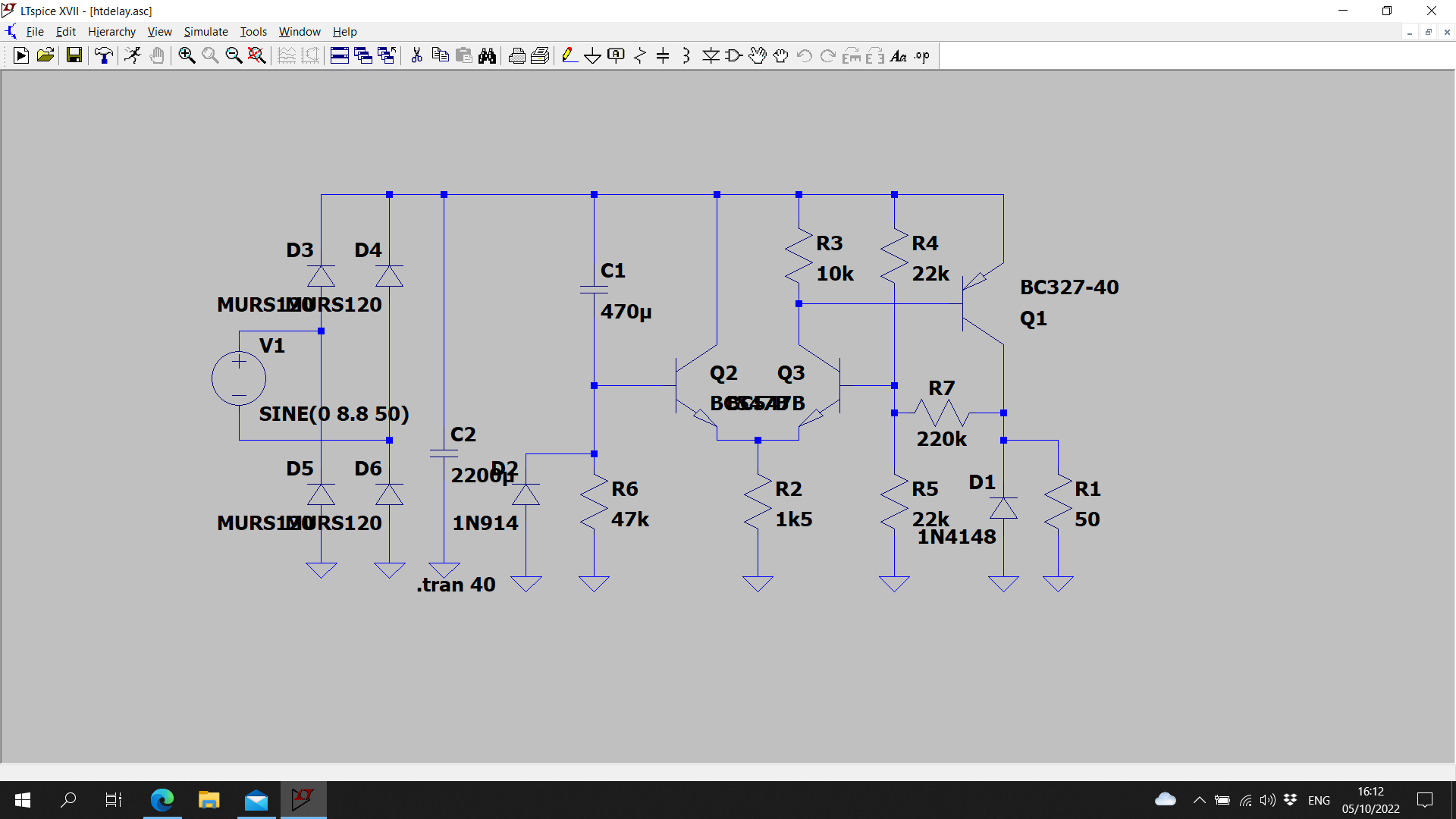

I have a B+ delay. It's two 2k2 very watty resistors connected in series with each AC HT winding shorted out with a relay. But the grids are held negative too on the KT88's so the main caps can charge. Here's my implementation R1 is a 6V double pole relay, V1 is 6.3V AC. You could use an additional small relay to do the grids. A 7555 timer may be simpler. As for the transformer using two 3A windings will be fine.

Last edited:

One problem with most B+ delay's is that instead of current rising slow and controlled during

tube warmup current slams on violently when a relay closes.

This causes current pulses that might be dangerous to the tubes, and also might create

instabilities that actually damages output tubes.

