And i'd also want to keep my mono main option open....it still surprises me how much better some recorded music sounds mono than stereo..up to 3 cents haha

The four 1/4-space horns (two half-space stereo horns) should act as a single full-space 15 Hz "mono" horn - assuming that bass is pretty much recorded mono anyway.

Before I go and load each horn with a half-dozen 18" drivers each, I'm going to try a more traditional design. My first iteration of driver selection will be to install (qty 1) 12" B&C driver into each 1/4 space bass horn throat (with a phase plug), and see how well they sound over an extended frequency range. If they sound clean up to 300 Hz (or even much higher) - that would introduce some interesting design options to say the least. I'm assuming I'll be adding more drivers. Nonetheless, considering how few "true" full-size exponential bass horns are in existence, who really knows - right??? One consistent idea within the old engineering horn texts, is that bass horns can effortlessly reproduce crystal clear sounds, deep into the bottom octaves. I kinda want to hear that.

Unless there's a convincing reason not to, I'll probably build cavities into the wall - one on each side of the bass horn mouth (similar to storage unit vaults). This way I can simply swing a door shut to remove the mid/high horns from the elements - and obviously open the doors to play music. . . I'm not planning to install doors over the bass horn mouths. That would be a really big door, and it would probably rattle like a 1963 Pontiac 2+2 running 87 octane fuel. . . .

Just a thought - There can be other xo points rather than 80Hz for your subs.

You could run a mono sub horn 15Hz - 40Hz then have large stereo kick bins running 40Hz up. That way you can lose some of the lobing issues that have been raised and have more of the 'stereo bass' you wanted in the first place.

That's the nice thing about DIY stuff - you can make it how you choose it to be....(you may have noticed nobody agrees on what 'the best' is because it is nearly always subjective )

You could run a mono sub horn 15Hz - 40Hz then have large stereo kick bins running 40Hz up. That way you can lose some of the lobing issues that have been raised and have more of the 'stereo bass' you wanted in the first place.

That's the nice thing about DIY stuff - you can make it how you choose it to be....(you may have noticed nobody agrees on what 'the best' is because it is nearly always subjective )

Thanks for horn sketch. Can you please make a quick hand-drawn loose sketch of the whole yard with the horn location, hot tub, beer cooler, walls, berms, etc. too.

While I can't offer any trustworthy horn design ideas (a gesture of modesty not often heard in these parts), my impression is that your design is vastly "over the top". On this forum, folks are always doing grade-7 math and coming up with inconceivable (and unaffordable) power requirements.

On that basis, maybe it is a good idea to bring the wife's speaker(s) outside and measure what's going in and what's coming out and how loud is about right. And how it sounds to you. Easy to do. Buy an SPL meter at Radio Shack and a digital voltmeter at Harbor Freight (if you don't have an oscilloscope.... a tool some of your "experts" have never used).

You can buy a $40 meter or you can buy 15 extra 18-inch drivers (for $4500 and another $4500 for amps) you might not need.

Substantial benefit raising your crossover point from 80 to 120 Hz.

Ben

While I can't offer any trustworthy horn design ideas (a gesture of modesty not often heard in these parts), my impression is that your design is vastly "over the top". On this forum, folks are always doing grade-7 math and coming up with inconceivable (and unaffordable) power requirements.

On that basis, maybe it is a good idea to bring the wife's speaker(s) outside and measure what's going in and what's coming out and how loud is about right. And how it sounds to you. Easy to do. Buy an SPL meter at Radio Shack and a digital voltmeter at Harbor Freight (if you don't have an oscilloscope.... a tool some of your "experts" have never used).

You can buy a $40 meter or you can buy 15 extra 18-inch drivers (for $4500 and another $4500 for amps) you might not need.

Substantial benefit raising your crossover point from 80 to 120 Hz.

Ben

Last edited:

My building location is open half-space - i.e. relatively flat earth, with a tree line in the distance. If I build on the North side of my property, the only nearby structure would be my shop building, which is about 45 degrees off-axis from the horns, roughly 100 feet way. The tree line would be about 150 feet away.

If I build on the South side of my property, there will be no nearby structures. The house would be greater than 90 degrees off-axis. The shop would be 400 plus feet away, about 30 degrees off-axis. I'm not overly concerned about the shop, as the shop walls are orientated such as to not reflect sound directly back into the listening area.

My plan for the tree line is to selectively thin the trees, so that there is a less pronounced impedance mismatch at the boundary (so that the woods will work to scatter & absorb sound, rather than reflect it back.)

In either regard, there's no berm, no beer cooler, no nothing - just ground. The hot tub will be an in-ground unit. The only wall will be the wall housing the bass horns. It's as pure of open half-space (aka outside) that I can reasonably achieve on my property.

If I build on the South side of my property, there will be no nearby structures. The house would be greater than 90 degrees off-axis. The shop would be 400 plus feet away, about 30 degrees off-axis. I'm not overly concerned about the shop, as the shop walls are orientated such as to not reflect sound directly back into the listening area.

My plan for the tree line is to selectively thin the trees, so that there is a less pronounced impedance mismatch at the boundary (so that the woods will work to scatter & absorb sound, rather than reflect it back.)

In either regard, there's no berm, no beer cooler, no nothing - just ground. The hot tub will be an in-ground unit. The only wall will be the wall housing the bass horns. It's as pure of open half-space (aka outside) that I can reasonably achieve on my property.

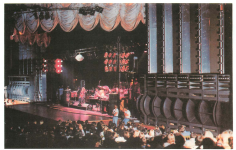

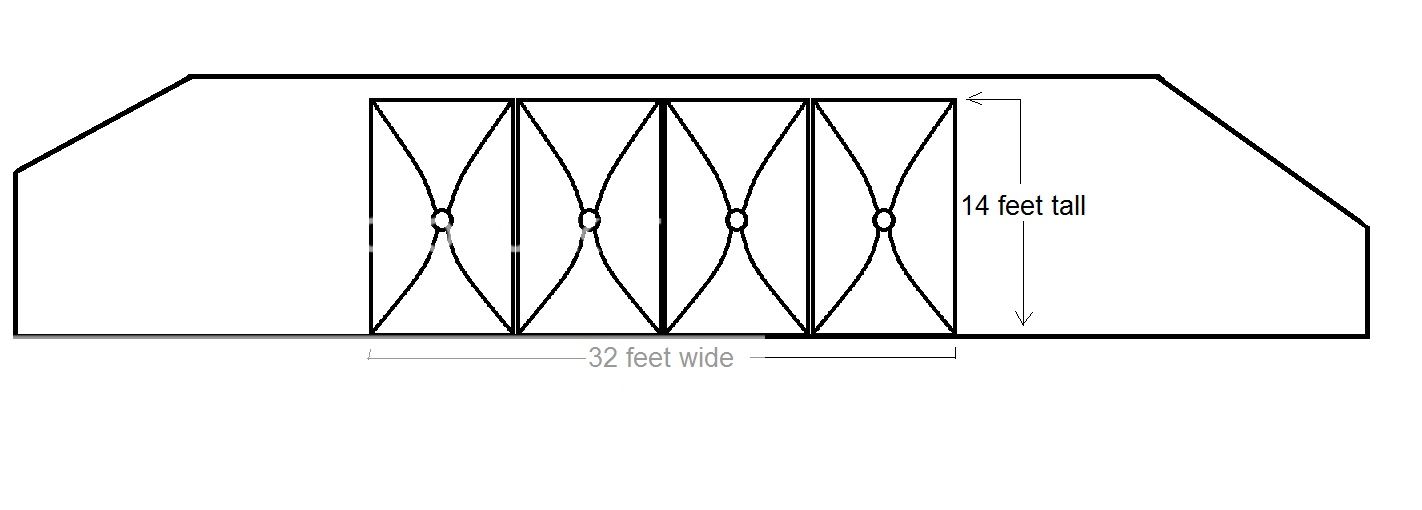

Above is a good visual representation of the overall mouth dimensions of my bass horns (four 1/4 space 15 Hz straight exponential horns, joined side-by side). The overall bass horn mouth will be approximately the size of my shop’s two garage doors (less the green center divider). Each garage door is about 14 feet tall, and 16 feet wide. So imagine you’re standing (or sitting) about where this picture was taken, and my garage doors are actually bass horns. Where should I place my mains for best fidelity?

