Hi Carlo,

There is nothing wrong with keeping vertical and lateral effective masses the same. This is a safe approach to take. I believe (based on sound physical principles) that making the lateral effective mass in the region of 4-5 times that of the vertical has big advantages.

Niffy

There is nothing wrong with keeping vertical and lateral effective masses the same. This is a safe approach to take. I believe (based on sound physical principles) that making the lateral effective mass in the region of 4-5 times that of the vertical has big advantages.

Niffy

Hmm, not really..... 😉

Tried to apply the F=mxa to an hypothethical arm- taking a page of your post 2599+some Kuzma sauce

Length 20 cm, weight eff 20 grams- no bearing friction

Gives an F of 0,004 Newton (0,2x0,02) multiplied with a cartridge compliance of 22 mu/mN would give a deflection of the cantilever of 0,088 mm, or 88 microns- this seems a reasonable number- any bearing friction would be additional-potentially pushing it to 0,1-0,2 mm

Food for thought:does a normal pivot arm do a better job than TT’s in keeping the cantilever/stylus at right angles vs the groove, due to the ability to use antiskating??

Best,

Coolerooney

Hi Coolerooney,

The length of the arm is not relevant. You can have a 9" arm with an effective mass of 15g, you can also have a 12" arm with an effective mass of 15g.

In the equation F=ma

F is force, m is mass and a is acceleration.

In your example you are multiplying the mass by a distance not an acceleration. This will not give a result as a force.

No. A pivoted arm does not keep the cantilever better aligned with the groove. The geometry of a pivoted arm only allows the cantilever to be aligned correctly at only two points, the rest of the time there is a misalignment. Antiskate is used to try and correct for the skating force that is a result of the geometry of the arm. Antiskate only approximates skating force and doesn't completely counter it. One of the advantages of a linear arm is that no Antiskate is required. Most people who build linear arms do so in order to reduce lateral tracking errors.

Niffy

For a pivot arm, its vertical and lateral masses are almost same. Such statement has a precondition, i.e. both fictions vertically and laterally are same.

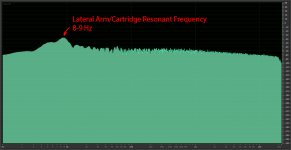

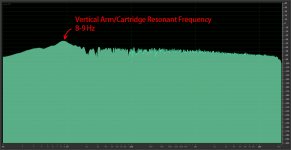

On my air bearing arms, the vertical and lateral resonant frequencies are same. So, it is safe to reason that its vertical and lateral masses are almost same as well. Please see attached images. The vertical and lateral fictions of the bearing is same, too, just as pivot arm.

For mechanical linear arm, its vertical and lateral frictions should be same ideally. However, it is not always same due to its construction. In order to have same resonant frequencies vertically and laterally for a mechanical linear arm, its fictions and masses should be similar vertically and laterally.

On my air bearing arms, the vertical and lateral resonant frequencies are same. So, it is safe to reason that its vertical and lateral masses are almost same as well. Please see attached images. The vertical and lateral fictions of the bearing is same, too, just as pivot arm.

For mechanical linear arm, its vertical and lateral frictions should be same ideally. However, it is not always same due to its construction. In order to have same resonant frequencies vertically and laterally for a mechanical linear arm, its fictions and masses should be similar vertically and laterally.

Attachments

Hi Jim,

It would definitely appear that the vertical and horizontal effective masses of your arm are very similar to each other.

With an air bearing arm damping is applied externally usually via silicone fluid. A common misconception is that horizontal damping needs to be greater than vertical. In fact it is the vertical damping that needs to be greater. The actual amount of damping required will mainly be affected by the mass of the arm and the compliance of the cartridge.

With a mechanical bearing linear arm the friction of the bearing acts as the damping. As with the air bearing arm the damping needs to be greater in the vertical plane. This means that you actually want the friction to be greater in the vertical plane.

Niffy

It would definitely appear that the vertical and horizontal effective masses of your arm are very similar to each other.

With an air bearing arm damping is applied externally usually via silicone fluid. A common misconception is that horizontal damping needs to be greater than vertical. In fact it is the vertical damping that needs to be greater. The actual amount of damping required will mainly be affected by the mass of the arm and the compliance of the cartridge.

With a mechanical bearing linear arm the friction of the bearing acts as the damping. As with the air bearing arm the damping needs to be greater in the vertical plane. This means that you actually want the friction to be greater in the vertical plane.

Niffy

Hi Niffy,

I don’t disagree what you said. Yes. Vertical damping is more important than lateral damping. For a mechanical linear arm, slight more friction on vertical panel may be beneficial if its fiction on lateral panel is very low. However, it is a dilemma. Too much friction on vertical panel may cause displacement of cantilever vertically. On the one of linear arm, the maker claimed that the edge of ball bearing contacts the glass tube and it is knife edge effect which is benefit to playing back. I personally don't buy that. Clear Audio's linear arm surly is an improvement over that arm.

Jim

I don’t disagree what you said. Yes. Vertical damping is more important than lateral damping. For a mechanical linear arm, slight more friction on vertical panel may be beneficial if its fiction on lateral panel is very low. However, it is a dilemma. Too much friction on vertical panel may cause displacement of cantilever vertically. On the one of linear arm, the maker claimed that the edge of ball bearing contacts the glass tube and it is knife edge effect which is benefit to playing back. I personally don't buy that. Clear Audio's linear arm surly is an improvement over that arm.

Jim

Last edited:

For a pivot arm, its vertical and lateral masses are almost same. Such statement has a precondition, i.e. both frictions vertically and laterally are same.

Quote, that's the key: or at least that's what the cartridges manufacturers continue to think

With a mechanical bearing linear arm the friction of the bearing acts as the damping.

Imho the effect of the bearings seems the opposite of viscous damping: the bearing starts moving overcoming the stiction (friction that decreases with movement) - the viscous damping on the contrary does not oppose the slow movement but contrasts the fast one (eg vibrations).

The problem with linear geometry is that almost inevitably needs heavy carriages and very short wands, with small CW. Captious question: are we trying to compensate with damping the difference in effective masses?

carlo

Quote, that's the key: or at least that's what the cartridges manufacturers continue to think

With a mechanical bearing linear arm the friction of the bearing acts as the damping.

Imho the effect of the bearings seems the opposite of viscous damping: the bearing starts moving overcoming the stiction (friction that decreases with movement) - the viscous damping on the contrary does not oppose the slow movement but contrasts the fast one (eg vibrations).

The problem with linear geometry is that almost inevitably needs heavy carriages and very short wands, with small CW. Captious question: are we trying to compensate with damping the difference in effective masses?

carlo

Hi Coolerooney,

The length of the arm is not relevant. You can have a 9" arm with an effective mass of 15g, you can also have a 12" arm with an effective mass of 15g.

In the equation F=ma

F is force, m is mass and a is acceleration.

In your example you are multiplying the mass by a distance not an acceleration. This will not give a result as a force.

No. A pivoted arm does not keep the cantilever better aligned with the groove. The geometry of a pivoted arm only allows the cantilever to be aligned correctly at only two points, the rest of the time there is a misalignment. Antiskate is used to try and correct for the skating force that is a result of the geometry of the arm. Antiskate only approximates skating force and doesn't completely counter it. One of the advantages of a linear arm is that no Antiskate is required. Most people who build linear arms do so in order to reduce lateral tracking errors.

Niffy

Hi Niffy

You are right off course

I got the equations confused

Well.... the search continued

Best

Coolerooney

For a pivot arm, its vertical and lateral masses are almost same. Such statement has a precondition, i.e. both frictions vertically and laterally are same.

