springs - help needed

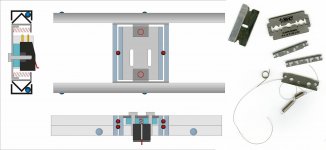

I am looking in every way to reduce the weight of this nested cart from 10-15 gr to a normal VTF.

Many on the web love magnetic levitation and other devilry, not me. So only the springs remain. But again I understand almost nothing. I dusted off Hooke law, and found this too for leaf springs

Leaf spring calculator

Doubt:

with a normal CW we implement a condition of equilibrium (almost, there is a minimum angular variation), so that on warps the cartridge can get up simply by overcoming the friction of the pivot.

But with a spring, or a leaf spring, even when placed in the linear thrust condition, any elongation requires a proportional force. (?)

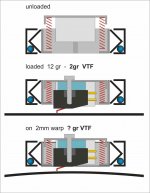

in my case - let's say that I have reduced the weight on disc from 12 gr to the 2gr VTF, thanks to 10mm of spring compression - So just a 1mm warp will add a 1 gr push (! ?) which is obviously intolerable.

Yet spring loaded CWs have been used for decades, and someone still uses them. Where am I wrong?

carlo

and then there is the problem of finding/make such sensitive springs: 5 cm of 0.25mm piano wire already exercise a 3-4 gr push!

I am looking in every way to reduce the weight of this nested cart from 10-15 gr to a normal VTF.

Many on the web love magnetic levitation and other devilry, not me. So only the springs remain. But again I understand almost nothing. I dusted off Hooke law, and found this too for leaf springs

Leaf spring calculator

Doubt:

with a normal CW we implement a condition of equilibrium (almost, there is a minimum angular variation), so that on warps the cartridge can get up simply by overcoming the friction of the pivot.

But with a spring, or a leaf spring, even when placed in the linear thrust condition, any elongation requires a proportional force. (?)

in my case - let's say that I have reduced the weight on disc from 12 gr to the 2gr VTF, thanks to 10mm of spring compression - So just a 1mm warp will add a 1 gr push (! ?) which is obviously intolerable.

Yet spring loaded CWs have been used for decades, and someone still uses them. Where am I wrong?

carlo

and then there is the problem of finding/make such sensitive springs: 5 cm of 0.25mm piano wire already exercise a 3-4 gr push!

Attachments

Last edited:

Constant force springs don't change their force with extension, but i dont know how small they go............springs - help needed

I am looking in every way to reduce the weight of this nested cart from 10-15 gr to a normal VTF.

Lee Spring

mike

Great result Mike.

What are planning on replacing the vertical pivot bearings with?

Its raining heavily here so i mounted my latest Mylar hinge parallelogram on my original carbon cart, the workmanship is not pretty but i sense it feels OK as a concept, counterweight, bearings and cartridge to add, i might run it on the TT later.........then if it works i can refine construction, all as usual to be done with a hand saw, files and sandpaper.

Its got notably less expensive as well!

Attachments

better explaining what i'm trying to understand - calculate

c2

If you take a long but very weak spring, which is compressed almost totally by the weight of the cartridge assembly, then the relative change of the spring force will be very small for 2 mmm displacement.

Hello Carlo,

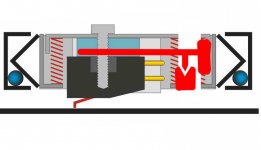

I have not followed all the posts of this linear arm. So please consider this as broad concept of solution to your VTF problem. As in the picture a small knife edge bearing and counterweight can be arranged. The rest of the contraption could be modified.

Best regards.

I have not followed all the posts of this linear arm. So please consider this as broad concept of solution to your VTF problem. As in the picture a small knife edge bearing and counterweight can be arranged. The rest of the contraption could be modified.

Best regards.

Attachments

Last edited:

I think a hanging spring is vertically straighter than a push up spring due to gravity. But since the cartridge needs to travel horizontally the springs might not be rigid enough to avoid bending sideways during play... unless you introduce some kind of vertical guide. Now, as always, I do like where your mind is going with this: to create a bearing system for purely vertical movement. Keep up the good work, Carlo!

Thank you all, friends.

Meanwhile I did some practical tests (trivial doubts come to me more and more often, will I have to worry?) with a digital scale, two rubber bands, a weight of 100 gr and a thickness of 2 mm. I zeroed the scale with the suspended weight above, then I added the thickness under and that's it = 14 grams more (of which 1.5 is the thickness weight)

So it is as I feared (Hooke law) - if I have a spring with 10 mm of compression for 10 grams - when the warp raises by 2mm, the compression is now only 8mm, that is, I am compensating for only 8 grams, and therefore VTF has increased by the 2 grams. Horrible

So how the hell could they use springs in the past? because Alighiszem's reasoning is right: if the spring was very long (or instead the elongation of the spring a few tenths, thanks to the wand's lever) with 1-2 mm warp the variation of VTF would be minimal.

So sadly we still have to go to the moon (cart weight 1/6, near to needed VTF) to hear this cart playing. Or use that of #4061 or, maybe better, Mike's or Koldby's clever parallelograms (near to what you've sketched, Hiten)

carlo

hi Dd, thanks for appreciation - this carriage (#4061) has also a non recirculating bearing to get his pistonic effect . What you fear could be really dangerous, i knew.

Meanwhile I did some practical tests (trivial doubts come to me more and more often, will I have to worry?) with a digital scale, two rubber bands, a weight of 100 gr and a thickness of 2 mm. I zeroed the scale with the suspended weight above, then I added the thickness under and that's it = 14 grams more (of which 1.5 is the thickness weight)

So it is as I feared (Hooke law) - if I have a spring with 10 mm of compression for 10 grams - when the warp raises by 2mm, the compression is now only 8mm, that is, I am compensating for only 8 grams, and therefore VTF has increased by the 2 grams. Horrible

So how the hell could they use springs in the past? because Alighiszem's reasoning is right: if the spring was very long (or instead the elongation of the spring a few tenths, thanks to the wand's lever) with 1-2 mm warp the variation of VTF would be minimal.

So sadly we still have to go to the moon (cart weight 1/6, near to needed VTF) to hear this cart playing. Or use that of #4061 or, maybe better, Mike's or Koldby's clever parallelograms (near to what you've sketched, Hiten)

carlo

hi Dd, thanks for appreciation - this carriage (#4061) has also a non recirculating bearing to get his pistonic effect . What you fear could be really dangerous, i knew.

Last edited:

Carlo,

To follow up on DD's idea of a hanging spring - the three pivoting arms I'm familiar with which have spring adjusted VTF all have the spring in tension rather than compression meaning the spring is adding proportional acceleration to the arm's upward movement in response to warps.

Mike56,

I'm seriously impressed with your ingenious solutions and persistence.

To follow up on DD's idea of a hanging spring - the three pivoting arms I'm familiar with which have spring adjusted VTF all have the spring in tension rather than compression meaning the spring is adding proportional acceleration to the arm's upward movement in response to warps.

Mike56,

I'm seriously impressed with your ingenious solutions and persistence.

Mike56's idea mylar hinge is excellent. I am not sure but springs will probably have motions in horizontal plane too. Mylar hinge and knife edge bearing have solid mechanical ground plus only one directional motion. Dual tonearm had spiral leaf springs but it had vertical bearings too.

Regards

Regards

ciao Doug, what a pleasure to hear you again, and that you have not lost interest in TAs.

With the limitations of weights and dimensions of this kind of carriages the solutions are damn few and difficult. An extension spring was also on my Rabbit PLT (mixed 1/2 spring 1/2 CW, to decrease hor. eff mass). Recently making some cosmetic changes I took it off. Imperceptible change, it seems to move better on warps, maybe just autosuggestion.

Until now with the springs I had naively trusted the magic word - linear - but this cart forced to understand that Hooke law says much more than this: as Alighiszem rightly notes, when elongation is relevant it is also the change of the force to get it, that is the VTF. Always linear, but relevant,

This also explained the strange behavior of the springed version (Luxo lamp style) of Lil Casey Mk1: the elongation was small, but already sufficient to alter 10-20% the VTF.

Unfortunately despairing for a true pistonic movement, I see magnets in my future....(the desperate designer's last resort - sob)

carlo

Mike & Koldby are taking another important step towards a truly, completely linear arm. Someone has to do it, before the vinyl saurs go extinct...

With the limitations of weights and dimensions of this kind of carriages the solutions are damn few and difficult. An extension spring was also on my Rabbit PLT (mixed 1/2 spring 1/2 CW, to decrease hor. eff mass). Recently making some cosmetic changes I took it off. Imperceptible change, it seems to move better on warps, maybe just autosuggestion.

Until now with the springs I had naively trusted the magic word - linear - but this cart forced to understand that Hooke law says much more than this: as Alighiszem rightly notes, when elongation is relevant it is also the change of the force to get it, that is the VTF. Always linear, but relevant,

This also explained the strange behavior of the springed version (Luxo lamp style) of Lil Casey Mk1: the elongation was small, but already sufficient to alter 10-20% the VTF.

Unfortunately despairing for a true pistonic movement, I see magnets in my future....(the desperate designer's last resort - sob)

carlo

Mike & Koldby are taking another important step towards a truly, completely linear arm. Someone has to do it, before the vinyl saurs go extinct...

Last edited:

Good morning everybody,

i liked the idea of magnets as well, did quite a lot of work towards isolation platforms with them, trouble was they are also very position dependent and vary the force very quickly with displacement.

Springs, two tension springs, one up one down, leaving the net force sufficient to provide vtf, then as the cartridge displaces vertically one stretches one reduces stretch, maybe it adds up to the same total as a single partly elongated.

You can also do something with changing angles, so a reducing angle compensates an increased stretch, maths is beyond me

i liked the idea of magnets as well, did quite a lot of work towards isolation platforms with them, trouble was they are also very position dependent and vary the force very quickly with displacement.

Springs, two tension springs, one up one down, leaving the net force sufficient to provide vtf, then as the cartridge displaces vertically one stretches one reduces stretch, maybe it adds up to the same total as a single partly elongated.

You can also do something with changing angles, so a reducing angle compensates an increased stretch, maths is beyond me

what if

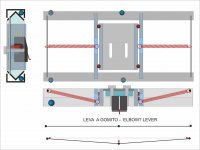

Doug, Dd your words gave me an idea.

What if we used a "leva a gomito"(elbow lever- how do you say?)

When a rope is taut, a minimum force in the center is enough to flex it, with great traction on the constraints. Maybe that's what we need: a vertical displacement on warps obtained with irrelevant force (ie VTF change).

What you think about?

carlo

Doug, Dd your words gave me an idea.

What if we used a "leva a gomito"(elbow lever- how do you say?)

When a rope is taut, a minimum force in the center is enough to flex it, with great traction on the constraints. Maybe that's what we need: a vertical displacement on warps obtained with irrelevant force (ie VTF change).

What you think about?

carlo

Attachments

Last edited:

what if

Doug, Dd your words gave me an idea.

What if we used a "leva a gomito"(elbow lever- how do you say?)

When a rope is taut, a minimum force in the center is enough to flex it, with great traction on the constraints. Maybe that's what we need: a vertical displacement on warps obtained with irrelevant force (ie VTF change).

What you think about?

carlo

I guess the vertical balls will fall out due to gravity.

Sorry, in this sketch I didn't draw the end stops, not even for the horizontal carriage. If it worked, there would be in the realization, and also in the executive draw.

But would it work? what do you think about, Karsten?

c

But would it work? what do you think about, Karsten?

c

Unfortunately despairing for a true pistonic movement, I see magnets in my future....(the desperate designer's last resort - sob)

Apparently someone has thought of this idea before. Simply Physics, a company known for making air-bearing tonearms, proposed an experimental turntable that included a magnetic bearing that allows pistonic motion. Unfortunately it never materialized into a product.

Magnets are far from linear, magnetic force obeys an inverse square law with distance, this is not the way to go.

The "elbow lever" is better, it diminishes the relative shortening of the spring because of the geometry.

The "elbow lever" is better, it diminishes the relative shortening of the spring because of the geometry.

Yes and no--maybe.Sorry, in this sketch I didn't draw the end stops, not even for the horizontal carriage. If it worked, there would be in the realization, and also in the executive draw.

But would it work? what do you think about, Karsten?

c

It looks like you have drawn vertical bearing like the horizontal bearing : a non recirculating ball bearing. IMHO this cannot work, end stop or no end stop, as

the only thing that would prevent the balls from sliding down would be friction!

But it made me think that a sliding bearing (teflon , bronze or whatever) maybe could have very little friction as long as the side thrust was near zero ?

Then I think it could work. Problem could be to have two springs behaving exactly the same way to avoid side thrust.

Carlo,

Mike56,

I'm seriously impressed with your ingenious solutions and persistence.

Mike56's idea mylar hinge is excellent. I am not sure but springs will probably have motions in horizontal plane too. Mylar hinge and knife edge bearing have solid mechanical ground plus only one directional motion. Dual tonearm had spiral leaf springs but it had vertical bearings too.

Regards

Its raining heavily here so i mounted my latest Mylar hinge parallelogram on my original carbon cart, the workmanship is not pretty but i sense it feels OK as a concept, counterweight, bearings and cartridge to add, i might run it on the TT later.........then if it works i can refine construction, all as usual to be done with a hand saw, files and sandpaper.

Its got notably less expensive as well!

Good evening gents, and it all seemed to be going so well, (Carlo and others talked of the wrong turnings and so on!) ........so i mounted it on the arm, by which time the lower arm that holds the counterweight has sagged the Mylar hinge a touch and its clear all is not moving parallel as it has a slight spring centring action, whereas before that it was very free. Anyway i played a few tracks and unfortunately the current set up is a backward move from my BB parallelogram that sounded rock solid in pitch, this is warbly by comparison so what apparently cannot flex noticeably is doing so as things move in warp. More thinking required at this point, i still like the mylar hinge but its inexact to construct and its not carrying the weight well. The hinges might be wider to counteract those things, the counterweight split between upper and lower, the hinge shorter etc etc more experimentation now required

You're right Karsten, it takes a little friction to keep the spheres from falling - in my drawings gray is used for aluminum, yellow = brass and colors for various plastics; if you notice the guides are light blue = teflon and the spheres red = delrin. But it's also needed a small cage to keep the 2 balls detached.

And I still don't know if all this "bric à brac" can work.

Normally I start to use my hands when, thanks to drawings, I have clear enough ideas not to waste too much time. But with these damn springs, with no relative experience, some mock ups are surely needed, and so well made enough to derive valid measurements and indications for designing.

thanks for hintalighiszem t: if i'm not mistaking on that kind of levers (but with rigid shafts) forces ratio goes by tan alpha, isn't it?

magnetic piston Unfortunately it never materialized into a product. Directdriver

...no difficulty in figuring out why.

carlo

And I still don't know if all this "bric à brac" can work.

Normally I start to use my hands when, thanks to drawings, I have clear enough ideas not to waste too much time. But with these damn springs, with no relative experience, some mock ups are surely needed, and so well made enough to derive valid measurements and indications for designing.

thanks for hintalighiszem t: if i'm not mistaking on that kind of levers (but with rigid shafts) forces ratio goes by tan alpha, isn't it?

magnetic piston Unfortunately it never materialized into a product. Directdriver

...no difficulty in figuring out why.

carlo

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm