Now back sides of the stereo pair Fane Sovereign 15 300 tc are covered with aluminum foil.

It is now a sandwich cone alu/paper/alu. A double magnet same size will be added.

Also all metal surfaces of the basket behind the cone got some textile dampening first reflections.

Attachments

Don't you think world best driver manufactures would do this if it has benefficial effect?

Without data this is useless.

Without data this is useless.

You are so right Adason!

I did all that.

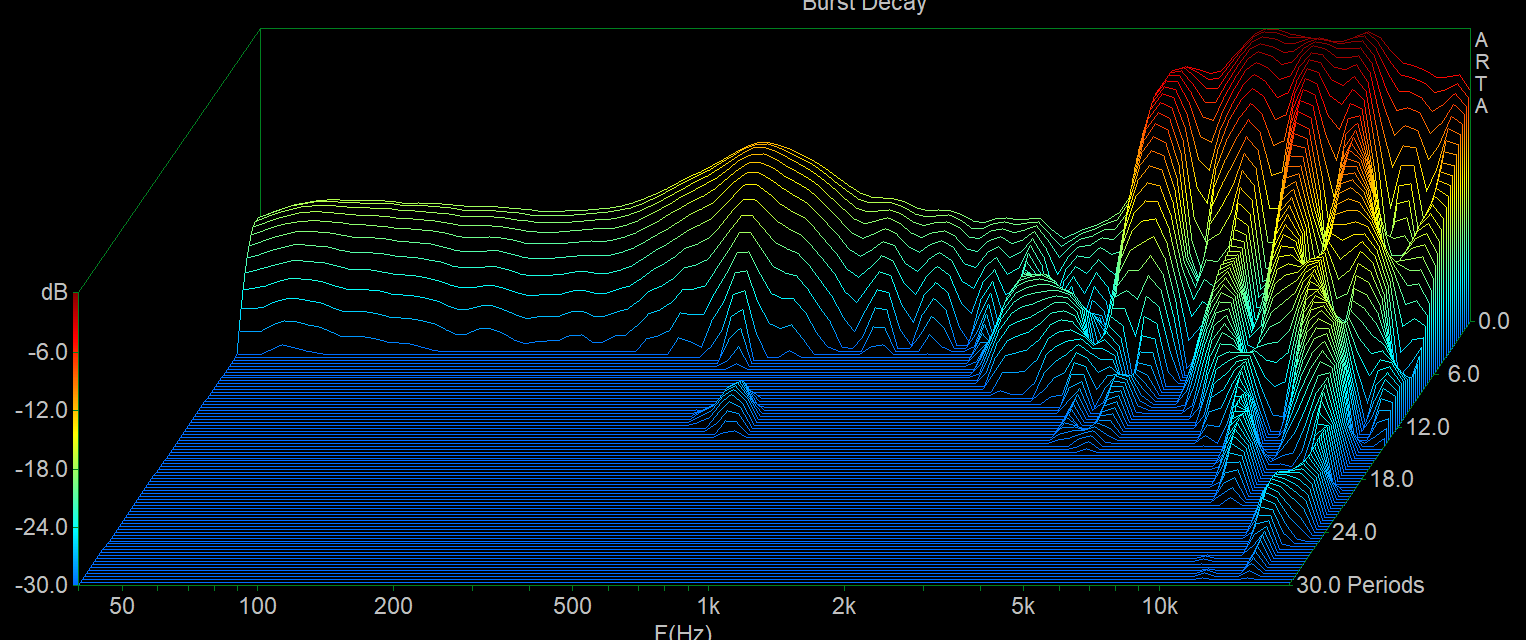

Here measurements with waterfall spectrum. It's aluminium foil 3x thicker than household foil.

The resonances in the highs are from the full metal foil from the Diy dustcap not from the aluminized paper cone.

Dsp corrected fullrange driver sandwiched with aluminium foil of thick quality - with measurements:

https://www.diyaudio.com/community/...w-distortion-with-a-2-way.334757/post-6711184

What concerns manufacturers:

It's all been done by them. However alu foil on paper by hand is a DIY thing which I never saw in mass production.

Lastly I saw Kef IQ series with plastic cone and one sided titanium vapoured on. Historically it's Podzus Goerlich, Zellaton, Kef and Leak who sandwiched loudspeaker cones with aluminum. And some other brands.

The link above you can find in this post from this thread:

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7444206

Also on loudspeaker history I wrote in this thread.

On history from my first link in this "How to...." thread

https://www.diyaudio.com/community/...cone-speaker-cone-profile.402470/post-7432593

I did all that.

Here measurements with waterfall spectrum. It's aluminium foil 3x thicker than household foil.

The resonances in the highs are from the full metal foil from the Diy dustcap not from the aluminized paper cone.

Dsp corrected fullrange driver sandwiched with aluminium foil of thick quality - with measurements:

https://www.diyaudio.com/community/...w-distortion-with-a-2-way.334757/post-6711184

What concerns manufacturers:

It's all been done by them. However alu foil on paper by hand is a DIY thing which I never saw in mass production.

Lastly I saw Kef IQ series with plastic cone and one sided titanium vapoured on. Historically it's Podzus Goerlich, Zellaton, Kef and Leak who sandwiched loudspeaker cones with aluminum. And some other brands.

The link above you can find in this post from this thread:

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7444206

Also on loudspeaker history I wrote in this thread.

On history from my first link in this "How to...." thread

https://www.diyaudio.com/community/...cone-speaker-cone-profile.402470/post-7432593

Last edited:

This is what D A Barlow wrote in 1970:

A method of obtaining still greater stiffness is sandwich construction. ... In bending, the maximum stress and strain occur at the outer fibers, the material at the neutral axis being unstressed.

Better use of material can thus be made by concentrating it at the outer fibers. A familiar example is the tube. In the case of large areas, the same effect is obtained by using a thin high-modulus material for the outer surfaces, and a light-weight material or form of construction for the core. ... This sandwich will of course be much stiffer than the same total weight of either material used separately

https://www.aes.org/e-lib/browse.cfm?elib=1505

A method of obtaining still greater stiffness is sandwich construction. ... In bending, the maximum stress and strain occur at the outer fibers, the material at the neutral axis being unstressed.

Better use of material can thus be made by concentrating it at the outer fibers. A familiar example is the tube. In the case of large areas, the same effect is obtained by using a thin high-modulus material for the outer surfaces, and a light-weight material or form of construction for the core. ... This sandwich will of course be much stiffer than the same total weight of either material used separately

https://www.aes.org/e-lib/browse.cfm?elib=1505

Similar technique is Kevlar on honeycomb cores. The newer Eton drivers managed to tame the hard cone resonances I think due to elastic glue. Their waterfalls look nearly perfect, too.

I would be so glad to see a fullrange driver using this cone.

Once I DSPed an Eton and it was quite good sounding. It had a metal dust cap which was directly fixed on the voice coil. Only pity was the voice coil was not for fullrange with low enough inductivity. So too much correction had to be applied.

It was this one

I would be so glad to see a fullrange driver using this cone.

Once I DSPed an Eton and it was quite good sounding. It had a metal dust cap which was directly fixed on the voice coil. Only pity was the voice coil was not for fullrange with low enough inductivity. So too much correction had to be applied.

It was this one

Attachments

Last edited:

Now the big whizzer cones / double cone are covered one sided with aluminum metal foil.

In the evening with different light the aluminized loudspeaker diaphragms shine golden....

In the evening with different light the aluminized loudspeaker diaphragms shine golden....

Attachments

The drivers are ready. Will see if I manage to install them and make measurements.

Aluminized small double cone with thin foil from the goldsmith.

Aluminized small double cone with thin foil from the goldsmith.

Attachments

Thank you. The sound is addictive. For that I cannot stop giving fullrange drivers some extra kick!

Extra magnet on it

https://www.diyaudio.com/community/threads/new-15-full-range-fane.308652/post-7467752

Extra magnet on it

https://www.diyaudio.com/community/threads/new-15-full-range-fane.308652/post-7467752

I will see if I can activate my ATB PC 501 measurement system from Kirchner Electronic Germany. It can do IMD, too.

I have the other two Fanes (I got 4 of them) with aluminized small whizzers and damping on the metal backside. So not quite original any more.

Still need some box / enclosure but maybe I will do some quick measurements without box in the 10cm nearfield . I can work on it next summer as I am on the way from home for this time.

Please remember that I already did measure aluminized 25cm fullranges here in the thread and Saba Greencones with thin aluminum foil. With Arta waterfall measurements.

I have the other two Fanes (I got 4 of them) with aluminized small whizzers and damping on the metal backside. So not quite original any more.

Still need some box / enclosure but maybe I will do some quick measurements without box in the 10cm nearfield . I can work on it next summer as I am on the way from home for this time.

Please remember that I already did measure aluminized 25cm fullranges here in the thread and Saba Greencones with thin aluminum foil. With Arta waterfall measurements.

