The Heil is designed to cross much lower than that. It actually works well at 800hz and is sort of like a FAST alignment. I am looking at using a pair of B&C 8MDN51-16ohms in parallel.

Oops ... that was my typo. I meant I wanted to cross over at 800hz, and not 1800hz.

I will look at this woofer you want to use. Thanks

Hi Flaxxer,

If 800Hz is the goal, you can safely use the Deltalite II 2512 midwoofer. It wants about 120 liters of volume to play low but it will handle 800Hz without any problem and it is quite sensitive.

If largish cabinet size isn't restricted, of course.

If 800Hz is the goal, you can safely use the Deltalite II 2512 midwoofer. It wants about 120 liters of volume to play low but it will handle 800Hz without any problem and it is quite sensitive.

If largish cabinet size isn't restricted, of course.

Hi Flaxxer,

If 800Hz is the goal, you can safely use the Deltalite II 2512 midwoofer. It wants about 120 liters of volume to play low but it will handle 800Hz without any problem and it is quite sensitive.

If largish cabinet size isn't restricted, of course.

I can build up to about 3 sq feet of enclosure volume. So I can build large cabinets. Thanks for the suggestion.

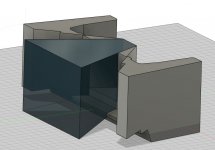

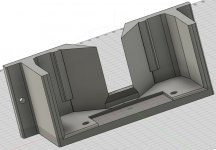

This is a work-in progress on getting closer to the diaphragm. It shows a half cut of the front attachment (not finished) and half of the horn inner volume ("glass" material). The horn is 50 x 30 as shown. Is there any particular pattern I should aim for? I think the HF vertical is limited by the length of the diaphragm anyway.

The port of the Synergy mid driver can be located in the AMT slot (the inner edge of the port can be 20 mm from the diaphragm at minimum) or any distance further - any suggestions on that - like the center should be 1/4 WL of the expected 800 Hz crossover frequency? Two drivers can be fitted (top, bottom) or four smaller on the sides, but they would need to be a bit further away.

The port of the Synergy mid driver can be located in the AMT slot (the inner edge of the port can be 20 mm from the diaphragm at minimum) or any distance further - any suggestions on that - like the center should be 1/4 WL of the expected 800 Hz crossover frequency? Two drivers can be fitted (top, bottom) or four smaller on the sides, but they would need to be a bit further away.

Attachments

Nice work Pelanj!

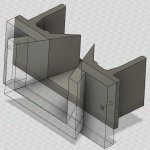

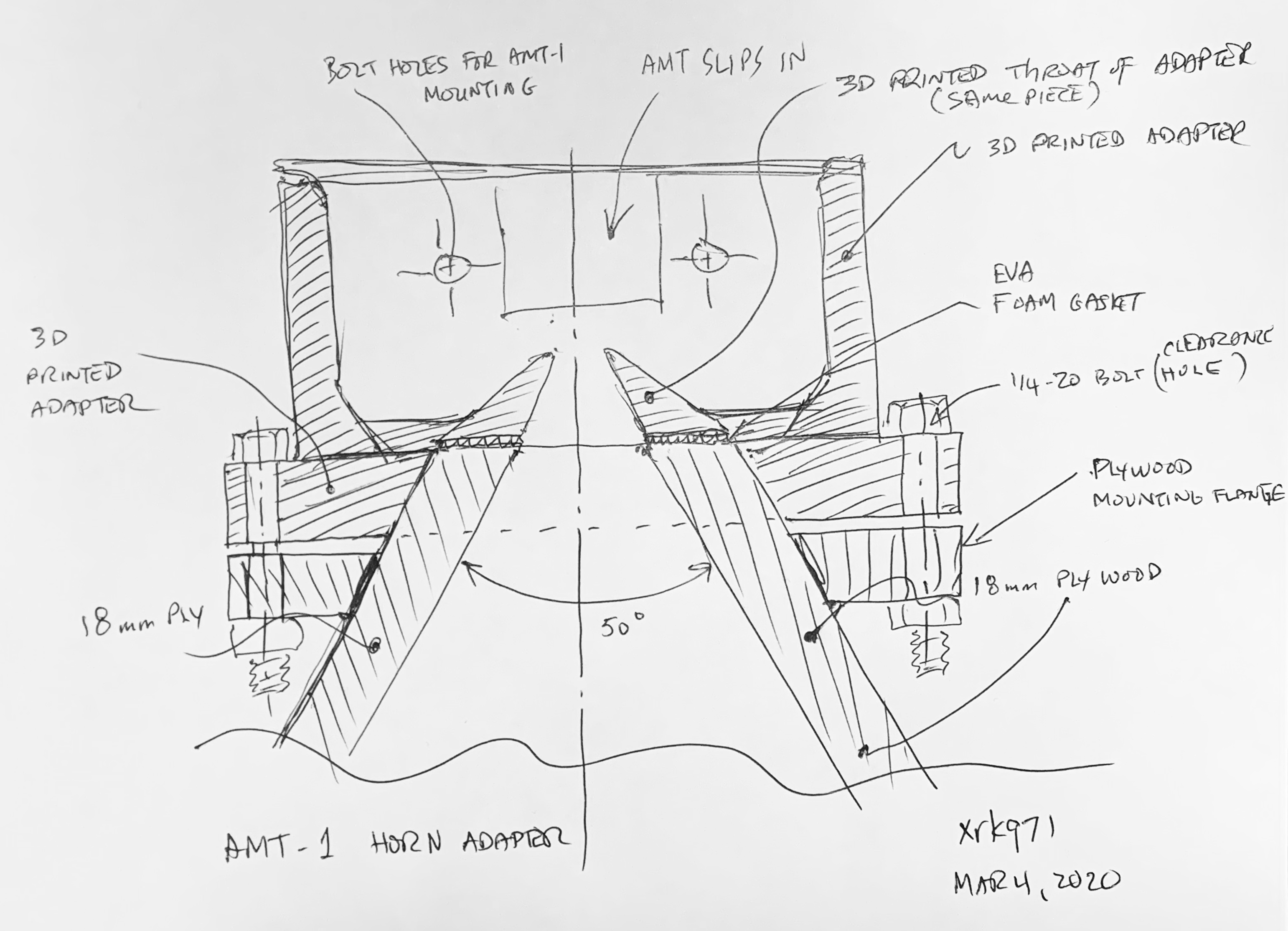

What would be helpful is if you can make the adapter to mate readily with say a Synergy horn constructed of 18mm BB ply walls. The ends would be flush sanded and slip right in. The way it looks now, it appears that the walls would need to be made into a wedge and additional layers added.

Can you make a model with the 50x30 horn constructed of 18mm ply as clear glass material and shown mated to the adapter. What we need to see is that it allows a horn of simple planar construction be connected to the adapter.

Thank you.

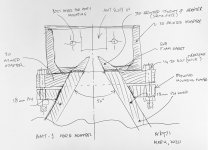

Please see my sketch for concept. Only a concept but up to you how we attach the adapter to the horn. I would recommend 4 bolts on the corners attached to glued on plywood flange plate on horn body. Or even 4 solid wooden blocks which are drilled later for the bolts.

What would be helpful is if you can make the adapter to mate readily with say a Synergy horn constructed of 18mm BB ply walls. The ends would be flush sanded and slip right in. The way it looks now, it appears that the walls would need to be made into a wedge and additional layers added.

Can you make a model with the 50x30 horn constructed of 18mm ply as clear glass material and shown mated to the adapter. What we need to see is that it allows a horn of simple planar construction be connected to the adapter.

Thank you.

Please see my sketch for concept. Only a concept but up to you how we attach the adapter to the horn. I would recommend 4 bolts on the corners attached to glued on plywood flange plate on horn body. Or even 4 solid wooden blocks which are drilled later for the bolts.

Attachments

Last edited:

You could leave the expansion as is, and have the horn wall contract to 50deg. That could work too, although the 50deg from the aperture throat is probably best.

Why narrow? Synergy horns work better when horn is restricted and directional circa 45 deg to 60 deg. Too wide and it’s not effective at integrating the multiple taps. 50deg is a tired and true Danley geometry. I have tried it and can confirm it works better than 90deg horn.

Why narrow? Synergy horns work better when horn is restricted and directional circa 45 deg to 60 deg. Too wide and it’s not effective at integrating the multiple taps. 50deg is a tired and true Danley geometry. I have tried it and can confirm it works better than 90deg horn.

The front part was not finished, it just shows the relations. I will work on this a bit tomorrow and I will separate the holder from the flange so that various options can be made.

Hey fellas. If the desired horizontal angle is 50 degrees, then the resultant horn will be quite large unless the lowest frequency pattern control is raised to something closer to 500Hz, and even then, the horn will be 30 inches wide (~80cm).

I thought that making a speaker cabinet for my Audio Nirvana 15s would be large (~60cm wide), but these horns will be even wider!

Is that just the reality of building a horn? That it will need to be very wide to get a good result?

Also, is 500Hz ok for the pattern control? That seems on the high side if I look at some other builds online..

I thought that making a speaker cabinet for my Audio Nirvana 15s would be large (~60cm wide), but these horns will be even wider!

Is that just the reality of building a horn? That it will need to be very wide to get a good result?

Also, is 500Hz ok for the pattern control? That seems on the high side if I look at some other builds online..

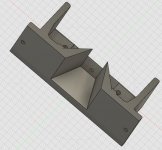

So this is the preview and a STEP model - one half. This one was not printed whole yet, the fit was tested in parts only. A 90x40 version in the same format will follow later.

Edit: It all says 50x40, but it is in fact 50x30.

Edit: It all says 50x40, but it is in fact 50x30.

Attachments

Last edited:

ESS--midwoofer

flaxxer: I'm crossing my new Heils at 800, and they sound great. I've been breaking them in, and am very pleased with the sound. I think my next move is going to be to add in one of my TAD 12" midbass drivers, and run them from about 150/175 up to 800. That midbass only needs as little as 1cf.

Oops ... that was my typo. I meant I wanted to cross over at 800hz, and not 1800hz.

I will look at this woofer you want to use. Thanks

flaxxer: I'm crossing my new Heils at 800, and they sound great. I've been breaking them in, and am very pleased with the sound. I think my next move is going to be to add in one of my TAD 12" midbass drivers, and run them from about 150/175 up to 800. That midbass only needs as little as 1cf.

Thank you for replying. I am told by the gent at ESS, he sells a lot of the AMT-1 to diy people. I was hiding in the corner, just hoping a few people may post up their two way designs using the large Heil. I'm really excited to use it with a high efficiency 10 or 12 inch mid bass driver. I'm at the mercy of others, as xover design and I do not get along so well, lol.flaxxer: I'm crossing my new Heils at 800, and they sound great. I've been breaking them in, and am very pleased with the sound. I think my next move is going to be to add in one of my TAD 12" midbass drivers, and run them from about 150/175 up to 800. That midbass only needs as little as 1cf.

Yes Pharos, that is what I am going for. But I won't necessarily be keeping the original ESS speaker design. I'll be making mine in to huge top cabinets, for my huge bass bins.The result of my build

Yes Pharos, that is what I am going for. But I won't necessarily be keeping the original ESS speaker design. I'll be making mine in to huge top cabinets, for my huge bass bins.

I extensively modded the cabinets, the lower plinth has been increased from 3" to 7" to both increase the height and align the Heil with ears, and to increase internal volume to 105lt.

Each cabinet has 53 braces in it. Switch gives -5dB and the pot -5dB in 0.3dB increments.

Wow Pharos! Sounds like amazing cabinets. You really did some labor on those! I've always thought their design to keep the covering grill in place was intelligent.

Yes I worked hard, gave it my all.

The upper and lower sections are covered in 1mm EPDM rubber to both dampen the panels, and also for durability and cleaning.. The insides were covered in carpet underlay, the type which is composed of shredded car tyre and felt/wool, (usually pink).

There is a frame behind the mid/woofer which contains a 'cushion' of BAF wadding contained in a sleeve of dacron holofill. This forces the low frequency air down into the bottom and back up behind to drive the rear passive, and also blocks mid range from being reflected back through the mid/woof cone.

The walls in the lower chamber have similar cushions around thew walls, leaving a 'tunnel' for bass resonance airflow. It is wired with 3.8 mm sq Xsection wire.

The back frame of the mid/woof also has carpet felt on any reflecting basket frame surfaces, and the surround has been superglued because it was designed for rear mounting, and I have front mounted it, didn't want it pulling away.

I supported the large coil with a drain piping.

The upper and lower sections are covered in 1mm EPDM rubber to both dampen the panels, and also for durability and cleaning.. The insides were covered in carpet underlay, the type which is composed of shredded car tyre and felt/wool, (usually pink).

There is a frame behind the mid/woofer which contains a 'cushion' of BAF wadding contained in a sleeve of dacron holofill. This forces the low frequency air down into the bottom and back up behind to drive the rear passive, and also blocks mid range from being reflected back through the mid/woof cone.

The walls in the lower chamber have similar cushions around thew walls, leaving a 'tunnel' for bass resonance airflow. It is wired with 3.8 mm sq Xsection wire.

The back frame of the mid/woof also has carpet felt on any reflecting basket frame surfaces, and the surround has been superglued because it was designed for rear mounting, and I have front mounted it, didn't want it pulling away.

I supported the large coil with a drain piping.

Attachments

Last edited:

ESS Mods

Pharos: I really like what you did with your project. Excellent work! For my on-going project, I've considered buying some of the brand new top grills from ESS, because I'd never get around to making any, and I really like the look. They remind me a lot of my old Kef 105.4's.

What is the woofer you are using?

Flaxxer: one of the things that really appealed to me about the ESS is how low they can cross over, without pushing them at all.

Rick at ESS mentioned he is working on a kit for the dual stacked Heil units, with wings. That will be interesting to follow also.

Have fun..

Pharos: I really like what you did with your project. Excellent work! For my on-going project, I've considered buying some of the brand new top grills from ESS, because I'd never get around to making any, and I really like the look. They remind me a lot of my old Kef 105.4's.

What is the woofer you are using?

Flaxxer: one of the things that really appealed to me about the ESS is how low they can cross over, without pushing them at all.

Rick at ESS mentioned he is working on a kit for the dual stacked Heil units, with wings. That will be interesting to follow also.

Have fun..

Last edited by a moderator:

- Home

- Loudspeakers

- Multi-Way

- ESS AMT-1 in my projects