Basics ?

Probably due to my cognitive and operative limitations, but also to some previous experiences, I would already be happy to build a tonearm capable of exploiting correctly only the weak, unreliable, tracking forces, and to move in every direction coherently with the stylus motions, while maintaining the needed stiffness of the whole.

Overcoming the inevitable defects of the different parts of the system (eccentrycity, warps, resonances and so on), and their boring, evident consequences seems to me to be a further complex chapter, to be faced only after an effective solution of the first.

Still not up with that, unfortunately: so i'm anxious to see other's new achievements

c

PS - imho the so called Side Force or skating (= bending = L / R distortion) appears every time the tracking forces (in brief, the Stylus Drag) are, as usual, wasted on the constraint, or spent in the wrong direction, or both (L TAs vs P TA vs P T TA).

The eccentrics etc. may just emphasize the tonearm's basic issues.

Probably due to my cognitive and operative limitations, but also to some previous experiences, I would already be happy to build a tonearm capable of exploiting correctly only the weak, unreliable, tracking forces, and to move in every direction coherently with the stylus motions, while maintaining the needed stiffness of the whole.

Overcoming the inevitable defects of the different parts of the system (eccentrycity, warps, resonances and so on), and their boring, evident consequences seems to me to be a further complex chapter, to be faced only after an effective solution of the first.

Still not up with that, unfortunately: so i'm anxious to see other's new achievements

c

PS - imho the so called Side Force or skating (= bending = L / R distortion) appears every time the tracking forces (in brief, the Stylus Drag) are, as usual, wasted on the constraint, or spent in the wrong direction, or both (L TAs vs P TA vs P T TA).

The eccentrics etc. may just emphasize the tonearm's basic issues.

Hi Andrey,

I'm sorry but I haven't received any notifications from diyaudio of posts on this thread. I am at work at the moment but will read through everything posted since our last communication as soon as I can.

Niffy

I'm sorry but I haven't received any notifications from diyaudio of posts on this thread. I am at work at the moment but will read through everything posted since our last communication as soon as I can.

Niffy

Hi, Carlo

After reading your last post, I found my own thoughts in it.

Not only am I following this path, I hope to follow it to the end.

I will say it a little pompously.

The path you have taken with your Syrinx is a pathon thin slippery ice in the middle of a swamp.

One step to the left, one step to the right and you are lost.

You stumbled and left this path and that is why your Syrinx did not sing.

I have been following your path for almost a year and have already made mistakes and started over more than once.

I am ready for failure. But I will go to the end, until my thoughts run out.

This is excitement - about the same as a mountain climber who climbs another peak.

And now I have started another construction. I just need to defeat the eccentricity.

And then it is either victory or defeat.

I like such puzzles.

I'll wait for Niffy and then move on to the Angling for 90° - tangential pivot tonearms topic.

A good topic, but it's dying. Too bad. We need to support it.

P.S. Your P.S. is not entirely clear to me.

Give me a breakdown of your abbreviations.

I'll write them down on a piece of paper and look at them.

Best regards,

AG.

After reading your last post, I found my own thoughts in it.

Not only am I following this path, I hope to follow it to the end.

I will say it a little pompously.

The path you have taken with your Syrinx is a pathon thin slippery ice in the middle of a swamp.

One step to the left, one step to the right and you are lost.

You stumbled and left this path and that is why your Syrinx did not sing.

I have been following your path for almost a year and have already made mistakes and started over more than once.

I am ready for failure. But I will go to the end, until my thoughts run out.

This is excitement - about the same as a mountain climber who climbs another peak.

And now I have started another construction. I just need to defeat the eccentricity.

And then it is either victory or defeat.

I like such puzzles.

I'll wait for Niffy and then move on to the Angling for 90° - tangential pivot tonearms topic.

A good topic, but it's dying. Too bad. We need to support it.

P.S. Your P.S. is not entirely clear to me.

Give me a breakdown of your abbreviations.

I'll write them down on a piece of paper and look at them.

Best regards,

AG.

For Niffy and other experts on linear tonearms.

The second question.

This is not really a question, but rather my thoughts on a compromise solution to the first question.

Perhaps such a solution has long been known, but I do not know it.

I propose to consider the following change in the tonearm design.

Allow freedom to rotate the lever with the cartridge relative to the carriage at a small anglein the horizontal plane.

The lever is fixed with two springs in the middle of the angle strictly perpendicularto the direction of movement of the carriage. The stiffness of the springs is selected.

Thus, when working with a record with zero eccentricity, the tonearm workslike a conventional linear tonearm.

