Creating such bilateral anti-skating is real challenge. I'm surprised to see what Morsiani already did that. Wow! It will be no wonder, if perfect linear arm finally will be created in the next 50 years...😛

Check out Coppleman's Patent #2522997 from 1950: the idea is identical. As with all arms, however, execution is primary.

It is doubtful that this arm has anti-skating. All arms that are offset require it, but may not use it, for reasons ranging from difficulty to the designer deciding it is of limited value, plus everything in between.

[The trick with anti-skating is to recognize that the correcting action must complement the arm's path across the record. There have been many arms in this thread that had zero tracking error (which, by itself, is not the holy grail of arms) but they did not also have correct skating compensation, correct h-axis height, plus a few other important design points.]

Each of the Thales arms has a different design approach & targets different perceived user needs. It will be interesting to follow this one in the marketplace.

Andy

It is doubtful that this arm has anti-skating. All arms that are offset require it, but may not use it, for reasons ranging from difficulty to the designer deciding it is of limited value, plus everything in between.

[The trick with anti-skating is to recognize that the correcting action must complement the arm's path across the record. There have been many arms in this thread that had zero tracking error (which, by itself, is not the holy grail of arms) but they did not also have correct skating compensation, correct h-axis height, plus a few other important design points.]

Each of the Thales arms has a different design approach & targets different perceived user needs. It will be interesting to follow this one in the marketplace.

Andy

It's actually supremely easy to institute antiskate on any arm which uses quasi-Thales Circle geometry, as all these arms do.

The trick lies in the property of similarity of triangles: since the vectors of the stylus friction reaction force at various points across the arc followed by the stylus all meet at the opposite Thales locus (see for instance my posts on geometry somewhere in the 200s in this thread), one can construct a series of triangles representing the various forces, all of which share a common base line (the line from the main pivot to the opposite Thales locus).

One can then choose an arbitrary point on this baseline and construct a series of similar triangles using the line from the pivot to this point as one side. The point shall be called the antiskate locus.

A force appled between the arm and this antiskate locus which is proportional to the stylus reaction force by the ratio of the lengths of the pivot to Thales locus line divided by the pivot to antiskate locus line will provide perfect antiskate compensation.

You read it here first, folks. If you use this idea, give me some credit. If you use it commercially, you owe me.

The trick lies in the property of similarity of triangles: since the vectors of the stylus friction reaction force at various points across the arc followed by the stylus all meet at the opposite Thales locus (see for instance my posts on geometry somewhere in the 200s in this thread), one can construct a series of triangles representing the various forces, all of which share a common base line (the line from the main pivot to the opposite Thales locus).

One can then choose an arbitrary point on this baseline and construct a series of similar triangles using the line from the pivot to this point as one side. The point shall be called the antiskate locus.

A force appled between the arm and this antiskate locus which is proportional to the stylus reaction force by the ratio of the lengths of the pivot to Thales locus line divided by the pivot to antiskate locus line will provide perfect antiskate compensation.

You read it here first, folks. If you use this idea, give me some credit. If you use it commercially, you owe me.

Last edited:

Hearing a good unipivot, and knowing that the cause of being good, comes down to the minimum number of "joints" in the design, must lead to the notion that there are trade offs in a system thad needs 6 or more bearings. Regarding antiskating, or the loss of it, my skills are not as good as I could wish for, but my 12 inch Ortofon arm has also no antiskating system, and it works flawlessly in spite of that.

Majority of members who previously participated in this thread knew this entire thread is really for entertainment so don't take it too seriously. Continue to enjoy your 12" arm, sit back, and watch us masochists here racking our brains out trying to theorize a perfect arm. 😀

Wow! It will be no wonder, if perfect linear arm finally will be created in the next 50 years...😛

Maybe by then CD will make a come back. 😀

(see for instance my posts on geometry somewhere in the 200s in this thread)

I can't wrap my head around so much math so I tallied up those posts here, here, and here for those interested can check them out.

You read it here first, folks. If you use this idea, give me some credit. If you use it commercially, you owe me.