This is very sad since there is no need to delay B+ for Kt88 type tubes. The only reason is

that marginally limited electrolytic caps will have overvoltage before the tubes start to load

B+ and thus reduce the voltage.

tube warmup current slams on violently when a relay closes.

This causes current pulses that might be dangerous to the tubes, and also might create

instabilities that actually damages output tubes.

This is very sad since there is no need to delay B+ for Kt88 type tubes. The only reason is

that marginally limited electrolytic caps will have overvoltage before the tubes start to load

B+ and thus reduce the voltage.

Thanks! It was a great ride so far. I must say I was pleasantly surprised by the sound. The noval tubes are using a separate toroidal transformer and two LM317 ic's to provide 6.3Vdc in the heaters. I totally agree that the limitation is the heat when it comes to transformers. I will most probably use each 3A winding for a channel and see if this is ok long term. Heater voltages on the kt88s were 6.3Vac, so it should be fine.Congratulations!It was enjoyable looking over your shoulder as you put it all together. Great job!

Regarding heating your tubes - how are you heating the noval tubes now? As far as the KT88: As hooked up now, do you get close to 6.3 Vac across the heaters? My belief is that the ratings of a power transformer is limited by the overall heat generations in the coils and the dissipation thereof, more that the current limitation of wire in individual coils. So, I think drawing 3.2A rather than 3A from a coil should not be a problem if the whole transformer stays at acceptable temperature. If I were you I would heat each pair of KT88 with one 6.3V, 3 amp coil (as long as you get ~6.3 v) and monitor the power transformer temperature carefully until I’m convinced it stays benign.

Just a short update regarding the filament windings I mentioned above. I measured the currents between the paralleled windings and these are around 1.5uA. So basically zero 🙂. This is the same for the smaller 2A winding. So in my opinion there is no problem to have all three windings in parallel (3A + 3A + 2A). The mains transformer still gets hot but now at least I'm not stressing it outside its specs. I measured a bit below 60C on top of it (it's potted inside a metal enclosure) after 3h of continuous music playing. The transformer does not have anything specified about it's thermal performance in the datasheet so I contacted Toroidy and they quickly replied and told me that 75-80C is considered normal for this transformer and that it should never get above 115C. They also mentioned that it does not have a thermal fuse inside the windings. Considering that I measured a bit below 60C, I would say that inside the transformer it was 75-80C. So it should be fine.

In the coming days I will post the latest version of the schematic and BOM so that you guys can build it as well if you want to do so.

In the coming days I will post the latest version of the schematic and BOM so that you guys can build it as well if you want to do so.