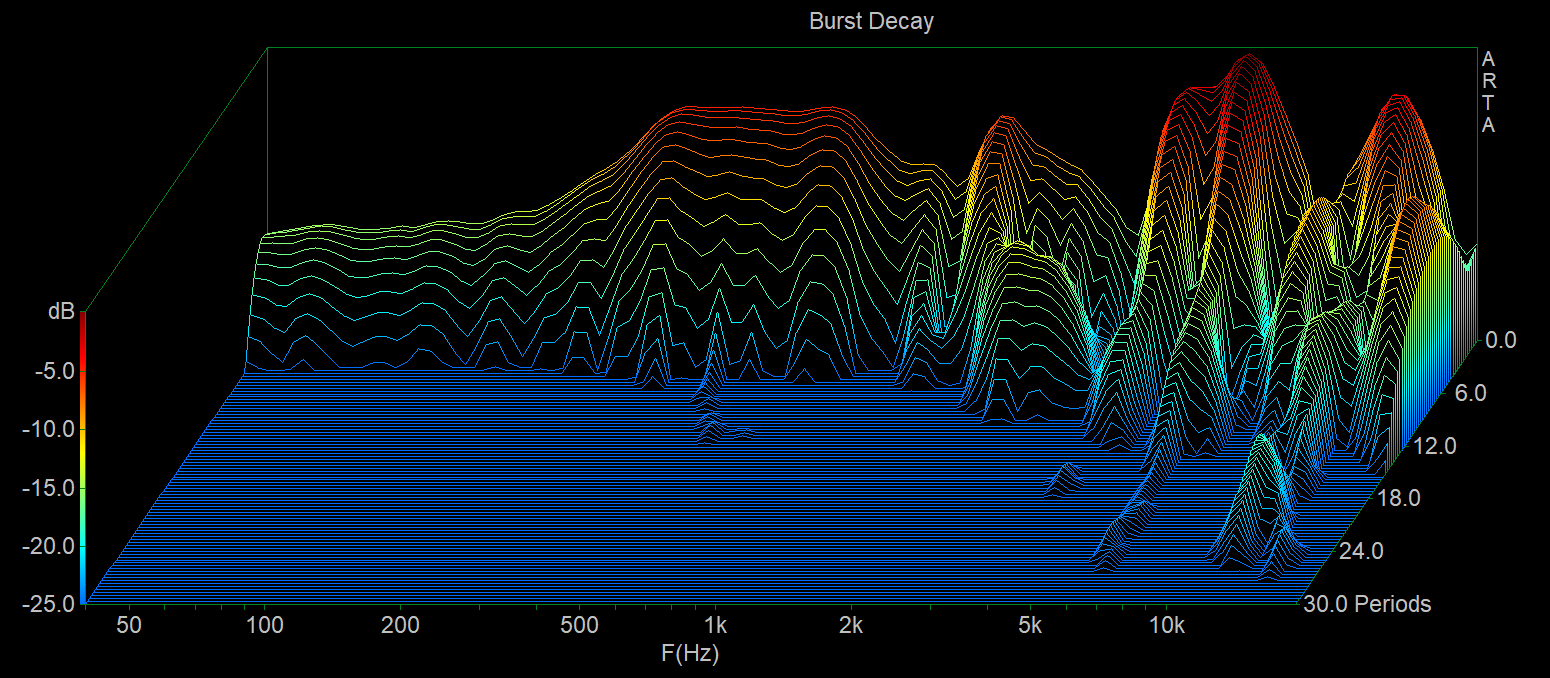

Quick waterfall measurement without enclosure / box. Fane Sovereign 15-300tc with aluminized cone both sides, sandwich, whizzers only one side.

Nearfield 10cm on axis. Measurement with ATB PC 501 measurement system (amplifier and microfone linear).

Headroom 30db

Do not know if this measurement is perfect done its just a first hint

Nearfield 10cm on axis. Measurement with ATB PC 501 measurement system (amplifier and microfone linear).

Headroom 30db

Do not know if this measurement is perfect done its just a first hint

Last edited:

some better measurement with damping with cloths around the driver, driver laying on the floor, off axis measurement 30 degrees, 15cm, aluminized cone from both sides, the whizzers only one side.

These are only first hint measurements as there is no real box.

As in the first measurement the highs on axis are so loud you cannot well see the lower frequencies. Therefore off axis measurement just to see more in the low region.

These are only first hint measurements as there is no real box.

As in the first measurement the highs on axis are so loud you cannot well see the lower frequencies. Therefore off axis measurement just to see more in the low region.

Attachments

Last edited:

Fullrange drivers with sandwich aluminium foil:

https://www.diyaudio.com/community/threads/loudspeaker-for-current-drive.403936/post-7479266

https://www.diyaudio.com/community/threads/corner-horn-meets-open-baffle-cfa.398842/post-7356332

https://www.diyaudio.com/community/threads/corner-horn-meets-open-baffle-cfa.398842/post-7355867

https://www.diyaudio.com/community/threads/loudspeaker-for-current-drive.403936/post-7479266

https://www.diyaudio.com/community/threads/corner-horn-meets-open-baffle-cfa.398842/post-7356332

https://www.diyaudio.com/community/threads/corner-horn-meets-open-baffle-cfa.398842/post-7355867

One side nearly completed - metal foil on loudspeaker paper diaphragm.

