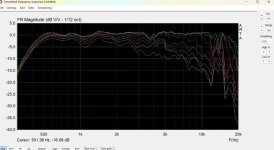

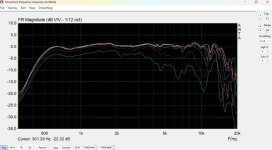

Some polars - roughly evenly spaced to 40 deg.

A400G2 SSH3301 no esp

A400G2 SSH3301 with esp

Now I see that the polar axis is about 8cm off centre. So I guess the off-axis are a bit higher level than they should be. That might explain the plots a bit.

A400G2 SSH3301 no esp

A400G2 SSH3301 with esp

Now I see that the polar axis is about 8cm off centre. So I guess the off-axis are a bit higher level than they should be. That might explain the plots a bit.

Attachments

Last edited:

I am playing around with a squared horn for low frrquency driver. Since this must work up to 700Hz the cone shape of the 8" gets relevant. I managed to get source contour working. But the mesh of the source contour is insanely dense and therefore computing time is not anymore reasonable. Although using only 1 quadrant I aborted now after 12hrs at 49%.

So how to change mesh density of source contour?

So how to change mesh density of source contour?

Thanks. I find it a bit difficult to comment or to figure out what to take from it, as there are things in the data I don't understand. For example, the plug should have no to very little effect on directivity below ~7 kHz...Some polars - roughly evenly spaced to 40 deg.

Are these all raw (not EQed) responses?

Last edited:

Perhaps it's also worth making sure that the orientation of the petals stays the same. Hard to say what effect that has.

- If the plug improved the HF directivity, the on-axis level would need to decrease, which is not what happened, so there's probably not any real improvement in this case. It seems just different to me. At least the region 5-10 kHz seems a bit nicer with the plug.

BTW, I've updated the 50mm ESP set, there's also a new one specifically designed for the Axi2050 (the vane positions).

And there's also a 1.5" version with a new (more universal) housing -

- If the plug improved the HF directivity, the on-axis level would need to decrease, which is not what happened, so there's probably not any real improvement in this case. It seems just different to me. At least the region 5-10 kHz seems a bit nicer with the plug.

BTW, I've updated the 50mm ESP set, there's also a new one specifically designed for the Axi2050 (the vane positions).

And there's also a 1.5" version with a new (more universal) housing -

Last edited:

Hi Marcel,

The AXi ESP looks fantastic—hoping my 3D printer can do it justice. I’ll reach out via email to arrange payment.

I’ll be CNC machining the A620G2 horn. Is it acceptable to use XPS rigid foam for the final 150mm of the horn mouth?

The AXi ESP looks fantastic—hoping my 3D printer can do it justice. I’ll reach out via email to arrange payment.

I’ll be CNC machining the A620G2 horn. Is it acceptable to use XPS rigid foam for the final 150mm of the horn mouth?

is there any measurements available? good job on the 3d designPerhaps it's also worth making sure that the orientation of the petals stays the same. Hard to say what effect that has.

- If the plug improved the HF directivity, the on-axis level would need to decrease, which is not what happened, so there's probably not any real improvement in this case. It seems just different to me. At least the region 5-10 kHz seems a bit nicer with the plug.

BTW, I've updated the 50mm ESP set, there's also a new one specifically designed for the Axi2050 (the vane positions).

And there's also a 1.5" version with a new (more universal) housing -

View attachment 1451991

Must have spent 200+ hours reading about Unity and Synergy horns. Learned a lot from Danley sharing by stimulating you to connect the dots yourself, P-Bateman attacking every angle, Bwaslo making the "Spreadsheet" and all the other guys. Only to just wing it when I finally got around to print an AT version myself.

The ports is obviously inspired by the CMI coherent midrange integrator. Was aiming (from the hip) to support the 1" Peerless from 350 to 800Hz somewhere. The ports ended a bit further out than planned as I decided on the ports distance from the entry before i tilted the ports away from the entry.

The main reason for doing this besides because I can is to see if its possible to make a simple but nice sounding cheap 1" + some cheap midranges compete or even sound better than a heavyweight BMS/B&C coax compression driver. To make full use of this I will print a 620 or even larger horn if this sounds and measures as planned.

The 1.5K Hz dip in the tweeters response disappears completely if I cover the midrange injection holes with painters tape.

The ports is obviously inspired by the CMI coherent midrange integrator. Was aiming (from the hip) to support the 1" Peerless from 350 to 800Hz somewhere. The ports ended a bit further out than planned as I decided on the ports distance from the entry before i tilted the ports away from the entry.

The main reason for doing this besides because I can is to see if its possible to make a simple but nice sounding cheap 1" + some cheap midranges compete or even sound better than a heavyweight BMS/B&C coax compression driver. To make full use of this I will print a 620 or even larger horn if this sounds and measures as planned.

The 1.5K Hz dip in the tweeters response disappears completely if I cover the midrange injection holes with painters tape.

Attachments

Do you agree that distortion looks under control? Maybe crossover somewhere around 7-850Hz. FDW 15 Cycles. 9ms

Awesome! What happens if you cover the port holes with very thin felt?Must have spent 200+ hours reading about Unity and Synergy horns. Learned a lot from Danley sharing by stimulating you to connect the dots yourself, P-Bateman attacking every angle, Bwaslo making the "Spreadsheet" and all the other guys. Only to just wing it when I finally got around to print an AT version myself.

The ports is obviously inspired by the CMI coherent midrange integrator. Was aiming (from the hip) to support the 1" Peerless from 350 to 800Hz somewhere. The ports ended a bit further out than planned as I decided on the ports distance from the entry before i tilted the ports away from the entry.

The main reason for doing this besides because I can is to see if its possible to make a simple but nice sounding cheap 1" + some cheap midranges compete or even sound better than a heavyweight BMS/B&C coax compression driver. To make full use of this I will print a 620 or even larger horn if this sounds and measures as planned.

The 1.5K Hz dip in the tweeters response disappears completely if I cover the midrange injection holes with painters tape.

And do you have any theories about the ~900 Hz dip in the mid response?

Yes. Will turn the horn 90 degrees to see how much the ports are affecting when they are not in the horisontal position. But it will be hard to fix the assembly to my measurement rig when turned.

Can you show the normalized plot additionally? 700 Hz appears to be <= 1%, so that is quite acceptable.Do you agree that distortion looks under control?

Have you thought about using acoustically transparent tape? It has been been discussed before I think even in this thread.The 1.5K Hz dip in the tweeters response disappears completely if I cover the midrange injection holes with painters tape.

Looks stunning!

Duct tape to the rescue! Managed to fix the horn to the rig with the entry holes in the vertical plane.

Horisontal vs vertical looks more similar than I expected.

@sheeple Will try to cover the entry holes with something thats acousticaly transparent for mid frequencies. Open for suggestions on what to use.

Horisontal vs vertical looks more similar than I expected.

@sheeple Will try to cover the entry holes with something thats acousticaly transparent for mid frequencies. Open for suggestions on what to use.

As @sheeple mentioned there has been some discussions on how to cover the midrange holes without messing up the response from the mids. Was looking around the house for some mesh or anything worth trying even if I would think that any kind of mesh would at some point start to resonate when playing louder, a concern raised by @mjvbl earlier in this thread. So I grabbed a box of Magic Sponge in stead. That really did the trick. 1 meter, no FDW, 9ms gate.

Great!That really did the trick.

How much (thick) sponge material did you use?

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)