Can't wait to learn how it fits.

Regarding the finish, I think about filling an epoxy coating (the XTC-3D perhaps) with a metal powder. I don't want to spend hours making the surface perfect, which it wouldn't be anyway, so I thought to make it intentionally looking old and battered instead 🙂

Regarding the finish, I think about filling an epoxy coating (the XTC-3D perhaps) with a metal powder. I don't want to spend hours making the surface perfect, which it wouldn't be anyway, so I thought to make it intentionally looking old and battered instead 🙂

Way to go! Old, battered bronze could be cool.

Quickly Adding a Metallic Finish to a 3D Print - YouTube

//

Quickly Adding a Metallic Finish to a 3D Print - YouTube

//

Last edited:

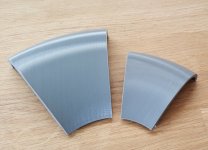

Suddenly it's funny how is the ST260 actually small - ST260 vs CE360 petals.

And I also already know the tolerance needed - the groove on the petal is 0.3 - 0.4 mm too narrow in my case. Shouldn't be problem to fix this.

And I also already know the tolerance needed - the groove on the petal is 0.3 - 0.4 mm too narrow in my case. Shouldn't be problem to fix this.

Attachments

I could try this new version of the ST260. The pieces I printed earlier were a disaster.

Could You Mabat add holes for three mounting screws, like for a BMS 5530ND?

Could You Mabat add holes for three mounting screws, like for a BMS 5530ND?

Last edited:

When I tried it was already too close to the throat but maybe someone else will find a way how to make it differently.

I like the Peerless DFM-2535R00-08, that has 4 holes at ⌀76 mm. Overall a nice driver, use that 🙂

I like the Peerless DFM-2535R00-08, that has 4 holes at ⌀76 mm. Overall a nice driver, use that 🙂

I'm sure there's a way how to do that, probably it would need to split the mounting flange into two parts.

One could almost have 'standard' petals for different size horns with the horn mouth interchangeable and adjusted (throat angle) to a specific CD this way, like a modular library of parts that fits certain conditions 🙂.

That's not as easy as it may seem, since a different throat angle changes the whole profile. You would have to compromise the whole thing to have it more "universal".

YES! 🙂

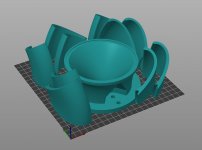

- No sanding yet, these are raw pieces as they left the printer, no glue yet.

I only wish the inner surface of the base was better but it seems I can't figure out how to do that in this case.

- No sanding yet, these are raw pieces as they left the printer, no glue yet.

I only wish the inner surface of the base was better but it seems I can't figure out how to do that in this case.

Attachments

Last edited:

Here's the updated petal that works for me (you need ten of those per waveguide).

Attachments

Last edited:

I know! Hence the 'almost' 🙂.That's not as easy as it may seem, since a different throat angle changes the whole profile. You would have to compromise the whole thing to have it more "universal".

Rough after the first 1/2" of throat is good.YES! 🙂

- No sanding yet, these are raw pieces as they left the printer, no glue yet.

I only wish the inner surface of the base was better but it seems I can't figure out how to do that in this case.

I've found I like fine sand in the paint roughening the surface.

Fun seeing you do this.

I've turned several pairs of Tractrix 550Hz horns on my lathe, and adapted an end sander to allow me to turn the larger diameter Le Clèac'h 550Hz horns.

You could experiment with small ridges ala Cessaro horns and see what sounds best.

What will the resonace / stability be like? Use bitument to dampen?

I've found the softer the wood the better the sound for higher frequency applications.

I don't know how printed plastic compares.

What will the resonace / stability be like? Use bitument to dampen

If I am able to print one of these I'm going to place the horn on it’s mouth and fill the trough with self-leveling polyurethane via a caulking gun. More expensive but it comes in black, white and grey and I like the clean look.

Last edited:

The petal with greater tolerance works for me. The question is now if 10 of them would fit as well. I think when building a larger horn, I will go for a combination of 3D printed throat and CNC'd mouth, I hope to test that approach soon.

Using the same print scheme, what would the requirement for a printer be in terms of size (x,y,z) if a 360 WG was to be printed?

//

//

As I have it now, it would fit into 170 x 170 x 110 mm (x,y,z) build volume (e.g. Prusa MINI+ is fine).

Continuing on the ST260 (no filler, no sanding, no glue yet) -

(Wonder what angle ajustment will require the last petal. So far it looks pretty accurate.)

Continuing on the ST260 (no filler, no sanding, no glue yet) -

(Wonder what angle ajustment will require the last petal. So far it looks pretty accurate.)

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)