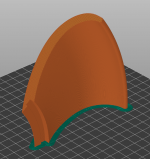

How and why?I wonder if the petals would print better with a flat back - and low or no infill.

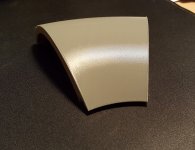

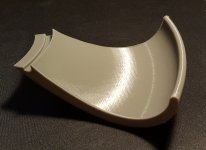

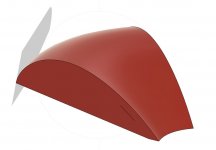

This is my current approach that seems to work very well (hollow, no supports) -

Attachments

Attachments

Last edited:

I mean like on the sand horn was IIRC. Curved front, straight back of the roundover. I think it would make it slightly easier to print - especially with 90 degree segments, there would be no overhangs if printed with the flat part on the bed. It might reduce the printing time and material consumption a bit and provide more volume for filling.Also there would be more area for gluing. Printed infill is not necessary if it will be filled later. The 45 degree segment should print fine as is. I was only playing a bit with PrusaSlicer. I think I will try that.

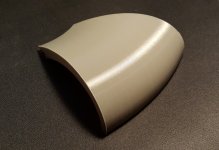

This is probably the cleanest I can make it (0.2 mm layer, 2 perimeters, completely hollow, thickness from 5 to 11 mm).

Now I need twenty of them for a pair...

Now I need twenty of them for a pair...

Attachments

Last edited:

Nice! What was the approximate print time? The side walls, how thick? It can be opened (how?) for filling?

Fill first, then assemble or assemble, then fill?

//

Fill first, then assemble or assemble, then fill?

//

Something over an hour, 50 mm/s.

Probably assemble first - easier to correct for any residual warps. It seems pretty flat but still.

Probably assemble first - easier to correct for any residual warps. It seems pretty flat but still.

Last edited:

It's not cheap, but ColorFabb NGEN really blew me away. It's far and away the best filament I've ever come across. It's about as resistant to warping and cracking as PETG is, but the finish is much nicer.

PETG is probably my favorite filament option, but the finish just looks terrible when compared to NGEN, PLA and ABS.

One of these days I probably need to just break down and start using PLA again, because annealing it seems to make it about as good as anything, as long as you complete that extra step.

The main thing that's been stopping me is that I keep trying to figure out how to get ABS to print nicely. If I succeeded at that, it would probably make PLA and NGEN unnecessary.

decisions decisions decisions...

PETG is probably my favorite filament option, but the finish just looks terrible when compared to NGEN, PLA and ABS.

One of these days I probably need to just break down and start using PLA again, because annealing it seems to make it about as good as anything, as long as you complete that extra step.

The main thing that's been stopping me is that I keep trying to figure out how to get ABS to print nicely. If I succeeded at that, it would probably make PLA and NGEN unnecessary.

decisions decisions decisions...

Man, I should reach out locally. I have a decent large format 3D printer (Folgertech FT5) with a lot of aftermarket structural parts such as CNC aluminum components for the printer head, gantry, z-axis bed, etc. If someone could help me get it going I would be happy to run it stateside for diyaudio people wanting prints at cost.

Maybe I should visit you John. Are you in Vegas now? Last I checked you were in San Diego..

Yep, nearly finished with my move out of California. Goodbye high taxes.

I'd be happy to help. But asking me for advice on 3D printers is kinda like asking a blind man for directions lol

I'm not known for making good prints...

Make it cardioid. Oversized D&D 8C.

From what I can see, the Dutch & Dutch 8C is nearly at the limit, as far as size goes.

Basically the bigger the delay is between the radiation from the front of the cone to the rear of the cone, the more issues you get with the radiation pattern. You reach a point where there's more SPL to the SIDE of the speaker than to the front!

The Linkwitz and Kreskovsky speakers ran into the same problem, which is why the baffle kept getting smaller and smaller and smaller over time.

Linkwitz baffle circa 1999:

Linkwitz baffle circa 2012:

Two perimeters 0.4 mm each, so ~ 0.8 mm wall (seems strong enough). For filling it must be drilled at a suitable place.... The side walls, how thick? It can be opened (how?) for filling?

I have, and for accuracy I would not recommend it.

Kind of hard to control the process and sometimes the outer layer dries and trap the acetone vapors inside the print.

Best so far is a thin layer epoxy and sanding.

Like this product: XTC-3D™, High Performance 3D Print Coating | Smooth-On, Inc.

Kind of hard to control the process and sometimes the outer layer dries and trap the acetone vapors inside the print.

Best so far is a thin layer epoxy and sanding.

Like this product: XTC-3D™, High Performance 3D Print Coating | Smooth-On, Inc.

A thin coat of epoxy that fills the ridges in the print also bind the layers together making sure it’s air tight. So it’s not only for esthetics actually.

A quick test is to make yourself a printed cup and fill it with water. I can almost bet some money that it will leak.

A quick test is to make yourself a printed cup and fill it with water. I can almost bet some money that it will leak.

Sure, why not. When I simulated a flat back side like this, it wasn't as nice as the bent profile, but the difference will be probably negligible for any practical matter. Would be interesting to verify.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)