And below is what 120 tons of fresh concrete looks like (40’ x 60’ x 8” thick slab). I needed a thick slab, so that I can park my bulldozer without cracking the floor. I’m hoping my horns will not require this much concrete. . . . .

How about a quick sketch in what architects call "plan view" photographed by a cellphone? No one will judge your artistic talents.

Garage looks like an acoustical train wreck to me but others may be wiser on this issue. Neglecting the general question of making a $40,000 outdoor PA system (for Seattle weather!!!), in terms of reasonable sound results, I think I'd trade* three of the horns for sound deadening treatment of the shed. Spray-on cork/latex stuff is great for large expanses of sheetmetal in vans.

Funny, at the start, I thought we were looking at a fabulous HiFi horn speaker feeding a living room. A million times more sensible to me.

Ben

*we are all rooting for Entropy, but only feasible systems have a chance of getting built

Garage looks like an acoustical train wreck to me but others may be wiser on this issue. Neglecting the general question of making a $40,000 outdoor PA system (for Seattle weather!!!), in terms of reasonable sound results, I think I'd trade* three of the horns for sound deadening treatment of the shed. Spray-on cork/latex stuff is great for large expanses of sheetmetal in vans.

Funny, at the start, I thought we were looking at a fabulous HiFi horn speaker feeding a living room. A million times more sensible to me.

Ben

*we are all rooting for Entropy, but only feasible systems have a chance of getting built

Last edited:

Just some more thoughts.

Hi Entropy455,

I did a little comparison between the 18SW115 and the 12NW76 on similar horns using the '10ft x 21.5ft' mouth you earlier suggested. I'm pretty sure the same holds true for the latest greatest... A common 10ft x 21.5ft (or so) mouth looks like it would be plenty big to reach to 20Hz (15Hz cut-off). I would probably use 4 long throat/inital horn sections combining into a common final/mouth section. Looks like w/ about a 16ft break point between the throat and mouth sections you could arrive @ 8ft height @ 16', and then gently taper your height to 10ft @ the mouth, using the width for majority of the mouth expansion... I also would use Hornresp Hyp to calculate the flare, and would not exceed a 4:1 compression ratio.

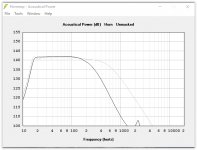

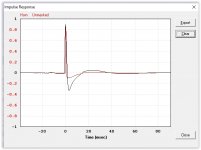

It's interesting, that you need 16x12" v. 4x18" to arrive at similar SPL (looks like I used Xvar for the 12", and Xmax for the 18", so you might even need more 12"); the 12"s have much wider high end extension, and an improved impulse response, maybe that's what you are hearing when comparing these. I cannot hear a difference between 12" and 18" subwoofers of equal quality, in an appropriate enclosure, with the correct bandpass filter, but then I'm old. 🙂

Regards,

Hi Entropy455,

I did a little comparison between the 18SW115 and the 12NW76 on similar horns using the '10ft x 21.5ft' mouth you earlier suggested. I'm pretty sure the same holds true for the latest greatest... A common 10ft x 21.5ft (or so) mouth looks like it would be plenty big to reach to 20Hz (15Hz cut-off). I would probably use 4 long throat/inital horn sections combining into a common final/mouth section. Looks like w/ about a 16ft break point between the throat and mouth sections you could arrive @ 8ft height @ 16', and then gently taper your height to 10ft @ the mouth, using the width for majority of the mouth expansion... I also would use Hornresp Hyp to calculate the flare, and would not exceed a 4:1 compression ratio.