Quote, that's the key: or at least that's what the cartridges manufacturers continue to think

With a mechanical bearing linear arm the friction of the bearing acts as the damping.

Imho the effect of the bearings seems the opposite of viscous damping: the bearing starts moving overcoming the stiction (friction that decreases with movement) - the viscous damping on the contrary does not oppose the slow movement but contrasts the fast one (eg vibrations).

The problem with linear geometry is that almost inevitably needs heavy carriages and very short wands, with small CW. Captious question: are we trying to compensate with damping the difference in effective masses?

carlo

Hi Carlo,

Indeed the way friction damping works is different to viscous damping. An ideal situation is where you have zero bearing friction and apply viscous damping in the way Jim has with his arm. If you have a mechanical linear arm you will inevitably have some friction regardless of how good your bearings are. This friction will be more than adequate to damp the lateral motion of the arm so no additional damping is required or even desirable . With a linear arm it is very difficult to apply vertical damping independently from the lateral, if you added a silicone trough to damp vertical motion it would enviably increase lateral damping as well. A knife edge bearing would offer virtually zero vertical friction and thus no damping. That is why I am using a two rod rail and relatively wide wheels (2mm), the wheels have to slide on the rails in order to pivot vertically. I've set the size of the rail and wheels so that vertical friction, and hence damping, is three times as great as laterally. Vertical damping needs to be greater than lateral as the arm is much more likely to be excited by vertical motion (warps) than is by lateral motion (eccentricity). Even on perfectly flat and centred records the natural motion of the arm is to bounce up and down on the suspension of the cartridge making vertical damping even more important. This is because the main restorative force, gravity, acts vertically.

The two biggest advantages of linear arms is that they can have short arm tubes and small counterweights. By making the arm short the resonant frequency of bending can be pushed to much higher frequencies. Bending mode resonance is the single biggest source of colouration in most arms. A higher resonant frequency is also easier to damp. A small counterweight will cause less reflection of compression waves reducing distortions further.

That the carriage is heavy can be made to work in your favour. I could have made my carriage lighter but chose its mass in order to have the optimum lateral mass for my cartridge. I did build a lightweight carriage to compare with my heavier one. It didn't sound anywhere near as good.

No we are not trying to compensate with damping the difference in effective masses. The effective mass controls how much the cartridge body moves at audio frequencies, a higher mass allows less movement so a higher mass is desirable. The mass also has to be selected to keep the resultant resonance away from frequencies that can excite it. As these frequencies are different vertically and laterally the resonant frequencies and hence the masses can be different. Damping is applied to control these resonances and prevent excess motion of the arm. The damping is there to compliment the effective mass. Additionally as the suspension of the cartridge is preloaded vertically by the tracking force its vertical and lateral compliances do end up being slightly different. Some manufacturers list both vertical and lateral compliance. Ideally the choice of effective mass and damping would take this difference into account. As the difference tends to be small and my manufacturer only quotes lateral compliance I have worked assuming that they are the same.

Niffy

Damping can’t be used as a means to compensate effective mass. I tried some experiments. I had to increase the viscosity of silicone fluid greatly and the size of paddle, too, to see a meaningful reduction in resonant frequency. It was certainly too much for regular operation of the arm.

Silicone damping is to reduce inertia of arm movements. Due to its physical feature, stiction, it makes excellent damping fluid.

The similarity of vertical and lateral effective masses is because of short arm. For short arm, leverage plays no or less role in effective masses.

Silicone damping is to reduce inertia of arm movements. Due to its physical feature, stiction, it makes excellent damping fluid.

The similarity of vertical and lateral effective masses is because of short arm. For short arm, leverage plays no or less role in effective masses.

Last edited:

Hi Jim,

I don't agree with your statement in the third paragraph. My arm is really short with an effective length of only 55mm yet my vertical effective mass is only a quarter of the lateral. I could easily increase the vertical effective mass by using a smaller counterweight set further from the pivot or reduce it with a heavier weight closer in.