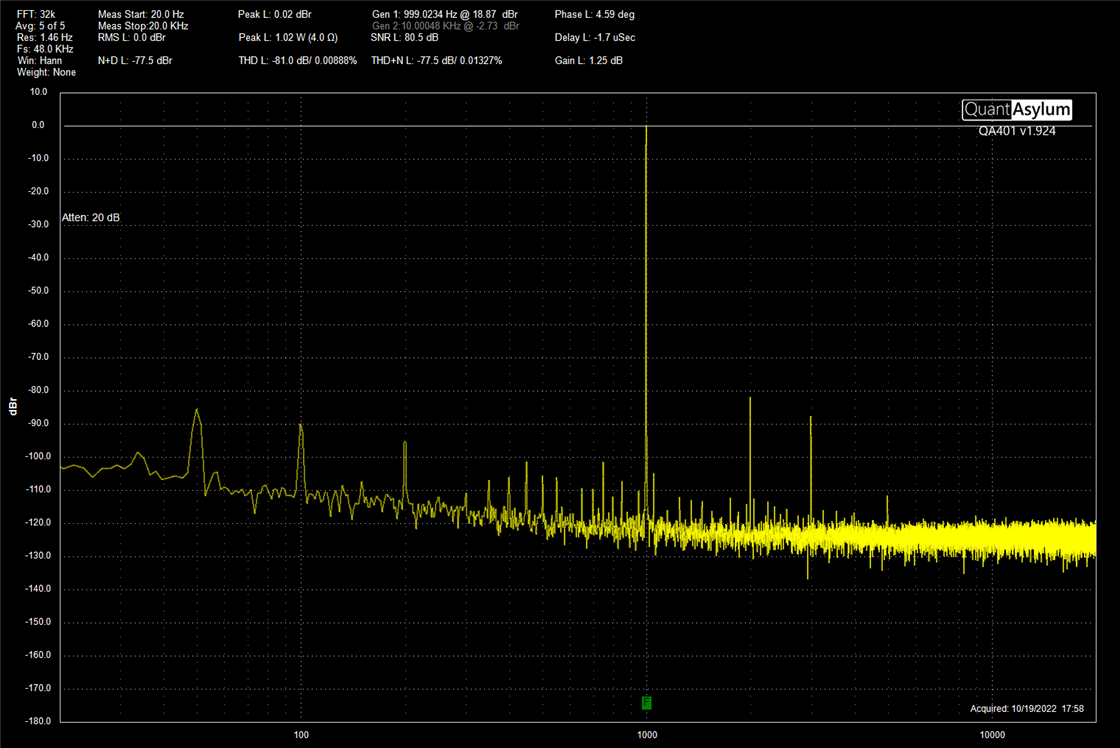

I was curious if the measurement setup mistake affected the THD measurement for the tube amp. So I measured the THD again but this time with the actual speaker connected, not a resistor load. The speakers I have are 4OHM so I measured on the 4OHM output. It seems that the THD performance is even better than what I measured previously.

I will repeat the measurement on the 8OHM output with a resistive load so that I can compare like for like but this is looking really good. To have a THD of -81dB using tubes is really something 🙂.

On another subject, I noticed something when turning the amp off. There is a thump in the speakers (nothing really loud, just that you hear it) and I see a small light coming from the tubes. I was not able to pinpoint the actual source of the light. I think that it might have something to do with the fact that the +10V I use for the driver tube is also used by the PHONO preamp and due to this fact, the 10V will decrease very fast when I turn the amp off. Is this something that will have a negative impact on tube life? To verify this, I will perform a test by disconnecting the PHONO preamp and see is this happens again or not.

I will repeat the measurement on the 8OHM output with a resistive load so that I can compare like for like but this is looking really good. To have a THD of -81dB using tubes is really something 🙂.

On another subject, I noticed something when turning the amp off. There is a thump in the speakers (nothing really loud, just that you hear it) and I see a small light coming from the tubes. I was not able to pinpoint the actual source of the light. I think that it might have something to do with the fact that the +10V I use for the driver tube is also used by the PHONO preamp and due to this fact, the 10V will decrease very fast when I turn the amp off. Is this something that will have a negative impact on tube life? To verify this, I will perform a test by disconnecting the PHONO preamp and see is this happens again or not.

As for the turn-off ( and turn-on "thump") dave gillespie has written an article about the dangers :

Techniques To Maximize Power Tube Life

In your case it seems that a large pulse emanates from the pre stages and finds it's way to the

power stage, with potential damaging effects.

One way of reducing this is to sequence the power down , power stage first, then pre stage. Or, short

the powerstage with a fast relay before B+ have started to fall at power off. Same relay might also

somewhat protect the power stage at power on.

Same effects may also be present of delayed B+ is applied at power on, a sudden surge might

hammer the power tubes, that's one of the reasons rectifier tubes is beneficial to tube life.

Techniques To Maximize Power Tube Life

In your case it seems that a large pulse emanates from the pre stages and finds it's way to the

power stage, with potential damaging effects.

One way of reducing this is to sequence the power down , power stage first, then pre stage. Or, short

the powerstage with a fast relay before B+ have started to fall at power off. Same relay might also

somewhat protect the power stage at power on.

Same effects may also be present of delayed B+ is applied at power on, a sudden surge might

hammer the power tubes, that's one of the reasons rectifier tubes is beneficial to tube life.

Interesting article. Thanks for sharing. My amp does not have any turn-on "thump" as the tubes are not warm enough to conduct when the B+ is applied. I guess this is OK. I do have a "thump" at turn-off. So I think the solution would be to use a relay to turn the B+ going to the power tubes as fast as possible when I disconnect the AC. This is similar to the protection circuit I have for solid state amps. This has a turn-o delay before connecting the power amp to the speaker terminals and it disconnects the speakers as quick as possible when the loss of AC is detected. I could adapt this design so that when I turn the amp on, I will delay the application of B+ to the output tubes only. The input and driver will be turned ON instantly and the power stage will be delayed let's say 30s. At turn-off, I will disconnect the B+ from the output tubes as quick as possible when I detect loss of AC. I know that the solution presented in the article delays the application of B+ to the input and driver tubes as well. It waits 30s so that the input and driver stages will heat up. And then it waits another 10s to connect the power stage. I'll try to think of a practical way to implement this scheme.

Try and hold on to the negative bias rail for longer. I had issues with this and helps.

