Don't worry, you don't need a speaker or input connected to set the bias you are supposed to just let it "idle" until stable and then re-adjust.Thank you so much for the immediate help and the detailed answers! I will redo the fan test after letting both heatsinks warm up for at least 30 minutes. I will have to try it with a smaller fan to directly point the airflow to the heatsinks, since I did not assemble the case yet. Wanted to make sure everything works as intended prior to that. I have some old 4 ohms speakers attached to the output and unfortunately do not own any 8 ohms speakers.

Jeremy's suggested test will let you know if the amp is behaving properly thermally.

Once you have done this and you are you are happy the bias is set and you have done the burn in procedure in the build guide 4 ohm speakers won't be a problem to use.

- Daniel

I retried the fan test after letting everything stabilize thermally and the amp behaved differently this time. Both boards reply with an increase in bias as soon as the heatsinks are being cooled via a fan. Within five minutes of cooling the heatsinks, which previously had a temperature of about 40°C went down to ~30°C and the bias increased accordingly to around 62mV. After that time I stopped the test and the bias immediately began to slowly recede. In the following 15 minutes the bias almost returned back to the previous value and was still dropping (46mV at that time).

I think in my first run I put too much air to the exposed boards and less air to the heatsinks directly as well as not waiting long enough to warm everything up properly.

What do you think? Is everything within acceptable ranges?

Thanks a lot for the help!

Best regards

Michael

I think in my first run I put too much air to the exposed boards and less air to the heatsinks directly as well as not waiting long enough to warm everything up properly.

What do you think? Is everything within acceptable ranges?

Thanks a lot for the help!

Best regards

Michael

65mV=150mA of bias per output pair

44mV=100mA of bias per output pair

35mV=80mA of bias per output pair

Everything sounds normal except when you say the bias voltage drops when you put a fan on the heatsink.

Ideally the bias should not change with temperature but it is hard to get this level of accuracy. You don't want a positive slope meaning as the temperature goes up the bias goes up, this could lead to thermal run away. What you want is a slight negative slope so as temperature goes up the bias comes down, this helps keep the amp thermally stable. A aggressive negative slope is undesirable also because it could lead to under biasing when hot causing crossover distortion.

If you could try the fan test again that would be appreciated. Is the output loaded with 8ohms?

-Make sure the amp as been idle for 30min so the everything is thermally stabilized.

-Next turn on a fan only blowing on the heatsink fins and monitor the bias. The bias should go slightly up as the heatsink cools from the fan.

Jeremy

Nice work, Sounds like the amp is behaving normally.I retried the fan test after letting everything stabilize thermally and the amp behaved differently this time. Both boards reply with an increase in bias as soon as the heatsinks are being cooled via a fan. Within five minutes of cooling the heatsinks, which previously had a temperature of about 40°C went down to ~30°C and the bias increased accordingly to around 62mV. After that time I stopped the test and the bias immediately began to slowly recede. In the following 15 minutes the bias almost returned back to the previous value and was still dropping (46mV at that time).

I think in my first run I put too much air to the exposed boards and less air to the heatsinks directly as well as not waiting long enough to warm everything up properly.

What do you think? Is everything within acceptable ranges?

Thanks a lot for the help!

Best regards

Michael

I am relieved 🙂 Now I can continue with the build knowing the amp works as expected. Thank a bunch!

Hi Guy’s

As most of you know, we have been refining the Wolverine V4.0 schematic and BOM since @danieljw released the base distortion Youtube video and numbers a few weeks ago. In an effort to improve those number even further, the first thing we wanted to test and refine was the capacitance multiplier. After many, many, many hours of simulation by @jjs , myself and real world testing by @danieljw one the latest build we can confirm that we have managed to reduce the rail voltage ripple seen by the IPS to extremely low numbers.

We have also replaced R130 & R131 with Schottky diodes to further improve capacitance multipliers performance and improve the available rail voltage to the OPS which will give an increase in output power.

I have added the updated BOM to the Dropbox folder and plan to update the schematics over the weekend. Once the schematics are updated, I will upload them to the Dropbox folder and make them public here on the forum.

We are still working on other possible improvements and component tweaks and will update everyone before the second group buy boards are purchased.

As most of you know, we have been refining the Wolverine V4.0 schematic and BOM since @danieljw released the base distortion Youtube video and numbers a few weeks ago. In an effort to improve those number even further, the first thing we wanted to test and refine was the capacitance multiplier. After many, many, many hours of simulation by @jjs , myself and real world testing by @danieljw one the latest build we can confirm that we have managed to reduce the rail voltage ripple seen by the IPS to extremely low numbers.

We have also replaced R130 & R131 with Schottky diodes to further improve capacitance multipliers performance and improve the available rail voltage to the OPS which will give an increase in output power.

I have added the updated BOM to the Dropbox folder and plan to update the schematics over the weekend. Once the schematics are updated, I will upload them to the Dropbox folder and make them public here on the forum.

We are still working on other possible improvements and component tweaks and will update everyone before the second group buy boards are purchased.

I'm continually impressed by the dedication of the development group. You guys are world-class.

YesHi Stuart, are the changes you are working on compatible with the boards of the first group buy?

Thank you,

Gaetano.