Effective mass has more to do with the distribution of mass and has little to do with the overall length of the arm.

Niffy

I don't agree with your statement in the third paragraph. My arm is really short with an effective length of only 55mm yet my vertical effective mass is only a quarter of the lateral. I could easily increase the vertical effective mass by using a smaller counterweight set further from the pivot or reduce it with a heavier weight closer in.

Effective mass has more to do with the distribution of mass and has little to do with the overall length of the arm.

Niffy

Hi all,

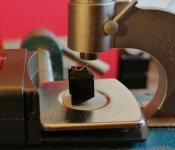

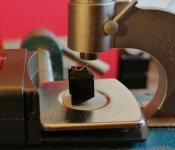

I have just had a go at measuring the static compliance of one of my old cartridges, an Ortofon 520 moving magnet. The set up is really simple. It consists of a micrometer clamped in a vice and a stylus force gauge sat between the open jaws of that micrometer. My micrometer is marked in increments of 10um (0.01mm) so I can accurately lower the upper jaw towards the force gauge in small steps. As I am only measuring the compliance I don't need the whole cartridge, just the detachable stylus assembly. The stylus assembly is placed upside down on the force gauge and secured with a blob of blutak. As the micrometer closes the upper jaw presses on the stylus. The force of this contact is registered by the gauge.

Before I measured the stylus I measured how much the force gauge deflected under load. I varied the load from 0g to the gauges maximum of 5g by gradually lowering the micrometer in 10um increments. I had attached a small ball bearing to the gauge so that the contact would be in the centre of the measuring plate. I was basically measuring the compliance of the force gauge. This would need to be subtracted from the results of measuring the cartridge compliance. I repeated this 5 times so that I could take an average. The tests gave consistent results and showed that the force gauge had a compliance of 1.52um/mN.

I first measured the vertical compliance. Again I made several sets of measurements. I had planned on presenting the results in the form of a graph so changes in compliance with load could be seen. This was unnecessary as the compliance remained consistent with varying load, nothing is more boring than a straight line graph.

Measuring lateral compliance was a bit more tricky. I turned the stylus on its edge and aligned the upper jaw of the micrometer so that its edge touched just the very tip of the cantilever. I again recorded the force resulting from deflecting the cantilever in 10um steps up to 150um. I repeated several times then turned the stylus body over and repeated pushing the stylus in the opposite direction.

The Ortofon 520 cartridge has a listed dynamic lateral compliance of 25um/mN. I had anticipated that the measured static lateral compliance would be a bit higher than this. I also expected that the vertical compliance would be a bit lower than the lateral. I was surprised to find that the static lateral compliance was 16.3um/mN and the static vertical was 11.6um/mN. I had always thought that compliance increased with decreasing frequency so that static compliance would be higher than dynamic. This would tend to suggest the opposite. It is possible that I had mixed up stiffness and compliance somewhere along the lines. Stiffness increases with decreasing frequency? Vertical compliance was lower than lateral as predicted.

Another possibility is that the suspension of this particular cartridge had stiffened with time. It has been 10 years since it was last used. I will have to dig out another stylus and test that to see if I get a different result.

If static compliance is lower than dynamic then it would follow that tracking error due to bearing friction and tonearm inertia would be lower than I had previously calculated, which wouldn't be a bad thing.

Of course the third possibility is that I totally messed up this test and that the results are in error. I don't think this is the case and I really don't like the idea of throwing away data just because it doesn't fit my model.

Niffy

I have just had a go at measuring the static compliance of one of my old cartridges, an Ortofon 520 moving magnet. The set up is really simple. It consists of a micrometer clamped in a vice and a stylus force gauge sat between the open jaws of that micrometer. My micrometer is marked in increments of 10um (0.01mm) so I can accurately lower the upper jaw towards the force gauge in small steps. As I am only measuring the compliance I don't need the whole cartridge, just the detachable stylus assembly. The stylus assembly is placed upside down on the force gauge and secured with a blob of blutak. As the micrometer closes the upper jaw presses on the stylus. The force of this contact is registered by the gauge.

