I know your dislike of BOM. I understand why. I incorrectly learned when building to use BOM, not necessarily for ordering, parts as availability and numbers change cause problems. But I used them also for organizing parts. Bad. Your method avoids problem. When I look at BOM I know parts in bag may not be same as "BOM" said. I get it If BOM calls for 2 pieces of 5k resistor, and at end of day I have 2 4.7 pieces its close enough. Im just organizing parts prior to assembly. otherwise I'm searching schematic for part, then searching board for location there. I've got it backwards, in my mind I want resistor labled as "R5" then I see it on board and schematic. Note value on schematic, measure part to assure it is correct. Leaves me dependent on pre made BOM.it can't be easier

either form list of parts you need to populate for chosen variant, or

form list of parts not needed fro chosen variant

that later one you can make comparing cumulative schmtc (most likely in post #1) vs. schm of chosen variant (post #624)

I despise generated BOMs; best way of learning is when one is making own BOM, from actual schematic and presented graphical files; if help of unfortunate designer is on disposal, even easier and better

Or, if part not available, to get similar part and value, asking here if uncertain. Im used to reading volumes of boring writing, better in younger days with perfect eyesight. Making ones own BOM from schematic as you say has advantages. All organizational activity will raise my questions before Iron heats up.

Thanks again,

Russellc

strategic help example:

https://www.testequipmentdepot.com/...-magnifier-with-4-lenses-16x-20x-25x-35x.html

even more strategic help: https://www.dewars.com

evenevenmore strategic help (whatever you ookoop, you don't care):

https://www.testequipmentdepot.com/...-magnifier-with-4-lenses-16x-20x-25x-35x.html

even more strategic help: https://www.dewars.com

evenevenmore strategic help (whatever you ookoop, you don't care):

very niceShe is alive again and has been playing for about 5 hours. 😀

what Is module In small horisontal pcb - soft start ?

how much are your trafo V ac secondary and your rail voltages

I am a bit curious so have a question @Zen Mod. Some power amplifiers have an air core inductor and resistor in series together with a capacitor and resistor in parallel between the amplifier and the output. Its purpose is to protect the amplifier against capacitive speaker and cable loads as well as BEMF feedback and/or resonance etc. Main goal with a Zoble network is to have an even impedance load on the amplifier.

If this have been covered before, redirect me and if now, why is is not used and if the amplifier would benefit from it in terms of stability, are there any issues if I add a zobel ?

If this have been covered before, redirect me and if now, why is is not used and if the amplifier would benefit from it in terms of stability, are there any issues if I add a zobel ?

Last edited:

XA252 is very well behaved, existing filtering covering all 3 iterations of amp

in latest batch of pcbs I did include placement for RC in parallel to speaker, just because, but there is no need for that nor I can advise inclusion of any additional filtering

even if intuitive more filtering looks "more safe", it can result in phase changes leading to oscillations

so, sometimes more of the good thing is ....... simply too much of good thing

in latest batch of pcbs I did include placement for RC in parallel to speaker, just because, but there is no need for that nor I can advise inclusion of any additional filtering

even if intuitive more filtering looks "more safe", it can result in phase changes leading to oscillations

so, sometimes more of the good thing is ....... simply too much of good thing

I guess its fair to conclude with when an amplifier is developed, one spend time, or rather you spent time, checking against real world scenario and how the amp behaves with an impedance load. I am certainly not implying that you didn't, the only reason I asked about the zobel is because it is used sometimes and sometimes not, for reasons beyond my understanding. One would think that always is good, but like you point out, sometimes it is not.

To zoble or not is a complex topic, but your answer is good enough for me 🙂

To zoble or not is a complex topic, but your answer is good enough for me 🙂

it's "just" that there are different ways of achieving same results

goal is to have predicted and benign phase behavior through entire (intended) frequency spectrum, across entire power range, loaded with real world load

anyhow, I'm sure that I have enough stones left un-turned, so one day maybe I'll know more than I know now

(result of daily occurrence of sentence "ha!! why I didn't think of that yesterday!?!?")

goal is to have predicted and benign phase behavior through entire (intended) frequency spectrum, across entire power range, loaded with real world load

anyhow, I'm sure that I have enough stones left un-turned, so one day maybe I'll know more than I know now

(result of daily occurrence of sentence "ha!! why I didn't think of that yesterday!?!?")

Oh! That's a lot if strategic help. My boiler is 8 gallons only.strategic help example:

https://www.testequipmentdepot.com/...-magnifier-with-4-lenses-16x-20x-25x-35x.html

even more strategic help: https://www.dewars.com

evenevenmore strategic help (whatever you ookoop, you don't care):

View attachment 1190836

Russellc

"You know what you know until you know something else" and ... "the student became the master" 😉anyhow, I'm sure that I have enough stones left un-turned, so one day maybe I'll know more than I know now

(result of daily occurrence of sentence "ha!! why I didn't think of that yesterday!?!?")

very nice

what Is module In small horisontal pcb - soft start ?

how much are your trafo V ac secondary and your rail voltages

PCB is the Soft Start board from DIYAudio Store. Transformer is the Antek AN-10425. I think I am getting about 32.6 volts if memory is correct.

Getting ready to prepare heatsinks from 5U deluxe case for mounting the big MOSFETs.

Since it is "pre drilled" for store boards, maybe I should buy another set of "plain" heatsinks to drill for the big MOSFETs?

Use existing ones for M25 fun.

Bubba

Since it is "pre drilled" for store boards, maybe I should buy another set of "plain" heatsinks to drill for the big MOSFETs?

Use existing ones for M25 fun.

Bubba

Buy a piece of 3/8 in aluminum and fasten it to your UMS heat sinks.

There are two reasons it's a good idea.

one, it makes for a heat spreader, secondly you can through tap instead of bottom tap. Much less risky.

There is a eBay store. I believe they are in New Hampshire. They sell their scraps at a pretty fair price. Usually in quantities of two three or four matching pieces.

Also, another thought is you can remove the heat spreader and not disturb the amplifier boards. Not such a big deal with these MOSFETs that screw to the PCB board but for other designs...

There are two reasons it's a good idea.

one, it makes for a heat spreader, secondly you can through tap instead of bottom tap. Much less risky.

There is a eBay store. I believe they are in New Hampshire. They sell their scraps at a pretty fair price. Usually in quantities of two three or four matching pieces.

Also, another thought is you can remove the heat spreader and not disturb the amplifier boards. Not such a big deal with these MOSFETs that screw to the PCB board but for other designs...

no need for spreaders and further complication

as far as I remember, I did made dimensions of thingie in a way that you can simply oogle position of mosfets on heatsink, shooting that holes are between heatsink fins

then you can either drill 3.2mm through holes and cut M4, without too much troubles

or simply drill 4.2mm holes and use smaller head Allen bolts and nuts to fasten mosfets

smaller heads so you can squeeze them between fins

or file them heads to get them in between fins

as far as I remember, I did made dimensions of thingie in a way that you can simply oogle position of mosfets on heatsink, shooting that holes are between heatsink fins

then you can either drill 3.2mm through holes and cut M4, without too much troubles

or simply drill 4.2mm holes and use smaller head Allen bolts and nuts to fasten mosfets

smaller heads so you can squeeze them between fins

or file them heads to get them in between fins

Boards almost done. Two orientation questions:

LED...pad on RIGHT looks like it has a mark or some kind of marking, is that for the short cathode leg?

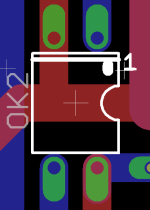

OK1 and OK2... part doesnt have indentation as silk screen, but does have a round mark in one corner. How should these two be oriented?

Thanks,

Russellc

LED...pad on RIGHT looks like it has a mark or some kind of marking, is that for the short cathode leg?

OK1 and OK2... part doesnt have indentation as silk screen, but does have a round mark in one corner. How should these two be oriented?

Thanks,

Russellc

C at LED top overlay/symbol means Cathode

short ot long pin - dunno - ZM always forgetting that, so I'm using my DMM for re-establishing short knowing/memory

opto - see enclosed - it's covering all possible scenarios of marking pin 1 - notch at side, or long stripe, or dot

short ot long pin - dunno - ZM always forgetting that, so I'm using my DMM for re-establishing short knowing/memory

opto - see enclosed - it's covering all possible scenarios of marking pin 1 - notch at side, or long stripe, or dot

Attachments

- Home

- Amplifiers

- Pass Labs

- Babelfish XA252 / Babelfish XA252 SIT / Babelfish XA252 SET