Hi tnargs,

Please be so kind to pm me with examples of outrageous and non-sensical claims from 650/653.

Just remove all the comments about CD vs vinyl vs analog vs digital vs hi-res etc etc, please. It is in any case off-topic, and there are huge bun fights about it in other threads and forums all over the 'net. This is not the time or place, nor is PM, and I am not in the mood to have that argument yet again. If you want to move it to another thread, that is fine.

And if someone else started it, perhaps they could remove theirs too. Thank you.

Hi. With comparable effective mass (I'm aware of longer and so heavier pivot arm-wand), pivot arm definitely has advantage over LT in that aspect. But, after reading above mentioned posts 505-516, I was a bit surprised with such a low mass of LT arms. Thanks. Seems not to be supposed to work well with low compliance MC carts...Hi walter, the opposite is true, see my posts from 505 to 516. A good LT is the best tonearm. This thread is about fun and clever simulations. cheers

As to going off topic: a little of it keeps thread more alive. IMHO.

So, lets go back to linear arms.

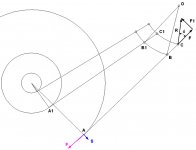

LT geometry and skating force

I'm trying to figure out how to implement Frank's clever (as always) design in my home-brewed clone. Playing with different versions of the arm I found that the skating force can be minimized by the right choice of geometry. Yes, the skating force does exist, but it can be kept way below conventional gimbal arm values. Referring to the picture below: friction force F applied to the needle in modulated groove shall be reacted by the magnet moving along the guiding rail CC1, and the reaction force R is normal to the rail arc. So, the lateral force component F1 is acting on the arm lower lever BC and the resulting moment cause the skating force S which in turn, will be reacted by the record's groove inner wall (in opposite to conventional overhang arm direction). The skating force S=F*tg(alpha)*BC/AB when the needle is in the outermost groove. Obviously, the smaller alpha angle and BC/AB, the lower the skating force is. For example, if you set AB=230mm (arm effective length), BC=30mm, OB=100mm you get the alpha angle around 35 deg and the skating force S=0.09F. It is really low comparing with the typical gimbal arm with offset angle of 21 deg and S=0.38F. But, for some geometries you may end up with much larger skating force exceeding gimbal arm value in on the outermost grove and largely decreasing towards the record's center. Hope I'm not missing something..

I'm trying to figure out how to implement Frank's clever (as always) design in my home-brewed clone. Playing with different versions of the arm I found that the skating force can be minimized by the right choice of geometry. Yes, the skating force does exist, but it can be kept way below conventional gimbal arm values. Referring to the picture below: friction force F applied to the needle in modulated groove shall be reacted by the magnet moving along the guiding rail CC1, and the reaction force R is normal to the rail arc. So, the lateral force component F1 is acting on the arm lower lever BC and the resulting moment cause the skating force S which in turn, will be reacted by the record's groove inner wall (in opposite to conventional overhang arm direction). The skating force S=F*tg(alpha)*BC/AB when the needle is in the outermost groove. Obviously, the smaller alpha angle and BC/AB, the lower the skating force is. For example, if you set AB=230mm (arm effective length), BC=30mm, OB=100mm you get the alpha angle around 35 deg and the skating force S=0.09F. It is really low comparing with the typical gimbal arm with offset angle of 21 deg and S=0.38F. But, for some geometries you may end up with much larger skating force exceeding gimbal arm value in on the outermost grove and largely decreasing towards the record's center. Hope I'm not missing something..

Attachments

diyrayk,

I just spotted your post at #651. Your scale drawing is the one I saw earlier and thanks for reposting it along with the further information about the patent. I have my doubts about some aspects of the design, but it might make a nice project, regardless.

Have you tried to build it?

I just spotted your post at #651. Your scale drawing is the one I saw earlier and thanks for reposting it along with the further information about the patent. I have my doubts about some aspects of the design, but it might make a nice project, regardless.

Have you tried to build it?

diyrayk,

I just spotted your post at #651. Your scale drawing is the one I saw earlier and thanks for reposting it along with the further information about the patent. I have my doubts about some aspects of the design, but it might make a nice project, regardless.

Have you tried to build it?

