Effective length is the distance between the pivot and the stylus.

Offset angle is the angle between the effective length and cantilever.

In every tonearm based on the Thales circle the effective length is the radius of the Thales circle.

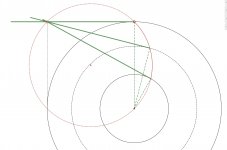

For illustration a Linkage model by Carlo. From the viewpoint of force vectors all realizations are the same.

Offset angle is the angle between the effective length and cantilever.

In every tonearm based on the Thales circle the effective length is the radius of the Thales circle.

For illustration a Linkage model by Carlo. From the viewpoint of force vectors all realizations are the same.

Attachments

What is the effective length for PT arms?

I still don't have any opinion about it yet. 2wice's view has its merit. In his view, the effective length is a force vector not a geometric parameter. In traditional view about effective length, people pay more attention on its geometric characteristics, not its force vector unless you are dealing with skating. Both factors, force vector and geometry, are combined together for pivot arms. For PT arms, do we really need the concept of effective length, a geometric concept? I don't see the usefulness of effective length. Force vector is enough for understanding the skating force.

I still don't have any opinion about it yet. 2wice's view has its merit. In his view, the effective length is a force vector not a geometric parameter. In traditional view about effective length, people pay more attention on its geometric characteristics, not its force vector unless you are dealing with skating. Both factors, force vector and geometry, are combined together for pivot arms. For PT arms, do we really need the concept of effective length, a geometric concept? I don't see the usefulness of effective length. Force vector is enough for understanding the skating force.

How can a distance be a force vector?

From what I remember from the engineering 1a class I took, the x,y,and z axes all had two components - force and distance.

My Mac won't open the 3 guy file. Would you reference the thread and page number, please.

Last edited:

In every tonearm based on the Thales circle the effective length is the radius of the Thales circle.

This is wrong. Here is an example of a pivoting tangential tracking tonearm. The effective length increases from the outer groove to the inner groove. This has to be the case for the stylus to remain tangential to the groove on the Thales circle.

Attachments

Bon said:The effective length increases from the outer groove to the inner groove. This has to be the case for the stylus to remain tangential to the groove on the Thales circle.

Hi Bon,

The effective length of the pivoting tangentially tracking tone arm I have designed, never changes. The stylus/cantilever of any tangentially tracking tone arm is NEVER tangent to the groove!

Sincerely,

Ralf

From what I remember from the engineering 1a class I took, the x,y,and z axes all had two components - force and distance.

My Mac won't open the 3 guy file. Would you reference the thread and page number, please.

No, a force vector has both magnitude and direction.

Do you have Linkage installed?

“Magnitude and direction.” You’re absolutely right. Sigh. I failed that class.

The file is downloaded, but there’s no app to open it.

The file is downloaded, but there’s no app to open it.

Hi Bon,

The effective length of the pivoting tangentially tracking tone arm I have designed, never changes. The stylus/cantilever of any tangentially tracking tone arm is NEVER tangent to the groove!

Sincerely,

Ralf

Ralf,

I think Bon meant the PT arm which is similar to my 6B. So does alighiszem. If we include all kinds of PT arms in our discussion, we can’t continue to have a meaningful dialogue. Yes. The groove is a spiral. Even it is a spiral, I don't see the reason why the stylus can't be tangent to the groove. However, it is beyond the topic of this thread.

Let’s examine alighszem’s statement.

In every tonearm based on the Thales circle the effective length is the radius of the Thales circle.

Please see the diagram. The radius for the Thales circle is XY while the diameter is XZ. The blue line is arm effective length( let’s assume it is the effective length for now in order to carry on this discussion). Obviously, his statement is incorrect. The effective length is neither the radius of the Thales circle nor the diameter of the Thales circle.

As I suggested early, let’s forget the geometric concept, effective length. For the purpose of analyzing skating force, all we need are force vectors, and the interactions of all the force vectors.

Attachments

Last edited:

Hi Bon,

The effective length of the pivoting tangentially tracking tone arm I have designed, never changes. The stylus/cantilever of any tangentially tracking tone arm is NEVER tangent to the groove!

Sincerely,

Ralf

Hi Ralf.

You may have answered my questions in previous threads and if so, maybe you can put links to the discussion.

Is your tonearm servo controlled or passive?

I realise my language may have been slightly imprecise.

Discounting the infinitesimal discrepancies caused by tracking a spiral with finite pitch rather than a locked perfectly circular groove, off centred discs, or cantilever displacement by sidethrust, do you accept a tonearm whose straight armtube is tangential to the locked groove, as tangentially tracking or not?

If not, what is your criterion for tangential tracking? It seems sensible to agree on the definition of tangential tracking to have a meaningful discussion.

Regards

Bon

Bon said:Is your tonearm servo controlled or passive?

do you accept a tonearm whose straight armtube is tangential to the locked groove, as tangentially tracking or not?

Hi Bon,

First I would like to assure super10018 that I am not trying to hi-jack his thread.

The tone arm I mentioned, is propelled across the LP by the frictional pulling force of the rotating LP. The inward force resulting from the off-set head shell is opposed electronically. To my way of thinking, that is not servo control.

If the center line of said straight arm tube, the center line of the cantilever and the center line of the pivot for horizontal rotation occupy the same vertical plane, and where the stylus is engaged in said 'locked groove" then yes, that tone arm would be tangentially tracking.

Any reference to tangential tracking should refer to a "concentric circle of random diameter between the limits of the start and the end of the modulated groove" I know it is a mouth full but it is a fact.

Sincerely,

Ralf

Last edited:

"The tone arm I mentioned, is propelled across the LP by the frictional pulling force of the rotating LP. The inward force resulting from the off-set head shell is opposed electronically. To my way of thinking, that is not servo control."

Is this a sort of electronic antiskating? What are the input parameters?

"Any reference to tangential tracking should refer to a "concentric circle of random diameter between the limits of the start and the end of the modulated groove" I know it is a mouth full but it is a fact."

This is sort of overkill. The manufacturing precision of cartridges is not as good.

"One day I asked a cartridge manufacturer friend of mine, “What is the average error?” After a little pause he said, “Degrees, three or four? Or ten?! It all depends!”

Manufacturers cannot easily keep the necessary precision under control. Some of them even accept that the product will vary in quality and select their cartridges from good to bad and price them accordingly. You always buy the same basic cartridge, but the better they are the more expensive. This is usual practice in the business."

Is this a sort of electronic antiskating? What are the input parameters?

"Any reference to tangential tracking should refer to a "concentric circle of random diameter between the limits of the start and the end of the modulated groove" I know it is a mouth full but it is a fact."

This is sort of overkill. The manufacturing precision of cartridges is not as good.

"One day I asked a cartridge manufacturer friend of mine, “What is the average error?” After a little pause he said, “Degrees, three or four? Or ten?! It all depends!”

Manufacturers cannot easily keep the necessary precision under control. Some of them even accept that the product will vary in quality and select their cartridges from good to bad and price them accordingly. You always buy the same basic cartridge, but the better they are the more expensive. This is usual practice in the business."

This is sort of overkill. The manufacturing precision of cartridges is not as good.

Hi alighiszem,

My definition of tangential tracking has nothing to do with sloppy manufacturing of phono cartridges.

If it wasn't for the perfectionists among us, we would still be living in caves with burlap sacks for doors!

Sincerely,

Ralf

Hi Ralf.

Hear, hear. I welcome respectful debate on the means to achieve an objective as distinct from attempting to undermine the objective by introducing non sequiturs.

I agree completely with your definition of tangential tracking.

Regards

Bon

Hear, hear. I welcome respectful debate on the means to achieve an objective as distinct from attempting to undermine the objective by introducing non sequiturs.

I agree completely with your definition of tangential tracking.

Regards

Bon

PTT Skate

SFx3

I did the simulation slightly different, the mechanism is seized, this allows the velocity to represent the SF at a single point instead of a range in translation as in the previous simulation. 2nd pivot is lifted, so we can see the velocity instead of reading a reaction force in numbers. The magnitude of the velocity is directly proportional to the SF at that position. Obviously exaggerated, there is no mass, so no inertia or friction for damping.

Green - Red - Blue

You can deduce that the SF reduces towards the spindle fairly constantly, it is nearly linear, my previous calculation showed a slight increase in the rate of change, but it was not much. Very similar to Al's calculations but with a little bow downwards at the end, might just be a scaling issue on the axes.

I did note something in the Geometry, if the distance between the fixed pivots is increased by 0.7mm the sum of the adjacent sides is equal to the sum of the opposing sides, so I did that. It does not change the outcome.

Not sure if it is of any interest.

SFx3

I did the simulation slightly different, the mechanism is seized, this allows the velocity to represent the SF at a single point instead of a range in translation as in the previous simulation. 2nd pivot is lifted, so we can see the velocity instead of reading a reaction force in numbers. The magnitude of the velocity is directly proportional to the SF at that position. Obviously exaggerated, there is no mass, so no inertia or friction for damping.

Green - Red - Blue

You can deduce that the SF reduces towards the spindle fairly constantly, it is nearly linear, my previous calculation showed a slight increase in the rate of change, but it was not much. Very similar to Al's calculations but with a little bow downwards at the end, might just be a scaling issue on the axes.

I did note something in the Geometry, if the distance between the fixed pivots is increased by 0.7mm the sum of the adjacent sides is equal to the sum of the opposing sides, so I did that. It does not change the outcome.

Not sure if it is of any interest.

Attachments

- Home

- Source & Line

- Analogue Source

- Building a Tuthill/Reed 5A Tangential Tracking Pivot Tonearm