@Niffy

The arm used for both the sapphire/carbide and pen tips is a pivoting arm of 239.4mm effective length. The mass was placed at the stylus point and the arm wand at the time of this test was 99g total mass. Effective mass (without cart mounted) was calculated at 12.9g for a 6g cartridge.

The sapphire/carbide were 0.1mm and 0.025mm radius respectively. I suspect these radii were too small for the arm mass.

Mike,

I bought medium Parker pen refills (1mm) yesterday to install in the arm. These use oil based ink. It'll take a few days to get the carriers machined and installed. I'll report back when done.

The arm used for both the sapphire/carbide and pen tips is a pivoting arm of 239.4mm effective length. The mass was placed at the stylus point and the arm wand at the time of this test was 99g total mass. Effective mass (without cart mounted) was calculated at 12.9g for a 6g cartridge.

The sapphire/carbide were 0.1mm and 0.025mm radius respectively. I suspect these radii were too small for the arm mass.

Mike,

I bought medium Parker pen refills (1mm) yesterday to install in the arm. These use oil based ink. It'll take a few days to get the carriers machined and installed. I'll report back when done.

Hi,

Has anyone attempted to replace the ink in the nib with a light oil, maybe sewing machine oil? After the nib has been removed from the ink tube replace the tube with one filled with oil then scribble until you only have oil coming out. Just a thought.

Niffy

Has anyone attempted to replace the ink in the nib with a light oil, maybe sewing machine oil? After the nib has been removed from the ink tube replace the tube with one filled with oil then scribble until you only have oil coming out. Just a thought.

Niffy

Hi Warren,

The radii of the sapphire and carbide pivots are way to small to support 99g. Also the radius ratio between the two should be around 1:2-1:3. The lower the ratio the higher the maximum load, 1:4 is a little high. This would probably explain both the high friction and why the pivot broke. For my arm, which is about half the mass of yours and has that mass supported by twice the number of pivots, I used pivots with a radius of 0.125mm and vees of 0.25mm and have had years of trouble free service.

For a 1mm nib ,0.5mm radius, the 0.1mm vee will be too small. A vee, cold forged, in the end of a grub screw should work better. You will get lower friction if the ball rotates in the vee rather than the ball rotating in the nib. I described how I made these in this thread several years ago. I can describe the process again if you think that will be of use to you.

Niffy

The radii of the sapphire and carbide pivots are way to small to support 99g. Also the radius ratio between the two should be around 1:2-1:3. The lower the ratio the higher the maximum load, 1:4 is a little high. This would probably explain both the high friction and why the pivot broke. For my arm, which is about half the mass of yours and has that mass supported by twice the number of pivots, I used pivots with a radius of 0.125mm and vees of 0.25mm and have had years of trouble free service.

For a 1mm nib ,0.5mm radius, the 0.1mm vee will be too small. A vee, cold forged, in the end of a grub screw should work better. You will get lower friction if the ball rotates in the vee rather than the ball rotating in the nib. I described how I made these in this thread several years ago. I can describe the process again if you think that will be of use to you.

Niffy

Carlo tried replacing the ink with lube and he advised me against it.

The sapphire and carbide came from True Point UK and were bought as a set.

The pen pivots are in M4 setscrews with no polishing. The ball rotates in the pen seat not the vee.

I made a version your arm with 1.5mm HSS drill bits as the pivot in forged and highly polished M3 setscrews.

The sapphire and carbide came from True Point UK and were bought as a set.

The pen pivots are in M4 setscrews with no polishing. The ball rotates in the pen seat not the vee.

I made a version your arm with 1.5mm HSS drill bits as the pivot in forged and highly polished M3 setscrews.

warrjon,

How did you polish setscrews? I am thinking of polishing setscrews but I haven't found a way to do it so far.

How did you polish setscrews? I am thinking of polishing setscrews but I haven't found a way to do it so far.

I made a forge from a Cobalt drill with the needed radius and forged the end of the setscrew.

The polishing was done with tooth picks and diamond paste of varying grades down to 0.25microns.

There is write up in this thread somewhere.

The polishing was done with tooth picks and diamond paste of varying grades down to 0.25microns.

There is write up in this thread somewhere.

The ball rotates in the pen seat not the vee.

Ideally you want the ball to rotate in the vee.

We can assume that the coefficient of friction between the ball and the pen seat will be similar to the coefficient of friction between the ball and vee. The ball/seat will be lubricated by the ink. I found that using petroleum jelly in the vee similarly helped to reduce friction between my steel pivots and steel vees. (I run the jewel bearings dry). The sliding friction at the contact point on the ball will therefore be similar between the two.

The torque required to rotate the bearing is determined by the level of the contact friction and distance between the contact point and the axis of rotation.

With a 1mm nib the distance between seat and axis will be in the region of 350μm. The radius of the contact patch between ball and vee will be 2-3μm for a 100g load. The average friction occurs at about 80% of the contact radius from the axis. The introduction of end shake, the small amount of play required to prevent binding, will increase this.

The torque required to revolve the ball in the vee should be orders of magnitude lower than that required to revolve the ball in the seat. In order to get the ball to revolve in the seat the bearing would have to be over tightened or the vee to have too small a radius compared to the balls or the surface of the vee too rough.

Niffy

Ideally you want the ball to rotate in the vee.

We can assume that the coefficient of friction between the ball and the pen seat will be similar to the coefficient of friction between the ball and vee. The ball/seat will be lubricated by the ink. I found that using petroleum jelly in the vee similarly helped to reduce friction between my steel pivots and steel vees. (I run the jewel bearings dry). The sliding friction at the contact point on the ball will therefore be similar between the two.

The torque required to rotate the bearing is determined by the level of the contact friction and distance between the contact point and the axis of rotation.

With a 1mm nib the distance between seat and axis will be in the region of 350μm. The radius of the contact patch between ball and vee will be 2-3μm for a 100g load. The average friction occurs at about 80% of the contact radius from the axis. The introduction of end shake, the small amount of play required to prevent binding, will increase this.

The torque required to revolve the ball in the vee should be orders of magnitude lower than that required to revolve the ball in the seat. In order to get the ball to revolve in the seat the bearing would have to be over tightened or the vee to have too small a radius compared to the balls or the surface of the vee too rough.

Niffy

Where did this post start at ? Sounds like a pretty cool and workable idea

It started a while ago with a post from Carlo. I am building a pivoting arm and tested cheap Bic pen tips for sensitivity and another DIYer asked me to post the results here

These pivots are cheap and work well. They can be adapted to an LTA which is why I posted.

These pivots are cheap and work well. They can be adapted to an LTA which is why I posted.

Last edited:

@Niffy,

In my application (pivoting arm) I'm more interested in bearing rigidity ie no end shake than ultra low friction. As long as sensitivity is around 10mg I'll be happy.

In my application (pivoting arm) I'm more interested in bearing rigidity ie no end shake than ultra low friction. As long as sensitivity is around 10mg I'll be happy.

Hi Warren,

I would definitely agree that when you get down to the level of friction that you have achieved any further reduction is unlikely to be audible. It might actually be useful to have a little friction as this will help to damp the motion of the arm.

In my opinion the most important aspect of bearing performance is not low friction. It is mechanical grounding, how well the bearing couples the cartridge to the sub-chassis/plinth. There are 6 degrees of movement. You want the arm to move freely in 2 of them and be held absolutely rigidly in the other 4. Spikes/pin bearings are the best way to achieve this. Your pen nibs should be excellent at coupling the armtube to its base.

Niffy

I would definitely agree that when you get down to the level of friction that you have achieved any further reduction is unlikely to be audible. It might actually be useful to have a little friction as this will help to damp the motion of the arm.

In my opinion the most important aspect of bearing performance is not low friction. It is mechanical grounding, how well the bearing couples the cartridge to the sub-chassis/plinth. There are 6 degrees of movement. You want the arm to move freely in 2 of them and be held absolutely rigidly in the other 4. Spikes/pin bearings are the best way to achieve this. Your pen nibs should be excellent at coupling the armtube to its base.

Niffy

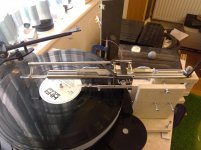

The latest incarnation of my prototype/experimental arm appears in pictures below, now hinges away reliably and lands back on 3 magnets repeatably.

This is an Avonite mount with a 12mm bolt as pivot.

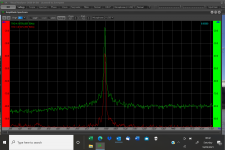

Measured results confirm the best i have achieved with a hinge away mechanism

best,

Mike

This is an Avonite mount with a 12mm bolt as pivot.

Measured results confirm the best i have achieved with a hinge away mechanism

best,

Mike

Attachments

Mike,

Great improvements! How does it sound now?

Jim

Hi Jim, Unfortunately my answers to any questions on sound are less reliable than others because i have not heard any set ups that are reliably quantified as really good and my only comparisons are with my own equipment and set up.

However, lets have a go.

- Many of my LTA experiments give low surface noise, this one included.

- Bass is full, deep, tuneful and precise as opposed to what i feel is over resonant and flabby that some have been.

- High end, cymbals etc open and easily discerned.

- I think the most noticeable thing i find with any improvements i make is when instruments are separated out as opposed to blended in, one can hear the whole but pick out the individual instruments more, a full symphony orchestra is not just a wall of sound, one can hear the individual parts and little intonations in a voice.

- Dynamic range from quiet to loud is significant.

- Enjoyable to listen to, definitely encourages digging out those old discs!

Mike

Morning Gents, pleased with where it is, but i always assume there is more to be had as well.

There are certainly some function details to work on, the cueing is fiddly and could be more rigid, so i have ordered some bits to make that.

But how do you decide where to look for the next step in sound improvements?

M

There are certainly some function details to work on, the cueing is fiddly and could be more rigid, so i have ordered some bits to make that.

But how do you decide where to look for the next step in sound improvements?

M

Ideally you want the ball to rotate in the vee.

Niffy

I have been pondering this a few days Niffy, and am intrigued, first of all, how does anyone know which is doing what?

I can hardly see if the ball is in the V at all when i assemble and certainly cannot tell what's happening in there!

Then, my grub screw vees are left as manufactured and are certainly rough in comparison to the ball seat that is carefully made to be smooth so the writing action is smooth.

Surely the ball will chose by lowest friction which it rotates in and its likely in my set up its the smooth ball cup not the vee?

Mike

CORKSCREW MK2

Hi all, friends - here again.

Struggling in vain for a decent solution for the MoonTracker (the vertical RTA #4333) I thought back to my corkScrew RTA # 4174 #4219 (starting from # 3762-70 ....... #4084- 4144 - 4150) and it's original sin, which is precisely the central spring blade of the corkscrew joint itself.

Perhaps someone will recall, even from the videos of tracking #4208, that on LPs with small warps the corkScrew performs effortlessly, however my measurement set showed that, over 1.5 mm warp, i.e. beyond the elbow lever effect, the VTF tended to to vary increasingly. Nothing worrying for a correct listening of well stored discs, but from a theoretical point of view, yes. What is inacceptable for me; and others, i know.

The only alternative for a Radial rail TA with true parallel H and V articulation seems therefore just my previous Lil Casey MK 2 - 3 or the new smart moving parallelogram invented by Mike56, now perfected at truly excellent levels, confirmed by incontrovertible measures and signal graphs: but that solution is unfortunately too bulky for present corkScrew structures.

Why not, however, to make a sort 90 ° turn: using the parallelogram the "wrong side", "squeezing" it almost to a flat one seems clearly a desperate fool's solution. However a parallelogram remains a parallelogram at every angle: a rectangle at 90 °, a line at 0 °, but always a parallelogram.

Will it be feasible?

- attachment A simulation

Full of doubts I have made a super quick cardboard mockup, that seemed to work. and made me understand that the horizontal arrangement is a limit condition, better to start from a less uncertain, more stable one.

- attachment B - C simulations

Loads on pentip bearings with angles close to zero may be relevant, so there must be almost no play to maintain parallelism. Fortunately the force is applied from below, but it's behavior must be verified in practice.

There are also problems with miniaturization (levers, pentips seats and tuning screwcups) to use the same previous corkScrew rail and base. Even the distribution of weights would be problematic: for this Mike gave me the clever idea to position one CW moving inside a hole in the first lever. (thanks again, M)

- attachment - drawings

Here are the results for a prototype: small parts require considerable precision and consequent time. Luckily for the cart I had kept the assembly jigs, but the mini parallelogram was really challenging.

The first results seem interesting, and the behavior reliable. My usual set of measures (videos of the crash test - 3mm warp +- 1,5 eccentric; vert + hor friction - VTF variation) will come later. And again no personal listening impressions: i trust mine even less than other's ones

ciao - carlo

Hi all, friends - here again.

Struggling in vain for a decent solution for the MoonTracker (the vertical RTA #4333) I thought back to my corkScrew RTA # 4174 #4219 (starting from # 3762-70 ....... #4084- 4144 - 4150) and it's original sin, which is precisely the central spring blade of the corkscrew joint itself.

Perhaps someone will recall, even from the videos of tracking #4208, that on LPs with small warps the corkScrew performs effortlessly, however my measurement set showed that, over 1.5 mm warp, i.e. beyond the elbow lever effect, the VTF tended to to vary increasingly. Nothing worrying for a correct listening of well stored discs, but from a theoretical point of view, yes. What is inacceptable for me; and others, i know.

The only alternative for a Radial rail TA with true parallel H and V articulation seems therefore just my previous Lil Casey MK 2 - 3 or the new smart moving parallelogram invented by Mike56, now perfected at truly excellent levels, confirmed by incontrovertible measures and signal graphs: but that solution is unfortunately too bulky for present corkScrew structures.

Why not, however, to make a sort 90 ° turn: using the parallelogram the "wrong side", "squeezing" it almost to a flat one seems clearly a desperate fool's solution. However a parallelogram remains a parallelogram at every angle: a rectangle at 90 °, a line at 0 °, but always a parallelogram.

Will it be feasible?

- attachment A simulation

Full of doubts I have made a super quick cardboard mockup, that seemed to work. and made me understand that the horizontal arrangement is a limit condition, better to start from a less uncertain, more stable one.

- attachment B - C simulations

Loads on pentip bearings with angles close to zero may be relevant, so there must be almost no play to maintain parallelism. Fortunately the force is applied from below, but it's behavior must be verified in practice.

There are also problems with miniaturization (levers, pentips seats and tuning screwcups) to use the same previous corkScrew rail and base. Even the distribution of weights would be problematic: for this Mike gave me the clever idea to position one CW moving inside a hole in the first lever. (thanks again, M)

- attachment - drawings

Here are the results for a prototype: small parts require considerable precision and consequent time. Luckily for the cart I had kept the assembly jigs, but the mini parallelogram was really challenging.

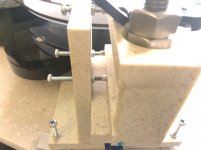

- attachment - photo of parts

- attachment - photo of assemblage

The first results seem interesting, and the behavior reliable. My usual set of measures (videos of the crash test - 3mm warp +- 1,5 eccentric; vert + hor friction - VTF variation) will come later. And again no personal listening impressions: i trust mine even less than other's ones

ciao - carlo

Attachments

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm