat the rolled/folded layers to extract most of the air?

Would that stay extracted by enclosing inside some plastic package?

Would that stay extracted by enclosing inside some plastic package?

Hi Andrew,

As Richard said,

-Chris

As Richard said,

This would exclude the air as the material has bonded together. The cap is only to provide physical protection for the actual capacitor.The next step is to anneal the part and fuse all the layers together into a solid mass. This slow process is usually not done on low cost caps.

-Chris

yellow Wima are old polycarbonate from memory

Exxelia (was eurofarad) still make polystyrene-capacitors caps

the Nissei copper foil Styrene caps are getting rarer and expensive on ebay

Exxelia (was eurofarad) still make polystyrene-capacitors caps

the Nissei copper foil Styrene caps are getting rarer and expensive on ebay

Attachments

Higher temperature annealing will expell some air from between the layers, but I suspect not nearly as much as a vacuum treatment.

Hi tvi,

Thanks for pointing them out. We have very few options on this continent.

It would be great if those could be ordered at reasonable prices here.

-Chris

Thanks for pointing them out. We have very few options on this continent.

It would be great if those could be ordered at reasonable prices here.

-Chris

HP used a 7th order LC passive filter in the 3581C. Each section has to be tuned. This would only be good for a fixed frequency.

That's how I took the data for my 797 pre-print there was not a better option. I had a Soundtech 1700a and filtered the oscillator with film cap/air core inductors down another 30db or so. Had to put the whole setup on a wooden stand.

Hi Richard,

At Rel Cap, when Bas was making the caps that you helped design

were these some of the special winding machines used to make

the multi wound capacitor?

Please click the pic to zoom in on the cap and the pic from

the Rel Cap catalog.

Shown here is the PPMFX

cap that I'm going to use (one of three different caps, 20uf total)

as tweeter protection in series with the neg line at the tweeter.

It's like 2.5" x 1"x1/2" large. We think we should be fine as that is

around 2kHz fco. I'll actually bring in the tweeter at about 2.5kHz

so there should be no capacitor artifacts.

You can also imagine my surprise when with an old amp I purchased

the "tech" I got it from has bypassed the large coupling caps which

were .22uf x 600V RTX film and foils. He bypassed them with the

crappy metalized poly caps with the spray end caps. : (

What a way to ruin arguably the best performing cap on the market.

It's always nice to meet the daddy of one of these. : )

At Rel Cap, when Bas was making the caps that you helped design

were these some of the special winding machines used to make

the multi wound capacitor?

Please click the pic to zoom in on the cap and the pic from

the Rel Cap catalog.

Shown here is the PPMFX

cap that I'm going to use (one of three different caps, 20uf total)

as tweeter protection in series with the neg line at the tweeter.

It's like 2.5" x 1"x1/2" large. We think we should be fine as that is

around 2kHz fco. I'll actually bring in the tweeter at about 2.5kHz

so there should be no capacitor artifacts.

You can also imagine my surprise when with an old amp I purchased

the "tech" I got it from has bypassed the large coupling caps which

were .22uf x 600V RTX film and foils. He bypassed them with the

crappy metalized poly caps with the spray end caps. : (

What a way to ruin arguably the best performing cap on the market.

It's always nice to meet the daddy of one of these. : )

Attachments

Last edited:

I've seen some yellow Wima's but I don't have any handy--that I know of.

Yellow Wima, probably polycarbonate.

Attachments

Hi Richard,

At Rel Cap, when Bas was making the caps that you helped design

were these some of the special winding machines used to make

the multi wound capacitor?

Please click the pic to zoom in on the cap and the pic from

the Rel Cap catalog.

Shown here is the PPMFX

cap that I'm going to use (one of three different caps, 20uf total)

as tweeter protection in series with the neg line at the tweeter.

It's always nice to meet the daddy of one of these. : )

yes, the machine was a newly made one under a NDA to not sell the machine design to others. The MIT logo is there in the early dayz as they were first exclusive to sell to audiophiles. Now the Multicap name has stuck but anyone can buy thru REL-CAP distributors or directly (for large vol).

It is annealed.

THx-RNMarsh

Last edited:

Thanks for posting this. I bought one of the Panasonic 2722's on eBay that you mentioned before and was looking for something to benchmark against. I'm between houses - and workbenches - now and just using a loop-back to learn about the thing.

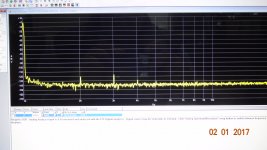

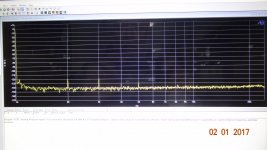

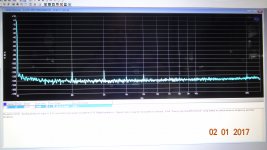

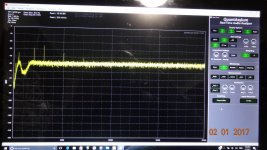

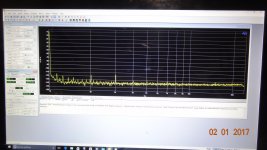

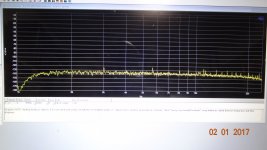

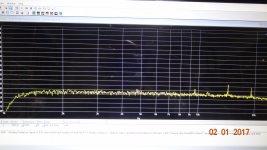

The FFT measured on an AP 2722 on 3 generators:

KH 4402B mod.

AP 2722

Panasonic 7722

View attachment 589075

View attachment 589076

View attachment 589077

I need better generators !!

THx-RNMarsh

That looks like analyzer residual.

Why not use the Shibasoku and run the 725 monitor output into the 2722 in spectrum mode.

Concur. Pls measure Rdg ratioThat looks like analyzer residual.

Why not use the Shibasoku and run the 725 monitor output into the 2722 in spectrum mode.

Attachments

Richard,

i can follow the arguement for film and foil caps for high current crossover applications. The literature for the Multicaps also refers to filter networks like servos, what performance inprovement in that type of application over a cap like Wima FKP film/foil or MKP metalized end attachment?

i can follow the arguement for film and foil caps for high current crossover applications. The literature for the Multicaps also refers to filter networks like servos, what performance inprovement in that type of application over a cap like Wima FKP film/foil or MKP metalized end attachment?

- Home

- Design & Build

- Equipment & Tools

- Low-distortion Audio-range Oscillator