It's interesting, that you need 16x12" v. 4x18" to arrive at similar SPL (looks like I used Xvar for the 12", and Xmax for the 18", so you might even need more 12"); the 12"s have much wider high end extension, and an improved impulse response, maybe that's what you are hearing when comparing these. I cannot hear a difference between 12" and 18" subwoofers of equal quality, in an appropriate enclosure, with the correct bandpass filter, but then I'm old. 🙂

Regards,

Attachments

Here's the general layout of the property (not to scale). Sorry the picture looks squished - you'll need to click on it to achieve the proper aspect ratio. Everything in green is woods. Horn (1) was my original proposed position, because there's several hundred acres of vacant land to the north (north is top of picture). Horn position (2) is what I'm leaning towards building now - mainly because the wife said ok. The area in light green is currently woods, and I can either clear it completely, or clear it mostly (for an open, yet woodsey feel - also known as selective thinning). The property has an overall gentle slope to the west for drainage.

My hope for horn position (2), is that the shop would be about 400 feet from the horns. This should significantly reduce the impact on the sound field (and hopefully keep the shop's sheet-metal from rattling like a can of marbles when I play the soundtrack to TRON). If I selectively thin the woods shown in light green (leaving a moderate amount of trees standing), it would provide attenuation between the horns and the shop (more so than open air) - while hopefully not causing an appreciable echo off the thinned tree line.

Concrete is about 50 bucks per ton (100 bucks per cubic yard), and rebar is about 600 dollars per ton (in bulk, if I go and pick it up). I do not expect the horns to cost more than 8 grand in concrete & rebar, plus another 2 grand in form materials (a bunch of plywood and 2x6 lumber).

Last edited:

I see! Thanks. Getting warmer. Drawing scale?

Hot tub, patio, seats, neighbours?

Not just bass that causes "sympathy" in sheetmetal panels... hard to predict... but easy to hear. But 400 feet (and back to your ears another 400 feet) pretty far. But pretty slight attenuation through trees.

$10,000 for electronics? Much cheaper if you rent it just for sunny days in Seattle.

I hope some of your work can be honestly expensed as business.

Ben

Hot tub, patio, seats, neighbours?

Not just bass that causes "sympathy" in sheetmetal panels... hard to predict... but easy to hear. But 400 feet (and back to your ears another 400 feet) pretty far. But pretty slight attenuation through trees.

$10,000 for electronics? Much cheaper if you rent it just for sunny days in Seattle.

I hope some of your work can be honestly expensed as business.

Ben

A thought: like Hasselblad backs, can you build the concrete horn body and then start with a single driver and then add drivers as needed easily in wood? I'd certainly aim for that kind of experimentation. In days of yore, there were Western Electric horns with two throats, if I recall. The concrete work is in your pocket but you'll be paying cash for the drivers and amps.

B.

B.

I'm leaning towards building (qty 4) quarter-space 15 Hz straight exponential bass horns, joined together side-by-side, so that two horns act as one half-space stereo channel, and the other two horns are the other half-space stereo channel.

I'm just back from an unexpected vacation and yeah, of course I have opinions.

Starting here, two horns that were designed to be used in quarter space sitting side by side and operating in half space do NOT equal one half space horn. Quarter space means you have two infinitely large boundaries (or at least large enough to reinforce the wavelengths at the bottom of the passband, in this case 15 hz), I can assure you, you don't. There's a sizable difference between taking a horn designed to be used in half space and cutting it into two modular sections and taking two horns designed for quarter space and putting them side by side in a half space environment. I can prove this if necessary but it would be a lot easier if you just take my word for it.

Moving on, the whole point of a single mono central sub was to alleviate comb filtering issues. Now you are back to stereo horns, and not just stereo but four horns operating in pairs. There will be comb filtering issues. The comb filtering won't be anywhere near as bad as with dual subs placed 60 feet apart but in this case you have a 16 foot spacing, there's very likely going to be comb filtering in the passband especially if you insist on pushing for a high crossover frequency.

As I see it, I've got a few options for the mains.

Personally I don't even want to talk about mains until you sort out mono or stereo sub. And as I mentioned, I would hope you keep your mind open about the possibilities until you have a chance to do some actual testing in your backyard with your stereo. I would strongly suggest you have a measurement mic in hand for these tests - you are going to need one at some point anyway, might as well get it now, it's only $100, only 2x more than the price of the spl meter Ben wants you to get, and it covers all the functions of the spl meter and so much more. You absolutely do not need an oscilloscope, suggesting that is just silly, but you should have a DMM (I'd find it hard to believe you don't already have one) and maybe an impedance jig or WT2 or DATS so you can measure impedance. If you are seriously going to be building speakers you will need this stuff at some point anyway. You will also need some music and pink noise for testing.

Hi JAG,

Just a question, what do you think about this: run the horns physically into a single mouth with a center divider. Electronically sum all low frequency sources up to a chosen frequency, and apply this mono signal to all horns, and then (let's say @ 80 Hz) have the signal electronically converted back into stereo (the transition does not have to be steep), and applied these signals to the left and right horns respectively? To difficult to predict?

Regards,

Just a question, what do you think about this: run the horns physically into a single mouth with a center divider. Electronically sum all low frequency sources up to a chosen frequency, and apply this mono signal to all horns, and then (let's say @ 80 Hz) have the signal electronically converted back into stereo (the transition does not have to be steep), and applied these signals to the left and right horns respectively? To difficult to predict?

Regards,

Another cryptic, and completely useless answer. . . .

My question was where I should place my mains. You respond with - that's not how it's done anymore. Question - that's not how WHAT is done anymore? Please advise? How does the industry typically build their outdoor 15 Hz full-size straight exponential bass horns - to feed a small & focused backyard listening area?

My bass horns will have roughly 450 square feet of mouth area. Are you taking issue with my proposed mouth area geometry? Or are you simply taking issue with my project in general?

No worries - I'm sure others will provide some helpful "constructive" feedback. . . .

His statement "Your side by side diagram is functionally like a much larger version of the "VIP" updated "Ubangi" bass horns ..." is patently untrue. There are a million systems with side by side subs, including a lot of weltersys' own systems.

From post 709 - "

A 10 block system using 20 Welter Systems (WS) L4 front loaded horns (FLH), each cabinet 45" x 45" x 32" in size would result in a bass array 15 foot tall (225 inches, 5.77 meters) by 12' 8" (128 inches, 3.28 meters) wide ...

- same thread different system - ... mouth area of the bass horns almost 12 foot wide ...

- same thread different system - The mono delay tower systems provided for NZE were dwarfed by the system we worked with the next year.

He doesn't say how wide the stack was but it wasn't a vertical line array, so it must have been very wide.

Weltersys has almost exclusively used side by side subs (also stacked vertically) and he boasted that a 12' 8" width was not uncommon and not the largest he had used. Logically, any time you have a lot of subs to stack, unless you put them all in a vertical line array you will have to put at least some of them side by side, this is so common it's unbelievable that he would say "

There are no successful live sound reinforcement companies in the USA using the type of setup you propose outdoors anymore ..."

Horizontal rows of subs are everywhere, including in almost all the welter systems paid gigs. The only exception was when he used line arrays or single subs, which was near/past the end of his career.

Taking a broader look at horrid 1970s system he described we have this -

"... 2x15" bass section, and two dual driver JBL radial horns topped by an arc of "Bullet" tweeters. "

Sounds like two 15s side by side, two mid horns side by side on top of the 15s and a horizontal row of bullet tweeters across the top of the box.

In this system, the only part that makes sense is the woofers. If they are crossed over low enough it makes no difference if they are side by side. The rest of the system though, is a comb filtering nightmare - side by side mids and a horizontal row of tweeters is terrible design and this was known well before the 70s.

This is the epitome of bad design and has nothing at all in common with your system except for the fact that the woofers are side by side - the only part of the 70s system that is arguably ok (as long as they are close enough to each other and the crossover point is low enough).

So why did he chose to talk about this botched example of engineering while referencing your system? HINT - your first sentence assessment of his post is right on the money.

Hi JAG,

Electronically sum all low frequency sources up to a chosen frequency, and apply this mono signal to all horns, and then (let's say @ 80 Hz) have the signal electronically converted back into stereo (the transition does not have to be steep) ...

Regards,

How would you accomplish this?

Anyway, I don't see the point. The subs are not far enough apart to get any sense of stereo separation and somewhere south of 120 hz there's no localization at all. And when you do have a signal panned hard to one side and only half the drivers are working the frequency response changes. By my count that's two benign reasons not to bother and one harmful reason not to bother.

I say design a horn for 2 pi space. Divide it up into two modular units if you want. Divide it up into 4 modular units if you want. Then you can play with stereo if you want. I'm pretty sure that after playing with stereo OP will find there's no point and just run it mono.

The problem with dividing it up like this is comb filtering. One large horn will beam but I don't think it will comb filter with itself. Once you cut it up into modular units you don't have a single central beam anymore, you have a bunch of side by side beams and they will destructively interfere with each other. We can sim this with Direct.

Hi JAG,

Post #774: "How would you accomplish this?"

I would probably do it in analog in an opamp/matrix kind of electronic filter, prior to digital delays and amplifiers... The reason the thought popped up in my head is that the OP wants to explore the upper frequency range of the horn using multiple 12NW76, and that would require stereo for the upper frequencies, but I still believe that mono to 80-or so-Hz would be best.

Just pondering the subject (see Post #324). 🙂

Regards,

Post #774: "How would you accomplish this?"

I would probably do it in analog in an opamp/matrix kind of electronic filter, prior to digital delays and amplifiers... The reason the thought popped up in my head is that the OP wants to explore the upper frequency range of the horn using multiple 12NW76, and that would require stereo for the upper frequencies, but I still believe that mono to 80-or so-Hz would be best.

Just pondering the subject (see Post #324). 🙂

Regards,

Hi JAG,

Post #774: "How would you accomplish this?"

I would probably do it in analog in an opamp/matrix kind of electronic filter, prior to digital delays and amplifiers...

That's going to be a non starter for OP - he wants to go from a digital source and keep it digital as long as possible.

The reason the thought popped up in my head is that the OP wants to explore the upper frequency range of the horn using multiple 12NW76, and that would require stereo for the upper frequencies, but I still believe that mono to 80-or so-Hz would be best.

Just pondering the subject (see Post #324). 🙂

Regards,

I'm all for experimentation but I don't think the 300 hz he is pondering is feasible in any way. So I would suggest that this experimentation is done well before the project is set in stone.

Isn't acoustic coupling a fundamental property of horns?two horns that were designed to be used in quarter space sitting side by side and operating in half space do NOT equal one half space horn.

A generic full-space 15 Hz straight exponential horn:

Throat = 0.123 m^2

Mouth = 41.37 m^2

Length = 10.66 m

The half-space equivalency, is quite literally half the full-space area:

Throat = 0.061 m^2

Mouth = 20.68 m^2

Length = 10.66 m

Acoustically, when you put two half-space horns side-by-side, do you not get one full-space horn?

1)Moving on, the whole point of a single mono central sub was to alleviate comb filtering issues. Now you are back to stereo horns, and not just stereo but four horns operating in pairs. There will be comb filtering issues. The comb filtering won't be anywhere near as bad as with dual subs placed 60 feet apart but in this case you have a 16 foot spacing, there's very likely going to be comb filtering in the passband especially if you insist on pushing for a high crossover frequency.

2)His statement "Your side by side diagram is functionally like a much larger version of the "VIP" updated "Ubangi" bass horns ..."

3)From post 709 - "A 10 block system using 20 Welter Systems (WS) L4 front loaded horns (FLH), each cabinet 45" x 45" x 32" in size would result in a bass array 15 foot tall (225 inches, 5.77 meters) by 12' 8" (128 inches, 3.28 meters) wide ...

4)same thread different system - The mono delay tower systems provided for NZE were dwarfed by the system we worked with the next year.

He doesn't say how wide the stack was but it wasn't a vertical line array, so it must have been very wide.