Hi Guy's, We have decided to offer Green, Blue & Black PCB's again for the 2nd Group buy. If anyone would like to change their color preference please send me and PM with the subject "Wolverine PCB Order - Color Change - XXXXX" ( XXXXX = your DIY Username ) and specify you updated color choice.

I will then update the 2nd Group buy database. 🙂

If you would like to Join the 2nd Group buy all the detail can be found in #1 here The Wolverine 2nd Group buy

I will then update the 2nd Group buy database. 🙂

If you would like to Join the 2nd Group buy all the detail can be found in #1 here The Wolverine 2nd Group buy

Hi Guy's,

I have added the Wolverine Schematics to the 1st post.

They are now public and you may view and download them from there.

Wolverine 57v & 64v Schematic:

Please see the attached PDF files. These schematic show.

The Wolverine IPS - V3.7 (1st Group Buy) & V3.8 (2nd Group Buy)

The Precision EF3 - Both

EF3-3 (3 Pairs of Output Transistors) - V3.9 (1st Group Buy) & V4.0 (2nd Group Buy)

EF3-4 (4 Pairs of Output Transistors) - V3.9 (1st Group Buy) & V4.0 (2nd Group Buy)

For those with Dropbox links the schematics have been updated in that folder as well. 😉

I have added the Wolverine Schematics to the 1st post.

They are now public and you may view and download them from there.

Wolverine 57v & 64v Schematic:

Please see the attached PDF files. These schematic show.

The Wolverine IPS - V3.7 (1st Group Buy) & V3.8 (2nd Group Buy)

The Precision EF3 - Both

EF3-3 (3 Pairs of Output Transistors) - V3.9 (1st Group Buy) & V4.0 (2nd Group Buy)

EF3-4 (4 Pairs of Output Transistors) - V3.9 (1st Group Buy) & V4.0 (2nd Group Buy)

For those with Dropbox links the schematics have been updated in that folder as well. 😉

Now that the schematic is made public, I like to ask some questions about the design. I start of with the following two matters that are not clear to me.

1. What problem is Q-help solving? I don't remember seeing it before in a Input Stage with LTP, cascade, current mirror, current source.

2. Why the choice for a polyester cap for C 112, is a polypropylene cap not better here?

1. What problem is Q-help solving? I don't remember seeing it before in a Input Stage with LTP, cascade, current mirror, current source.

2. Why the choice for a polyester cap for C 112, is a polypropylene cap not better here?

Qhelp increases the accuracy of the mirrored currents for the LTP by reducing the current that is stolen from Q4 to bias the the mirror transistors Q3 and Q4.

Jeremy

Jeremy

A polyester cap was chosen as they're readily available and will fit in that position. Polypropylene caps in that value and lead spacing are very hard to find.

My preference is polypropylene but there is a practical aspect to creating a BOM.

The subject of which components to use in an amp is endless as everyone has their own preferences. Don't forget that the boards have been tested, by many, with very low distortion results.

If you can find a polypropylene that fits on the PCB, go for it.

My preference is polypropylene but there is a practical aspect to creating a BOM.

The subject of which components to use in an amp is endless as everyone has their own preferences. Don't forget that the boards have been tested, by many, with very low distortion results.

If you can find a polypropylene that fits on the PCB, go for it.

jjs, Thanks for the explanation, appriciated.

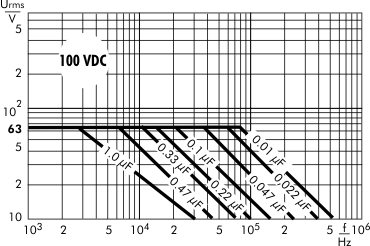

Harry3, I did look for a polypropylene cap with correct LS, a miniature type from WIMA, MPK2-100 VDC might fit. Unfortunate such a cap is rated only 15 Vrms @ 20 kHz.

And that's the reason for my question above. Apparently it was decided a polypropylene cap is not needed for C112, that's what the available LS on the PCB tells me, not just the BOM. Knowing the arguments that led to formentioned decision might help me with my choice.

Harry3, I did look for a polypropylene cap with correct LS, a miniature type from WIMA, MPK2-100 VDC might fit. Unfortunate such a cap is rated only 15 Vrms @ 20 kHz.

And that's the reason for my question above. Apparently it was decided a polypropylene cap is not needed for C112, that's what the available LS on the PCB tells me, not just the BOM. Knowing the arguments that led to formentioned decision might help me with my choice.

Zulässige Wechselspannung in Abhängigkeit von der Frequenz bei 10° C Eigenerwärmung (Richtwerte)

https://www.wima.de/de/produkte/metallisierte-kondensatoren-im-rm-7-5-52-5-mm/mkp-2/Hi Theodosis,@OmeEd, This Kemet fits. https://gr.mouser.com/ProductDetail/80-F461BS105J250A

Nice work, what model C9 are you using ? Is it a Nichicon Muse ?

-Dan

Datasheet states 1000 hours life at 105°C with polarity inverted every 250 hours. I think it is a good choice.For C9 I bought this 647-UEP1J470MPD from Mouser. 1000 hours life though.

Hi Theodosis,good luck!Thank you,

Yes it is.

What is the C9 value?

- Home

- Amplifiers

- Solid State

- DIY Class A/B Amp The "Wolverine" build thread