I tried increasing the capacitor from the +/-10Vdc rail and this improved the situation a bit, but it did not completely remove the "thump" at power off. When turning the amp off, I see the woofer moving about as all the capacitors discharge, and right at the end I hear a smaller "thump". It will have to do for now. I'll try and come up with a more elegant solution, but for now I'll use it as it is. In the evening, I'll do a test in the evening to see if the very faint light coming from the tubes is still there.

So have been following this post, fantastic job. I am also building my first tube amp but from a different perspective. I wanted more power than the usual 30-40W versions. I'm following KODABMX plans with the MA1 scalable amplifier. Mine will put out 90W/Ch to handle low sensitivity speakers(82dB). Mine is just breadboarded at this point but sounds very good. Using pairs of KT-90s and Edcor 100W output trannies. Had lots of excellent help from Kodabmx throughout.

Some points, have you actually measured your filament currents? The reason I ask is that my tube compliment says it should be pulling between 7-8A total. Now I'm running at 6vdc on the filaments but when I measure, I'm only pulling 6A when cold and 4.4A after about 5min. Much less than I expected.

Your QA401, is that just for your own DIY? Very nice setup. I would like to do all the measurements you are running.

I too have some slight hum havent got too serious yet on tracking down. It's just breadboarded now, all tightly twisted pair but a spaghetti mess for sure. I only here it with ear to speaker and maybe up to a foot or two away. Don't hear anything at listening position in very quiet room. Anybody have a guess at what level that might be -60-70dB down??

Anyway excellent job. I'm on to designing toplate at this point.

Some points, have you actually measured your filament currents? The reason I ask is that my tube compliment says it should be pulling between 7-8A total. Now I'm running at 6vdc on the filaments but when I measure, I'm only pulling 6A when cold and 4.4A after about 5min. Much less than I expected.

Your QA401, is that just for your own DIY? Very nice setup. I would like to do all the measurements you are running.

I too have some slight hum havent got too serious yet on tracking down. It's just breadboarded now, all tightly twisted pair but a spaghetti mess for sure. I only here it with ear to speaker and maybe up to a foot or two away. Don't hear anything at listening position in very quiet room. Anybody have a guess at what level that might be -60-70dB down??

Anyway excellent job. I'm on to designing toplate at this point.

Try elevating your heater when it’s floating, this works with DC heaters too to a certain extend.

Regards, Gerrit

Regards, Gerrit

I don't believe it is floating. I have two resistors and a center tap between them connected to the star gnd point. Now that isn't elevating them to any potential except GND. Do I need to put them at 25-35% of B+. My power tubes filaments are in series and the signal tubes are on their own. So 12vdc to the outputs and 6vdc to the signal tubes.

I've just noticed the input has a hum bucker very cleaver. It's a very well-engineered design. Being symmetrical should be thump free on turning off. Your blue glow is the output tubes conducting heavily. Try and arrange for the negative bias rail to discharge more slowly by increasing the main negative res cap. The input CCS needs to remain as active as long as possible.

I added 2000uF on the +10V rail and the "thump" is still there at turn off but reduced. I did not notice any light effects coming from the tubes. I'll keep an eye on this and see if the very faint glow is still here. The challange is ti keep the +10V rail up as much as possible so the B+ voltage has enough time to drop as much as possible.I've just noticed the input has a hum bucker very cleaver. It's a very well-engineered design. Being symmetrical should be thump free on turning off. Your blue glow is the output tubes conducting heavily. Try and arrange for the negative bias rail to discharge more slowly by increasing the main negative res cap. The input CCS needs to remain as active as long as possible.

Change the absurd coupling caps ( 4.7uF) to 0.47 or 0.22uF That will cure most of the thumping andI've updated the schematics for both the amplifier and the power supply.

does not reduce fidelity as the transformers will only transform infra sound to distorsion.

The second CCS I think I would use a zener and get the volts from HT removing the need for +10V. There's quite a bit of voltage across the CCS collector resistor to reduce power dissipation in the transistor - that will narrow the compliance range partially when the HT collapses.

I will post some pictures with the "final" product soon. Before I do that, I was thinking of adding a nice milliamp meter on the front panel so that I can see the bias current of the KT88s. I would also like to be able to switch between the four tubes. The thing is that I do not want to wire the cathode current through the windings of the analog ammeter. So this leaves me with the only option of measuring the voltage drop over the 3.3R cathode resistors. This means that will most probably need a V-I transconductance stage. This will convert the voltage drop over the cathode resistor (~190mV) into mA that will be displayed using the analog milliamp meter. I will also use a variable resistor in order to "calibrate" the whole thing. Are there any other solutions?

- Home

- Amplifiers

- Tubes / Valves

- KT88 amplifier