5)Weltersys has almost exclusively used side by side subs (also stacked vertically) and he boasted that a 12' 8" width was not uncommon and not the largest he had used.

6)Logically, any time you have a lot of subs to stack, unless you put them all in a vertical line array you will have to put at least some of them side by side, this is so common it's unbelievable that he would say "

There are no successful live sound reinforcement companies in the USA using the type of setup you propose outdoors anymore ..."

7)Horizontal rows of subs are everywhere, including in almost all the welter systems paid gigs. The only exception was when he used line arrays or single subs, which was near/past the end of his career.

8)Taking a broader look at horrid 1970s system he described we have this -

"... 2x15" bass section, and two dual driver JBL radial horns topped by an arc of "Bullet" tweeters. "Sounds like two 15s side by side, two mid horns side by side on top of the 15s and a horizontal row of bullet tweeters across the top of the box.

JAG,

1) I am in complete agreement with you on this point.

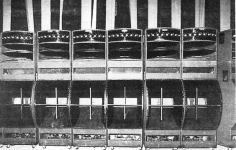

2) If you would research the "VIP" system I described, you would recognize the similarities. The RCA or Western Electric (I don't recall which) "Ubangi" horns featured the 2x15" in a vertical radial exponential horn, the mid frequency horns were placed horizontally in the cabinet above the LF section, then multiple units were rolled into place, side by side, just as the OPs picture shows.

One specific difference- the "VIP" acoustic point of origin for the bass and mid drivers are at the same vertical depth, but as the OP has not suggested putting his top cabinets at the acoustic point of origin of the 15 foot deep bass horn, the off axis distance to the mains and subs will be different everywhere, the cancellation will be almost random. In that respect, the upper comb filtering of the side by side "VIP" system was not quite as horrible as one would expect looking at polar response, it changed so much with so little movement from side to side that it almost sounded the same everywhere- uniformly lousy sound!

3) You failed to include the part where I stated I never set up a 10 block system with central subs, in most cases the vertical sub array was only 64 or 90 inches wide.

4) I specifically stated in that thread that each of the four pass bands of the main 12 block system that dB Sound provided were flown in vertical arrays around 60 foot tall. dB Sounds top cabinets and subs could be flown either horizontally or vertically. The subs may have been flown in two 32" wide columns, or one 50" wide column, I don't recall which. The top cabinets were flown horizontally, mid 15" horns flanking either side of the bass hang, the mid and high horns on the outside, splayed out about 10 degrees for minimal overlap.

My four block vertically arrayed addition to the main system were located stage right and left of dB main "hangs" to cover the seats located to either side of stage that were not in the coverage pattern of dB's main system coverage of roughly 90 degrees per side. Mine were not as closely coupled, due to the limitation of stacking on scaffold decks rather than flying from chain motors as dBs system was. My 4 block system took more stagehands working a longer time to assemble than dBs 12 blocks of flown gear, a real lesson to me of letting machines do the work, and taking it easy pushing the "up" or "down" control on the motor control "pickle",

5) In my entire career starting with the PA I provided for the Minneapolis bands "Rockinghorse" in 1974 and "Emerald" in 1976, to my tenure with Eclipse Concert Systems, my ownership of Southern Thunder Sound using Welter Systems speakers from 1979 to 1992, and after the sale of STS, my company Welter Systems has exclusively avoided the use of side by side subs, mids or high frequency drivers, unless their coverage pattern does not overlap more than 10 degrees or so, whenever possible. The exceptions to that rule has been when a client has placed sheer SPL over sonic purity, and my NIHL at 4kHz is a stark testament to the damage that practice may result in, aside from the crap sound it produces.

6) Just because a practice is "common" in no way means I follow that practice in such ignorant array placements. I find no "logic" in using a horizontal bass array that results in a poor phase response in the low to low-mid crossover region in virtually every location but one when using L/R stereo mains.

