you're moving pretty fast - how are you fastening the internal panels into place? - just glue and pressure? - I want to do something but had fever for >week plus horrible apnea

All credit goes to the number of clamps (thx, Ken)I've had available this time

Yes, glue and pressure are typically what I've used in the past. Sometimes, when the angles make clamping difficult, I've used a couple of drywall screws to hold things together until the glue sets.

I'll report on what technique I use for this build when I get there

Yes, glue and pressure are typically what I've used in the past. Sometimes, when the angles make clamping difficult, I've used a couple of drywall screws to hold things together until the glue sets.

I'll report on what technique I use for this build when I get there

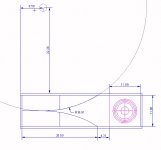

This drawing contains the dimensions needed to accurately describe the k-slot contour.

Attachments

Last edited:

Slots Kut

K-slots cut on both cabinets. Rouch cuts made with a jigsaw and the final cuts were with a router + template bit using an MDF template clamped onto the board

K-slots cut on both cabinets. Rouch cuts made with a jigsaw and the final cuts were with a router + template bit using an MDF template clamped onto the board

Attachments

Last edited:

attractive build including grain patterns - what actions do you expect of the K-slot vs a rectangular terminus?

The next steps will involve

1. cutting the driver hole. Arauco plywood is pretty soft so I'm considering using a supra baffle of solid wood for this purpose. Haven't decided yet.

2. bracing. I cannot over emphasize how important this is, IMO. Many folks try to improve their enclosures by the "brute force approach", ie. using multiple layers of ply / MDF, constrained layers etc on the cabinet walls with little attention to actually bracing between the walls. For a change, bracing the contours of a horn is actually easier than bracing a conventional cabinet. Since the contour walls are mostly non-parallel to each other , my technique involves

a. rough tracing of the profile on pieces of scrap

b. cutting the brace out on the saw, the brace usually ends up wedge shaped

c. buttering the brace with liquid nails or PL brand polyurethane adhesive and gently pounding it in with a rubber mallet and leaving it to cure

Taking a leaf out of Bill Fitzmaurice's book, use a brace when possible where there is more than 8" of unsupported substrate.

1. cutting the driver hole. Arauco plywood is pretty soft so I'm considering using a supra baffle of solid wood for this purpose. Haven't decided yet.

2. bracing. I cannot over emphasize how important this is, IMO. Many folks try to improve their enclosures by the "brute force approach", ie. using multiple layers of ply / MDF, constrained layers etc on the cabinet walls with little attention to actually bracing between the walls. For a change, bracing the contours of a horn is actually easier than bracing a conventional cabinet. Since the contour walls are mostly non-parallel to each other , my technique involves

a. rough tracing of the profile on pieces of scrap

b. cutting the brace out on the saw, the brace usually ends up wedge shaped

c. buttering the brace with liquid nails or PL brand polyurethane adhesive and gently pounding it in with a rubber mallet and leaving it to cure

Taking a leaf out of Bill Fitzmaurice's book, use a brace when possible where there is more than 8" of unsupported substrate.

Last edited:

attractive build including grain patterns - what actions do you expect of the K-slot vs a rectangular terminus?

Not so sure about arauco grain patterns being attractive 🙂

What I'm expecting the K-slot to do is:

1. smoothing the impedance match between the mouth and free air

2. from previous experiments with k-slot tweeters, I (and you, probably) had observed that the slot seems to diffract the sound beam towards the narrow end of the slot. What this could mean in this rear loaded horn design is , to an extent, direct the sound towards the floor as opposed to towards the driver, ... possibly reducing interference with the front wave. This is just a hypothesis, .K-slots are a bit of funny science.

2. bracing. I cannot over emphasize how important this is, IMO. Many folks try to improve their enclosures by the "brute force approach", ie. using multiple layers of ply / MDF, constrained layers etc on the cabinet walls with little attention to actually bracing between the walls.

Bears repeating.

dave

That's looking good. I'm intrigued by the novelty of the exotic 'Arauco' which was simply known as 'pine' where i grew up. I might have to build a scaled version for my FE108E sigmas. The grain looks OK to me. Pine always looks rustic.

I've used K-slots on TLs and TQWTs before and they do tend to improve FR -- presumably by lowering the pipe Q.

I've used K-slots on TLs and TQWTs before and they do tend to improve FR -- presumably by lowering the pipe Q.

Cabinet joints caulked. I'm going to let the caulk cure and the cabs air out for a day or so (caulk fumes contain acetic acid which may be harmful to some surrounds).

The area of that slot is not equal or greater then the cross-section of the horn,

I don't see that working as a proper extension of the horn. The taper of the horn

in that section is expanding, so I don't see it working as a proper Karlson either.

I'm thinking you will eventually have to cut additional slots in the sides to get the

mouth area up, or block-off some back part of that section to taper downward as

the K-slot expands to merge with the larger volume of the room.

I don't see that working as a proper extension of the horn. The taper of the horn

in that section is expanding, so I don't see it working as a proper Karlson either.

I'm thinking you will eventually have to cut additional slots in the sides to get the

mouth area up, or block-off some back part of that section to taper downward as

the K-slot expands to merge with the larger volume of the room.

Last edited:

I never claimed it was meant to work as a proper Karlson 🙂

Re. the slot area vs mouth area, we'll see how this whole project turns out. I should mention that , in practice, I have seen horn mouths partially choked off to extend the low frequency response (notice I said response, not efficiency).

Re. the slot area vs mouth area, we'll see how this whole project turns out. I should mention that , in practice, I have seen horn mouths partially choked off to extend the low frequency response (notice I said response, not efficiency).

Indeed; that's exactly what boxes that have come to be known as ML TQWTs (or, using the traditional nomenclature I lean toward, Tapped, Mass Loaded Conical Horns) are.

Last edited:

there's several things going on. Bill posted his AJ input mouth and did 13 builds to arrive to this cabinet. To my limited knowledge, Karlson kept a cavity or pipe in "front" of drivers. Norman C. Fulmer ran the first (I think) article and had the patent on this style termination in a line.

patent

http://news.google.com/patents/down...qO77IsJ0F9hN6Q9Gg&source=gbs_overview_r&cad=0

Fulmer article

http://gainclone.com/Karlson/index.php?topic=64.msg308#msg308

or direct links to images of Fulmer's article - -anyone care to simulate this enclosure with MJK's sheets?

Pg1

http://img455.imageshack.us/img455/8639/ful11oy.jpg

Pg2

http://img455.imageshack.us/img455/2694/ful20tm.jpg

Pg3

http://img455.imageshack.us/img455/5733/ful37mu.jpg

Plan larger

http://img451.imageshack.us/img451/8349/fuld3px.jpg

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

patent

http://news.google.com/patents/down...qO77IsJ0F9hN6Q9Gg&source=gbs_overview_r&cad=0

Fulmer article

http://gainclone.com/Karlson/index.php?topic=64.msg308#msg308

or direct links to images of Fulmer's article - -anyone care to simulate this enclosure with MJK's sheets?

Pg1

http://img455.imageshack.us/img455/8639/ful11oy.jpg

Pg2

http://img455.imageshack.us/img455/2694/ful20tm.jpg

Pg3

http://img455.imageshack.us/img455/5733/ful37mu.jpg

Plan larger

http://img451.imageshack.us/img451/8349/fuld3px.jpg

Last edited:

zobsky - you might ask Bill how he arrived at a 41x41cm mouth for his AJ simulation input- how much area would you say there is in the entire opening?

sealed up both cabinets last night with PL expanding polyurethane glue . Currently waiting for the glue to cure

Sorry for the suspense, Freddy

Sorry for the suspense, Freddy

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Build Thread K-Slot Rear Loaded Horn for Tangband W8-1772