iirc you are to refrigerate solder paste, to extend its shelf life.

iaef, read the specs.

jeff, since you like your manual control, having a thermocouple is really nice to have. Another reason to build a good temp meter.

In the past. we used to use tape a number of thermocouples on a populated board and run it through the oven a few times to get the dwells,temp,soaks correct.

Another caution, popcorning, that is when the plastic package takes on too much moisture. this is why you get parts in a sealed bag with desiccant and a humidity indicator. if you leave parts out for extended periods of time in a humid environment and then process, you take the risk of damage or failure. you are supposed to store in temp/humidity env or pre-bake to drive out moisture. no risk if you hand solder. so there you go, some smt 101 for you today.

They don't say anything about refrigerating it on their packaging but mine just showed up with an ice pack in a cooler bag today. They've never done that before.

I'd like to do a proper oven controller again some day but with better mosfets next time.

Attachments

Last edited:

It is actually pretty easy to modify most of those toaster ovens with a better controller. I've also done the same thing with room heaters when using them in a heater box or other equipment. A nice simple digital controller with a thermo-couple for a sensor and you can do whatever you want. You could go a step further and put a controller for the ramp rate up and down. About as basic as you could go with a PLC. But you don't need to go that far really.

It's a transparent "oily" jelly sort of paste with very narrow dispenser (pin hole) - I keep it without any covers and I'm sure it will work fine for some years. Very good as a flux by the way - clean, efficient, easy to apply...

Hi Valery,

This is the stuff I bought and used but it has no solder in it.

8341-10ML MG Chemicals | Mouser

I believer the stuff Jeff is using has solder in it and all you need to do is provide heat.

This smd is interesting but I wonder if I will ever do enough of it to justify the investment in all the equipment and special materials.

On the electrolytic cap issue, I have stripped a few commercial boards for parts and a lot of them are all smd except for the electrolytics, which were through hole. I'm not sure if that is because of cost.

Blessings, Terry

Hi Valery,

This is the stuff I bought and used but it has no solder in it.

8341-10ML MG Chemicals | Mouser

I believer the stuff Jeff is using has solder in it and all you need to do is provide heat.

This smd is interesting but I wonder if I will ever do enough of it to justify the investment in all the equipment and special materials.

On the electrolytic cap issue, I have stripped a few commercial boards for parts and a lot of them are all smd except for the electrolytics, which were through hole. I'm not sure if that is because of cost.

Blessings, Terry

There isn't much available in larger sizes of SMD caps. I think the risk of them popping in the oven likely has a lot to do with that.

As for the required investment, a toaster oven is cheaper than a good soldering iron and a syringe of solder is cheaper than a roll of Kester 44. The whole second inventory of parts and storage space needed for them is a big drawback though.

Very similar to what I've got. I use it not only for SMD now - just a good flux in general for any soldering...

Yes, Jeff has got the one with solder in it.

Yes, Jeff has got the one with solder in it.

There isn't much available in larger sizes of SMD caps. I think the risk of them popping in the oven likely has a lot to do with that.

As for the required investment, a toaster oven is cheaper than a good soldering iron and a syringe of solder is cheaper than a roll of Kester 44. The whole second inventory of parts and storage space needed for them is a big drawback though.

Yeah, I am starting to build a collection of smd parts already just from the little bit I've done. A while back I did a board for Dado's thermaltrak amp and he used 100V .1u smd caps for decoupling on the bottom of the boards. I liked that idea so I ordered 200 of them to use on other projects as well. I guess I will begin to add other values of caps and resistors to future orders until I can build a good base of parts. It is only the electrolytics that have me concerned.

Bessings, Terry

Newark is a good place to stock up from. They have inventory reduction sales regularly. A 1206 1% resistor goes for $.003 each. 200 for under a buck is nice.Yeah, I am starting to build a collection of smd parts already just from the little bit I've done. A while back I did a board for Dado's thermaltrak amp and he used 100V .1u smd caps for decoupling on the bottom of the boards. I liked that idea so I ordered 200 of them to use on other projects as well. I guess I will begin to add other values of caps and resistors to future orders until I can build a good base of parts. It is only the electrolytics that have me concerned.

Bessings, Terry

I hardly ever use smt ecaps. only use them when you are into mass production. hand stuffing components, on a large scale is expensive compared to pick n place. low leakage Nichicon UKL are my favourites.

you do not not have to invest very much $ at all to do successful smt work. I have yet to need a reflow oven. all i use is two irons, some 15mil glow-core no-clean solder and a 10x jewelers loup and that is about it. it is much faster than tht, no leads to form and cut. think of all that material waste on tht component leads. gee how many jumper wires do i need 🙂

I bought a sparkfun hot air machine to remove/reflow one "dfn" package.

using smt saves $ all around, because you reduce pcb area significantly!! Smaller,tighter layouts outperform ones that occupy larger areas. except for power, go smt!! one caveat, smt usually requires a multi-layer pcb.

P.S. found another t/c pcb, http://www.adafruit.com/products/269 with ardunio lib

you do not not have to invest very much $ at all to do successful smt work. I have yet to need a reflow oven. all i use is two irons, some 15mil glow-core no-clean solder and a 10x jewelers loup and that is about it. it is much faster than tht, no leads to form and cut. think of all that material waste on tht component leads. gee how many jumper wires do i need 🙂

I bought a sparkfun hot air machine to remove/reflow one "dfn" package.

using smt saves $ all around, because you reduce pcb area significantly!! Smaller,tighter layouts outperform ones that occupy larger areas. except for power, go smt!! one caveat, smt usually requires a multi-layer pcb.

P.S. found another t/c pcb, http://www.adafruit.com/products/269 with ardunio lib

Last edited:

So it isn't paste with solder mixed in.It's a transparent "oily" jelly sort of paste with very narrow dispenser (pin hole) - I keep it without any covers and I'm sure it will work fine for some years. Very good as a flux by the way - clean, efficient, easy to apply...

Wow Valery, that looks really nice! May I ask, what are the small boards between the IPS and the filter cap board? Also, which OPS are you planning to use?

Blessings, Terry

Blessings, Terry

Yep - those are the Shuntie boards - shunt regulators for supplying the front-ends with heavily filtered, regulated power.

Wow Valery, that looks really nice! May I ask, what are the small boards between the IPS and the filter cap board? Also, which OPS are you planning to use?

Blessings, Terry

Hi Terry,

I plan to use the IRFP-based SlewMonsters here. Huge current supply capability, no matter what the load is - 8/4/2 ohm 😉

Cheers,

Valery

Valery and others, i think when talking about other circuits it is useful to post the link.Hi Terry,

I plan to use the IRFP-based SlewMonsters here. Huge current supply capability, no matter what the load is - 8/4/2 ohm 😉

Cheers,

Valery

Valery and others, i think when talking about other circuits it is useful to post the link.

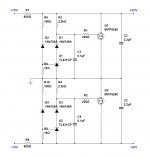

No problem - my "simplified" schematic (showing changes to the original one) is located earlier in this thread:

>IRFP-based SlewMonster<

Attachments

I still need to fix my hexfet boards. I'll probably start by replacing all the diodes. I think that is what got damaged. I'm really interested in trying this IPS with those.

I ran them in this configuration during a few weeks - like the sound a lot. With powerful PSU and "21-st century" control board - great performer

That's it!No problem - my "simplified" schematic (showing changes to the original one) is located earlier in this thread:

>IRFP-based SlewMonster<

Is this as built?Yep - those are the Shuntie boards - shunt regulators for supplying the front-ends with heavily filtered, regulated power.

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- CF-FET V2.0 front-end - going high-tech (SMD)