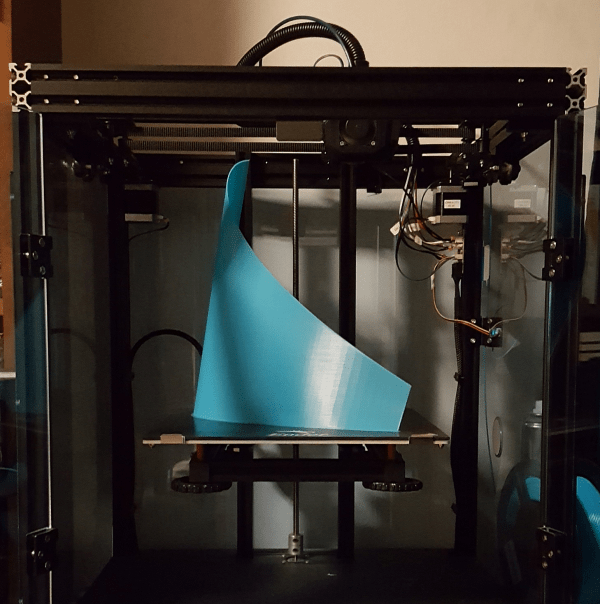

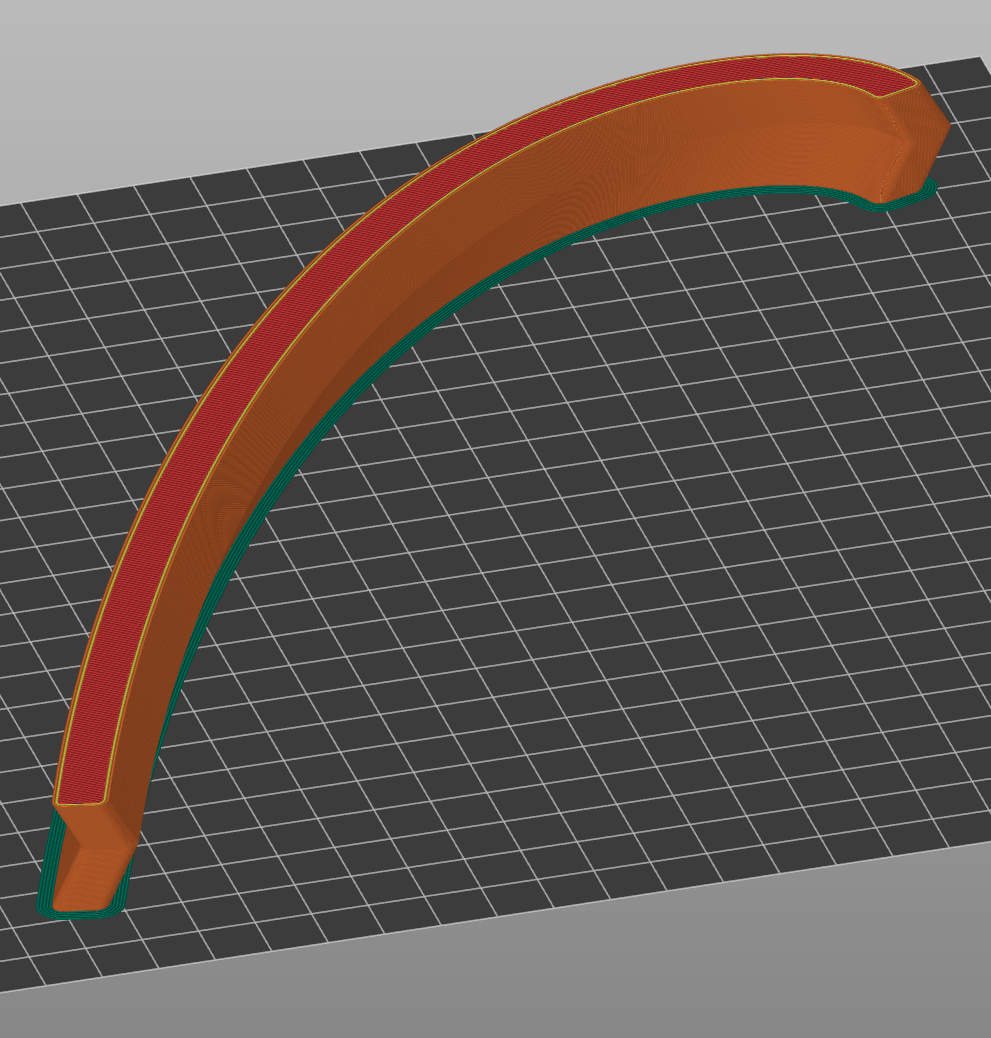

Hmm, there's a slicing problem (PrusaSlicer) - the nozzle, instead of making smooth movements along the whole curve, "jumps" in small steps, leaving small blobs along the path... Has anybody faced the same issue when printing such objects?