I already owed you few beers so might as well give you a keg

if you can calculate the math and provide illustrations and photos other than the ones here and here. 😀

if you can calculate the math and provide illustrations and photos other than the ones here and here. 😀

will provide perfect antiskate compensation.

You read it here first, folks.

Reading and believing are two different things. 😛 When you use that word, you provoke me, Mark. 😀

I predict that with your compensation, the skating force will be zero, zero per cent of the time.

But then I'm a smart-@55 LT fan, here for the fun and amazing eye candy. Love this thread.

I'm with ColinA here. Hearing a good unipivot, and knowing that the cause of beeing good, comes down to the minimum number of "joints" in the design, must lead to the notion that there are trade offs in a system thad needs 6 or more bearings.

That's why Huber/Thales makes a point of the excellence of their bearings.

Regarding antiskating, or the loss of it, my skills are not as good as I could wish for, but my 12 inch Ortofon arm has also no antiskating system, and it works flawlessly in spite of that.

It's what we're used to, I guess, that defines one's personal level of flawless. For sure, making reference to longer arms is a good way to invite discussion of tradeoffs.

A force appled between the arm and this antiskate locus which is proportional to the stylus reaction force by the ratio of the lengths of the pivot to Thales locus line divided by the pivot to antiskate locus line will provide perfect antiskate compensation.

You left out the important qualifier in the second clause in that sentence.

Since the geometry ensures that the compensation force required is exactly proportional to the stylus reaction force, it is possible to compensate exactly for any given stylus reaction force. At a practical level, this mean that we get perfect antiskate compensation if and only if the stylus reaction force is known and constant.

My arm design incorporates a method of measuring the stylus reaction force directly. It isn't constant, but it's pretty close on a given surface with a given stylus downforce.

(see for instance my posts on geometry somewhere in the 200s in this thread)

Mark also posted "An Analysis of Skate force" with equations at post#345 in response to whether the Schroeder LT tonearm exhibits skating force. Check it out for those interested in number crunching.

here for the fun and amazing eye candy. Love this thread.

There's more eye candy in post#349 that shows a Japanese tonearm that sets the zero point in the middle of the record. Apparently it's not really for tangential tracking... more like low-bias tracking.

- - - - - - - - - - - - -

Oh, what the hell, let me just repost all the pictures here!

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Mark also posted "An Analysis of Skate force" with equations at post#345 in response to whethe the Schroeder LT tonearm exhibits skating force. Check it out for those interested in number crunching.

Frank has stated that there is no measureable skating force in the Schroeder LT arm.

I assume this means he's done something clever with the magnetic track that cancels skate force, which would invalidate one of the assumptions in that analysis.

Thales Simplicity II

According to this announcement, not only Thales will release the new Easy tonearm but also the newer version of their most popular tonearm, Simplicity II.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Recently the Simplicity got a less than enthusiastic review in an American magazine and the reviewer concluded the arm is bright sounding. But during set up the reviewer noticed a problem:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

And here's the hilarious and sad part, in a French review the headshell was installed backward, rendering nothing tangent! It got a glowingly positive review! I asked the designer about this if he's aware that the arm was set up incorrectly in the review. His response:

"Of course we know about this; it's the French way of life... However, the headshell was installed wrongly for the photos only; we corrected the mistake before they made the review."

A funny dig on c'est la vie! Wait, maybe that's the inspiration of the Easy tonearm! 😀

Incorrectly mounted headshell is shown:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

It is the maker's responsibility to supply a flawless item under review. It would also be courteous for the reviewer to notify the maker when encountering issues. The moral of the story for the readers is to trust your own ears!

According to this announcement, not only Thales will release the new Easy tonearm but also the newer version of their most popular tonearm, Simplicity II.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Recently the Simplicity got a less than enthusiastic review in an American magazine and the reviewer concluded the arm is bright sounding. But during set up the reviewer noticed a problem:

It is obvious the bearings have some issues and possibly "readjusted" by its importer but the writer went ahead with the review anyway and was using a tonearm with high friction bearings and then concluded that it has a bright sound. It will be interesting to see if the newer version will get a follow-up review. And I hope the manufacture will supply a trouble free review sample to the next reviewer. But marketing damage possibly has been done..."Measuring the Simplicity arm’s antiskating deflection using the Wally Tools Skater, which suspends the tonearm by a thread, revealed a serious problem: the Simplicity stuck in whatever position I placed it. A truly free bearing system would allow the arm to swing in the breeze, and let you measure the amount of antiskating deflection with a plumb-bob reference. In my listening room, the Simplicity’s arm stuck only once. But on the first day of the recent Rocky Mountain Audio Fest, ...the Simplicity stuck so often that it was unusable. A replacement arm flown in the next day was equally problematic."

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

And here's the hilarious and sad part, in a French review the headshell was installed backward, rendering nothing tangent! It got a glowingly positive review! I asked the designer about this if he's aware that the arm was set up incorrectly in the review. His response:

"Of course we know about this; it's the French way of life... However, the headshell was installed wrongly for the photos only; we corrected the mistake before they made the review."

A funny dig on c'est la vie! Wait, maybe that's the inspiration of the Easy tonearm! 😀

Incorrectly mounted headshell is shown:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

It is the maker's responsibility to supply a flawless item under review. It would also be courteous for the reviewer to notify the maker when encountering issues. The moral of the story for the readers is to trust your own ears!

Last edited:

Hi Mark,

Please check the pics of the arm I took to the European Triode Festival 2009:

European Triode Festival 2009/hb/DSC_0295

European Triode Festival 2009/hb/DSC_0293

European Triode Festival 2009/cg/DSC_0974

Pics were taken before the setup was (geometrically)properly aligned. The thread bearing/dropping point needs to be in line and equidistant from the pivot, relative to the center of the platter.

I little bit difficult to see, but the thread/hanging weight that pulls the pivoting headshell to maintain a tangential position acts as the skating compensation as well. Since its force is a function of the angle between the thread and the line: spindle/pivot/thread dropping point(aka antiskate locus) , your requirement is met and skating compensation is always perfect, as long as the dropping weight generates the correct force for a given VTF(tracking force). It will decrease with decreasing offset angle.

BUT, since skating force is also modulation dependent and varies with the friction coefficient(nothing one can do about that) of the vinyl formula used for a particular record(requiring readjustment of the skating compensation for each record), perfection can NEVER be achieved in this department.

The above solution and your suggestion come close though 🙂

Cheers,

Frank

[/COLOR]It's actually supremely easy to institute antiskate on any arm which uses quasi-Thales Circle geometry, as all these arms do.

The trick lies in the property of similarity of triangles: since the vectors of the stylus friction reaction force at various points across the arc followed by the stylus all meet at the opposite Thales locus (see for instance my posts on geometry somewhere in the 200s in this thread), one can construct a series of triangles representing the various forces, all of which share a common base line (the line from the main pivot to the opposite Thales locus).

One can then choose an arbitrary point on this baseline and construct a series of similar triangles using the line from the pivot to this point as one side. The point shall be called the antiskate locus.

A force appled between the arm and this antiskate locus which is proportional to the stylus reaction force by the ratio of the lengths of the pivot to Thales locus line divided by the pivot to antiskate locus line will provide perfect antiskate compensation.

You read it here first, folks. If you use this idea, give me some credit. If you use it commercially, you owe me.

Please check the pics of the arm I took to the European Triode Festival 2009:

European Triode Festival 2009/hb/DSC_0295

European Triode Festival 2009/hb/DSC_0293

European Triode Festival 2009/cg/DSC_0974

Pics were taken before the setup was (geometrically)properly aligned. The thread bearing/dropping point needs to be in line and equidistant from the pivot, relative to the center of the platter.

I little bit difficult to see, but the thread/hanging weight that pulls the pivoting headshell to maintain a tangential position acts as the skating compensation as well. Since its force is a function of the angle between the thread and the line: spindle/pivot/thread dropping point(aka antiskate locus) , your requirement is met and skating compensation is always perfect, as long as the dropping weight generates the correct force for a given VTF(tracking force). It will decrease with decreasing offset angle.

BUT, since skating force is also modulation dependent and varies with the friction coefficient(nothing one can do about that) of the vinyl formula used for a particular record(requiring readjustment of the skating compensation for each record), perfection can NEVER be achieved in this department.

The above solution and your suggestion come close though 🙂

Cheers,

Frank

That was my point. It's partly modulational. The skating force will be zero, zero per cent of the time. Thanks for backing me up. 🙂

Majority of members who previously participated in this thread knew this entire thread is really for entertainment so don't take it too seriously. Continue to enjoy your 12" arm, sit back, and watch us masochists here racking our brains out trying to theorize a perfect arm. 😀

I am enjoying my Ortofon arm, but I have also built many arms myself over the years. It is by learning the hard way, that I have reached the conclusion that the KISS way, nearly always is the right way. I can understand and appreciate the workmanship of the Thales arms, but its no denying that there have been problems with the bearings. My current project is a linear tracker, that by default accept a possible deviation from the exact 90 degree angle, to assure a simple design.

Steen

It is by learning the hard way, that I have reached the conclusion that the KISS way, nearly always is the right way. I can understand and appreciate the workmanship of the Thales arms, but its no denying that there have been problems with the bearings.

I subscribe to the "keep it simple, stupid" principle too. And as you said through learning the hard way, one arrives at that conclusion. The only difference for me is that I feel we are not yet done with the "hard way." And through brainstorming, experimenting, and/or thinking outside of the box can we reach the goal - "Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away." My thought process tends to jump to the most complex and then pare away the unnecessary parts...more of an essentialist than a minimalist. And it has been an educational and fun process!

I don't have building experience like you do but I have purchased dozens of arms before and through observing, playing around, disassembling, tweaking, modifying, and even destroying some that I have absorbed enough ideas to satisfy me intellectually and then I sold all of them except few and one I kept is a unipivot. 🙂

Back to the Thales, like you I also understand and appreciate its workmanship but at times I can't help to think that the maker is sometimes too enamored with their own watchmaking tradition to show off their micro precision parts when less bearings would have been suffice. Maybe it's a Swiss thing... And any mishandling of such delicate parts would be disastrous and it happened at the worse timing for a US review! That's why I think the Ease model is a better trend as it starts to pare down further in the number of parts. But it's too bad they abandoned the tetragon solution in favor of a Burne-Jones method. The Simplicity model would have been better off built like the Easy construction. The Simplicity arm is probably their best seller that most customers don't even want to bother with their Original model, which is too Rube Golberg for most audiophile and it's probably a pain to mount.

I look forward to seeing your next creation and feel free to share it here or other amazing linear arm threads in this forum. 🙂

Mr. Shroder smartly got rid off unnecessary precision bearings and substituted them with thread, so excluding any chatter. The only disadvantage is: it doesn't look such impressive and hi-tech, as ruby bearings etc. and so, manufacturers continue using complicated staff, looking expensive. I suspect, the same approach forced transition in tonearms from spring counterweights to gravitational ones, despite huge losses in tracking abilities together with ten times increased rumble. Really bad solution, especially for idler wheel turntables, prone to rumble.

Yes, Simplicity Rules. Even turntables are much too complicated. Look at motor controllers, so much to go wrong! Just get a 120/240V AC motor and plug it directly into the mains. The piezo cartridge is so simple, but modern carts introduce all these complexities, not to mention extra gain stages, all in the name of 'performance'. It's a disaster!

""Fun fun fun on the Autobahn"

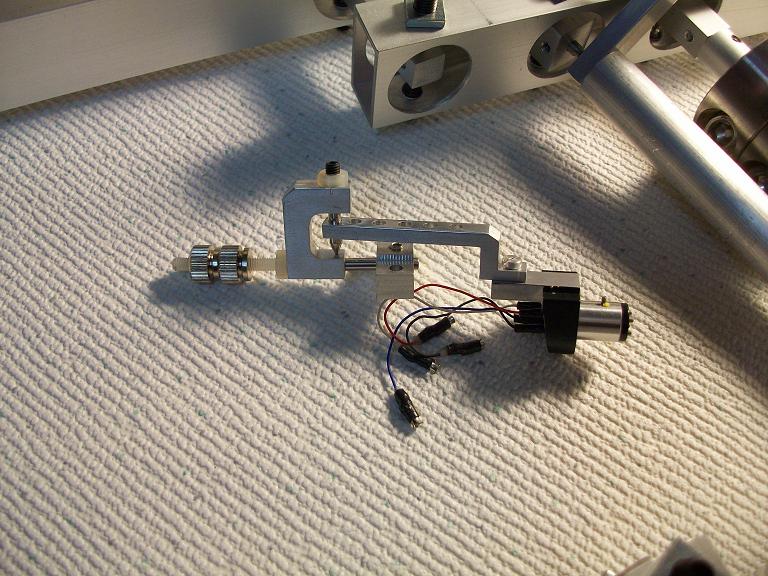

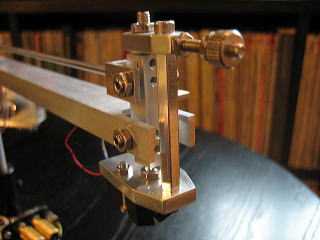

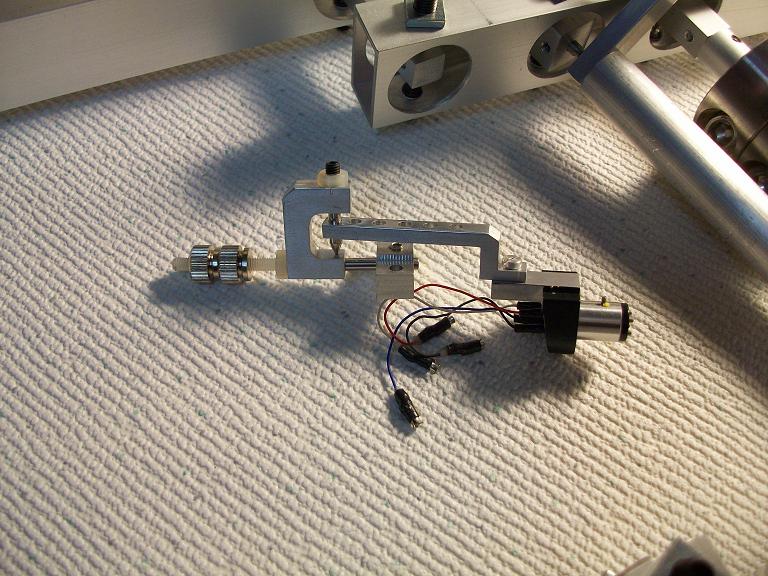

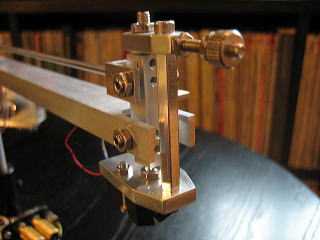

Speaking of Rube Goldberg, on this site we have an interesting tonearm here that pivots in all directions. Check it out!

- - - - - - - - - - - - - - - - - - - - -

More b&w images on this webpage.

This guy uses German avant-garde jazz records instead of the typical boring audiophile selections for testing. How cool is that?! Love FMP, Peter Brotzmann and Han Bennink!

I can't read Japanese and wonder if blogger is the same person who made these headshells...

.

Speaking of Rube Goldberg, on this site we have an interesting tonearm here that pivots in all directions. Check it out!

- - - - - - - - - - - - - - - - - - - - -

More b&w images on this webpage.

This guy uses German avant-garde jazz records instead of the typical boring audiophile selections for testing. How cool is that?! Love FMP, Peter Brotzmann and Han Bennink!

I can't read Japanese and wonder if blogger is the same person who made these headshells...

.

😕

All those pivot points, every one with some (all be it tiny) slack causing lost movement and noise as they move.

Or binding which will exert abnormal forces on the stylus.

They are going to do one or the other over a period of time!

I can not believe that the tracking compensation makes enough difference to the reproduction to overcome the mechanical losses

All those pivot points, every one with some (all be it tiny) slack causing lost movement and noise as they move.

Or binding which will exert abnormal forces on the stylus.

They are going to do one or the other over a period of time!

I can not believe that the tracking compensation makes enough difference to the reproduction to overcome the mechanical losses

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms