The fixed bolt position can be in the middle of the front two set screw movement to have verticle level adjustments. I guess we only need few turns to have significant movement at the headshell side.

@ super10018

From the video lookslike bearing are nice. I think the already known 1 sq. cm piece of paper on headshell to see lateral moving of tonearm can also be implemented. If arm is heavy we can use little large paper.

@directdriver,

The laserdisc idea was what I have read in the past on the net.

@ super10018

From the video lookslike bearing are nice. I think the already known 1 sq. cm piece of paper on headshell to see lateral moving of tonearm can also be implemented. If arm is heavy we can use little large paper.

@directdriver,

The laserdisc idea was what I have read in the past on the net.

Last edited:

more newbie thoughts.

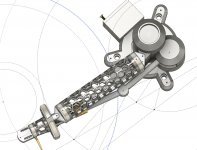

I know the tonearm was built to understand skating force. But it has turned out nice. I was wondering if extra mass and bearing are advantageous than regular tonearm. Obviously more bearings would have more friction but if we think that tangential tracking is more important for sound reproduction; these added friction helps in damping down whatever skating force there may be. Also I was wondering even if the four bearings are not perfectly precise in being parallel on axis to each other, it will have 'pseudo tight tolerance' As minor miniscul play in one bearing will be compensated by opposite bearing ?

sorry for abstract thoughts. 🙂

I know the tonearm was built to understand skating force. But it has turned out nice. I was wondering if extra mass and bearing are advantageous than regular tonearm. Obviously more bearings would have more friction but if we think that tangential tracking is more important for sound reproduction; these added friction helps in damping down whatever skating force there may be. Also I was wondering even if the four bearings are not perfectly precise in being parallel on axis to each other, it will have 'pseudo tight tolerance' As minor miniscul play in one bearing will be compensated by opposite bearing ?

sorry for abstract thoughts. 🙂

3 point plane

There's a fixed shim behind the bolt so the shim and two set screws created a three legged stool. The bolt is to fasten the 3 points to the armboard. The base is not flat or flush mounted. With such arrangement you get L-R-F-B tilts.

How about in the case of the front is too high even the set screws are all the way up?

There's a fixed shim behind the bolt so the shim and two set screws created a three legged stool. The bolt is to fasten the 3 points to the armboard. The base is not flat or flush mounted. With such arrangement you get L-R-F-B tilts.

I studied Schröder LT again. LT has one fixed mount screw in the back and two adjustable set screws in the front. It is clear that Frank thinks the adjustments need to be left and right side only, not front and back. In my opinion, the adjustments should be all way around. On my 6B, I added three set screws. The level can be adjusted 360 degrees. I am also trying to modify 6C to have an easy adjustment mechanism. Frank, if you are reading this thread, please correct me if I miss anything.

Two screws are enough for a "360 degree" adjustment.

There's a fixed shim behind the bolt so the shim and two set screws created a three legged stool. The bolt is to fasten the 3 points to the armboard. The base is not flat or flush mounted. With such arrangement you get L-R-F-B tilts.

Thanks DD! I have to say it is an elegant design although I still prefer 3 set screws. Attached is the base design for my 6C for now.

Attachments

@ super10018

From the video lookslike bearing are nice. I think the already known 1 sq. cm piece of paper on headshell to see lateral moving of tonearm can also be implemented. If arm is heavy we can use little large paper.

I am not exactly sure what you are talking about. Do you mean to see vertical movement? If so, please see the video I posted in this thread before.

IMG 2867 - YouTube

The small piece of paper is 0.1 grams.

I know the tonearm was built to understand skating force. But it has turned out nice. I was wondering if extra mass and bearing are advantageous than regular tonearm. Obviously more bearings would have more friction but if we think that tangential tracking is more important for sound reproduction; these added friction helps in damping down whatever skating force there may be. Also I was wondering even if the four bearings are not perfectly precise in being parallel on axis to each other, it will have 'pseudo tight tolerance' As minor miniscul play in one bearing will be compensated by opposite bearing ?

sorry for abstract thoughts. 🙂

Yes. My original purpose was to build a simple arm to study skating force, but it had been changed. My current goal is to compare it with air-bearing arms. Everything is very encouraging so far. Especially for the cantilever stress test, it is much better than I expected.

It is a bombshell for me that the arm doesn't skate or the arm has a neglect-able skating force. That completely changes my views about PTL arms.

Last edited:

Attached is the base design for my 6C for now.

Nice drawing! How do you adjust the height of the column or VTA?

Thats nice sci-fi looking arm 🙂.Thanks DD! I have to say it is an elegant design although I still prefer 3 set screws. Attached is the base design for my 6C for now.

I guess you already may have thought of it but I wonder if weight can still further be reduced. Will be easy on bearing. Dont know why one bearing point is moved near headshell ? I think all bearing at pivot (near base/far away from headshell) will act as a 'fulcrum' when stylus point is in the groove so the force/s required to move the bearing attachments will be considerably less.

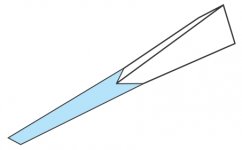

I also understand the tapering tube (Tonearm wand) will be stiffest but see if following image worth considering. It is based on NAD flat wand tonearm but little modified. The front light blue section is flat and remaining is triangular shape to give vertical stiffness which was lacking in NAD tonearm. All these and Broad end at the rear will somewhat avoid torsional movements.

Regards

Attachments

Nice drawing! How do you adjust the height of the column or VTA?

Please see the drawing. I plan to use a 1/4" screw in the center of base tower to adjust the height. There is a channel between the base and the tower. Two set screws for locking the tower. I also add a small window on the tower with a height indicator so I can know the position of the tower.

Attachments

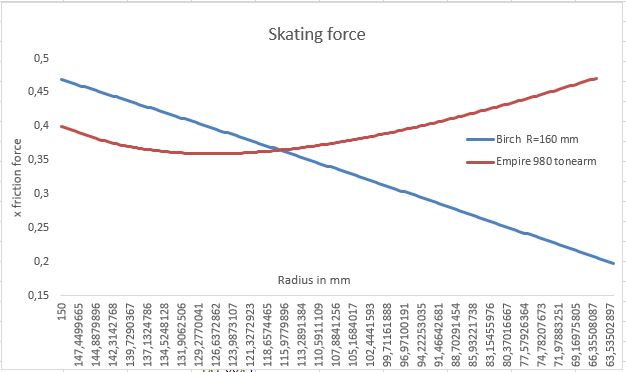

linear skating force

That's a rather linear drop off which means it's much easier to compensate or counter the force with some simple device like a stringed weight, magnet, spring, or offset side force, etc...

I have a feeling the sum of the fiction and whatever overlapping forces in the four horizontal bearings might have created some embedded counter force already that, in practice, it's not even noticeable.

A comparison of skating forces

Contestants: Empire 980 tonearm and Jim's (Super10018) Birch tonearm

That's a rather linear drop off which means it's much easier to compensate or counter the force with some simple device like a stringed weight, magnet, spring, or offset side force, etc...

I have a feeling the sum of the fiction and whatever overlapping forces in the four horizontal bearings might have created some embedded counter force already that, in practice, it's not even noticeable.

I don't know how do you get the blue line and am highly doubt the results since it is not possible that my 6B has higher skating force than a regular pivot arm at 150 mm radius. If my 6B arm's skating force is larger than the skating force of a regular pivot arm at 150 mm, my 6B will skate. In fact, the 6B arm doesn't skate at any radius.

In the early of this thread, I predicated that the skating force on a PLT arm is very small and linear because the stylus is always tangent to the groove.

Here is my thought about the skating force of my 6B. However, it is just a thought without any evidence at all.

There is one possibility. For my 6B, I tried to push all the linkages away from the base as far as possible. I don't treat the 6B as a 9" or 12" arm. Instead, I treated the arm as a linear arm. This may make the difference regarding skating. Frank admitted that his LT arm has a small skating force. Reed Audio claims it is no need for an anti-skating device. Their 5A may have a small amount of skating force as well. I don't think I can say Reed 5A doesn't skate because my 6B doesn't skate although they are all PLT arms and they have similar geometry. It is the same for Frank's LT arm although my 6B has the same geometry as the LT arm. I can't reason that the LT doesn't skate either.

I am not claiming my 6B is better than the two arms I mentioned above. However, I guess the short arm wand does benefit the performance of my 6B. The question is if the following statement is true. The shorter the arm wand, the smaller the skating force for PLT arms.

No matter what the reasons behind the non-skating behavior, a non-skating arm is a non-skating arm. It is safe to say that my 6B doesn't skate.

In the early of this thread, I predicated that the skating force on a PLT arm is very small and linear because the stylus is always tangent to the groove.

Here is my thought about the skating force of my 6B. However, it is just a thought without any evidence at all.