Using another slicer but know that problem. I solved it by increasing wall thickness. So there is only wall left without infill. This led to smooth run. Of course only ok if wall is not too thick then. Maybe works with prusa slicer, too.

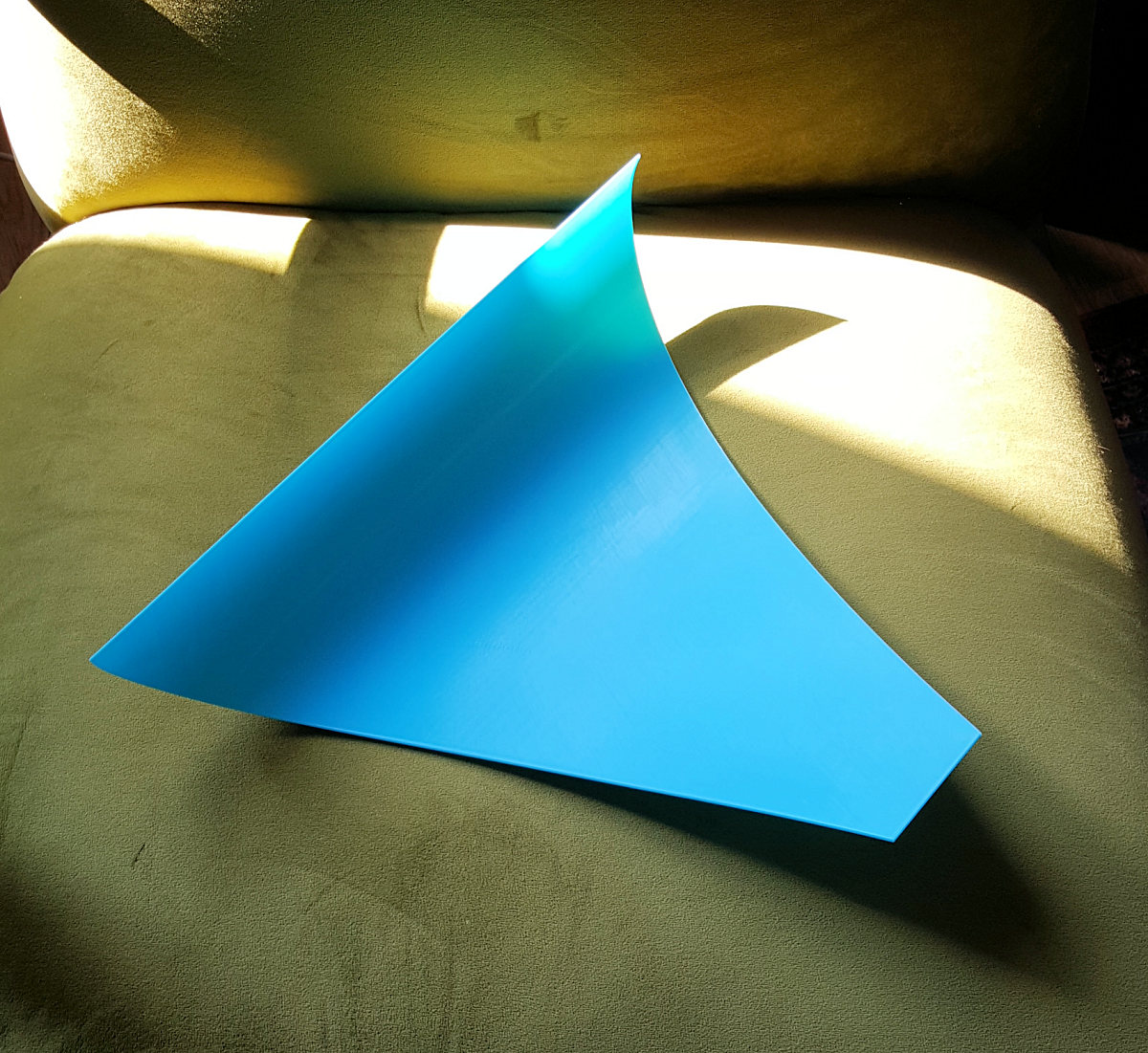

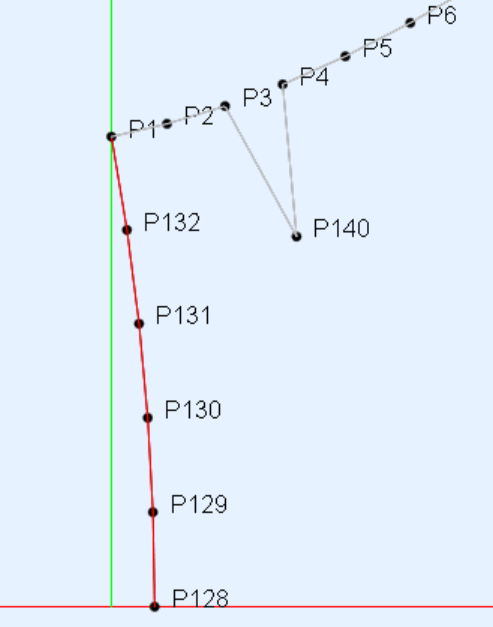

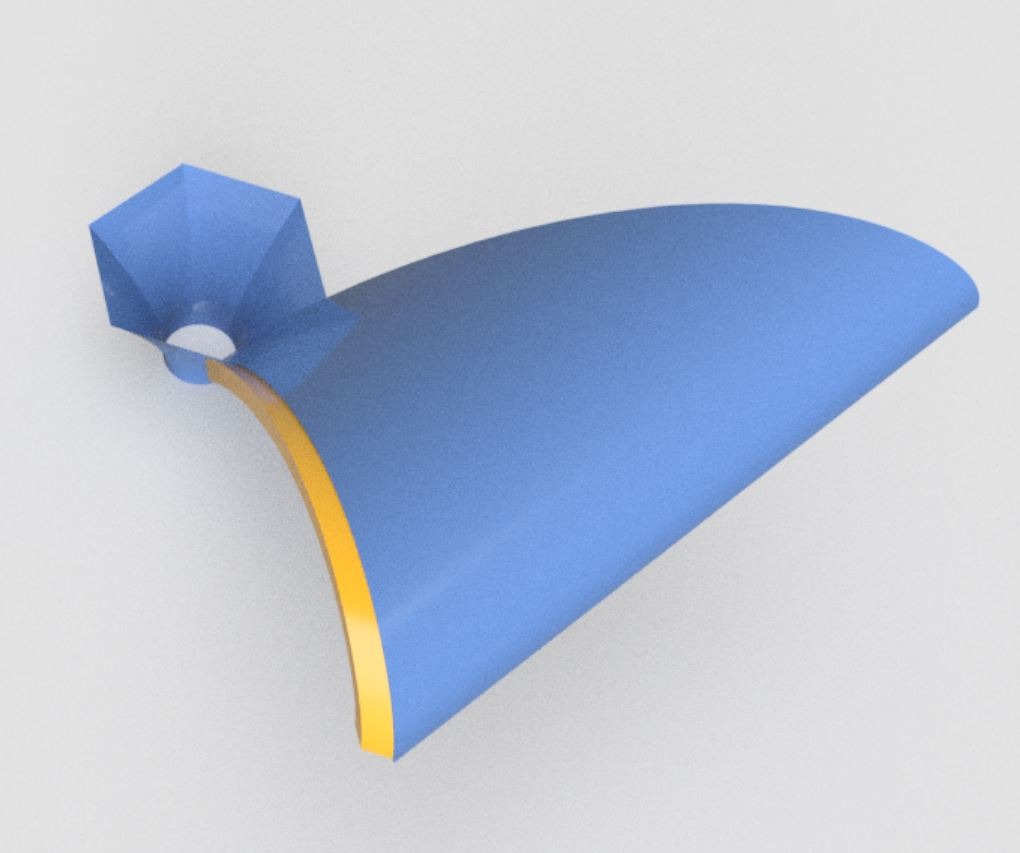

Success!