No, I think it has too much mass and bearing/friction issues that I don't have time or energy to go after. I find it interesting from an academic standpoint, but my solution was to jump into the servo driven linear tracker arena, where I've been happily camped out for 38 years.

Ray K

Post 571 by Directdriver shows the original drawings of the patent application by Mr. Schroeder. The guiding rail geometry does not resemble what you have drawn.

Last edited:

Thales Original

Some rare photos of the Thales Original in disassembled state. I can imagine the total parts count be up to a hundred -- not very DIY-able for a clone!

Some rare photos of the Thales Original in disassembled state. I can imagine the total parts count be up to a hundred -- not very DIY-able for a clone!

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

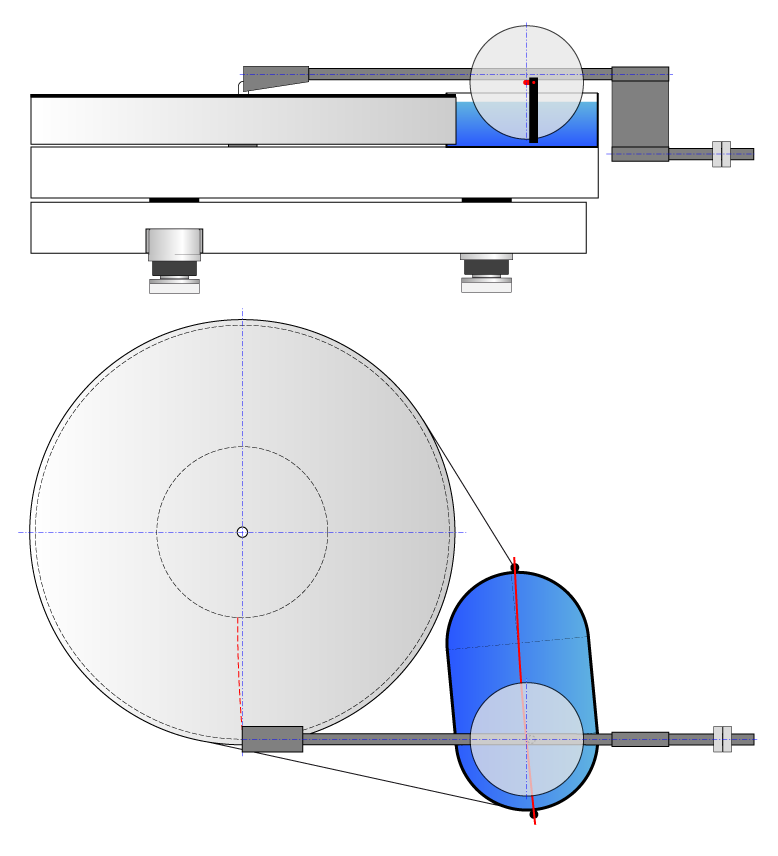

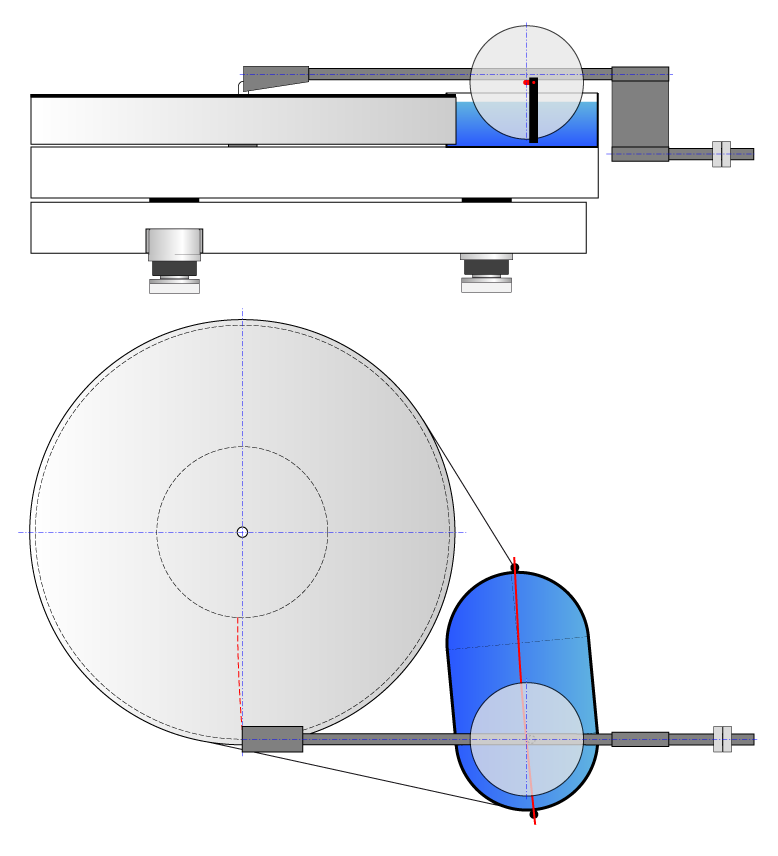

This is an incredible idea 🙂 The turntable will become unavoidably larger, but what the heck. Has it been finalized?

Yes your right. I have 3 SOTA vacuum tables and one will be sacrificed to accommodate the horizontal width it intails.

This means a whole new plinth design. Right now I have a slab of 6061t6 aluminum already cut, but haven,t decided whether to go ahead and make it a 4 spring or oracle style 3 spring configuration.

I have wound some new springs with .079" music wire (SOTA and Oracle use this same OD. Wire)

The trouble is with a wider and more stable platform (4spring) the arm is placed somewhat back and harder to handle.

With a big oracle style plinth I can put the arm at a right angle up front and make it easier to use.

It is not an easy undertaking to design a new suspension! I find it a pleasant challenge and will be winding many spring styles to get what I need.

The whole goal is to mimic the Versa dynamic style tone arm the easiest way possible.

It's not the same, but close enough for me..

The moto is similar..

No capacitor is better than a capacitor and

No tonearms is better than a tonearm

Or something like that....

Regards

David

This means a whole new plinth design. Right now I have a slab of 6061t6 aluminum already cut, but haven,t decided whether to go ahead and make it a 4 spring or oracle style 3 spring configuration.

I have wound some new springs with .079" music wire (SOTA and Oracle use this same OD. Wire)

The trouble is with a wider and more stable platform (4spring) the arm is placed somewhat back and harder to handle.

With a big oracle style plinth I can put the arm at a right angle up front and make it easier to use.

It is not an easy undertaking to design a new suspension! I find it a pleasant challenge and will be winding many spring styles to get what I need.

The whole goal is to mimic the Versa dynamic style tone arm the easiest way possible.

It's not the same, but close enough for me..

The moto is similar..

No capacitor is better than a capacitor and

No tonearms is better than a tonearm

Or something like that....

Regards

David

short arm, wide plinth

Speaking of short air-bearing tonearm and you might know about this, David, is that Infinity manufactured an arm designed by Bruce Thigpen with a very short arm, almost the length of a headshell. Here, from davidsaudio.com.

Yep, you do need a wide plinth!

And from Eminent Technology's history page.

Uh oh, I broke my rule of not talking about air bearing tonearms! 😀

.

Speaking of short air-bearing tonearm and you might know about this, David, is that Infinity manufactured an arm designed by Bruce Thigpen with a very short arm, almost the length of a headshell. Here, from davidsaudio.com.

Yep, you do need a wide plinth!

And from Eminent Technology's history page.

Uh oh, I broke my rule of not talking about air bearing tonearms! 😀

.

I remember those tables.

The Air colony on the bottom used magnet repulsion instead of a counterweight I believe.

This might work well with a vacuum platter since you would need only a small linear range of counter weight force that wasn't there in that design.

(Warped records and continuous varying downforce)

These tables never took off in the market place for whatever reason.

Regards

David

The Air colony on the bottom used magnet repulsion instead of a counterweight I believe.

This might work well with a vacuum platter since you would need only a small linear range of counter weight force that wasn't there in that design.

(Warped records and continuous varying downforce)

These tables never took off in the market place for whatever reason.

Regards

David

The first photograph shows a zero tracking angle tonearm without wiring (test arm).

The second photograph shows the same test arm, but now with attached wiring on top of the cartridge.

The costs of the tonearm - without wiring - is about 50 euro.

You can find details on Exploring vinyl audio: DIY "linear" tonearm

An externally hosted image should be here but it was not working when we last tested it.

The second photograph shows the same test arm, but now with attached wiring on top of the cartridge.

An externally hosted image should be here but it was not working when we last tested it.

The costs of the tonearm - without wiring - is about 50 euro.

You can find details on Exploring vinyl audio: DIY "linear" tonearm

You can find details on Exploring vinyl audio: DIY "linear" tonearm

Very novel idea, Tom! I am still trying to wrap my head around how you can keep the sliding object tangentially precise through out the playing surface. How does the guiding mechanism keep the tonearm from not overshoot or undershoot the mark. Please provide more pictures if possible and keep us posted on your progress. Thanks for your post!

Last edited:

more Schröder LT pix

Pictures linked from another forum with Frank's own comments. The new green headshell makes it look like a snake or some reptile! Cool!

I notice there's a set screw on the side of the headshell so I take it that it allows for azimuth adjustment? Has Frank ever thought of using SME style removable headshell? I know purists will criticize the extra break in the connection but detachable headshell is hugely popular in Asian and European audiophile circles. It would open up a huge market! Those SPU fans would like a taste of the LT too! I'm not a perfectionist nor purist and I am lazy so I would take convenience. 😀

.

Pictures linked from another forum with Frank's own comments. The new green headshell makes it look like a snake or some reptile! Cool!

I notice there's a set screw on the side of the headshell so I take it that it allows for azimuth adjustment? Has Frank ever thought of using SME style removable headshell? I know purists will criticize the extra break in the connection but detachable headshell is hugely popular in Asian and European audiophile circles. It would open up a huge market! Those SPU fans would like a taste of the LT too! I'm not a perfectionist nor purist and I am lazy so I would take convenience. 😀

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

Last edited:

ViV Rigid Float Tonearm

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Your floating tonearm reminds me of the VIV tonearm that uses viscous fluid for bearing. Although the VIV pays no attention to tangential tracking, only trying to reduce skating force, like the RS Lab arm, it does not have an offset headshell. In this review, the designer reveals aspects of his bearing.

You can find details on Exploring vinyl audio: DIY "linear" tonearm

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Your floating tonearm reminds me of the VIV tonearm that uses viscous fluid for bearing. Although the VIV pays no attention to tangential tracking, only trying to reduce skating force, like the RS Lab arm, it does not have an offset headshell. In this review, the designer reveals aspects of his bearing.

“There are…types of bearing pivot, [some] dipped in oil bath (oil damped types) available in the market, but still they require some string or other apparatus to fix fulcrum for arm rotary motion, but RF, thanks to automatic positioning mechanism, requires absolutely nothing to interfere with the force, for cartridge stylus to follow the inward path of the record groove”

“As oil is magnetic liquid, [the] single fulcrum point is positioned as horizontal center spin stem floats in bearing suspension cup, composed by [a] doughnut like bowl shaped magnet, just like [a] round shaped ball is fixed in center of cup.”

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

I have revisited this webpage and stared at this tangential design and blew up the pictures a bit so I can look at it more closely. I think this arm is more DIY-able as a project using the provided geometry to modify existing commercial tonearms. Essentially any 10' arm can be converted attaching a light mass guiding rod from the pivoting headshell to the additional pivot at the base. Notice it still requires an antiskating device using the string and weight method.

It deviates from absolutely tangency from the outer groove at 0.009º to the inner groove at 0.040º and while not as small a degree as the Thales Simplicity but it's not bad and less demanding on bearing design at the base since the two pivots don't have to be that close to each other.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I have a tonearm stripped out of a Kenwood KD-770D turntable that is suitable for the experiment since it has a straight armwand but with an angled headshell. Replace the headshell with a pivoting one and add guiding rod and we are in business.... This is reversible.

It deviates from absolutely tangency from the outer groove at 0.009º to the inner groove at 0.040º and while not as small a degree as the Thales Simplicity but it's not bad and less demanding on bearing design at the base since the two pivots don't have to be that close to each other.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I have a tonearm stripped out of a Kenwood KD-770D turntable that is suitable for the experiment since it has a straight armwand but with an angled headshell. Replace the headshell with a pivoting one and add guiding rod and we are in business.... This is reversible.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms