Good DIY work in repurposing the power supply enclosure with heatsinks for an amplifier project.

Hello,

I would like to ask if the soft start and speaker protection board is recommanded to be included? Or do you all run your projects without it?

I would like to ask if the soft start and speaker protection board is recommanded to be included? Or do you all run your projects without it?

Unless you have expensive speakers or one could short your output, but if you know what you're doing - i've been enjoing lots of diy amps without it.

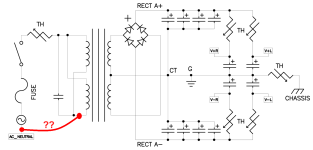

I have always just relied on the TH in series with the transformer primary to limit inrush current at turn-on. I haven't used DC protection and have not had a problem....yet (20+ years in the hobby).

If we were talking chip amps, I’d say speaker protection is a must, but the first watt designs are as reliable as it gets as long as they’re built and set up correct.

The PSU already has a soft starting function, so the soft start PCB isn’t not necessary.

If you wish to add the DC protection you may, however, I suggest doing this after you have your amp built and functioning properly.

If you wish to add the DC protection you may, however, I suggest doing this after you have your amp built and functioning properly.

Never used it (DC protection) here with the many Pass clone amps Ive had. All but the F6 are still running. I used its case and power supply

for Aleph J. Most of my builds have the CL-60 setup for inrush. I did follow 6l6's build guide instructions and used the store delay in my BA3 amp.. Both work fine.

for Aleph J. Most of my builds have the CL-60 setup for inrush. I did follow 6l6's build guide instructions and used the store delay in my BA3 amp.. Both work fine.

Hi coffee-fan

I have built the F5 several years ago. Sound was amazing. No noises when I switched it on or off. What, when it blows? Then you have 28V DC going directly to your loudspakers. In the end I returned to my Yamaha MX-2 which sounds quite good and has a very good protection circuit (tested it involuntary).

One of my next projects will be a F5M. I will add a Ls-protection circuit - for peace of mind. They are much cheaper than any loudspeaker in case of failure. Yes I am a coward. I can happily live with this.

I have built the F5 several years ago. Sound was amazing. No noises when I switched it on or off. What, when it blows? Then you have 28V DC going directly to your loudspakers. In the end I returned to my Yamaha MX-2 which sounds quite good and has a very good protection circuit (tested it involuntary).

One of my next projects will be a F5M. I will add a Ls-protection circuit - for peace of mind. They are much cheaper than any loudspeaker in case of failure. Yes I am a coward. I can happily live with this.

I must apologize. I did not disclose the fact that a top cover was not included in the purchase of my enclosure, and my temps are achieved while going topless.6 inches tall, 10 inches wide, approx 1 1/4 thick. Old Astron 50 amp DC power supply.

Have you tried a second test with a solid panel (cookie sheet, cardboard, whatever) place over the top for comparison. It seems to me that Imperfect as it is, simply sliding the panel over to allow a 5%, 10% etc opening may be helpful in laying out/buying a permanent lid. CheersI must apologize. I did not disclose the fact that a top cover was not included in the purchase of my enclosure, and my temps are achieved while going topless.

Tried and watched the bias go to about 1.5 amps per side. I will probably buy a bigger pair of sinks and fab an expanded metal of some kind for a lid.

Nice idea on the sheet pan. I cut aluminum by using a jig saw, then some clamps and a 2x4 for sanding a straight edge . I then use a belt sander (3x21or 3x24 is a good size) makes almost perfect results.Need to file the sharp edge with a file of course. I suppose a table saw with a metal blade would also work well. I assume one could use a masonite or plywood backer for thin gauges.

- Home

- Amplifiers

- Pass Labs

- F5m kit