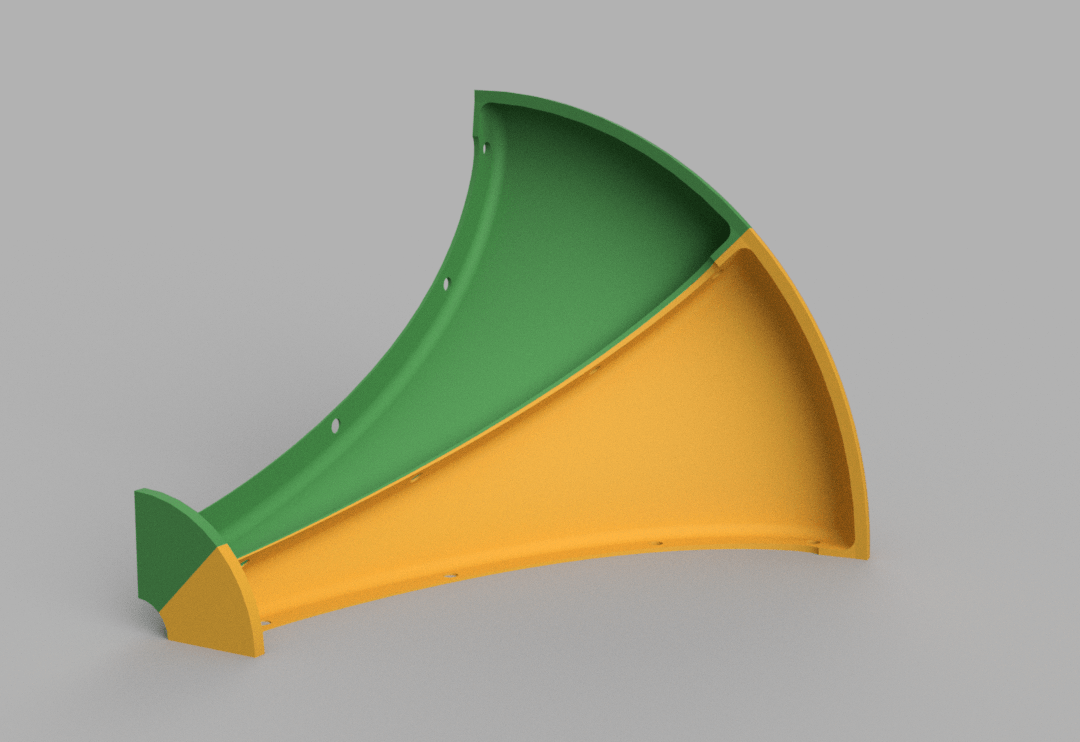

I think this has the potential to become the easiest DIY construction method by far.

- Now to print ribs for joints and it will be already usable. This is SUNLU PLA META and it doesn't ring at all. Too bad it seems discontinued now. It is perfect, strong, doesn't warp and it was dirt cheap. I only have maybe 8 spools left... 🙂

I think this has the potential to become the easiest DIY construction method by far.

- Now to print ribs for joints and it will be already usable. This is SUNLU PLA META and it doesn't ring at all. Too bad it seems discontinued now. It is perfect, strong, doesn't warp and it was dirt cheap. I only have maybe 8 spools left... 🙂

Last edited:

Mabat, try using Fusion's metal bending tool to generate a flat surface template, that you can then print flat and use as a template to cut paper, masonite or anything.

I've considered making a negative of just the inside of one of those pieces, but the curvature didn't help. I guess with flat pieces it should be easier.

Maybe it's even possible to print the pieces thin flat down on the bed and bend back when they are printed.

Using some "ears" with bolt holes.

I've considered making a negative of just the inside of one of those pieces, but the curvature didn't help. I guess with flat pieces it should be easier.

Maybe it's even possible to print the pieces thin flat down on the bed and bend back when they are printed.

Using some "ears" with bolt holes.

That was my first intention, to print a template (on paper) and cut it, it's no problem to generate it directly from the program (e.g. as a pdf via gnuplot). But now I already have all I need, I think - the printed sheet is fine. It's just less laborious this way.

Last edited:

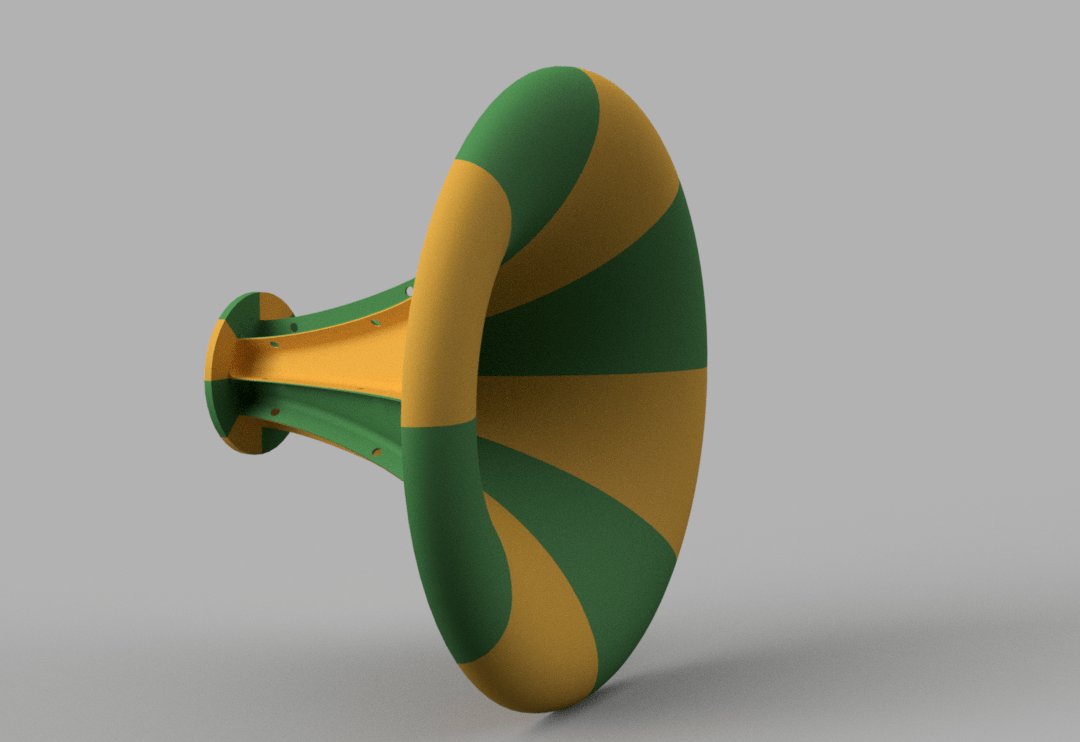

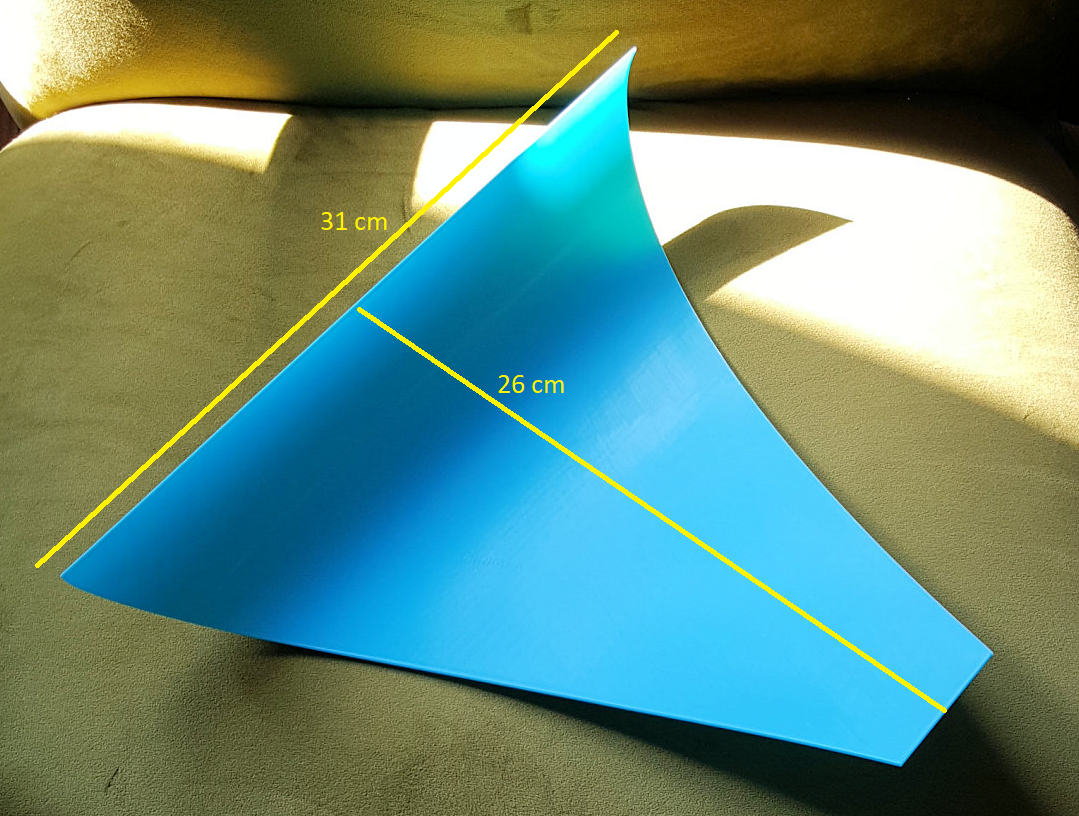

By coincidence, this is also the largest that fits my printer. The horn won't be a small one.

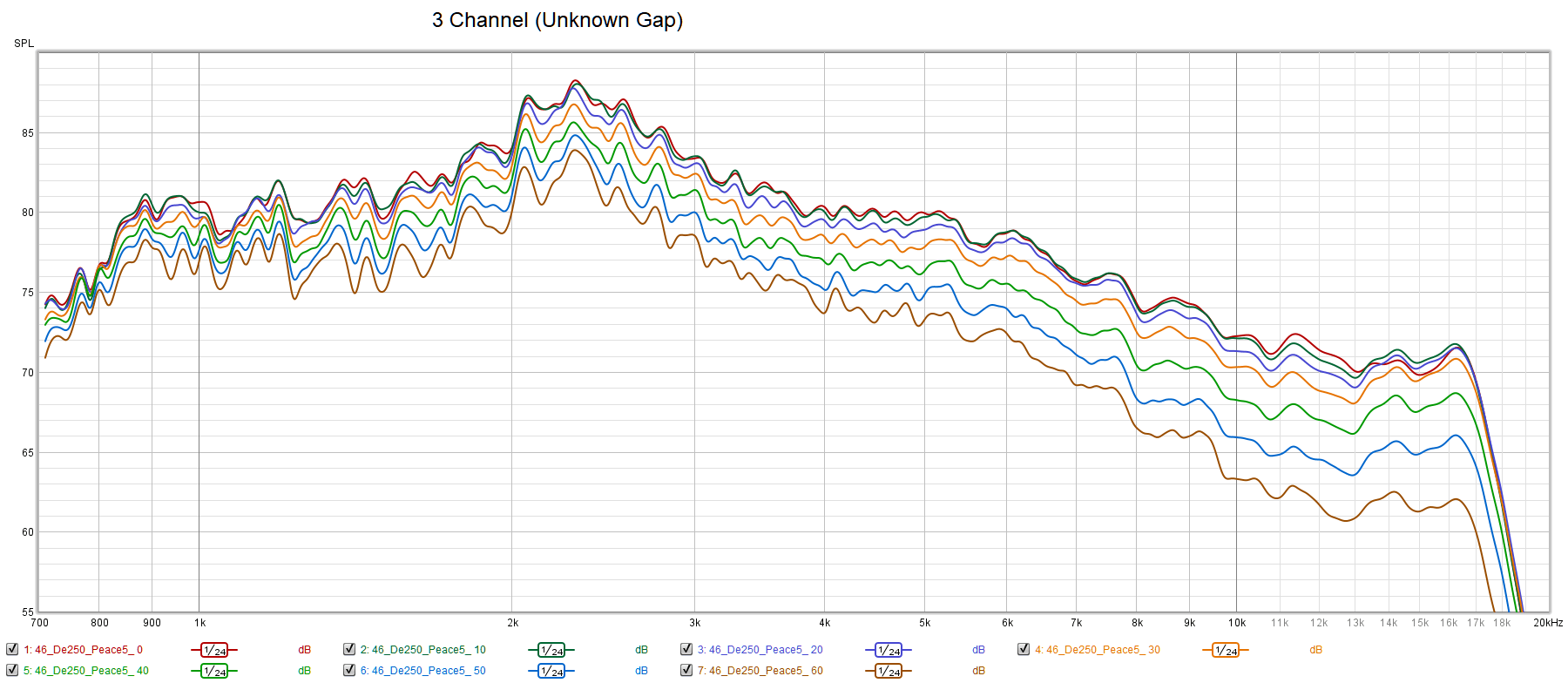

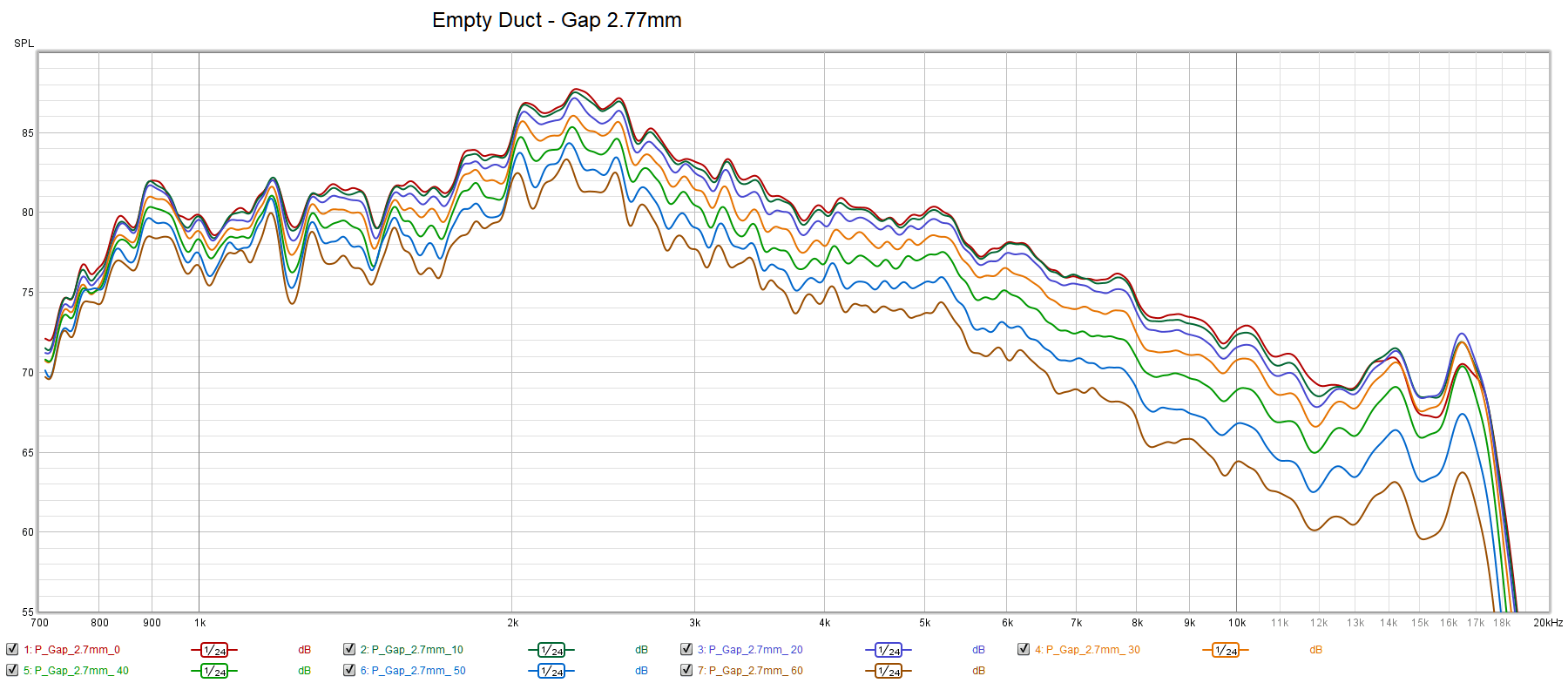

I couldn't get the 3 fin duct to replicate. Then I realized the first 3 fin plug I printed had a gap between the end of the plug and the start of the waveguide due to a combination of slicer settings and excess plumbers putty I placed on the surface of the compression driver to act as a gasket surface. So I printed an empty duct (no fins) but a shorter plug. After slicer adjustments it created a 7/64ths inch gap (2.77mm) between the end of the plug and the waveguide - the gap is a little over 2mm deep from the plug's inner diameter surface to the DE250's conical exit. The gap on that original 3 fin plug was just pure luck.

The fins create some level of impedance but the bulk of the work was done by the gap, aka Earl Geddes' Throat Tickler.

I attached the REW MDAT files.

The fins create some level of impedance but the bulk of the work was done by the gap, aka Earl Geddes' Throat Tickler.

I attached the REW MDAT files.

Attachments

The truth is that the previous results were a bit hard to comprehend. So this is all just alchemy. Hmm, a pity.

Thanks for the follow-up!

Thanks for the follow-up!

Last edited:

13 or 17 looks nice I think...I just want to minimize their number, and both 5 and 7 look really odd 🙂

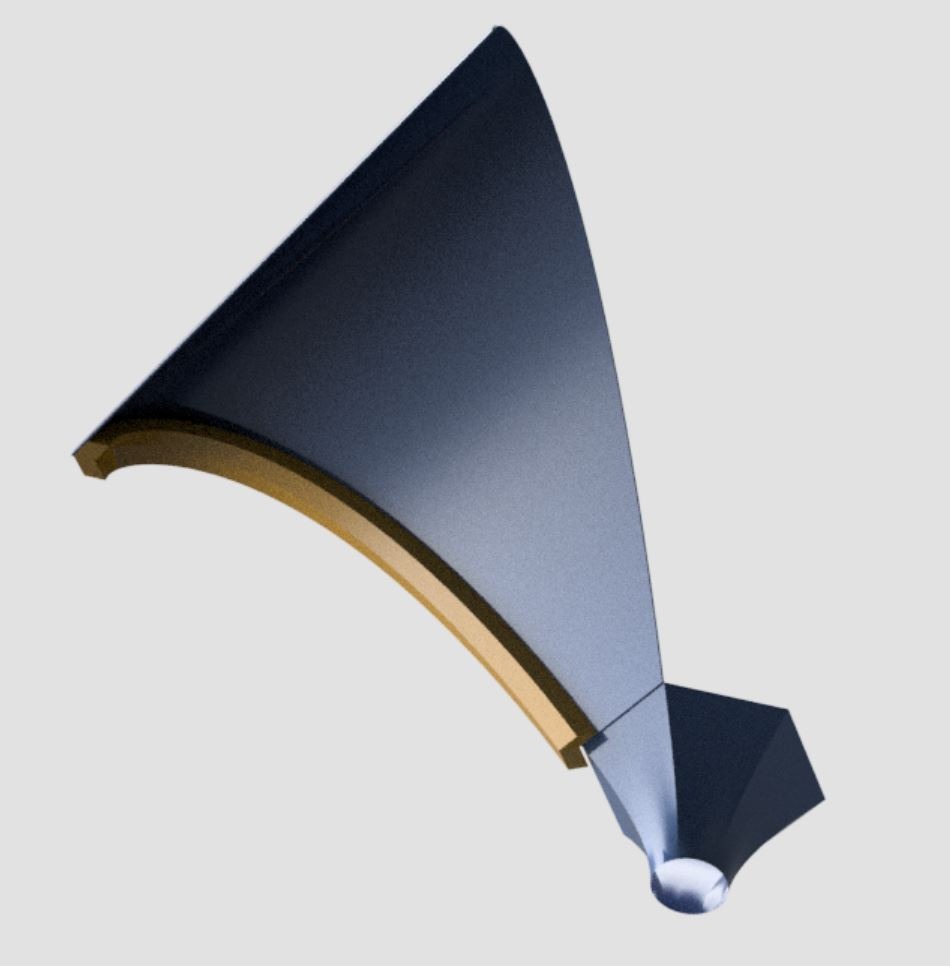

https://www.hifiwigwam.com/threads/wam-show-stoke-2022-photos.112417/page-18#post-2307954

Yeah, those are really beautiful (they would deserve bigger woofers). How much would cost such waveguide?

(I would still take 6 or 8 🙂. There's just something special about hexagons - for me.)

(I would still take 6 or 8 🙂. There's just something special about hexagons - for me.)

Last edited:

They take a lot of CNC machining...

Any number of leaves is possible. But I've found 13 is a good compromise. 12 would work too and be a bit easier to make. 9 is also a possibility.

Any number of leaves is possible. But I've found 13 is a good compromise. 12 would work too and be a bit easier to make. 9 is also a possibility.

Yep. It's all been guess and check meshed with my ignorance. We know it can potentially work but can't simulate it. I'm going to try to adjust the nodes like you showed me on the rear portion for the compression driver. But the nodes are just two points for the throat so I need to figure out how to add more in that section so I can move them inside the throat.The truth is that the previous results were a bit hard to comprehend. So this is all just alchemy. Hmm, a pity.

Thanks for the follow-up!

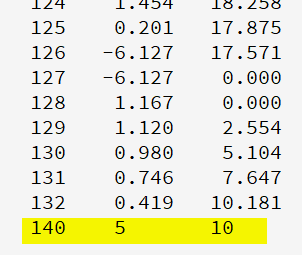

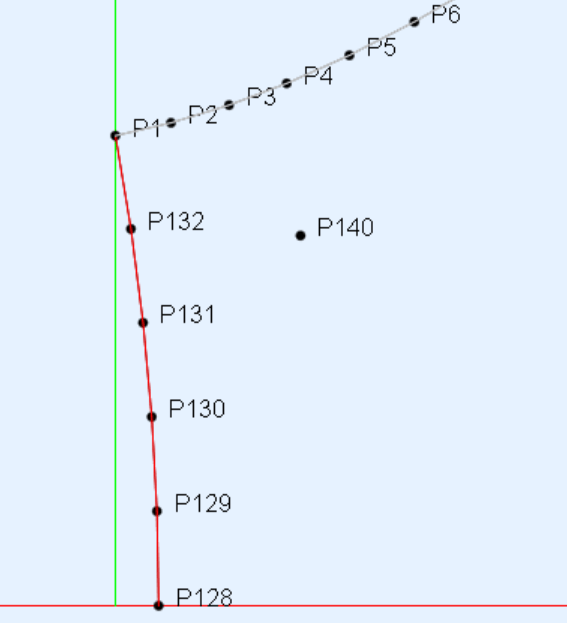

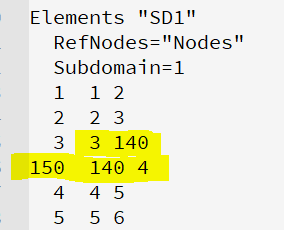

Adding new points is easy:

- define the new point(s) in nodes.txt (you can use any new unique numbers):

- reconnect the elements in solving.txt as needed:

- define the new point(s) in nodes.txt (you can use any new unique numbers):

- reconnect the elements in solving.txt as needed:

I'm still a hopeless noob in CAD but this goes extremely smoothly 🙂

(The mounting part may be tough. I'm still thinking how to do it.)

(The mounting part may be tough. I'm still thinking how to do it.)

Last edited:

In my experience it's always easier to 3d print some attachment guides/help.

Putting 3d parts together free hand always makes me want to cry.

Putting 3d parts together free hand always makes me want to cry.

(The mounting part may be tough. I'm still thinking how to do it.)

Why not make the guides integral to the petal: on one side a female, on the other a male?

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)