Before I measured the stylus I measured how much the force gauge deflected under load. I varied the load from 0g to the gauges maximum of 5g by gradually lowering the micrometer in 10um increments. I had attached a small ball bearing to the gauge so that the contact would be in the centre of the measuring plate. I was basically measuring the compliance of the force gauge. This would need to be subtracted from the results of measuring the cartridge compliance. I repeated this 5 times so that I could take an average. The tests gave consistent results and showed that the force gauge had a compliance of 1.52um/mN.

I first measured the vertical compliance. Again I made several sets of measurements. I had planned on presenting the results in the form of a graph so changes in compliance with load could be seen. This was unnecessary as the compliance remained consistent with varying load, nothing is more boring than a straight line graph.

Measuring lateral compliance was a bit more tricky. I turned the stylus on its edge and aligned the upper jaw of the micrometer so that its edge touched just the very tip of the cantilever. I again recorded the force resulting from deflecting the cantilever in 10um steps up to 150um. I repeated several times then turned the stylus body over and repeated pushing the stylus in the opposite direction.

The Ortofon 520 cartridge has a listed dynamic lateral compliance of 25um/mN. I had anticipated that the measured static lateral compliance would be a bit higher than this. I also expected that the vertical compliance would be a bit lower than the lateral. I was surprised to find that the static lateral compliance was 16.3um/mN and the static vertical was 11.6um/mN. I had always thought that compliance increased with decreasing frequency so that static compliance would be higher than dynamic. This would tend to suggest the opposite. It is possible that I had mixed up stiffness and compliance somewhere along the lines. Stiffness increases with decreasing frequency? Vertical compliance was lower than lateral as predicted.

Another possibility is that the suspension of this particular cartridge had stiffened with time. It has been 10 years since it was last used. I will have to dig out another stylus and test that to see if I get a different result.

If static compliance is lower than dynamic then it would follow that tracking error due to bearing friction and tonearm inertia would be lower than I had previously calculated, which wouldn't be a bad thing.

Of course the third possibility is that I totally messed up this test and that the results are in error. I don't think this is the case and I really don't like the idea of throwing away data just because it doesn't fit my model.

Niffy

Last edited:

I couldn't resist and did a quick measurement of my 2M blue cartridge. This is much younger than the 520 and has been in use much more recently. The 2M blue has a listed lateral compliance of 22um/mN. I measured the lateral static compliance at 19.53um/mN and the vertical at 16.54um/mN. This would indicate that I was indeed incorrect in my assertion that compliance increases with decreased frequency. It would also suggest that the suspension of the 520 cartridge had stiffened with age. The decrease in lateral static compliance compared to dynamic is not great, 11%. This would mean that the standard equation for determining the resonant frequency of the system based on published compliance figures will be reasonably accurate laterally. The vertical compliance is quite a bit lower than the published lateral figure, 25%. This may cause problems when calculating vertical resonance. You can probably use a slightly heavier arm than the equation would suggest.

If these measurements are accurate then, as I said in the last post, the tracking errors due to friction etc would be slightly lower than previously calculated.

Niffy

If these measurements are accurate then, as I said in the last post, the tracking errors due to friction etc would be slightly lower than previously calculated.

Niffy

Simple and brilliant idea - well done, Niffy.

it does not surprise me that the old elastomer has stiffened (never buy an old cartridge) it's surprising that the lateral compliance differs from the vertical one: maybe aligning at the center of the scale the stylus tip instead of the fulcrum can induce a momentum that alters the measure?

Measures are obtained subtracting the compliance of the scale from the total: linearly?

Curiosity: how much does the scale flex with 10 mN, and how much the scale + stylus?

I am re-reading your #2888, there are some "strange" things about the use of friction to be better understood; in the meantime my new arm is sounding clean as I like, following even bad warps with the agility of a good pivoted.

The problem was just the weight of moving masses, as expected: a radial rail TA can work fine.

proudly - carlo

it does not surprise me that the old elastomer has stiffened (never buy an old cartridge) it's surprising that the lateral compliance differs from the vertical one: maybe aligning at the center of the scale the stylus tip instead of the fulcrum can induce a momentum that alters the measure?

Measures are obtained subtracting the compliance of the scale from the total: linearly?

Curiosity: how much does the scale flex with 10 mN, and how much the scale + stylus?

I am re-reading your #2888, there are some "strange" things about the use of friction to be better understood; in the meantime my new arm is sounding clean as I like, following even bad warps with the agility of a good pivoted.

The problem was just the weight of moving masses, as expected: a radial rail TA can work fine.

proudly - carlo

Last edited:

To Niffy. Carlo, I totally agree, that idea is brilliant, as many others of Niffy. By the way, yesterday I did some experiments with improvised reflex clamp, and was pleased to see, that it flattens records very well. The idea is ingenious by its simplicity and effectiveness. And it is cost effective, like it or no...

😀

😀

As a result, I will bury my own design of peripheral collet clamp, as too complex, expensive, and somewhat problematic.

😀

😀As a result, I will bury my own design of peripheral collet clamp, as too complex, expensive, and somewhat problematic.

Hi Niffy,

What I said is actually not conflict to your opinion. Both length and distribution of weight have impacts on effective masses. Take Kuzma air line as example. Its vertical and lateral masses can never be same due to long arm wand no matter how the weights are distributed. For short wand arm such as mine, it provides a possibility of similar vertical and lateral masses through distributing weights, adjusting the length and weight. All these three means have impacts on vertical effective mass and lateral effective mass, too.

For your arm, the effective masses was calculated based on an assumption, i.e. there is no damping. However, in reality, there is damping on vertical plane due to its construction.

Jim

What I said is actually not conflict to your opinion. Both length and distribution of weight have impacts on effective masses. Take Kuzma air line as example. Its vertical and lateral masses can never be same due to long arm wand no matter how the weights are distributed. For short wand arm such as mine, it provides a possibility of similar vertical and lateral masses through distributing weights, adjusting the length and weight. All these three means have impacts on vertical effective mass and lateral effective mass, too.

For your arm, the effective masses was calculated based on an assumption, i.e. there is no damping. However, in reality, there is damping on vertical plane due to its construction.

Jim

Hi all,

It looks like the whole compliance thing just got really complicated. I was having a browse on the Internet looking at the specifications listed by a number of cartridge manufacturers. Quite a few of them don't even have compliance in their spec lists. Most of the rest only have a single figure and don't specify whether it's a static or dynamic measurement. It is possible that most manufacturers have designed their cartridges so that dynamic and static compliances are the same. This is the case with most sprung items. The only manufacturer that hinted that vertical and lateral compliance might be different is Ortofon and this is only because they specify their figures as dynamic lateral implying that vertical is different. I have seen specifications that list vertical and horizontal separately.

Audiotechnica is the only manufacturer who lists both dynamic and static compliance and actually states the frequency at which the dynamic measurement was taken, 100hz. I have seen 315hz specified before but I can't remember who by. The interesting thing is that the static compliance is between 2 and 4 times as high as the dynamic across the range. Before measuring my ortofon styluses I thought all cartridges had higher static compliance, but not to this extent.

Goldring probably had the most useful information. They specify their cartridges at 10hz and "dynamic" though they don't specify what the dynamic frequency is. As most people aim to tune their arms to 10hz giving the compliance at this frequency is really useful. I can only assume that the dynamic frequency is much higher, probably 100hz. With the Goldring cartridges the dynamic compliance is higher than that at 10hz. This appears to be the opposite way round to the Audiotechnica cartridges.

So it would appear that compliance can either increase, decrease or remain the same with frequency and can either be the same or different in different directions. Doesn't leave us much to go on.

Having a compliance that increases with frequency seems like a much better idea to me. Also having a cartridge with higher compliance in the lateral plane makes a lot of sense.

Hi Carlo.

Great to hear your arm is passing all the tests

I'm pretty certain that the measurements I made were reasonably accurate. Both the scale and the cartridge seem to be very linear which makes calculations much easier. A 10mN force would deflect the scale by 15.2um. With the 2M stylus fitted the total deflection laterally would be 210.5um. The deflection of just the cantilever would therefore be 195.3um or about 0.2mm.

When measuring laterally the micrometer only touched the cantilever adjacent to the stylus so the readings will be the same as if the micrometer was actually touching the stylus. The difference in the vertical and lateral readings is due to the compliances actually being different and not how I took the measurements.

Hi Walter,

I'm glad the reflex clamp is working out for you.

Hi Jim,

If I extended the stub on the back of the airline to say 20cm and used a tiny counterweight at the end of this I could probably get the vertical effective mass to equal the lateral. Its all about the moment of inertia like putting all the mass at the periphery of a flywheel.

I did not include damping when calculating effective mass as it has no effect on effective mass. You proved this yourself as adding a crapton of damping didn't change the resonance of your arm. Damping and mass are different properties. Changing one doesn't change the other. Changing either will effect the way the arm behaves especially around resonance.

Niffy

It looks like the whole compliance thing just got really complicated. I was having a browse on the Internet looking at the specifications listed by a number of cartridge manufacturers. Quite a few of them don't even have compliance in their spec lists. Most of the rest only have a single figure and don't specify whether it's a static or dynamic measurement. It is possible that most manufacturers have designed their cartridges so that dynamic and static compliances are the same. This is the case with most sprung items. The only manufacturer that hinted that vertical and lateral compliance might be different is Ortofon and this is only because they specify their figures as dynamic lateral implying that vertical is different. I have seen specifications that list vertical and horizontal separately.

Audiotechnica is the only manufacturer who lists both dynamic and static compliance and actually states the frequency at which the dynamic measurement was taken, 100hz. I have seen 315hz specified before but I can't remember who by. The interesting thing is that the static compliance is between 2 and 4 times as high as the dynamic across the range. Before measuring my ortofon styluses I thought all cartridges had higher static compliance, but not to this extent.

Goldring probably had the most useful information. They specify their cartridges at 10hz and "dynamic" though they don't specify what the dynamic frequency is. As most people aim to tune their arms to 10hz giving the compliance at this frequency is really useful. I can only assume that the dynamic frequency is much higher, probably 100hz. With the Goldring cartridges the dynamic compliance is higher than that at 10hz. This appears to be the opposite way round to the Audiotechnica cartridges.

So it would appear that compliance can either increase, decrease or remain the same with frequency and can either be the same or different in different directions. Doesn't leave us much to go on.

Having a compliance that increases with frequency seems like a much better idea to me. Also having a cartridge with higher compliance in the lateral plane makes a lot of sense.

Hi Carlo.

Great to hear your arm is passing all the tests

I'm pretty certain that the measurements I made were reasonably accurate. Both the scale and the cartridge seem to be very linear which makes calculations much easier. A 10mN force would deflect the scale by 15.2um. With the 2M stylus fitted the total deflection laterally would be 210.5um. The deflection of just the cantilever would therefore be 195.3um or about 0.2mm.

When measuring laterally the micrometer only touched the cantilever adjacent to the stylus so the readings will be the same as if the micrometer was actually touching the stylus. The difference in the vertical and lateral readings is due to the compliances actually being different and not how I took the measurements.

Hi Walter,

I'm glad the reflex clamp is working out for you.

Hi Jim,

If I extended the stub on the back of the airline to say 20cm and used a tiny counterweight at the end of this I could probably get the vertical effective mass to equal the lateral. Its all about the moment of inertia like putting all the mass at the periphery of a flywheel.

I did not include damping when calculating effective mass as it has no effect on effective mass. You proved this yourself as adding a crapton of damping didn't change the resonance of your arm. Damping and mass are different properties. Changing one doesn't change the other. Changing either will effect the way the arm behaves especially around resonance.

Niffy

Hi Niffy,

I didn’t express my opinion clearly. So, let me clarify what I was saying.

Correct. Damping won’t have any impacts on effective mass. However, all I care about are arm/cartridge resonant frequencies. Damping will have effect on resonant frequencies. So to use simplified equation without including damping may not get correct results. For me, I don't care about effective masses as long as my test results show vertical and lateral resonant frequencies are almost same. It is good enough although I understand both are related.

Jim

I didn’t express my opinion clearly. So, let me clarify what I was saying.

Correct. Damping won’t have any impacts on effective mass. However, all I care about are arm/cartridge resonant frequencies. Damping will have effect on resonant frequencies. So to use simplified equation without including damping may not get correct results. For me, I don't care about effective masses as long as my test results show vertical and lateral resonant frequencies are almost same. It is good enough although I understand both are related.

Jim

Hi Jim,

I think we are pretty much in accord. In combination with the cartridges compliance the effective mass puts the resonance at the correct frequency. The damping then controls the amplitude of said resonance.

A lower resonant frequency will mean that the cartridge body will be moving less at audible frequencies (which is good) but will be more likely to be excited by warps or eccentricity (which is bad).

I still don't understand why it is important to have the resonant frequencies at the same (or similar) frequency.

Niffy

I think we are pretty much in accord. In combination with the cartridges compliance the effective mass puts the resonance at the correct frequency. The damping then controls the amplitude of said resonance.

A lower resonant frequency will mean that the cartridge body will be moving less at audible frequencies (which is good) but will be more likely to be excited by warps or eccentricity (which is bad).

I still don't understand why it is important to have the resonant frequencies at the same (or similar) frequency.

Niffy

Hi all,

Hi Carlo.

Great to hear your arm is passing all the tests

I'm pretty certain that the measurements I made were reasonably accurate. Both the scale and the cartridge seem to be very linear which makes calculations much easier. A 10mN force would deflect the scale by 15.2um. With the 2M stylus fitted the total deflection laterally would be 210.5um. The deflection of just the cantilever would therefore be 195.3um or about 0.2mm.

When measuring laterally the micrometer only touched the cantilever adjacent to the stylus so the readings will be the same as if the micrometer was actually touching the stylus. The difference in the vertical and lateral readings is due to the compliances actually being different and not how I took the measurements.

Niffy

Hi Niffy,

Red the post with interest, question: where does the 195,3 um comee from?

Is the 210,5 the standard deflection during operation?

Best,

Coolerooney

Hi Niffy,

Red the post with interest, question: where does the 195,3 um comee from?

Is the 210,5 the standard deflection during operation?

Best,

Coolerooney

Carlo asked what the deflection would be with a 10mN force. I assume this is because he used a 10mN force when testing his cartridge. I calculated the static lateral compliance to be 19.53um/mN. With 10mN of side force the cantilever would be deflected 195.3um. The 210.5um would be the total deflection measured on the test rig with a 10mN load. 195.3um of this is due to the deflection of the cantilever and 15.2um due to the flexing of the stylus force gauge itself. Added together they equal 210.5um and doesn't represent anything outside of this test. There is no "standard deflection" during operation. The deflection of the cantilever will be constantly changing due to the ever changing forces acting upon it. One of the aims of tonearm design is to make these deflections as small as possible so only the relative motion of the stylus due to groove modulation remain. The aim of these tests was to get a better understanding of the compliance of the cartridge. Compliance is a very important aspect of the cartridge that determines how it interacts with the record and the arm.

Niffy

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm