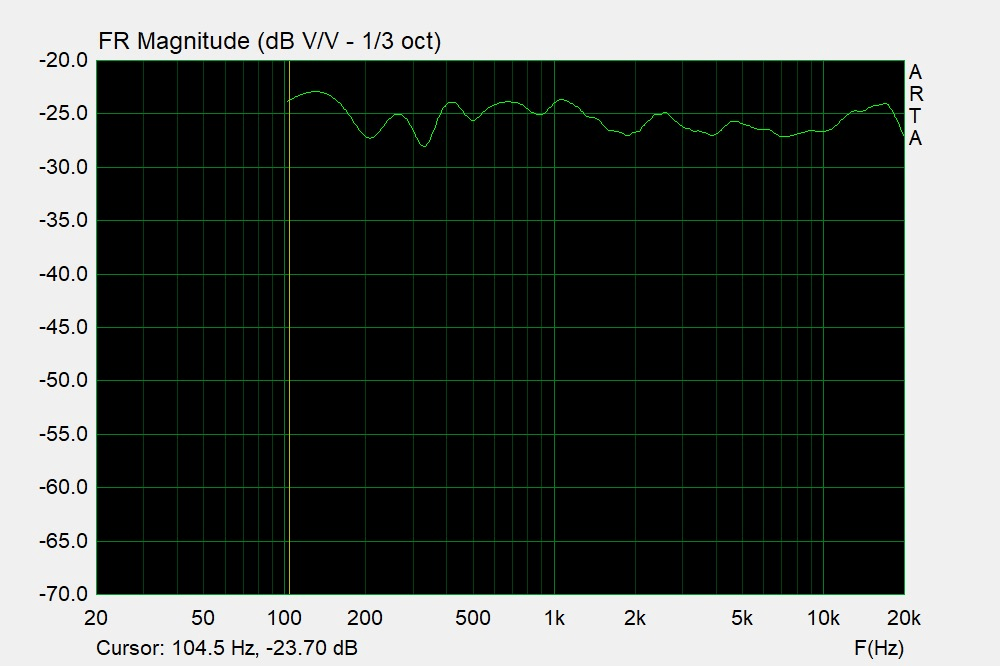

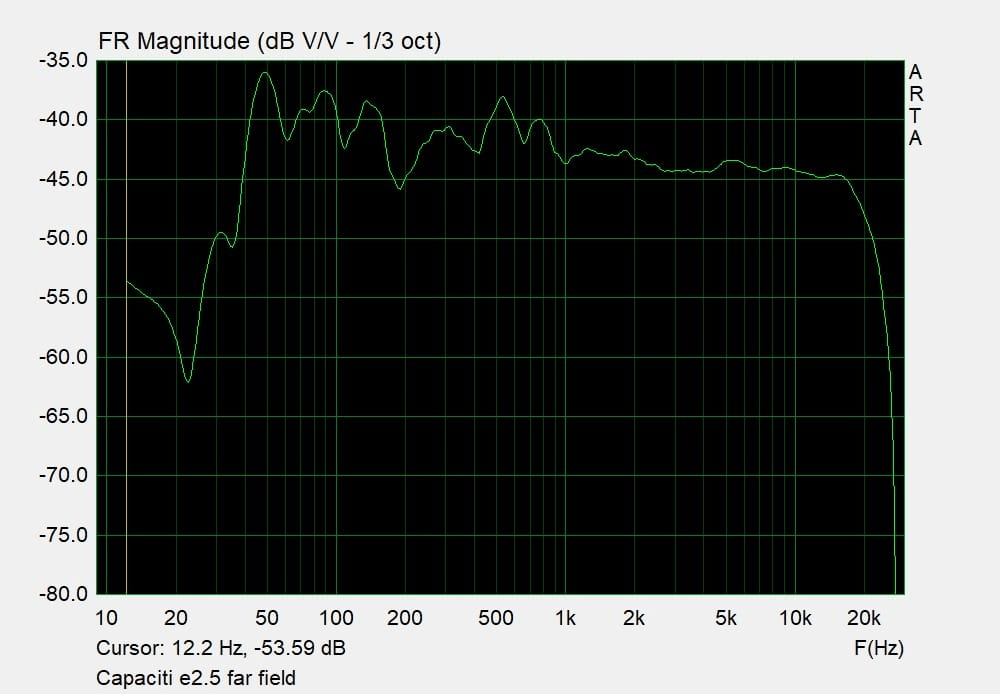

That almost looks like confirming the theory that dipoles are influenced less by the room - or am I reading that wrongly?

Could be coincidence but it surprised me, I didn't expect such smooth LF response. I'll measure more when setting up the final system.

Last edited:

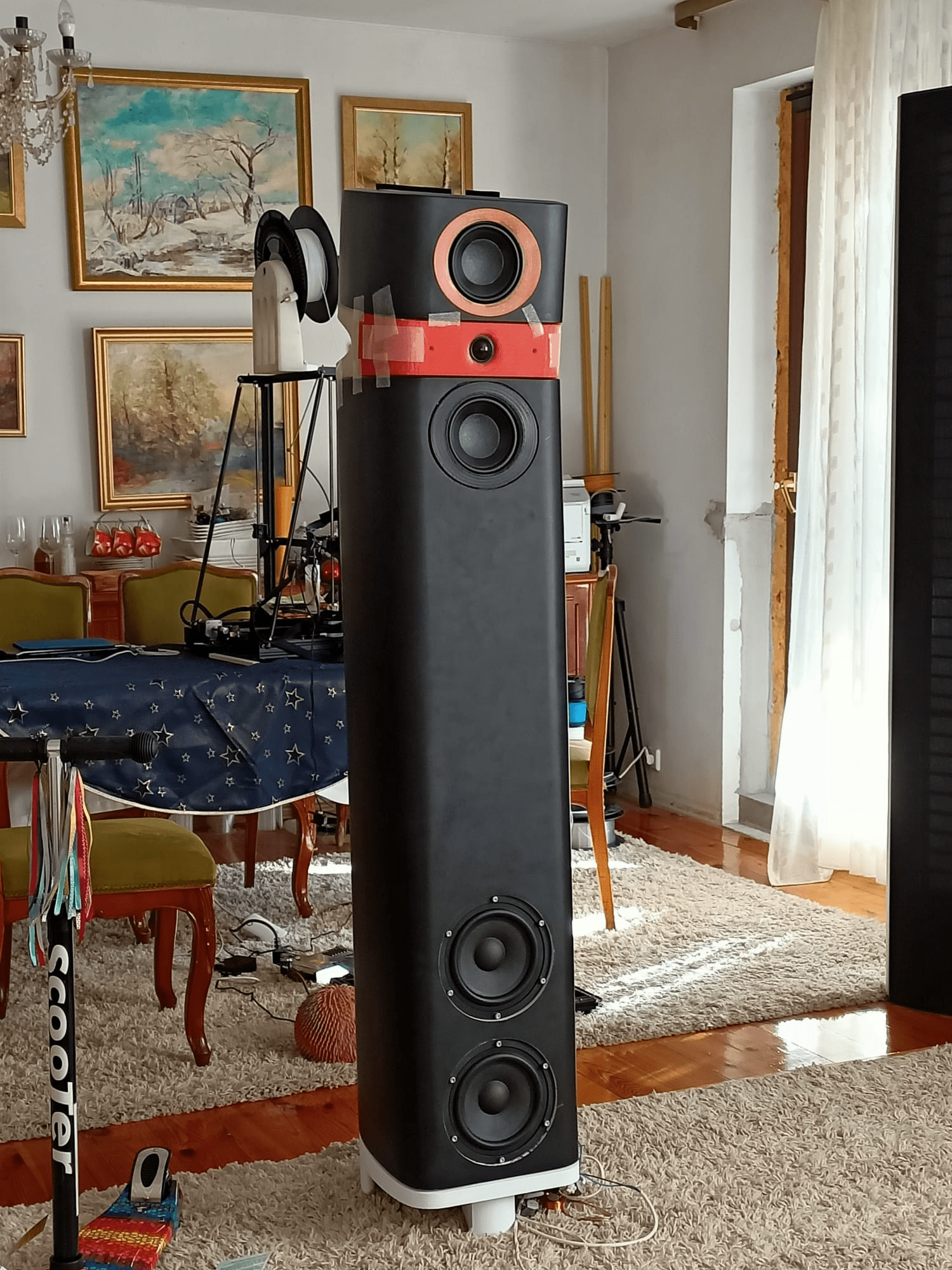

I've mounted woofers near floor and close to carpet, distance 1,5 meter and in the middle of a room:

below is 60x200cm electrostatic speaker so open baffle and along longer wall 2 meters apart, visible on the right side of above picture.

below is 60x200cm electrostatic speaker so open baffle and along longer wall 2 meters apart, visible on the right side of above picture.

Last edited:

Yeah, that basically removes the floor bounce. I could place two 18" (or 15") diagonally on even a larger baffle. I may actually do it some day 🙂

Last edited:

What can be learned from this? Regretfully I’m not sure what has the best response herePrinted these plugs to insert into an empty 18mm diameter duct on DE250 compression driver. 3D printer slicer "Cross" infill 20% with top and bottom layer set to zero.

10mm long

15mm long

20mm long

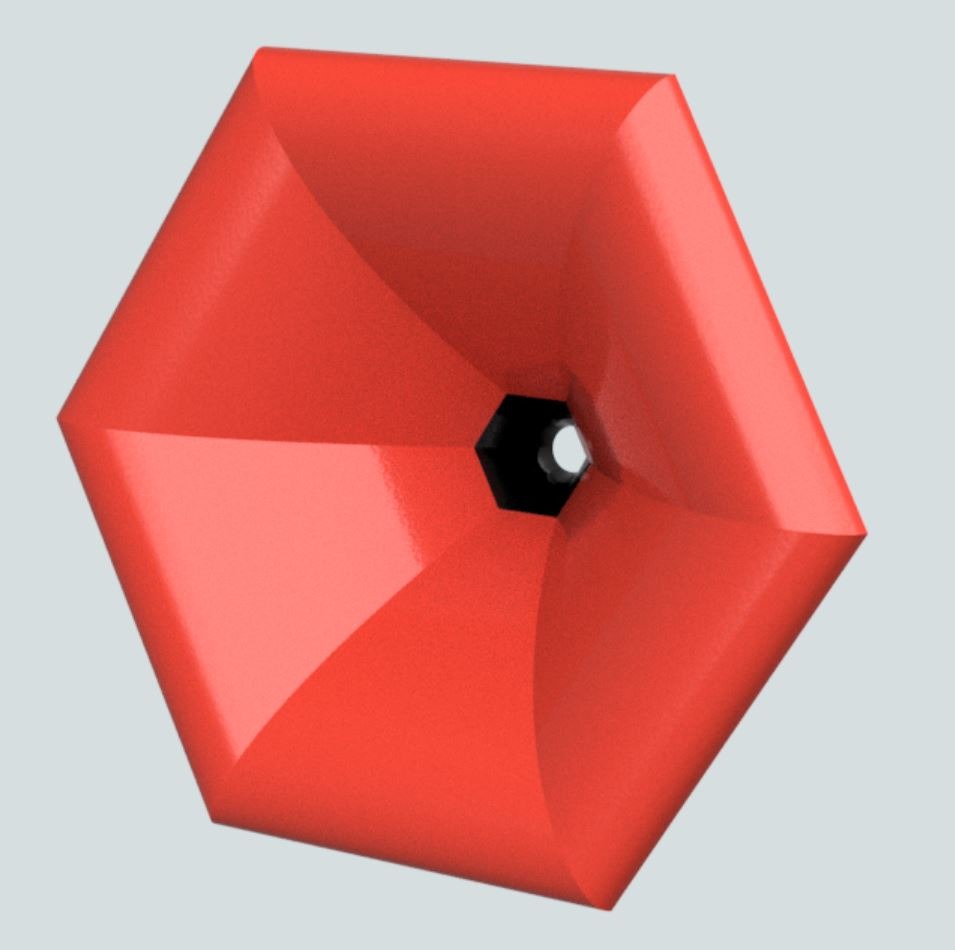

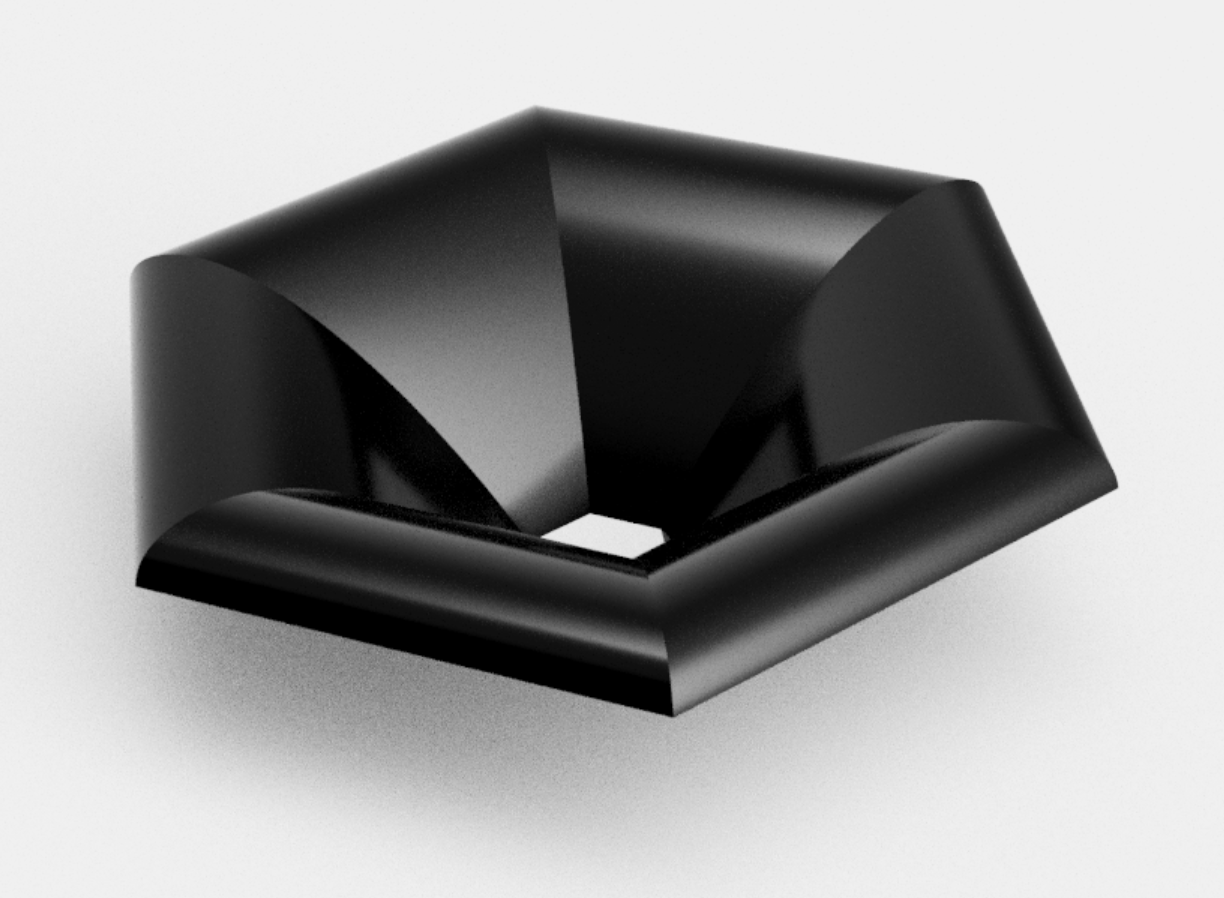

View attachment 1184417View attachment 1184418

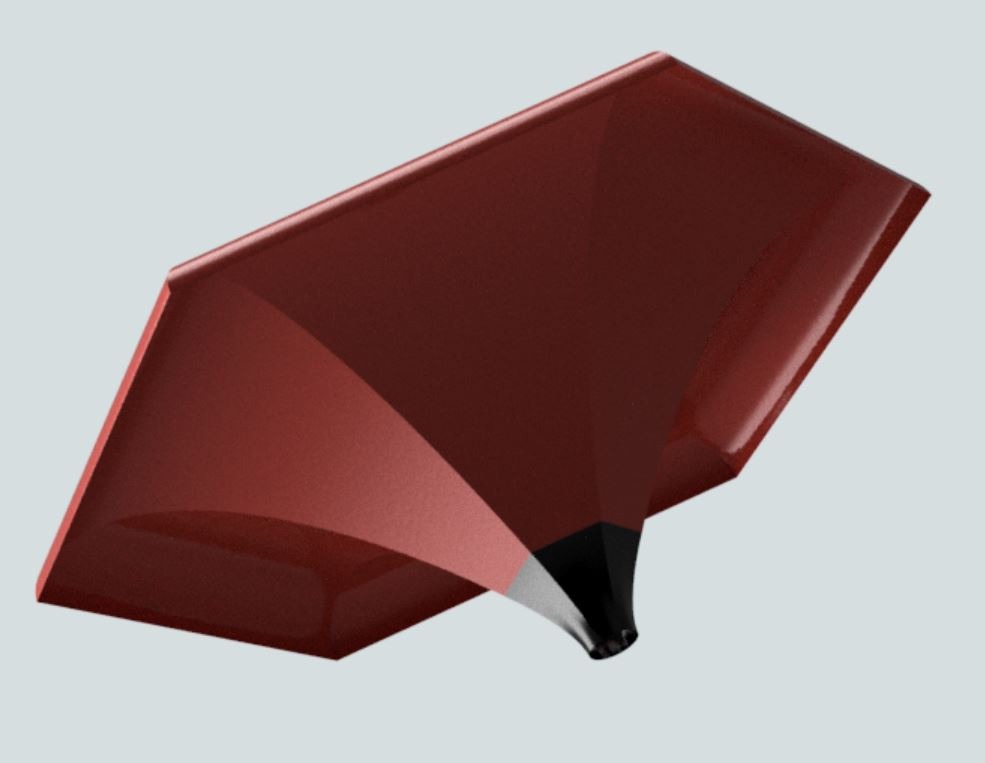

The segmented horn. I think it could have some appeal.

I'll try cardboard first.

I'll try cardboard first.

This is the manufacturing process I'm thinking about -

1) 3D-print ribs with grooves as the petal joints,

2) glue petals made of perforated cardboard into the ribs - this should create the overall shape of the horn,

3) cover the front side with petals cut of thin sheet metal (glue them to the ribs),

4) coat the back side with something that will glue together the (perforated) cardboard and the metal sheets.

Should this not be enough damped, another layer of metal sheets could be put at the back side.

Perhaps the cardboard could be replaced by (perforated) sheet metal right away.

The aim is to have a light and well-damped structure.

1) 3D-print ribs with grooves as the petal joints,

2) glue petals made of perforated cardboard into the ribs - this should create the overall shape of the horn,

3) cover the front side with petals cut of thin sheet metal (glue them to the ribs),

4) coat the back side with something that will glue together the (perforated) cardboard and the metal sheets.

Should this not be enough damped, another layer of metal sheets could be put at the back side.

Perhaps the cardboard could be replaced by (perforated) sheet metal right away.

The aim is to have a light and well-damped structure.

Last edited:

it would be interesting to audition this six sided version with a round version based on the same curvature just to see/hear if diffraction effects cloud perception......

i may be hearing with my eyes but if Earl i right this should be bad...

i may be hearing with my eyes but if Earl i right this should be bad...

No idea. I chose an arbitrary structure because I thought it looked neat then measured it with different lengths. Since I did it I thought I'd share it in case it helped anyone else.What can be learned from this? Regretfully I’m not sure what has the best response here

Here's my view: I believe that the segmented version will have a slight edge over a round one, at least objectively, as I don't really believe there will be an audible difference. Both should (and will) be very clean.

Last edited:

Do you think segmented will have a slight edge over round because it will have better diffraction characteristics?

There were some indications that the segmented shape could be very smooth indeed: https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7331853

Increasing the number of segments, i.e. approaching round shape, lead to a slightly worse response, from which I gather it helps to further break the axial symmetry this way. At the same time the radiation pattern is virtually the same as of round. That's all I know for now. It may not be a significant difference but certainly noticeable in the data.

Increasing the number of segments, i.e. approaching round shape, lead to a slightly worse response, from which I gather it helps to further break the axial symmetry this way. At the same time the radiation pattern is virtually the same as of round. That's all I know for now. It may not be a significant difference but certainly noticeable in the data.

Last edited:

The numbers 5 and 7 are indeed odd, and a horn with an uneven number of petals is undeniably not as aesthetically pleasing as one with an even number of petals 🙂

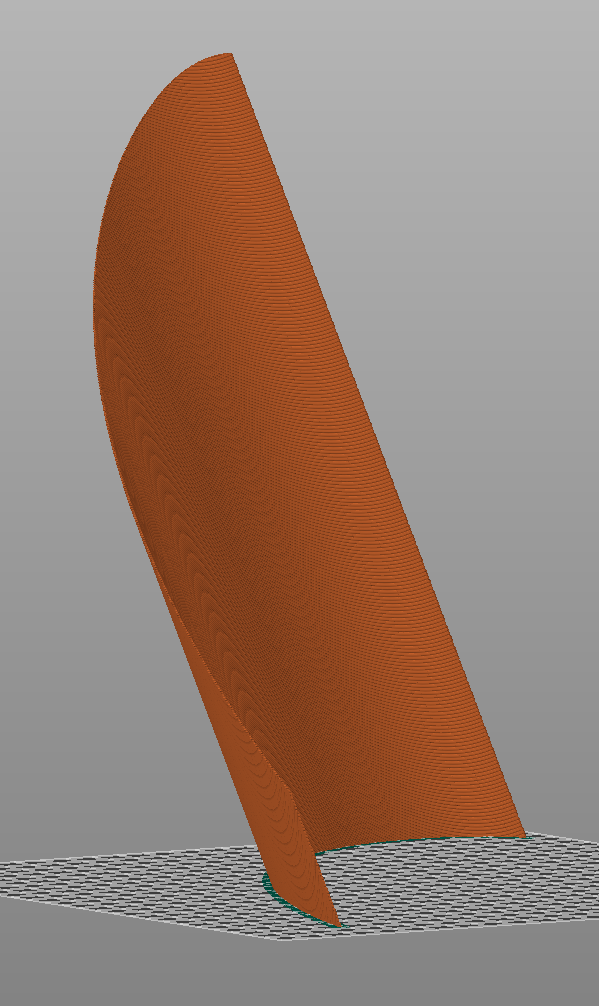

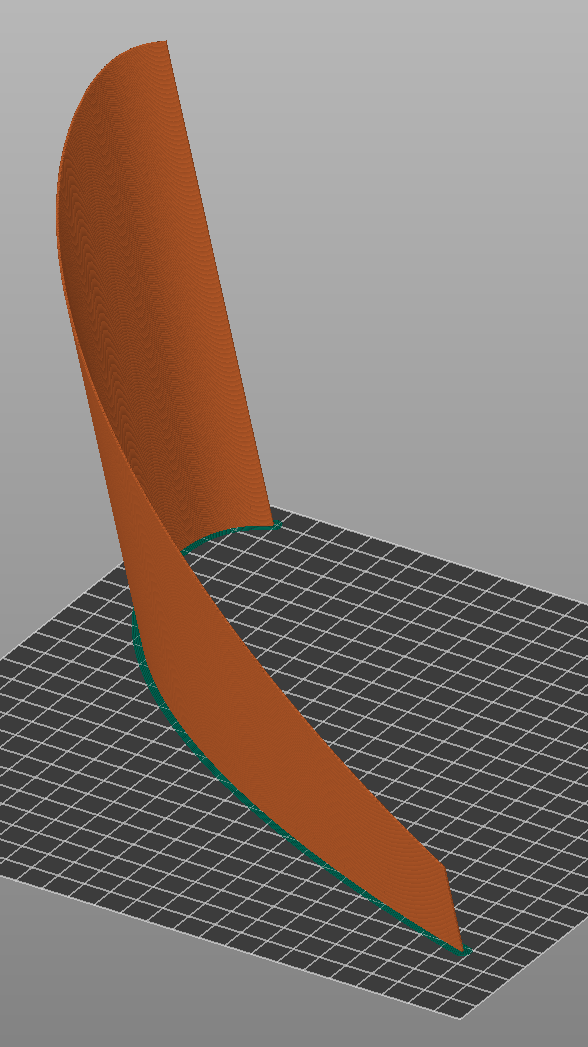

It should be also possible to print the basic petal sheets quite easily, directly in the shape - this is 1 mm thick:

I haven't tried yet but perhaps this could form the basic construction instead of cardboard, perhaps even as a damping layer.

Thin metal sheets would then cover one or both sides.

I haven't tried yet but perhaps this could form the basic construction instead of cardboard, perhaps even as a damping layer.

Thin metal sheets would then cover one or both sides.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)