There is one possibility. For my 6B, I tried to push all the linkages away from the base as far as possible. I don't treat the 6B as a 9" or 12" arm. Instead, I treated the arm as a linear arm. This may make the difference regarding skating. Frank admitted that his LT arm has a small skating force. Reed Audio claims it is no need for an anti-skating device. Their 5A may have a small amount of skating force as well. I don't think I can say Reed 5A doesn't skate because my 6B doesn't skate although they are all PLT arms and they have similar geometry. It is the same for Frank's LT arm although my 6B has the same geometry as the LT arm. I can't reason that the LT doesn't skate either.

I am not claiming my 6B is better than the two arms I mentioned above. However, I guess the short arm wand does benefit the performance of my 6B. The question is if the following statement is true. The shorter the arm wand, the smaller the skating force for PLT arms.

No matter what the reasons behind the non-skating behavior, a non-skating arm is a non-skating arm. It is safe to say that my 6B doesn't skate.

Last edited:

In addition to the comments I posted above, my 6B has a built-in silicone damping though. Once I start to use the damping though, the skating force will be even cancelled out more if there is a skating force. It will damp the inertia of the arm as well.

I don't know how do you get the blue line and am highly doubt the results since it is not possible that my 6B has higher skating force than a regular pivot arm at 150 mm radius.

....

No matter what the reasons behind the non-skating behavior, a non-skating arm is a non-skating arm. It is safe to say that my 6B doesn't skate.

Physics is not a matter of beliefs.

You do not try the string test but you are sure what is possible and what is not.

A tonearm welded to the plinth would not skate either, so it is of interest why a tonearm does not skate.

You could measure the skating force of your arm with the simplest antiskating device: a weight on a string on a pulley.

First you could determine with a blank disc the weight which causes the tonearm to skate inward, then the weight which causes the tonearm to skate outward. The skating force can be determined: (Fout-Fin)/2

Another idea: you could pull on the tonearm axially with a 10 g weight, and measure the skating force with a stylus pressure gauge.

You could compare it with a traditional tonearm - only after having compared and/or measured bearing friction, of course.

You could compare it with a traditional tonearm - only after having compared and/or measured bearing friction, of course.

Jim, if I can perhaps do a multibody physics simulation for you?

This might clarify that the reducing angle of the effective length/tangent force vector is the deciding factor in the magnitude of the skate force. To me the biggest win for Birch like arms as they reduce SF where it matters the most, and why it looks so linear.

If you could confirm your geometry, I can set it up.

For this to work, I have to make you moving pivot horizontally unconstrained, so we can see the force at work and not the geometry.

This might clarify that the reducing angle of the effective length/tangent force vector is the deciding factor in the magnitude of the skate force. To me the biggest win for Birch like arms as they reduce SF where it matters the most, and why it looks so linear.

If you could confirm your geometry, I can set it up.

For this to work, I have to make you moving pivot horizontally unconstrained, so we can see the force at work and not the geometry.

Jim, if I can perhaps do a multibody physics simulation for you?

This might clarify that the reducing angle of the effective length/tangent force vector is the deciding factor in the magnitude of the skate force. To me the biggest win for Birch like arms as they reduce SF where it matters the most, and why it looks so linear.

If you could confirm your geometry, I can set it up.

For this to work, I have to make you moving pivot horizontally unconstrained, so we can see the force at work and not the geometry.

2wice,

That would be nice if you can do it. Please see attachment. If you need other information, please let me know.

Attachments

Physics is not a matter of beliefs.

It is a fact. My 6B doesn’t skate at 150 mm radius at all. But your calculation indicates my 6B arm has stronger skating force than a regular pivot arm. So, you need to check your calculation to see if it is correct. I still don’t know how you got the results.

You do not try the string test but you are sure what is possible and what is not.

The string test is flawed. Are you aware of version 1 and version 2 of string test? Go back to this thread to find it out. The version 2 of string test is flawed as well. I am sure that my 6B doesn’t skate because I tested it and I see it. I don't understand why you insist string test. Is my skating test method much better than string test?

You could measure the skating force of your arm with the simplest antiskating device: a weight on a string on a pulley.

First you could determine with a blank disc the weight which causes the tonearm to skate inward, then the weight which causes the tonearm to skate outward. The skating force can be determined: (Fout-Fin)/2

The test makes no sense to me. In order to avoid senseless debate about your testing method, why don't you perform the test first?

Another idea: you could pull on the tonearm axially with a 10 g weight, and measure the skating force with a stylus pressure gauge.

You could compare it with a traditional tonearm - only after having compared and/or measured bearing friction, of course.

This testing method makes no sense to me either. Again, In order to avoid senseless debate about your testing method, why don't you perform the test first, too?

Last edited:

- Home

- Source & Line

- Analogue Source

- Building a Tuthill/Reed 5A Tangential Tracking Pivot Tonearm