In the case of eccentricity, a rotational movement is added to the reciprocating movement of the tonearm, like in a conventional rotary tonearm, and the tonearm leaves the tangential position at a small angle.

In my opinion, this will soften the mode of shifting the needle pressure from one side of the groove to the other side.

Of course, this is not an ideal solution. But as they say: of two evils, you need to choose the lesser. But which of them is the lesser is the question.

What do you say?

AG.

The second question.

This is not really a question, but rather my thoughts on a compromise solution to the first question.

Perhaps such a solution has long been known, but I do not know it.

I propose to consider the following change in the tonearm design.

Allow freedom to rotate the lever with the cartridge relative to the carriage at a small anglein the horizontal plane.

The lever is fixed with two springs in the middle of the angle strictly perpendicularto the direction of movement of the carriage. The stiffness of the springs is selected.

Thus, when working with a record with zero eccentricity, the tonearm workslike a conventional linear tonearm.

In the case of eccentricity, a rotational movement is added to the reciprocating movement of the tonearm, like in a conventional rotary tonearm, and the tonearm leaves the tangential position at a small angle.

In my opinion, this will soften the mode of shifting the needle pressure from one side of the groove to the other side.

Of course, this is not an ideal solution. But as they say: of two evils, you need to choose the lesser. But which of them is the lesser is the question.

What do you say?

AG.

Good afternoon Andrey,

I haven't looked for the problem you describe, or become aware of it.

Maybe I have not understood correctly!

If Niffy were to play a constant tone test record recorded on one or both channels and display the output or outputs showing the level, do you think there would be a noticeable variation in the level over time?

I perceive this is the problem you are trying to solve.

Am i correct please?

If there is no variation over time you may be trying to solve a problem that is not significant.

What do you think please?

I have not heard or perceived the variation you describe.

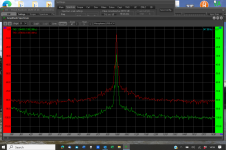

I picked an example at 1000Hz and attached it , showing a recorded tone and its crosstalk to the other channel, and other artefacts. I have also done this type of measurement at around 3000Hz, but I have never seen any variation of the peak signal level with time at these scales. I have also run higher frequencies for frequency response measurements. I guess a variation in level of 1Db would be noticeable, but not audible?

M

There are lots of other problems that do exist, don't worry, but maybe we should add this one as well!?

I haven't looked for the problem you describe, or become aware of it.

Maybe I have not understood correctly!

If Niffy were to play a constant tone test record recorded on one or both channels and display the output or outputs showing the level, do you think there would be a noticeable variation in the level over time?

I perceive this is the problem you are trying to solve.

Am i correct please?

If there is no variation over time you may be trying to solve a problem that is not significant.

What do you think please?

I have not heard or perceived the variation you describe.

I picked an example at 1000Hz and attached it , showing a recorded tone and its crosstalk to the other channel, and other artefacts. I have also done this type of measurement at around 3000Hz, but I have never seen any variation of the peak signal level with time at these scales. I have also run higher frequencies for frequency response measurements. I guess a variation in level of 1Db would be noticeable, but not audible?

M

There are lots of other problems that do exist, don't worry, but maybe we should add this one as well!?

Attachments

Mike56

You understood my question correctly.

But the research needs to be done differently.

I'll explain now. You need to take a record with high frequencies. Let's say from 10 kHz to 18 kHz.

Make artificial eccentricity in it with a file (see photo).

Connect the cartridge to a dual-beam oscilloscope.

You need to compare different frequencies at different eccentricities and see howthe signal changes in each channel.

Perhaps I'm exaggerating the problem, but most likely not.

High frequencies should decrease in turn, first in one channel,and then in the other.

The greater the eccentricity, the greater these swings will be. Left - right, left - right ....

If I'm wrong, I'll be happy.

AG.

You understood my question correctly.

But the research needs to be done differently.

I'll explain now. You need to take a record with high frequencies. Let's say from 10 kHz to 18 kHz.

Make artificial eccentricity in it with a file (see photo).

Connect the cartridge to a dual-beam oscilloscope.

You need to compare different frequencies at different eccentricities and see howthe signal changes in each channel.

Perhaps I'm exaggerating the problem, but most likely not.

High frequencies should decrease in turn, first in one channel,and then in the other.

The greater the eccentricity, the greater these swings will be. Left - right, left - right ....

If I'm wrong, I'll be happy.

AG.

Attachments

Hi, Mike56.

I want to add to my previous post.

I am considering only the purely technical side of the question: Is this or is it not.

I am not touching on the topic of my hearing, or yours, or anyone else's.

Only the technical side of the question.

I am not interested in answers like - this is not audible, I do not hear this and other similar ones.

I am only interested in objective technical measurements that will give an answer:at what eccentricities and at what frequencies the problem begins to manifest itself andunder what conditions it reaches critical values for perception.

The thing is that you could not pay attention to these changes in sound.

Take me as an example. I used to not pay attention to the poor work of anti-skating and was happy.

And when I did, now I am with you.

Respectfully,

AG.

I want to add to my previous post.

I am considering only the purely technical side of the question: Is this or is it not.

I am not touching on the topic of my hearing, or yours, or anyone else's.

Only the technical side of the question.

I am not interested in answers like - this is not audible, I do not hear this and other similar ones.

I am only interested in objective technical measurements that will give an answer:at what eccentricities and at what frequencies the problem begins to manifest itself andunder what conditions it reaches critical values for perception.

The thing is that you could not pay attention to these changes in sound.

Take me as an example. I used to not pay attention to the poor work of anti-skating and was happy.

And when I did, now I am with you.

Respectfully,

AG.

Andrey,

To a small extent i understand your point, but, and its a big BUT!

Making good tonearms as an amateur is difficult enough without coping with unrealistic situations.

I suggest to consider realistic technicalities.

So, having taken a look in the past at my records they have centre hole eccentricities of around 1mm maximum.

If the arm can cope with 1mm that's fine!!

However we also do experiments to see what happens at say 3mm of eccentricity, have a look at Carlo's torture tests and some of my videos on thread, this shows we might or might not be in the limits. but 5mm will not be relevant.

As another example, if you have warped records, put on a clamp, don't design your arm to come with unrealistic warps!

There are enough problems to cope well with realistic situations, the detail that our resident experts go to in order that their solutions work well already suggest that.

I found the best progress in my understandings was to make things and touch them, listen to them and measure them before comment.

I have made hundreds of improvements that seemed obvious before making them, only to discover they were rubbish! - they are all in the bin.

M

To a small extent i understand your point, but, and its a big BUT!

Making good tonearms as an amateur is difficult enough without coping with unrealistic situations.

I suggest to consider realistic technicalities.

So, having taken a look in the past at my records they have centre hole eccentricities of around 1mm maximum.

If the arm can cope with 1mm that's fine!!

However we also do experiments to see what happens at say 3mm of eccentricity, have a look at Carlo's torture tests and some of my videos on thread, this shows we might or might not be in the limits. but 5mm will not be relevant.

As another example, if you have warped records, put on a clamp, don't design your arm to come with unrealistic warps!

There are enough problems to cope well with realistic situations, the detail that our resident experts go to in order that their solutions work well already suggest that.

I found the best progress in my understandings was to make things and touch them, listen to them and measure them before comment.

I have made hundreds of improvements that seemed obvious before making them, only to discover they were rubbish! - they are all in the bin.

M

Hi Andrey,

It's great to see that you have been experimenting with arm builds to see how different things effect sound quality. I have done a lot of this myself.

Skating force is indeed a problem with pivoted tonearms. Skating force varies depending on groove modulation and arm position. A single antiskate setting will always be off by a bit.

I do not believe that it is possible to make a passive pivoted tonearm that does not suffer skating forces. This includes all tangential pivoted arms. Some geometries can minimise skating but not eliminate it. Analysis of the vectors involved supports this belief. To eliminate skating forces the drag vector on the stylus has to be exactly aligned with the pivot point

The addition of a servo motor to control the position of the arm could possibly eliminate skating. In my opinion servos can add more problems than they solve.

The only way to completely eliminate skating force in a passive arm is to use make it linear tracking.

Skating is not the only thing that can result in a sideways force being applied to the stylus. With a mechanical linear tracking tonearm the main contribution will be from bearing friction. I have done extensive research and testing in this area. The simplest type of bearings to use are ball-race bearings. These can easily result in higher sideways forces on the stylus than from skating with a conventional arm. Ball-race bearings will also suffer from bearing chatter where the non-loaded balls rattle around. My solution was to use pin bearings. These have a pin rotating in a fixed cup. My bearings use sapphires cups and tungsten carbide pivots. The same as used in precision mechanical clocks. These are very low friction and don't suffer from chatter. Much better than ball-race bearings. To further reduce friction my wheels are made from titanium and tungsten carbide. My rails are tungsten carbide. These materials minimise rolling resistance.