7) Wrong, I have been using vertical line arrays since the summer of 1975, as the photo below proves, as I still have 8 fingers and 2 thumbs in it- I lost 2 fingers and half my left thumb in a metal crushing accident just before Christmas of 1975. The only "side by side" horns in that system are the two EV diffraction horns near the top of the stack, their dispersion is about the same ether way, and I think we may have run out of speaker cord length, as we had rented several PA systems to put together the Big One for the concert after a road race at Donnybrook International Speedway. Although the system sounded great at over 100 meters distance, there was hardly more than 100 people that stayed for the show, they were all ready to leave as soon as the last race of the weekend was over.

The good thing about my hand accident was the "huge" $12,000.00 workman's compensation settlement allowed me to purchase equipment needed for Eclipse Concert Systems to tour with Sha Na Na across the country, setting up my DIY 3 way straight horn system in almost every conceivable configuration in venues ranging from "in the round" indoor and outdoor locations, to theaters with as many as three balconies, standard state fair grandstands, and arenas from 5000-to 15,000 capacity across the country, including "lost wages" (Las Vegas).

I got to hear the "VIP" system there, and thought "why are these clowns getting the big bucks for this re-furbished 1940s theater system that only should be used one per side, but is rolled in with as many cabinets wide as the stage allows?".

As I matured, I found out why they got the big bucks- once a system tours with a successful band, others that want to emulate that success story are more than happy to "jump on the bandwagon", and systems that roll directly off the trailer and on to the stage that only require a single AC and input connection (the "VIP" was an innovation in that regard, each cabinet had it's own three-way crossover, and amps built in) save stagehand expenses, which can easily exceed the cost of the rental price of a sound system if set up takes too much time or bodies.

JAG, please read my posts a bit more carefully, it is an aggravation to correct all the mistakes you continue to propagate about what you think I have, or have not done or said about my experience while doing those things.

Cheers,

Art

Attachments

Last edited:

Acoustical coupling is a fundamental property of any acoustic source located within 1/4 wave length of another acoustic source covering the same bandwidth with an identical signal.Isn't acoustic coupling a fundamental property of horns?

Acoustically, when you put two half-space horns side-by-side, do you not get one full-space horn?

Your horn spacing will preclude acoustical coupling in the upper range except at a great distance from the mouths, and only on axis.

Two half-space horns side-by-side are the equivalent of one full-space horn in the low frequency range, but at the upper frequency range of the pass band are two independent points of acoustical origin.

That will be 2 cents, please 😀 .

Art

My analog "meat computer" memory banks failed, the "A1 Audio" "VIP" cabinet's MI-9588 Motiograph Western Electric radial bass horn section's 2x15" were side by side, not vertical like my bass horns from that era. In their "normal" horizontal orientation, the MI-9588 had the drivers vertical- Western Electric engineers knew something about what worked, and what did not.2) If you would research the "VIP" system I described, you would recognize the similarities. The RCA or Western Electric (I don't recall which) "Ubangi" horns featured the 2x15" in a vertical radial exponential horn, the mid frequency horns were placed horizontally in the cabinet above the LF section, then multiple units were rolled into place, side by side, just as the OPs picture shows.

One specific difference- the "VIP" acoustic point of origin for the bass and mid drivers are at the same vertical depth, but as the OP has not suggested putting his top cabinets at the acoustic point of origin of the 15 foot deep bass horn, the off axis distance to the mains and subs will be different everywhere, the cancellation will be almost random. In that respect, the upper comb filtering of the side by side "VIP" system was not quite as horrible as one would expect looking at polar response, it changed so much with so little movement from side to side that it almost sounded the same everywhere- uniformly lousy sound!

Another errata from a prior post, the pair of 90 degree horizontal JBL 2350 horns above each VIP only used a single JBL 2482 mid driver per horn, it was ShowCo that used double drivers on their endless side by side stacks of Motorolas Piezo tweeter lined 2350 horns above the "Hurler" miid horns and "Pyramid" quad driver folded bass horns.

The A1 boxes were "Hi -Fi" compared to the ShowCo rig, but the ShowCo rig could tear your effing head off if you got near the mid-high section.

Sorry for the mistake, I guess Eric can put the 2 cents he owed me back into the kitty litter box 😱 .

Art

Attachments

Last edited:

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question