"50 cent trick" applied to top of the pole piece. 50 euro cent contains copper and is usable as Faraday ring reducing distortion of the driver.

Driver is a cheap 25cm bass converted to a fullrange driver by removing the dust cap and putting a Diy whizzer / double cone on it.

"50 cent trick" applied to top of the pole piece. 50 euro cent contains copper and is usable as Faraday ring reducing distortion of the driver.

Driver is a cheap 25cm bass converted to a fullrange driver by removing the dust cap and putting a Diy whizzer / double cone on it.

Attachments

Oval fullrange drivers with tinfoil tweak

Attachments

Professional loudspeaker from Roland with one sided aluminium foil on fullrange loudspeaker diaphragm / papercone of thin quality from the gold smith ("Schlagaluminium" = "beaten aluminium")

Tweeter got a crossover and the undamped box got damping foam inside on all sides. Reflex tuned lower.

Tweeter got a crossover and the undamped box got damping foam inside on all sides. Reflex tuned lower.

Finished second mono fullrange loudspeaker in box enclosure made of Galala marble. Down fire bass reflex.

Oval fullrange speaker drivers (with copper Faraday ring on the pole plate) with sandwich aluminum tinfoil. In series to the paralleled drivers is 0.8 ohms with 1.5uF C in parallel augmenting the highs. And reducing a little bit the distortion with Esa Merilainens simple resistor method.

Link to the tweaked mini Bluetooth TDA2003 bridged amp:

https://www.diyaudio.com/community/threads/tuning-tweaking-tda2003-btl-hifi-bass-power-amp.404136/

Oval fullrange speaker drivers (with copper Faraday ring on the pole plate) with sandwich aluminum tinfoil. In series to the paralleled drivers is 0.8 ohms with 1.5uF C in parallel augmenting the highs. And reducing a little bit the distortion with Esa Merilainens simple resistor method.

Link to the tweaked mini Bluetooth TDA2003 bridged amp:

https://www.diyaudio.com/community/threads/tuning-tweaking-tda2003-btl-hifi-bass-power-amp.404136/

Attachments

Metal foil tweak applied to a small Bluetooth box.

One box with thin foil from the gold Smith.

The other one with household aluminium foil.

Sounds different: Clearly the driver with the thicker foil sounds more correct.

With added diy whizzer / double cone I apply smartfone app EQ with 1 and 2khz reduced by 7 decibels for linearization.

Added inside damping material and added bass reflex pipe. Original was no damping at all in the box and closed box design.

The box can be also EQed for close to floor and wall placement (reduced 250 and 150hz. For real corner placement the bass can be reduced even more.)

One box with thin foil from the gold Smith.

The other one with household aluminium foil.

Sounds different: Clearly the driver with the thicker foil sounds more correct.

With added diy whizzer / double cone I apply smartfone app EQ with 1 and 2khz reduced by 7 decibels for linearization.

Added inside damping material and added bass reflex pipe. Original was no damping at all in the box and closed box design.

The box can be also EQed for close to floor and wall placement (reduced 250 and 150hz. For real corner placement the bass can be reduced even more.)

Attachments

-

IMG_20231215_202743.jpg257.9 KB · Views: 137

IMG_20231215_202743.jpg257.9 KB · Views: 137 -

IMG_20231215_202722.jpg228.7 KB · Views: 118

IMG_20231215_202722.jpg228.7 KB · Views: 118 -

IMG_20231214_172945.jpg551.6 KB · Views: 136

IMG_20231214_172945.jpg551.6 KB · Views: 136 -

IMG_20231214_172938.jpg375.6 KB · Views: 130

IMG_20231214_172938.jpg375.6 KB · Views: 130 -

IMG_20231215_202343.jpg386.1 KB · Views: 128

IMG_20231215_202343.jpg386.1 KB · Views: 128 -

Screenshot_20231215_203402_com.jazibkhan.equalizer.jpg81.7 KB · Views: 137

Screenshot_20231215_203402_com.jazibkhan.equalizer.jpg81.7 KB · Views: 137 -

Screenshot_20231215_203437_com.jazibkhan.equalizer.jpg82.6 KB · Views: 127

Screenshot_20231215_203437_com.jazibkhan.equalizer.jpg82.6 KB · Views: 127 -

IMG_20231215_204247.jpg249.5 KB · Views: 132

IMG_20231215_204247.jpg249.5 KB · Views: 132 -

IMG_20231215_204255.jpg282.5 KB · Views: 114

IMG_20231215_204255.jpg282.5 KB · Views: 114 -

IMG_20231215_204305.jpg172.7 KB · Views: 139

IMG_20231215_204305.jpg172.7 KB · Views: 139

- Home

- Loudspeakers

- Full Range

- How to make a loudspeaker sandwich cone