It is possible to get even lower friction by utilising an air bearing. The bearings job isn't just to be low friction. They also need to be dimensionaly accurate and stable. Both the pin bearing and the captured type of air bearings are excellent in this regard. The open style of air bearing not so much. The other important thing the bearings need to do is mechanically ground the arm. This involves giving the vibrational energy from the stylus/groove interface an easy path away from the arm. Pin bearings are excellent in this regard. Air bearings are not as good as they separate the two parts of the bearing with a thin layer of air.

The high lateral effective mass of a linear tracking arm is not actually a problem. It is in fact a big benefit.

It is true that there will be higher side forces acting on the stylus due to record eccentricity than with a normal pivoted arm. Take my arm playing an eccentric record that causes the arm to move back and forth by 1mm (bad eccentricity). This will result in a deflection of the cantilever of only about 0.04° with my Ortofon Quintet Black S cartridge. This is Completely inaudible. With records with more normal eccentricity it will be a lot less than this. With well centered records it will be zero. This deflection will be about 4 times that of a conventional arm.

The bass frequencies on records are modulated only laterally with no vertical content. Making the lateral mass of the arm high reduces the amount the cartridge body moves due to bass notes. Ideally you want the cartridge body to move as little as possible. With my arm this movement is about 1/4 of that with a pivoted arm. This improves the weight, authority and texture of bass notes. Especially those under 100hz. Vertical effective mass is similar to that of a conventional pivoting arm.

In my opinion the main advantage of a linear tracking tonearm is that the arm can be made very short. Making the arm shorter means that it becomes much more rigid. A more rigid arm will have a higher bending mode resonant frequency. The higher this resonant frequency the better. The bending mode resonant frequency of most tonearms is around 300-400hz. These arms will have a lot of harmonics in the audio band. These will colour the sound. With my short arm the bending mode resonant frequency is around 20khz. My arm acts as a rigid beam across the entire audio band. The sound is much less coloured with higher resolution.

Controlling resonance is much more important than reducing side forces acting on the stylus.

The only real downside to using a short arm is that they don't handle warps as well as longer arms. The use of a good warp flattening clamp is essential.

I have only skimmed over my design goals in this post. I have gone into a lot more detail in earlier posts in this thread. Unfortunately finding them in over 5000 posts will be difficult.

Niffy

It's great to see that you have been experimenting with arm builds to see how different things effect sound quality. I have done a lot of this myself.

Skating force is indeed a problem with pivoted tonearms. Skating force varies depending on groove modulation and arm position. A single antiskate setting will always be off by a bit.

I do not believe that it is possible to make a passive pivoted tonearm that does not suffer skating forces. This includes all tangential pivoted arms. Some geometries can minimise skating but not eliminate it. Analysis of the vectors involved supports this belief. To eliminate skating forces the drag vector on the stylus has to be exactly aligned with the pivot point

The addition of a servo motor to control the position of the arm could possibly eliminate skating. In my opinion servos can add more problems than they solve.

The only way to completely eliminate skating force in a passive arm is to use make it linear tracking.

Skating is not the only thing that can result in a sideways force being applied to the stylus. With a mechanical linear tracking tonearm the main contribution will be from bearing friction. I have done extensive research and testing in this area. The simplest type of bearings to use are ball-race bearings. These can easily result in higher sideways forces on the stylus than from skating with a conventional arm. Ball-race bearings will also suffer from bearing chatter where the non-loaded balls rattle around. My solution was to use pin bearings. These have a pin rotating in a fixed cup. My bearings use sapphires cups and tungsten carbide pivots. The same as used in precision mechanical clocks. These are very low friction and don't suffer from chatter. Much better than ball-race bearings. To further reduce friction my wheels are made from titanium and tungsten carbide. My rails are tungsten carbide. These materials minimise rolling resistance.

It is possible to get even lower friction by utilising an air bearing. The bearings job isn't just to be low friction. They also need to be dimensionaly accurate and stable. Both the pin bearing and the captured type of air bearings are excellent in this regard. The open style of air bearing not so much. The other important thing the bearings need to do is mechanically ground the arm. This involves giving the vibrational energy from the stylus/groove interface an easy path away from the arm. Pin bearings are excellent in this regard. Air bearings are not as good as they separate the two parts of the bearing with a thin layer of air.

The high lateral effective mass of a linear tracking arm is not actually a problem. It is in fact a big benefit.

It is true that there will be higher side forces acting on the stylus due to record eccentricity than with a normal pivoted arm. Take my arm playing an eccentric record that causes the arm to move back and forth by 1mm (bad eccentricity). This will result in a deflection of the cantilever of only about 0.04° with my Ortofon Quintet Black S cartridge. This is Completely inaudible. With records with more normal eccentricity it will be a lot less than this. With well centered records it will be zero. This deflection will be about 4 times that of a conventional arm.

The bass frequencies on records are modulated only laterally with no vertical content. Making the lateral mass of the arm high reduces the amount the cartridge body moves due to bass notes. Ideally you want the cartridge body to move as little as possible. With my arm this movement is about 1/4 of that with a pivoted arm. This improves the weight, authority and texture of bass notes. Especially those under 100hz. Vertical effective mass is similar to that of a conventional pivoting arm.

In my opinion the main advantage of a linear tracking tonearm is that the arm can be made very short. Making the arm shorter means that it becomes much more rigid. A more rigid arm will have a higher bending mode resonant frequency. The higher this resonant frequency the better. The bending mode resonant frequency of most tonearms is around 300-400hz. These arms will have a lot of harmonics in the audio band. These will colour the sound. With my short arm the bending mode resonant frequency is around 20khz. My arm acts as a rigid beam across the entire audio band. The sound is much less coloured with higher resolution.

Controlling resonance is much more important than reducing side forces acting on the stylus.

The only real downside to using a short arm is that they don't handle warps as well as longer arms. The use of a good warp flattening clamp is essential.

I have only skimmed over my design goals in this post. I have gone into a lot more detail in earlier posts in this thread. Unfortunately finding them in over 5000 posts will be difficult.

Niffy

Hi Niffy

Hi Mike56

Thank you for your detailed answers. I read them with great interest.

I live in Russia and political correctness is not in fashion here.

So please do not judge me harshly if I accidentally say something that is not politically correct.

I am not trained.

I will tell you something now that you better sit on a chair or a sofa.

When I got sick at the beginning of last year and was bedridden for almost two weeks,I read a lot of things on my laptop.

Including this thread from beginning to end and the thread on tangential pivot tonearms.

So, thank you for your brief excursion into the past - repetition is the mother of learning.

But I would still like to get an answer to my question.

We are DIYers.

And our task is not to hide the shortcomings, but to reveal them and look for solutions.

Or is it not so?

Respectfully,

AG

Hi Mike56

Thank you for your detailed answers. I read them with great interest.

I live in Russia and political correctness is not in fashion here.

So please do not judge me harshly if I accidentally say something that is not politically correct.

I am not trained.

I will tell you something now that you better sit on a chair or a sofa.

When I got sick at the beginning of last year and was bedridden for almost two weeks,I read a lot of things on my laptop.

Including this thread from beginning to end and the thread on tangential pivot tonearms.

So, thank you for your brief excursion into the past - repetition is the mother of learning.

But I would still like to get an answer to my question.

We are DIYers.

And our task is not to hide the shortcomings, but to reveal them and look for solutions.

Or is it not so?

Respectfully,

AG

Hi Andrey,

I would agree that our task is not to hide the shortcomings, but to reveal them and look for solutions.

We have a saying "there are more than one way to skin a cat". It means that there are often many different solutions to solving a problem. Several of these solutions are equally valid.

There are many very different designs of tonearm that are very good. One of these designs is not necessarily better than another. (There are also not so good designs.)

There are many ideas that are done as a standard design in tonearms. It is a good starting point to examine these ideas and determine why they are done and if these reasons are valid. Engineering is always about balancing compromises. There is no such thing as a no compromise design.

For example, putting the pivot point of a pivoting tonearm level with the record surface. This will eliminate something called warp wow. However with a 9" arm having the pivot 20-25mm above the record surface will still keep warp wow way below audibility. Will putting the pivot point level with the record surface compromise the structure of the arm compared to having the pivot level with the centre of the armtube?

There are also some things that are done because everyone does it that way. We need to examine these because often the reasoning behind them is flawed.

A couple of examples.

As I have previously mentioned. Most designers try to make the vertical and lateral effective masses the same. It just obvious that this is the best way. Except it isn't.

The frequency range laterally and vertically are very different. Lateral goes 2 octaves lower than vertical. Warps are only vertical. Eccentricity is only lateral. Most warps are at a higher frequency range than eccentricity. The compliance of your cartridge is different laterally and vertically. Vertical is usually about 80% of lateral.

If the frequency range, record flaws and compliance are all different then so should effective mass in order to balance them.

Many pivoted arm manufacturers offset the angle of the vertical bearing to match the offset angle of headshell. The thinking is to keep the headshell level as the arm goes up and down over warps. This will keep azimuth alignment more accurate. However warps are not 2 dimensional, they are 3 dimensional. Most warps slope down towards the centre of the record. Putting the bearing axis perpendicular to the armtube will cause the headshell to slightly tilt as the arm is raised. This tilt will be in the same direction that the record surface tilts. Azimuth will be better without bearing offset.

Don't do anything unless you fully understand why you are doing it.

I would agree that our task is not to hide the shortcomings, but to reveal them and look for solutions.

We have a saying "there are more than one way to skin a cat". It means that there are often many different solutions to solving a problem. Several of these solutions are equally valid.

There are many very different designs of tonearm that are very good. One of these designs is not necessarily better than another. (There are also not so good designs.)

There are many ideas that are done as a standard design in tonearms. It is a good starting point to examine these ideas and determine why they are done and if these reasons are valid. Engineering is always about balancing compromises. There is no such thing as a no compromise design.

For example, putting the pivot point of a pivoting tonearm level with the record surface. This will eliminate something called warp wow. However with a 9" arm having the pivot 20-25mm above the record surface will still keep warp wow way below audibility. Will putting the pivot point level with the record surface compromise the structure of the arm compared to having the pivot level with the centre of the armtube?

There are also some things that are done because everyone does it that way. We need to examine these because often the reasoning behind them is flawed.

A couple of examples.

As I have previously mentioned. Most designers try to make the vertical and lateral effective masses the same. It just obvious that this is the best way. Except it isn't.

The frequency range laterally and vertically are very different. Lateral goes 2 octaves lower than vertical. Warps are only vertical. Eccentricity is only lateral. Most warps are at a higher frequency range than eccentricity. The compliance of your cartridge is different laterally and vertically. Vertical is usually about 80% of lateral.

If the frequency range, record flaws and compliance are all different then so should effective mass in order to balance them.

Many pivoted arm manufacturers offset the angle of the vertical bearing to match the offset angle of headshell. The thinking is to keep the headshell level as the arm goes up and down over warps. This will keep azimuth alignment more accurate. However warps are not 2 dimensional, they are 3 dimensional. Most warps slope down towards the centre of the record. Putting the bearing axis perpendicular to the armtube will cause the headshell to slightly tilt as the arm is raised. This tilt will be in the same direction that the record surface tilts. Azimuth will be better without bearing offset.

Don't do anything unless you fully understand why you are doing it.

completely offtopic, I apologize to everyone.

Hi Andrey

the premise of the Syrinx was to faithfully follow the Thales geometry with an "extensible" arm, and it couldn't work.

first - because the stylus drag (that I measured only after), is just a third of the theoric data on web (and variable with musical content much more than with peripheral speed) therefore an insufficient "motor". (never trust the web!)

second - almost missing the SD, the arm, as it happens always, tried to rotate due to the SF. But this force was applied in the normal direction to the sliding rail and, multiplied by the lever of the wand. completely blocking the movement.

third - the sum of the frictions of the various movements was such as to make it even more critical than a linear.

So I advise you not to waste time on this path; my failure was more than enough: as a partial excuse consider that it was my first attempt to get out of the usual pivoted ones. But useful to understand - more, to touch! -that the arms do not move as we see, what matters are the micro tracing motions, and the way our design allows to make a coherent effective average of them.

good luck - carlo

mini glossary - Sorry, i thought that, reading our threads, you had already often met those abbreviations

L - left channel R - right channel

SD - stylus drag SF - side force

L TA - linear tonearm RTA - radial tonearm PTA - pivoted tonearm P T TA - pivoted tangential tonearm

T E - tracking error

PS . - RIIA eccentricity standard < 1,5mm . warps instead come from out bad storage, so no limits...

Hi Andrey

the premise of the Syrinx was to faithfully follow the Thales geometry with an "extensible" arm, and it couldn't work.

first - because the stylus drag (that I measured only after), is just a third of the theoric data on web (and variable with musical content much more than with peripheral speed) therefore an insufficient "motor". (never trust the web!)

second - almost missing the SD, the arm, as it happens always, tried to rotate due to the SF. But this force was applied in the normal direction to the sliding rail and, multiplied by the lever of the wand. completely blocking the movement.

third - the sum of the frictions of the various movements was such as to make it even more critical than a linear.

So I advise you not to waste time on this path; my failure was more than enough: as a partial excuse consider that it was my first attempt to get out of the usual pivoted ones. But useful to understand - more, to touch! -that the arms do not move as we see, what matters are the micro tracing motions, and the way our design allows to make a coherent effective average of them.

good luck - carlo

mini glossary - Sorry, i thought that, reading our threads, you had already often met those abbreviations

L - left channel R - right channel

SD - stylus drag SF - side force

L TA - linear tonearm RTA - radial tonearm PTA - pivoted tonearm P T TA - pivoted tangential tonearm

T E - tracking error

PS . - RIIA eccentricity standard < 1,5mm . warps instead come from out bad storage, so no limits...

Last edited:

Hi, Niffy

Russians have a saying: "Don't confuse horseradish with radish."

And you are right now confusing these two products.

I will explain in simple words why.

There are always two categories of people:

№1 - inventors;

№2 - those who bring inventions to perfection.

№1 is interested exclusively in the technical issue - the creation of a mechanism that solvesone or another technical problem.№2 bring this mechanism to perfection.

You like to give examples.

I will give an example too.

Let's take the classic pivot tonearm, for example.

A hundred years ago, its geometry was proposed by Lofgren.

What has changed fundamentally over the past hundred years?

NOTHING.

They only added anti-skating.

However, every year new pivot tonearms appear.

Every time I read stories from developers about new heights reached by their tonearms in conquering sound quality.

But if you look closely, there is nothing new there.

But there is a lot of smart talk.

In my understanding, people like Ralph, like Carlo, like dtut, like me belong to №1.

Our primary task is to create a mechanism.

And if this mechanism is successful, then team #2 will come and bring every bone of this mechanism to perfection.

But not the other way around - as you say.

P.S. I don't like your last words.

They smell of the grave.

The words of the Russian poet A.S. Pushkin, written in 1829, suit me better.

They breathe life and progress.

Unfortunately, my English does not allow me to show all the beauty of what was said,so I added the text in Russian

(find a good translation into Englishand you will see the truth of my words. Bad translation, meaningless and merciless)

Oh, how many wonderful discoveries

The spirit of enlightenment prepares for us

And experience is the son of difficult mistakes,

And genius is a friend of paradoxes,

And chance is a god-inventor...

О, сколько нам открытий чудных

Готовят просвещенья дух

И опыт - сын ошибок трудных,

И гений - парадоксов друг,

И случай - бог-изобретатель...

AG.

Russians have a saying: "Don't confuse horseradish with radish."

And you are right now confusing these two products.

I will explain in simple words why.

There are always two categories of people:

№1 - inventors;

№2 - those who bring inventions to perfection.

№1 is interested exclusively in the technical issue - the creation of a mechanism that solvesone or another technical problem.№2 bring this mechanism to perfection.

You like to give examples.

I will give an example too.

Let's take the classic pivot tonearm, for example.

A hundred years ago, its geometry was proposed by Lofgren.

What has changed fundamentally over the past hundred years?

NOTHING.

They only added anti-skating.

However, every year new pivot tonearms appear.

Every time I read stories from developers about new heights reached by their tonearms in conquering sound quality.

But if you look closely, there is nothing new there.

But there is a lot of smart talk.

In my understanding, people like Ralph, like Carlo, like dtut, like me belong to №1.

Our primary task is to create a mechanism.

And if this mechanism is successful, then team #2 will come and bring every bone of this mechanism to perfection.

But not the other way around - as you say.

P.S. I don't like your last words.

They smell of the grave.

Don't do anything unless you fully understand why you are doing it.

The words of the Russian poet A.S. Pushkin, written in 1829, suit me better.

They breathe life and progress.

Unfortunately, my English does not allow me to show all the beauty of what was said,so I added the text in Russian

(find a good translation into Englishand you will see the truth of my words. Bad translation, meaningless and merciless)

Oh, how many wonderful discoveries

The spirit of enlightenment prepares for us

And experience is the son of difficult mistakes,

And genius is a friend of paradoxes,

And chance is a god-inventor...

О, сколько нам открытий чудных

Готовят просвещенья дух

И опыт - сын ошибок трудных,

И гений - парадоксов друг,

И случай - бог-изобретатель...

AG.

Hi Carlo

Thank you for your glossary.

I read these two topics more than a year ago and all these abbreviations have been erased from my memory.

You advise not to waste time. But what about your words that doing what you love is fun?

Besides, my path is not exactly your path with Syrinx, this path is different from yours.

If everything ends well, I will finish the work in the fall and try to show the result.

But I will not take on any time commitments - as it turns out.

And now it's summer, children, grandchildren, sea, rest .... and a little hobby.

I will finish with this topic, I do not like meaningless talk, and next week I am moving to Pt TA.

I thought for a long time whether to show or not and decided to show one design to support a dying topic.

I wish everyone health and long life!

Ralph. I look at your tonearm and admire the filigree executionand the sophistication of your mind. Bravo!

With respect to all,

AG.

Thank you for your glossary.

I read these two topics more than a year ago and all these abbreviations have been erased from my memory.

You advise not to waste time. But what about your words that doing what you love is fun?

Besides, my path is not exactly your path with Syrinx, this path is different from yours.

If everything ends well, I will finish the work in the fall and try to show the result.

But I will not take on any time commitments - as it turns out.

And now it's summer, children, grandchildren, sea, rest .... and a little hobby.

I will finish with this topic, I do not like meaningless talk, and next week I am moving to Pt TA.

I thought for a long time whether to show or not and decided to show one design to support a dying topic.

I wish everyone health and long life!

Ralph. I look at your tonearm and admire the filigree executionand the sophistication of your mind. Bravo!

With respect to all,

AG.

Inventors? what Big Words, Andrey.

There is Loefgren and a few others, and we, old former something else, still playing with Lego bricks.

Or simply kicking the box, without knowing where it falls, as someone noted here around.

There is Dostoievskij and there is Pasternak, just to stay over there. The important is to feel always the difference.

Eg. for a long time I have been wanting to open a thread to know if there is a graphical way to construct a Loefrgren geometry. I try but I can't.

c

ps - Syrinx - I just tried to avoid that you stumble into the same holes

There is Loefgren and a few others, and we, old former something else, still playing with Lego bricks.

Or simply kicking the box, without knowing where it falls, as someone noted here around.

There is Dostoievskij and there is Pasternak, just to stay over there. The important is to feel always the difference.

Eg. for a long time I have been wanting to open a thread to know if there is a graphical way to construct a Loefrgren geometry. I try but I can't.

c

ps - Syrinx - I just tried to avoid that you stumble into the same holes

Carlo

I didn't say anything grand.

If the word "inventor" seems grand to you, I'll call it something else:

"An inquisitive mind striving to solve a technical problem.

"But what does this change in principle?

How is Lofgren different from us?

That his cube hit the target?

And this cube has been chewed over for a hundred years?

Who can say with 100% certainty that your cubes will notimprove the next hundred years?

No one.

So, Carlo, I disagree with you.

Of course, I appreciate your modesty, but I prefer to call things by their proper names.

AG.

I didn't say anything grand.

If the word "inventor" seems grand to you, I'll call it something else:

"An inquisitive mind striving to solve a technical problem.

"But what does this change in principle?

How is Lofgren different from us?

That his cube hit the target?

And this cube has been chewed over for a hundred years?

Who can say with 100% certainty that your cubes will notimprove the next hundred years?

No one.

So, Carlo, I disagree with you.

Of course, I appreciate your modesty, but I prefer to call things by their proper names.

AG.

lcsaszar

Apparently you are right. There is nothing new.

I voiced the problem of eccentricity for a linear tonearm and suggestedmy way to reduce its influence on the reproduction of high frequencies.

And in response - silence. Only moralizing.

How similar this is to our forums, they also like to puff out their cheeks.

But I wanted to hear a competent opinion with instrumental evidence.

Apparently it was not meant to be.

AG.

Apparently you are right. There is nothing new.

I voiced the problem of eccentricity for a linear tonearm and suggestedmy way to reduce its influence on the reproduction of high frequencies.

And in response - silence. Only moralizing.

How similar this is to our forums, they also like to puff out their cheeks.

But I wanted to hear a competent opinion with instrumental evidence.

Apparently it was not meant to be.

AG.

Modest? no Andrey, thanks, not at all. Simply trying to keep some sense of proportion, and a bit of humor. In Italy we prefer to be called a lucky dumb who stumbles in right solutions, rather than a boring, wise man. Do you remember what happened to Pinocchio's talking cricket?

...not a single piece of DIY linear tracking arm is shown, that could give inspiration to others .... Icsaszar

It' a general complaint? to everyone? ....quote!

c

Last edited:

...Is there really nothing new under the sun? Icsaszar

Thanks to the recent, fruitful contributions (sometime subtly hidden) in the long time discussion on the merits and defects of Linears vs Pivoted, I came to ask myself: "why not combine the defects of both to obtain an unique advantage?" not an usual PT TA, limited to the first stage, something simple and effective instead, as rightly asked about.

Here a first rough sketch of a "passive servo linear" trial

(attachment)

The Pivoted TA (the driving section) transfers its Skating (adjustable), via proper connexions, to the Linear TA (the reading section), drastically reducing the Side Force needed for cart motion, and related well known issues.

Of course there are problems, and anyone on this thread will immediately notice the small detail that could deeply affect it's behavior. But certainly defects and complexity do not scare we passionate diyers, the opposite.

carlo

Attachments

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm